Summary of Contents for Exmark VERTEX X Series

- Page 1 VERTEX ® X- AND S-SERIES For Serial Nos. 416,150,475 & Higher Part No. 4506-984 Rev. A...

- Page 2 To acquire a spark arrester for your unit, see your Engine Service Dealer. For all models that do not have Exmark engines, please refer to the engine manufacturer's information included with the machine. For models with Exmark engines, refer to this manual for information.

-

Page 3: Introduction

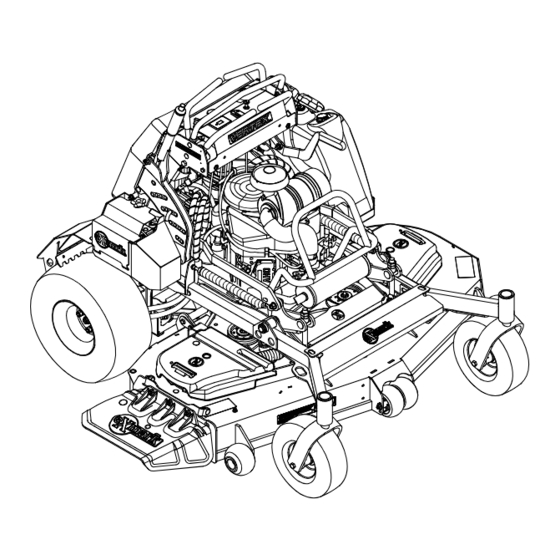

Introduction Service Dealer or Exmark Customer Service and have the model and serial numbers of your product ready. CONGRATULATIONS on the purchase of your Figure 1 identifies the location of the model and serial Exmark Mower. This product has been carefully numbers on the product. -

Page 4: Table Of Contents

Contents Mower Deck Drive Belt Tension .....51 Park Brake Adjustment–S-Series Only.....51 Motion Control Tracking Adjustment .....51 Introduction ............3 Motion Control Neutral Lock Safety ..............5 Adjustment ..........52 Safety Alert Symbol ......... 5 Cleaning ............53 General Safety ..........5 Cleaning and Storing Safety......53 Safety and Instructional Decals ....... -

Page 5: Safety

Safety Safety this material to them; other languages may be available on our website. Safety Alert Symbol • Only allow trained, responsible, and physically capable operators that are familiar with the safe This Safety Alert Symbol (Figure 2) is used both in operation, operator controls, and safety signs and this manual and on the machine to identify important instructions to operate the machine. -

Page 6: Safety And Instructional Decals

Exmark equipment dealer or labels. distributor or from Exmark Mfg. Co. Inc. • Replace all worn, damaged, or missing safety • Safety signs may be affixed by peeling off the signs. - Page 7 Safety decal116-8774 116-8774 decal116-7912 All S-Series Models and 116-7912 52 Inch Deck X-Series Models 1. Interval 4. Neutral 2. Power Take-off (PTO) 5. Operator presence control 3. Parking brake 6. Battery decal126-2055 126-2055 S-Series Models Only 1. Wheel lug nut—torque to 95 ft-lb (129 N-m). 2.

- Page 8 Safety decal146-1018 decal142-7432 146-1018 142-7432 60 and 72 Inch Decks S-Series Models Only X-Series Models Only 1. Read the instructions 5. Check hydraulic oil before servicing or level; refer to the performing maintenance Operator's manual or further instructions 2. Time interval 6.

- Page 9 Safety decal146-3284 146-3284 X-Series EFI Models Only 1. Fuse location 4. Main, 20A decalptoswitch PTO Switch Symbols 2. Relay location 5. Clutch saver relay S-Series Models Only 3. Auxiliary, 15A 6. Start relay 1. PTO–engage 2. PTO–disengage g224590 Lock Symbol decalptosymbols PTO Switch Symbols X-Series Models Only...

- Page 10 Safety decal146-0287 146-0287 S-Series Non-EFI Models Only 1. Forward 10. Optional light accessory 2. Neutral 11. Warning—Read the Operator’s Manual. Do Not operate this machine unless you are trained. Wear hearing protection. 3. Reverse 12. Warning—Stay away from moving parts; keep all guards in place.

