Graco ULTRA MAX 695 Instructions-Parts List Manual

Airless paint sprayer

Hide thumbs

Also See for ULTRA MAX 695:

- Operation (8 pages) ,

- Quick operator's manual (2 pages) ,

- Instructions-parts list manual (36 pages)

Table of Contents

Advertisement

INSTRUCTIONS-PARTS LIST

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

ULTRAr MAX 695

Airless Paint Sprayer

3000 psi (210 bar, 21 MPa) Maximum Working Pressure

230 VAC

232918, A

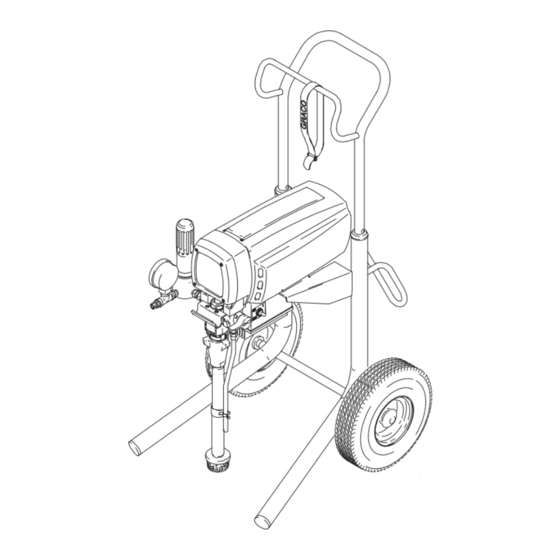

Hi-boy sprayer with hoses, gun,

RAC IVr DripLesstTip Guard and SwitchTipt

240 VAC

232914, A

Hi-boy sprayer with hoses, gun,

RAC IVr DripLesstTip Guard and SwitchTipt

232915, A

Lo-boy sprayer with hoses, gun,

RAC IVr DripLesstTip Guard and SwitchTipt

120 VAC

232919, A

Hi-boy sprayer with hoses, gun,

RAC IVr DripLesstTip Guard and SwitchTipt

120 VAC

232910 - 232913, A

232911 Hi-boy & 232913 Lo-boy sprayers with hoses, gun,

RAC IVr DripLesstTip Guard and SwitchTipt

232910 Hi-boy & 232912 Lo-boy sprayers

100 VAC

232916, A; 232917, A

Basic Hi-boy sprayer; Basic Lo-boy sprayer

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Table of Contents

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

ECOPYRIGHT 1999, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

First choice when

quality counts.t

232915

232917

Related Manuals

Operation

. . . . . . . . . . . . . . . . . . . . . . . . . .

Displacement Pump

Fluid Filter

. . . . . . . . . . . . . . . . . . . . . . . . . .

Spray Gun

Spray Tip

. . . . . . . . . . . . . . . . . . . . . . . . . . .

2

3

4

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14

14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14

309067

9659A

232918

232916

232919

232914

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

Rev. A

9660A

309067

308815

308249

309091

309055

. . . . . .

15

16

16

18

19

19

19

20

28

28

Advertisement

Table of Contents

Summary of Contents for Graco ULTRA MAX 695

-

Page 1: Table Of Contents

..... GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441 ECOPYRIGHT 1999, GRACO INC. Graco Inc. is registered to I.S. EN ISO 9001... -

Page 2: Component Function And Identification

Component Function and Identification 232918, 232916, 232919 and 232914 9661A Fig. 1 Motor (Under shield shown) DC motor, permanent magnet, totally enclosed, fan cooled Pressure Adjusting Knob Controls fluid outlet pressure ON/OFF Switch Power switch that controls VAC main power to sprayer Drive Assembly Transfers power from DC motor to the displacement pump Fluid Filter... -

Page 3: General Repair Information

General Repair Information WARNING CAUTION To reduce risk of pressure control malfunction: EXPLOSION HAZARD Motor and drive housing are very hot Use needle nose pliers to disconnect a wire. Never during operation and could burn skin if pull on wire, pull on connector. touched. -

