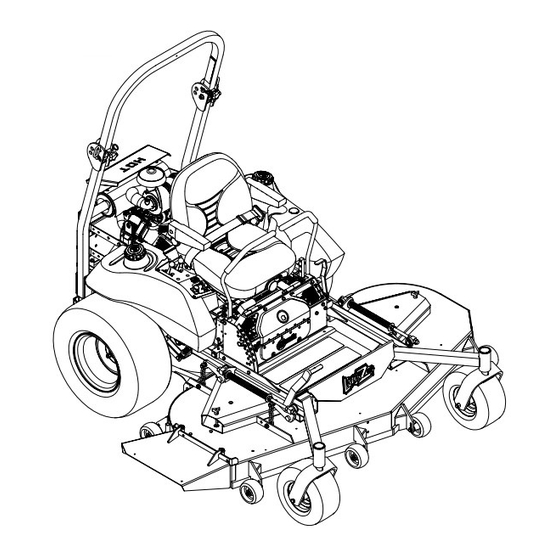

Exmark Lazer Z XS Operator's Manual

Exmark zero turn riding mower operator's manual

Hide thumbs

Also See for Lazer Z XS:

- Operator's manual (60 pages) ,

- Parts manual (32 pages) ,

- Setup instructions (5 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Exmark Lazer Z XS

- Page 1 For Serial Nos. 440,000 & Higher Part No. 103-6698...

- Page 2 Replacements may be ordered through the engine manufacturer. Exmark reserves the right to make changes or add improvements to its products at any time without incurring any obligation to make such changes to products manufactured previously. Exmark, or its distributors and dealers, accept no responsibility for variations which may be evident in the actual specifications of its products and the statements and descriptions contained in this publication.

- Page 3 3. Exmark being unable to ship the part and the Exmark parts order is received by 3:00 p.m., central time, Exmark pays for the part and freight. 4. If the part does not arrive overnight due to the shipper (UPS), the shipper pays for the freight and Exmark pays for the part.

- Page 4 If additional information is needed, or should you require trained mechanic service, contact your authorized Exmark equipment dealer or distributor. All Exmark equipment dealers and distributors are kept informed of the latest methods of servicing and are equipped to provide prompt and efficient service in the field or at their service stations.

-

Page 5: Table Of Contents

1. SAFETY Safety Alert Symbol... 1 Training ... 1 Preparation... 1-3 Operation... 4-7 Maintenance & Storage... 7-8 Safety Signs ... 8-10 2. SPECIFICATIONS Model Numbers ... 11 Engine ... 11 Fuel System ... 11 Electrical System... 11 Operator Controls... 11 Seat ... -

Page 6: Safety Alert Symbol

MAY result in minor or moderate injury. 1.2 TRAINING 1.2.1 Regard the Exmark mower as a piece of power equipment and teach this regard to all who operate this unit. 1.2.2 Read the instructions carefully. Familiarize yourself with the controls and the proper use of the equipment. - Page 7 1.3.4 Thoroughly inspect the area where the equipment is to be used and remove all stones, sticks, wires, bones, and other foreign objects which may damage the equipment or cause personal injury to the operator or bystanders. POTENTIAL HAZARD ♦ Engine exhaust contains carbon monoxide, which is an odorless deadly poison.

- Page 8 DANGER POTENTIAL HAZARD ♦ In certain conditions gasoline is extremely flammable and highly explosive. WHAT CAN HAPPEN ♦ A static charge can ignite gasoline vapors. A fire or explosion from gasoline can burn you, others, and cause property damage. HOW TO AVOID THE HAZARD ♦...

-

Page 9: Operation

1.4 OPERATION Although hazard control and accident prevention are partially dependent upon the design and configuration of the equipment, these factors are also dependent upon the awareness, concern, prudence, and proper training of the personnel involved in the operation, transport, maintenance, and storage of the equipment. It is essential that all Operator Safety Mechanisms be connected and in operating condition prior to use for mowing. - Page 10 POTENTIAL HAZARD ♦ Mowing on wet grass or steep slopes can cause sliding and loss of control. WHAT CAN HAPPEN ♦ Wheels dropping over edges, ditches, steep banks, or water can cause rollovers, which may result in serious injury, death or drowning. HOW TO AVOID THE HAZARD ♦...