- Page 11 Safety decal146-0288 146-0288 S-Series EFI Models Only 1. Forward 11. Warning—Read the Operator’s Manual. Do Not operate this machine unless you are trained. Wear hearing protection. 2. Neutral 12. Warning—Stay away from moving parts; keep all guards in place. Stop engine and remove key before adjusting, servicing, or cleaning.

- Page 12 Safety decal146-0993 146-0993 X-Series EFI Models Only 1. Forward 11. Warning—Read the Operator’s Manual. Do Not operate this machine unless you are trained. Wear hearing protection. 2. Neutral 12. Warning—Stay away from moving parts; keep all guards in place. Stop engine and remove key before adjusting, servicing, or cleaning.

- Page 13 Safety decal146-1969 146-1969 X-Series Models Only 1. Read the Operator’s manual. 3. Release button to lock 2. Push button down to unlock 4. Height of cut...

- Page 14 Safety decal146-2052 146-2052 X-Series Models Only 1. Read the Operator’s manual. 3. Release button to lock 2. Push button down to unlock 4. Height of cut...

- Page 15 Safety decal146-3598 146-3598 X-Series Non-EFI Models Only 1. Forward 10. Optional light accessory 2. Neutral 11. Warning—Read the Operator’s Manual. Do Not operate this machine unless you are trained. Wear hearing protection. 3. Reverse 12. Warning—Stay away from moving parts; keep all guards in place.

-

Page 16: Specifications

Engine • Polarity: Negative Ground • Engine Specifications: See your Engine Owner’s Manual • Fuses: • Engine Oil Type: Exmark 4-Cycle Premium – 20 amp charging system fuse Engine Oil – 15 amp accessory fuse • RPM: Full Speed: – 20 amp power fuse –... - Page 17 Semi-Pneumatic – X-Series: Hydro-Gear Quantity – S-Series: Parker Tread Smooth • Hydraulic Oil: Use Exmark Premium Hydro Oil. Size 13 x 5-6 • Hydraulic Oil Capacity: All X-Series Models – X-Series: 6.15 qt. (5.8 L) – S-Series: 2.25 qt. (2.1 L) Front Caster •...

-

Page 18: Dimensions

Specifications • Deck Depth: 5.5 inches (14 cm) X-Series • Cutting Height Adjustment: All models adjusts Drive from 1.5 inch (3.8 cm) to 5 inches (12.7 cm) in 1/4 inch (6.35 mm) increments. Pneumatic (Air-Filled) • Mulching Kit: Optional • Bagger: Optional 52 Inch 60 Inch 72 Inch... -

Page 19: Torque Requirements

Specifications Tread Width: (Outside to Outside of Curb Weight: Tires, Widthwise) 48 Inch Models 52 Inch Models 52 Inch Models (S-Series) (X-Series) 48 Inch Models 52 Inch Models 52 Inch Models (S-Series) (X-Series) 925 lb (420 kg) 936 lb (425 kg) 1250 lb (567 kg) 47.79 inches 47.79 inches... -

Page 20: Product Overview

Operation Product Overview Operation Note: Determine the left and right sides of the machine from the normal operating position. Controls Note: Become familiar with all the controls before starting the engine and operating the machine. Motion Control Levers There are two sets of motion control levers, located in front and behind the reference bar on the top console, that control the forward and reverse motion of the machine. - Page 21 Operation Throttle Control (All S-Series and Note: When the motion control levers are in the neutral position, and park brake is engaged, a LCD X-Series Non-EFI Models Only) indicator displays on the message display. Located on the center of the control console (red lever).

- Page 22 Operation The hour meter is recording when the decimal point is flashing in Hour/Voltage display. Hours are displayed when the key is off or when the machine is running. Note: If the ignition key is turned to the “ON” position for a few seconds before cranking the engine, the battery voltage will display in the area where the hours are normally displayed.