Page 4: Grounding

Grounding WARNING Grounded Grounding Plug Outlets Improper installation or alteration of grounding plug results in risk of electric shock, fire or explosion that could cause serious injury or death. 1. The 232918, 232915, 232914 require a 230 VAC, 50 Hz, 10A circuit with a grounding receptacle. 230 VAC plug and outlet 9248A Fig. - Page 5 Basic Problem Solving TYPE OF WHAT TO CHECK WHAT TO DO PROBLEM If check is OK, go to next check When check is not OK, refer to this column Electrical 4. Motor brushes for the following: 4. Refer to page 10. (continued) a.

- Page 6 Basic Problem Solving TYPE OF WHAT TO CHECK WHAT TO DO PROBLEM If check is OK, go to next check When check is not OK, refer to this column 11. Motor thermal cutout switch. Connect ohmmeter between 11. Allow motor to cool. Correct cause of motor yellow leads.

- Page 7 Intermediate Problem Solving TYPE OF WHAT TO CHECK WHAT TO DO PROBLEM If check is OK, go to next check When check is not OK, refer to this column Drain valve 1. Drain valve for correct torque and/or worn parts. Check for 1.

- Page 8 Intermediate Problem Solving TYPE OF WHAT TO CHECK WHAT TO DO PROBLEM If check is OK, go to next check When check is not OK, refer to this column Spray pattern 3. Pressure adjustment potentiometer (77) by replacing 3. Replace potentiometer. See page 14.. variations with a new one.

-

Page 9: Motor Test

Motor Test Armature Short Circuit Test Relieve pressure; page 3. 1. Remove fan cover (B). See Fig.3. 2. Spin motor fan by hand. If there are no shorts, motor coasts two or three revolutions before coming to complete stop. If motor does not spin For checking armature, motor winding and brush freely, armature is shorted and motor must be electrical continuity. -

Page 10: Motor Brushes

Motor Brushes NOTE: Replace brushes worn to less than13 mm WARNING (0.5 in.). Check both brushes. Use Brush Repair Kit 236967 (243268 for sprayers 232914 and 232915) for ELECTRIC SHOCK HAZARD motor brush repair. Do not touch the brushes, leads, springs or brush holders while the sprayer is plugged in to reduce the risk of electric Relieve pressure;... -

Page 11: Displacement Pump

4. Tighten packing nut (202) enough to stop leakage, 6. Use a screwdriver to push retaining spring (15) up but no tighter. Fill packing nut full with Graco TSL. and push out pin (14). Push plug (201) into packing nut. -

Page 12: Motor

Motor NOTE: See Fig. 12 except where noted. 10. Align new motor with cart and reinstall screws (75). 11. Assemble drive housing to motor. Follow steps 9 1. Try to stop pump with piston rod (222) in lowest position. To lower piston rod manually, remove to 15 on page 15. -

Page 13: Pressure Control Repair

Pressure Control Repair Motor control board removal 6. Install new motor control board (22a) with four screws. Reconnect all wires and secure heat sink Relieve pressure; page 3. (22) to junction box (20). 2. Remove screws (25, 26) and lower heat sink (22) CAUTION and motor control board (22a). -

Page 14: Motor Control Board

Power Cord 232916, 232917, 232910–232913 6. Install heat sink (22). Be sure no leads are pinched between heat sink and junction box (20). Relieve pressure; page 3. 232915, 232918, 232919 and 232914 2. Remove screws (25, 26) and lower heat sink (22). See Fig. -

Page 15: Drive Housing, Connecting Rod, Crankshaft

Drive Housing, Connecting Rod, Crankshaft NOTE: Inspect parts as they are removed. Replace 7. Tap lower rear of drive housing (2) with a plastic parts that are worn or damaged. mallet to loosen motor. Pull drive housing straight off motor. 8. -

Page 16: Pressure Transducer

Pressure Transducer NOTE: See Fig. 14 and 15 for this procedure. 3. Guide harness up through leg and notch of drive housing (2). Secure guide wire over connector. NOTE: The pressure transducer (67) cannot be re- 4. While pulling guide wire out through bottom of paired or adjusted. - Page 17 Pressure Transducer Seal Installation 4. Lightly grease or oil transducer (67) and install pump (18). See page 11. 1. Lightly coat cleaned packing recess in manifold with a light grease or oil. 2. Heat seal (69) in hot water for several minutes. CAUTION Excess pressure from the probes or fingernails will damage the packing and cause subsequent leakage.

