Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for White SPEEDYLOCK 1500

- Page 1 DIFFERENTIAL...

- Page 2 this applianc e toy. it is if it if it of lint, 6. Do 7. Do 8. To 9. Do 12. Do...

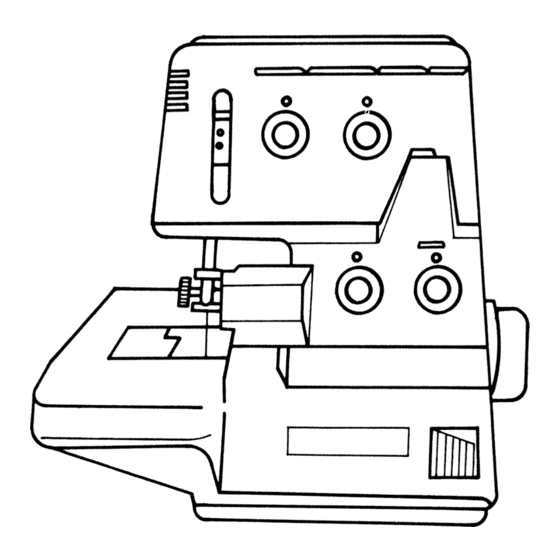

- Page 3 THANK YOU FOR CHOOSING OUR OVERLOCK MACHINE This overlock machine can stitch dependable seams on all kinds of fabric, both light and heavy, including cotton, wool, rayon, tricot, jersey, and knits. You do not need a special table for this portable machine. We suggest that you read this instruction manual carefully before you start to operate the machine.

-

Page 4: Table Of Contents

QEPNIENTS NAME OF MMN COMPONENTS SETTING UP YOUR MACHINE 4—6 The position of thread pole Spool holders Spool caps Connecting the foot control Controlling sewing speed Safety switch Attaching the waste catcher ACCESSORIES USING THE MACHINE Handwheel Front cover Free arm LOOPER THREADING NEEDLE THREADING TEST SEWING... -

Page 11: Needle Threading

NEEDLE THREADING 5.Turn the handwheel toward you until needles are fully raised. G.Pass the right and left needle threads as illustrated. Important: thread must correctly between the two discs inside the tension dials. Pass through the needle eyes from front to back as illustrated. -

Page 12: Test Sewing

— —... -

Page 13: Adjusting Thread Tensions

— —... -

Page 14: Needle Thread Tensions

— —... -

Page 15: Machine Adjustment Chart

The best tension for one fabric may not be correct for another. The required tensions depend upon stiffness and thickness of fabric, thread size and type. If necessary, readjust referring to the chart below. labrIcs Threads Needle Stitch length Standard Setting Light-weight Georgette Cotton... -

Page 16: Changing The Thread

— —... -

Page 17: Adjustment Of Stitch Length

— —... -

Page 18: Cutting Width

— —... -

Page 19: Changing The Needle

CHANGiNG THE NEEDLE Turn the power switch to “OFF’ before changing Hexagon wrench key needles. Do not use any needle which is bent or blunt. l.Turn the handwheel toward you until the needles are fully raised. 2.Open the front cover and lower the presser foot. 3. -

Page 20: Replacing The Cutters

REPLACINGIHE CUTTERS Turn the power switch to “OFF” before replacing the cutter blades. The lower cutter is made of special material and does not usually need to be replaced. However; should it become damaged, it can be replaced by your local dealer. To replace the upper cutter when it becomes dull: l.Open the front cover and turn the handwheel toward you until the needles are in the lowest position. -

Page 21: Three Thread Narrow Or Wide

This machine is a 3/4 thread convertible overlock. Remove either the right or left needle. Your machine is now ready for use as a 3-thread overlock. Refer to “CHANGING THE NEEDLE” Hexagon wrench key 4mm(0. 16”) Using the needle on the right only. The stitch width is 4mm (0.1611) 6mm(0.24”) Using the needle on the left only. -

Page 23: Rolled And Narrow Edge

— —... - Page 24 Important: It necessary, adjust the stitch length and cutting width. Threads Fabrics Narrow hemming Rolled hemming Spun polyester Spun polyester Georgette No5O—8O No.50—80 Needle thread Lawn Polyester continuous Polyester continuous Crepe-de No.50—80 No5O8O -chine Wooly-nylon Spun polyester Upper • Silk Spun polyester Wooly-nylon No.50—80...

-

Page 25: Differential Feed

— —... -

Page 26: Gathering

GATHERING] [WAVY KNITS knit perfectly flat seams stretchy garments, the front feed teeth need to feed faster than the rear feed teeth to prevent stretching the fabric. To Gather, the front feed teeth will also need to feed faster than the rear feed teeth. -

Page 27: Trouble Shooting Guide

RbUBLE SHOOTING GUIDE Check items below before calhng for service. Page Corrective action Problem Cause Needles are bent, blunt or Replace with new needles. points are damaged. Insert the needles correctly to the Needles not inserted correctly. needle clamp. Needles break You have forcibly pulled the Guide fabric gently with both fabric. -

Page 28: Cleaning And Lubricating

LCIJEANING AND LUBRICATING To keep your machine running smoothly ; it is necessary to clean using the brush from the ac cessory box now and then. This machine requires very little lubrication as the main components are made of special materials. - Page 29 S3J.ON...