-

Page 23: Before Operation

To raise to transport position, push the button down proper working condition. Replace worn or on top of the lever to disengage the deck lift latch. deteriorated parts with genuine Exmark parts Pull the handle all the way rearward and release when necessary. -

Page 24: Operating Safety

Operation Fuel Safety the tank allows gasoline to expand. Overfilling may result in fuel leakage or damage to the engine DANGER or emission system. • Gasoline is harmful or fatal if swallowed. Gasoline is extremely flammable and vapors are Long-term exposure to vapors may cause serious explosive. - Page 25 Operation • Do not operate the machine while ill, tired, or – Before refueling. under the influence of alcohol or drugs. – Before dumping the grass catcher. • Operate the machine only in good visibility and – Before making height adjustments. appropriate weather conditions.

- Page 26 Operation machine could suddenly roll over if a wheel goes attempts. Failure to follow these guidelines over the edge or the edge collapses. Keep a safe can burn out the starter motor. distance between the machine and any hazard. If the choke is in the “ON” position, gradually Use a hand held tool to operate in these areas.

- Page 27 Operation Note: For X-Series EFI Models Only, the engine Make sure the motion control levers are in the RPM will automatically reduce when the PTO neutral position. switch is disengaged to extend the clutch life. Release the parking brake. To move forward in a straight line, move both Stopping the Engine rear levers forward with equal pressure.

- Page 28 Operation The machine will move faster the farther the all the way rearward and release the button to motion control levers are moved from the neutral latch the cutting deck into the 5.0 inch (12.7 cm) position. transport position. To stop, position both motion control levers in The deck is raised by pushing the button down on the neutral operate position.

- Page 29 Operation Stop the machine and move the drive levers to the neutral position. Disengage the PTO. Engage the park brake. Stop the engine, remove the key and wait for all moving parts to stop. After adjusting the height of cut, adjust the anti-scalp rollers by removing the nyloc nut, spacer, and bolt.

-

Page 30: After Operation

Operation • Use full width ramps when loading the machine. • Engage the park brake, then block the wheels. Do Not rely solely on the parking brake to hold the machine on the trailer. • Securely fasten the machine to the trailer or truck with straps, chains, cable, or ropes. - Page 31 Operation WARNING Loading a machine on a trailer or truck increases the possibility of backward tip-over. Backward tip-over could cause serious injury or death. • Use extreme caution when operating a machine on a ramp. • Use only a single, full width ramp; Do Not use individual ramps for each side of the machine.

-

Page 32: Maintenance

Exmark parts could lead to serious Use only approved fuel lines and fuel filters injury or death. Unauthorized changes to the for high pressure systems. -

Page 33: Recommended Maintenance Schedule(S)

Maintenance • Keep your hands and feet away from moving parts or hot surfaces. If possible, do not make adjustments with the engine running. • Keep all parts in good working condition and all hardware tightened, especially the blade-attachment hardware. Recommended Maintenance Schedule(s) Maintenance Service Maintenance Procedure... -

Page 34: Periodic Maintenance

Maintenance Periodic Maintenance Lift the Thigh Pad for Rear Access Service Interval: As required The thigh pad can be removed for easy access to the hydro oil reservoir and pumps. Lift the thigh pad roughly thirty degrees and lift to remove from machine. g375969 Figure 17 1. -

Page 35: Check Engine Oil Level

If the oil level is low, wipe off the area around the • Always shield eyes and face from battery. oil fill cap, remove cap and fill to the “FULL” mark on the dipstick. Exmark 4-Cycle Premium Engine Oil is recommended; refer to the Engine DANGER Owner's manual for an appropriate API rating and viscosity. - Page 36 Maintenance Important: Make sure the negative battery cable DANGER is disconnected and the battery charger used for Jump starting a weak battery that is cracked, charging the battery should have an output of frozen, has low electrolyte level, or an 16 volts and 7 amps or less to avoid damaging open/shorted battery cell, can cause an the battery (see chart for recommended charger...