-

Page 18: Drain Valve

Drain Valve Repair Relieve pressure; page 3. 1. Unscrew spring retainer from valve body. Remove spring, washers and stem/ball. Clean any debris from ball or seat area. 2. Turn handle (54) to closed position. Drive out pin (53). Remove handle. 2. -

Page 19: Technical Data

If you have painters who do not read English, order one of the following labels to apply to your sprayer. The drawing below shows the best placement of these labels for good visibility. Order the labels directly from Graco, free of charge: Apply other 1–800–328–0211 language here... -

Page 20: Complete Sprayer Parts

Complete Sprayer Parts 232915, A 232917, A 50 Ref 47 Ref 21 75 20 Ref 107 108 67 Ref 116 Ref 20 Ref 78 Ref 77 Ref 232914, 232915, 232918, 232919 Pressure Control Box 232917; page 22 (Bottom View) 9668A 309067... - Page 21 Complete Sprayer Parts 232915, A; 232917, A Ref. Ref. Part No. Description Qty. Part No. Description Qty. 240057 KIT, housing, drive, U-695 187625 HANDLE, drain valve 100069 BALL, thrust 111699 GASKET, seat valve 101682 SCREW, sch, 1/4–20 x .625 187615 SEAT, valve, lapped 105510 LOCKWASHER, 1/4 hi-collar...

- Page 22 Complete Sprayer Parts 232914, A 232916, A 232918, A 232919, A 2a 13 20 Ref 107 108 67 Ref 116 Ref 77 Ref 232916, 232917 Pressure Control Box (Bottom View) 232918, 232919 and 232914; page 20 9669 309067...

- Page 23 Complete Sprayer Parts 232918, A; 232916, A; 232919, A; 232914, A Ref. Ref. Part No. Description Qty. Part No. Description Qty. 240057 KIT, housing, drive, U-695 187625 HANDLE, drain valve 100069 BALL, thrust 111699 GASKET, seat valve 101682 SCREW, sch, 1/4–20 x .625 187615 SEAT, valve, lapped 105510...

- Page 24 Complete Sprayer Parts Model 232912 and 232913, Series A 7 41 2a 13 47 Ref 80 Ref 50 Ref 67 Ref 77 Ref Pressure Control Box 30 Ref (Bottom View) 9670A 309067...

- Page 25 Complete Sprayer Parts Model 232912 and 232913, Series A Ref. Ref. Part No. Description Qty. Part No. Description Qty. 240057 KIT, housing, drive, U–695 195186 CLIP, spring 100069 BALL, thrust 241936 HOSE, drain assy 101682 SCREW, sch, 1/4–20 x .625 235014 ASSEMBLY, drain valve 105510...

- Page 26 Complete Sprayer Parts Model 232910 and 232911, Series A 2a 13 82 Ref 67 Ref 77 Ref Pressure Control Box 30 Ref (Bottom View) 9671A 309067...

- Page 27 Complete Sprayer Parts Model 232910 and 232911, Series A Ref. Ref. Part No. Description Qty. Part No. Description Qty. 240057 KIT, housing, drive, U–695 192648 CLIP, spring 100069 BALL, thrust 235014 ASSEMBLY, drain valve 101682 SCREW, sch, 1/4–20 x .625 includes 55 and 56 105510 LOCKWASHER, 1/4 hi–collar...

-

Page 28: Graco Warranty

Graco’s written recommendations. This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or sub- stitution of non–Graco component parts.