- Page 11 WARNING POTENTIAL HAZARD ♦ There is no rollover protection when the roll bar is down. WHAT CAN HAPPEN ♦ Wheels dropping over edges, ditches, steep banks, or water can cause rollovers, which may result in serious injury, death or drowning. HOW TO AVOID THE HAZARD ♦...

-

Page 12: Maintenance & Storage

1.4.17 Do Not mow with the discharge deflector raised, removed or altered unless there is a grass collection system or mulch kit in place and working properly. 1.4.18 Be aware of the mower discharge and direct discharge away from others. 1.4.19 Do Not operate mower under the influence of alcohol or drugs. -

Page 13: Safety Signs

When new components are installed, be sure that current safety signs are affixed to the replaced components. 1.6.4 New safety signs may be obtained from your authorized Exmark equipment dealer or distributor or from Exmark Mfg. Co. Inc. 1.6.5 Safety signs may be affixed by peeling off the backing to expose the adhesive surface. - Page 14 PART NO. 103-3794 LOCATION: LH Side of Console PART NO. 1-643222 LOCATION: Left of Center on Mower Deck, Under Floor Pan PART NO. 1-513746 LOCATIONS: Rear RH PART NO. 103-1798 LOCATION: Right of Throttle Control on RH Fuel Tank PART NO. 107-2102 LOCATION: Inside Surface of Upper Roll bar DO NOT OPERATE...

- Page 15 PART NO. 1-303508 LOCATION: RH Side on Top Rear of Mower Deck PART NO. 1-633922 LOCATION: Front Center on Top of Mower Deck PART NO. 107-2112 LOCATION: Top Center of Floorpan PART NO. 103-7218 LOCATION: Under Seat, Between Pumps on Frame PART NO.

-

Page 16: Specifications

2. SPECIFICATIONS 2.1 MODEL NUMBER Serial Nos. 440,000 and Higher: LZ31BV604; LZ31BV724 2.2 ENGINE 2.2.1 Engine Specifications: See your Engine Owner’s Manual 2.2.2 RPM: Full Speed: 3750 RPM (No Load) 2.3 FUEL SYSTEM 2.3.1 Capacity: 15.5 gal. (56.8 L.) 2.3.2 Type of Fuel: Regular unleaded gasoline, 87 octane or higher 2.3.3 Fuel Filter: In-line 30 Micron Briggs P/N 695327. -

Page 17: Seat

2.6 SEAT 2.6.1 Type: Deluxe suspension seat high back, low profile foam-in-place cushion (dampened, adjustable spring suspension) and armrests, adjustable back angle. 2.6.2 Mounting: Hinged to tilt up for access to hydraulic pumps, battery and other components. Held in tilted position with scissor-type links.. Adjustable fore and aft seat track. -

Page 18: Dimensions

2.10 DIMENSIONS 2.10.1 Overall Width: 60” Deck 72” Deck 2.10.2 Overall Length: 60” Deck 72” Deck 2.10.3 Overall Height: 60” Deck 72” Deck 2.10.4 Tread Width: (center to center of tires, widthwise) 60” Deck 72” Deck 2.10.5 Wheel Base: (center of caster to center of drive tire) 60”... - Page 19 c) LOOSELY install the lower roll bar hardware (four 3/8-16 x 1 capscrews, four spring disk washers and four 3/8-16 whizlock nuts) from the bolt bag to the tubes on each side as shown in Figure 2. NOTE: Be sure the spring disk washer cone is installed towards the head of the capscrew.

-

Page 20: Service Battery

UPPER ROLL BAR INSTALLATION 3.3 SERVICE BATTERY WARNING: Battery posts, terminals, and related accessories contain lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling. The machine is shipped with a filled lead acid battery. 3.3.1 Unhook seat latch and tilt seat up to gain access to the battery. -

Page 21: Install Seat

POTENTIAL HAZARD ♦ If the ignition is in the “ON” position there is potential for sparks and engagement of components. WHAT CAN HAPPEN ♦ Sparks could cause an explosion or moving parts could accidentally engage causing personal injury. HOW TO AVOID THE HAZARD ♦... -