-

Page 37: Check Mower Blades

Maintenance Install bushing through blade with bushing flange on bottom (grass) side of blade. g012785 Figure 18 g006780 1. Positive (+) cable on discharged battery Figure 19 2. Positive (+) cable on booster battery 1. Install bushing in blade prior to installing bushing in 3. - Page 38 Always install the original Exmark blades, blade bushings, and blade bolts as shown.

-

Page 39: Check Safety Interlock System

Maintenance Check Safety Interlock System Important: It is essential that operator safety mechanisms be connected and in proper operating condition prior to use. Note: If machine does not pass any of these tests, Do Not operate. Contact an Authorized Service Dealer. Note: To prevent PTO disengagement on rough terrain, the platform has a 1/2 second time delay before the PTO disengages after the operator leaves the platform. - Page 40 Maintenance Check Engine Starting Circuit Chart Note: In the Check Engine Starting Circuit Chart, the state of system item that is bold is being checked in each scenario. X- and S-Series System Parking Motion Control Levers Operator Outcome PTO (Blades) Brake Starter must Disengaged...

- Page 41 Maintenance Check Engine Starting Circuit Chart—continued X-Series Only System Parking Motion Control Levers Operator Outcome PTO (Switch) Brake Up position Starter must Disengaged In neutral On platform or off the not crank platform State of System Check Shutdown Circuit Chart Note: The state of system item(s) that is bold is being checked in each scenario.

-

Page 42: Check For Loose Hardware

Before reinstalling new filter, apply a thin coating When checking or replacing the air filter element, of Exmark 4–Cycle Premium Engine oil on the make sure the air filter assembly is installed in the surface of the rubber seal. Turn filter clockwise brackets. -

Page 43: Check Hydraulic Oil Level

Check Hydraulic Oil Level If the oil level is below the “ADD” or “COLD” Service Interval: Every 40 hours level, add Exmark Premium Hydro Oil. Do Not overfill. Stop engine and wait for all moving parts to stop, and remove key. Engage parking brake. - Page 44 Pack the bearings with a NLGI grade #1 multi-purpose grease. Insert one bearing, one new seal into the wheel. Note: Seals (Exmark P/N 103-0063) must be replaced. If the axle assembly has had both spacer nuts removed (or broken loose), apply a thread locking adhesive to one spacer nut and thread onto the axle with the wrench flats facing outward.

-

Page 45: Check Spark Plugs

Maintenance Note: Use only Exmark Part No. 109-4180 for Insert the second bearing and new seal into the wheel. Summer use above 32°F (0°C) or P/N 1-523541 for Winter use below 32°F (0°C) (Refer to Transmission Apply a thread locking adhesive to the 2nd spacer section in Specifications for filter specifications). -

Page 46: Change Hydraulic System Filter And Fluid (S-Series)

After first 250 hours Oil (Preferred) *Every 500 hours/Yearly Important: Before reinstalling new filter, fill thereafter it with Exmark Premium Hydro oil and apply a thin coat of oil on the surface of the rubber Mobil 1 15W50 After first 250 hours seal. - Page 47 Turn filter clockwise until rubber seal contacts the filter adapter. Then Note: Use only Exmark Part No. 109-4180 for tighten the filter an additional 2/3 to 3/4 turn. Summer use above 32°F (0°C) or P/N 1-523541 for Winter use below 32°F (0°C) (Refer to Transmission...

-

Page 48: Wheel Hub Nut Specification-S-Series Only

Maintenance Hydraulic System Air Purge hot to touch, turn off engine. The pumps may be damaged if the pump becomes too hot. Service Interval: As required If either drive wheel still does not rotate continue with step 4. Air must be purged from the hydraulic system when any hydraulic components, including oil Open the bypass valve (shown in Figure 27). -

Page 49: Thread Locking Adhesives

Maintenance Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake. Wait for muffler to cool. If any breaks in the screen or welds are observed, replace arrester. If plugging of the screen is observed, remove arrester and shake loose particles out of the arrester and clean screen with a wire brush (soak in solvent if necessary). -

Page 50: Adjustments

Maintenance Adjustments Position the mower on a flat surface. Stop engine, wait for all moving parts to stop, and Note: Disengage PTO, shut off engine, wait for remove key. Engage parking brake. all moving parts to stop, engage parking brake, and Check the tire pressure in drive tires and remove key before servicing, cleaning, or making any pneumatic front caster tires (if equipped). -

Page 51: Pump Drive Belt Tension

Maintenance Pump Drive Belt Tension If the parking brake still does not hold securely, an adjustment is required. To adjust the brake, Self-tensioning - No adjustment necessary. loosen whizlock nuts and slide the lower link up or down until the measurement is achieved. Mower Deck Drive Belt Tension Self-tensioning - No adjustment necessary. -

Page 52: Motion Control Neutral Lock Adjustment

Maintenance Replace thigh pad. Loosen upper and lower jam nuts at the top of the front control link. Drive the machine and check the full forward tracking. Lengthen link to move control rearward. Repeat steps 1 through 4 until desired tracking Shorten link to move control forward. -

Page 53: Cleaning

Maintenance Cleaning CAUTION Excessive debris around engine cooling air intake and exhaust system area can cause engine, Cleaning and Storing Safety exhaust area, and hydraulic system to overheat • Park machine on level ground, disengage drives, which can create a fire hazard. set parking brake, stop engine, remove key, Clean all debris from engine and exhaust system and disconnect spark plug wire. -

Page 54: Waste Disposal

Maintenance Waste Disposal Motor Oil Disposal Engine oil and hydraulic oil are both pollutants to the environment. Dispose of used oil at a certified recycling center or according to your state and local regulations. Battery Disposal DANGER Battery electrolyte contains sulfuric acid, which is poisonous and can cause severe burns. -

Page 55: Troubleshooting

Troubleshooting Troubleshooting Important: It is essential that all operator safety mechanisms be connected and in proper operating condition prior to mower use. When a problem occurs, do not overlook the simple causes. For example: starting problems could be caused by an empty fuel tank. The following table lists some of the common causes of trouble. - Page 56 Troubleshooting Problem Possible Cause Corrective Action Engine loses power 1. Engine load is excessive 1. Reduce the ground speed. 2. Air cleaner is dirty. 2. Clean or replace the air cleaner element. 3. Oil level in the crankcase is low. 3.

- Page 57 Troubleshooting Problem Possible Cause Corrective Action Clutch will not engage. 1. Fuse is blown. 1. Replace fuse. Check coil resistance, battery charge, charging system, and wiring connections and replace if necessary. 2. Low voltage supply at the clutch. 2. Check coil resistance, battery charge, charging system, and wiring connections and replace if necessary.

-

Page 58: Schematics

Schematics Schematics Electrical Logic Schematic- Kawasaki for X-Series EFI Models g449418... - Page 59 Schematics Electrical Logic Schematic- Kawasaki for X-Series Non-EFI Models g462015...

- Page 60 Schematics Electrical Logic Schematic- Kawasaki for S-Series Models g375992...

- Page 61 Schematics Electrical Logic Schematic- Kohler EFI g377622...

- Page 62 Schematics Hydraulic Diagram—X-Series Models HYDRAULIC TANK CASE DRAIN CASE DRAIN CASE DRAIN CASE DRAIN LEFT RIGHT PUMP PUMP MOTOR MOTOR LEFT RIGHT g451618 Hydraulic Diagram—S-Series Models g376004...

-

Page 63: Information

While the exposure from Exmark products may be negligible or well within the “no significant risk” range, out of an abundance of caution, Exmark has elected to provide the Prop 65 warnings. Moreover, if Exmark does not provide these warnings, it could be sued by the State of California or by... - Page 64 Notes:...

- Page 65 Notes:...

- Page 66 Service Record Date: Description of Work Done: Service Done By:...

- Page 68 Label Here (Included in the Literature Pack) or Fill in Below Engine Model No. and Spec. No. Model No. Engine Serial No. (E/No) Serial No. ©2023 Exmark Mfg. Co., Inc. Part No. 4506-984 Rev. A 415 Industrial Row (402) 223-6300 Beatrice, NE 68310 *4506-984* A...