Page 22: Position Discharge Chute

MOTION CONTROL LEVER MOUNT PLATE TO THE REAR & OUTSIDE OF ARM SHAFT FIGURE 4 CONTROL ARM SHAFT If the ends of the levers hit against each other, while in the drive position (levers rotated in as far as possible), make adjustments by moving the levers outwards to the neutral lock position and carefully bend them outward. -

Page 23: Operation Instructions

4. OPERATION INSTRUCTIONS 4.1 CONTROLS 4.1.1 Familiarize yourself with all controls before operating the mower. 4.1.2 Motion Control Levers: Located on each side of the console. The left lever controls the flow of hydraulic oil from the left hydrostatic pump to the left drive wheel motor. - Page 24 POTENTIAL HAZARD ♦ Machine can spin very rapidly by positioning one lever too much ahead of the other. WHAT CAN HAPPEN ♦ Operator may lose control of the machine, which may cause damage to the machine or injury. HOW TO AVOID THE HAZARD ♦...

-

Page 25: Pre-Start

4.1.9 Hour Meter: Located on the right fuel tank. The hour meter is connected to a pressure switch installed in the engine block and it records the number of hours that the engine has run. If the ignition switch is left on without engine running, hour meter will not run. - Page 26 On a cold engine, place the throttle midway between the “SLOW” and “FAST” positions and push choke lever forward into the “ON” position. Turn ignition switch to the “start” position. Release the switch as soon as the engine starts. IMPORTANT: DO NOT crank the engine continuously for more then ten (10) seconds at a time.

-

Page 27: Transporting

Rotate ignition switch to “OFF” position. Remove the key to prevent children or other unauthorized persons from starting engine. Close fuel shut-off valve when machine will not be used for a few days, when transporting, and when the unit is parked inside a building. 4.4 TRANSPORTING 4.4.1 Transporting a Unit: Use a heavy-duty trailer or truck to transport the machine. -

Page 28: Maintenance & Adjustments

not possible to use one full width ramp, use enough individual ramps to simulate a full width continuous ramp. Ramp should be long enough so that the angles between the ramp and the ground and the ramp and the trailer or truck do not exceed 15°. A steeper angle may cause mower deck components to get caught as the unit moves from ramp to trailer or truck. - Page 29 5.1.2 Check battery charge: Service Interval: Monthly Allowing batteries to stand for an extended period of time without recharging them will result in reduced performance and service life. To preserve optimum battery performance and life, recharge batteries in storage when the open circuit voltage drops to 12.4 volts.

- Page 30 POTENTIAL HAZARD ♦ Raising the mower deck for service or maintenance relying solely on mechanical or hydraulic jacks could be dangerous. WHAT CAN HAPPEN ♦ The mechanical or hydraulic jacks may not be enough support or may malfunction allowing the unit to fall, which could cause injury.

- Page 31 NOTE: If machine does not pass any of these tests, do not operate. Contact your authorized EXMARK SERVICE DEALER. IMPORTANT: It is essential that operator safety mechanisms be connected and in proper operating condition prior to use for mowing.

- Page 32 5.1.7 Check rollover protections systems (roll bar) pins Service Interval: Daily Make sure latch pin and hair pin are fully installed and lanyard is in good condition. 5.1.8 Check for loose hardware. Service Interval: Daily Stop engine, wait for all moving parts to stop, and remove key. Visually inspect machine for any loose hardware or any other possible problem.

- Page 33 5.1.11 Check hydraulic oil level: Service Interval: 40 hr. Stop engine and wait for all moving parts to stop. Clean area around hydraulic reservoir cap and remove cap. Oil level should be to the top of the baffle inside the tank. If not, add oil. Use only Mobil 1 15W-50 synthetic motor oil.

- Page 34 Pry out seals, and inspect bearings for wear or damage and replace if necessary. Pack the bearings with a NGLI grade #1 multi-purpose grease. Insert (1) bearing, (1) new seal into the wheel. NOTE: Seals (Exmark PN 103-0063) must be replaced. LUBRICATION CHART INITIAL NO. of...

- Page 35 If the axle assembly has had both spacer nuts removed (or broken loose), apply a thread locking adhesive to (1) spacer nut and thread onto the axle with the wrench flats facing outward. Do not thread spacer nut all of the way onto the end of the axle.

- Page 36 5.1.22 Change hydraulic system filter: Service Interval: After First 250 hrs. NOTE: Use only Exmark Part No. 103-2146. Stop engine, wait for all moving parts to stop, and remove key. Raise seat. Carefully clean area around filter. It is important that no dirt or contamination enter hydraulic system.

-

Page 37: Adjustments

5.1.24 Fuel Tank – mounting hardware specification. When installing the nuts on the fuel tank studs, fully tighten the nyloc nut and back off 1/2 turn. This allows for normal fuel tank expansion and contraction with changes in temperature and fuel levels. 5.1.25 Thread locking adhesives such as “Loctite 242”... - Page 38 Move lever out of transport (or 5” (12.7 cm) cutting height) position and down onto height adjustment pin to mow at selected height. To transport, move lever back up to transport (or 5” (12.7 cm) cutting height) position. Note: The foot operated deck lift assist lever can be used to momentarily lift the deck to clear objects.

- Page 39 On left side, adjust front swivel using the locking nut behind the swivel until the front chain is tight and all slack is removed from linkage. Do not lift front of deck off 3/4” (19 mm) block. Secure front swivel using locking nut in front of swivel.

- Page 40 MULE DRIVE BELT ADJUSTMENT 5.2.5 Deck Belt Tension. The deck belt is tensioned by a self-tensioning idler, no adjustment is necessary. 5.2.6 Belt Guide Adjustment. Stop engine, wait for all moving parts to stop, and remove key. Remove the belt shield on the right side of mower deck. Note belt guide bolted to deck near the shield support stud and right-hand pulley.

- Page 41 g) If a 1/4” to 5/16” (6.4 – 7.9 mm) gap can no longer be achieved because there is no clearance between nyloc nut below the spring and the jam nut above the trunion or there are no threads left on the bottom nyloc nut, the length of the brake rod can be adjusted.

- Page 42 If adjustment is needed, loosen the nut against the yoke and while applying slight rearward pressure on the motion control lever, turn the head of the adjustment bolt in the appropriate direction until lever is centered (keeping rearward pressure on the lever will keep the pin at the end of the slot and allow the adjustment bolt to move the lever to the appropriate position).

- Page 43 Run the unit at least 5 minutes with the drive levers at full forward speed to bring hydraulic system oil up to operating temperature. Unhook seat latch and tilt seat forward. Loosen lock nuts from the ball joints at each end of the RH pump control linkage.

-

Page 44: Waste Disposal

Return the switch to your Exmark dealer if it is faulty and is being replaced or if the unit containing the switch is no longer operating and is being scrapped. If the switch is damaged or broken open use extreme caution in handling. -

Page 45: Battery Disposal

6.3 BATTERY DISPOSAL POTENTIAL HAZARD ♦ Battery electrolyte contains sulfuric acid, which is poisonous and can cause severe burns WHAT CAN HAPPEN ♦ Swallowing electrolyte can be fatal or if it touches skin can cause severe burns. HOW TO AVOID THE HAZARD ♦... -

Page 46: Trouble Shooting

NOTE: After carefully checking the above steps, attempt to start the engine. If it does not start, contact your authorized Exmark service dealer. IMPORTANT: It is essential that all operator safety mechanisms be connected and in proper operating condition prior to mower use. -

Page 47: Electrical Diagram

8. ELECTRICAL DIAGRAM - 42 -... -

Page 48: Hydraulic Diagram

9. HYDRAULIC DIAGRAM - 43 -... -

Page 49: Warranty

(in the exercise of our reasonable discretion) to be defective in factory materials or workmanship. This warranty applies to Exmark turf equipment sold in the US or Canada. This warranty may only be assigned or transferred to a second (or third) owner by an authorized Exmark dealer. -

Page 50: Service Record

SERVICE RECORD Date Description of Work Done Service Done By... - Page 52 LAZER Z LAZER Z TURF TRACER METRO VIKING HYDRO ULTRA VAC SELF STEERING SULKY California to cause cancer, birth defects, or ©1997-2004 EXMARK MFG. CO. INC. INDUSTRIAL PARK BOX 808 BEATRICE, NE 68310 ALL RIGHTS RESERVED ® ® ® ® ®...