Table of Contents

Advertisement

Quick Links

INSTRUCTIONS

This manual contains important

warnings and information.

READ AND RETAIN FOR REFERENCE

Instructions

Air-Powered Premier

®

Hydra-Cat

Variable Ratio

Proportioning Pump

100 PSI (6.8 bar) Maximum Working Air Pressure

5000 PSI (333 bar) Maximum Working Fluid Pressure

Model: See Chart

Assembly

Ratio

Ratio

Part #

Min.

Max.

965-481

1.50

4.50

965-479

2.00

6.00

965-530

1.00

3.00

965-579

1.33

4.00

965-480

1.00

3.00

WARNING

MOVING PARTS HAZARD

Relieve fluid and air pressure to unit before

servicing unit.

Do not operate with panels

removed. Follow pressure relief procedure on

page 11.

Graco Inc. does not manufacture or supply any of the reactive chemical components that are used in this equipment

and is not responsible for their effects. Because of the vast number of chemicals that could be used and their

varying chemical reactions, the buyer and user of this equipment should determine all factors relating to the fluids

used, including any of the potential hazards involved. Particular inquiry and investigation should be made into

potential dangers relating to toxic fumes, fires, explosions, reaction times, and exposure of human beings to the

individual components or their resultant mixtures. Graco assumes no responsibility for loss, damage, expense or

claims for bodily injury or property damage, direct or consequential, arising from the use of such chemical

components.

GRACO INC.

H.P.

WARNING

P.O. BOX 1441

^

Copyright 1998 Graco Inc.

MINNEAPOLIS, MN

684-026

Revision C

55440-1441

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Graco Hydra-Cat 965-481

- Page 1 WARNING Graco Inc. does not manufacture or supply any of the reactive chemical components that are used in this equipment and is not responsible for their effects. Because of the vast number of chemicals that could be used and their varying chemical reactions, the buyer and user of this equipment should determine all factors relating to the fluids used, including any of the potential hazards involved.

-

Page 2: Table Of Contents

Disconnecting the Displacement Pump ....16 Adjusting the Ratio Setting........10 Reconnecting the Displacement Pump....17 Disconnecting the Air Motor ........17 Reconnecting the Air Motor........17 Replacing the Bearings ..........18 Dimensions..............19 Air Consumption ............19 Technical Data..............21 Graco Phone Numbers..........22 The Graco Warranty and Disclaimers ......22 684-026... -

Page 3: Symbols

Wear the appropriate protective clothing, gloves, eyewear, and respirator. Graco does not manufacture or supply any of the reactive chemical components that may be used in this equipment and is not responsible for their effects. Graco assumes no responsibility for loss, damage, expense or claims for personal injury or property damage, direct or consequential, arising from the use of such chemical components. - Page 4 Read all instruction manuals, tags, and labels before operating the equipment. INSTRUCTION Use the equipment only for its intended purpose. If you are uncertain about the usage, call Graco Technical Assistance at 1-800-543-0339. Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

- Page 5 Handle and route hoses and tubes carefully. Keep hoses and tubes away from moving parts and hot surfaces. Do not use the hoses to pull equipment. Do not expose Graco hoses to temperatures above 180ºF (82ºC) or below -40ºF (-40ºC).

-

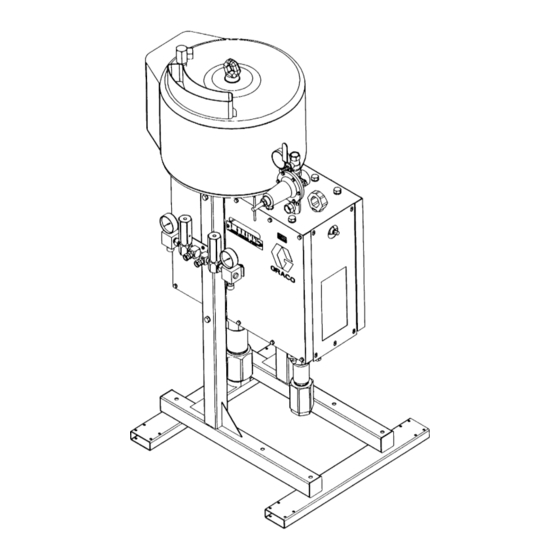

Page 6: Specification Of Hydra-Cat H

Hydra-Cat H.P. system. For assistance in outlet fittings. Tighten all of the fittings. designing a system to suit your particular needs, contact your nearest Graco representative. NOTE: The reference numbers and letters in the text correspond to the numbers and letters in the drawings. -

Page 7: System Accessories

(B) to the desired pressure. See the Typical sized to meet your system requirements and the pressure Installation and the Parts Drawing. limits of the pump. Use only genuine Graco parts and accessories. Pressure Relief Valve In the air line, install an air filter (F) to remove harmful dirt All components have rated working pressures of 5000 psi and moisture from the compressed air supply. -

Page 8: Electrical Grounding

Electrical Grounding 4. Spray gun or dispensing valve: Obtain grounding WARNING through connection to a properly grounded fluid hose and pump. 5. Fluid supply container: according to your local code. FIRE AND EXPLOSION HAZARD 6. Object being sprayed: according to local code. Static electricity is created by the high velocity flow of fluid through the pump and hose. -

Page 9: Ratio Adjustment

Ratio Adjustment Understanding the terms used with the Hydra–Cat (H.P.) The primary pump (A) is directly under the air motor (H); System, how it functions, and how to find and set the it usually pumps the base fluid. The secondary pump (B) correct ratios for your application is the key to easier, more is on the opposite end of the lever arm (E);... -

Page 10: Determine The Ratio

Relationship Between Primary with the base’s reducer. Contact your Graco Secondary Pumps representative for the correct seals to use. Moving the fulcrum point away from the primary pump reduces the secondary stroke length, reducing its fluid Procedure 1: Base is not pre-reduced output. -

Page 11: Operation

Operation WARNING System Flushing The pumps were tested with lightweight oil at the factory. INJECTION HAZARD Before operating the pump, thoroughly flush the Hydra-Cat The system pressure must be manually H.P. to prevent contamination of your fluids. relieved to prevent the system from starting or NOTE: spraying accidentally. -

Page 12: Checking The Ratio

The wet cups (18) and then remove the four sheet metal covers (17) from should be filled to 1/3 full with Graco Throat Seal Liquid the front and back of the proportioner. (TSL) or compatible solvent. -

Page 13: Air Lubrication

Make sure to use an Industrial Grade 1, Heavy Duty, If your air supply Is very dry, install an air line lubricator Extreme Pressure, Lithium Soap Grease, Graco Part between the air regulator and the pump air motor for Number 110-293 or equivalent. -

Page 14: Troubleshooting

Troubleshooting With the main bleed-type air valve (1) off, remove Troubleshooting Techniques the thumb screws (14) and guards (15) from each Because the pumps are mechanically linked, the action of side of the proportioner. one pump can affect the readings of the second pump. Unscrew the connecting rod nut (10) from the Therefore, the key to successful troubleshooting is to be primary pump. -

Page 15: Troubleshooting Chart

Troubleshooting Chart PROBLEM CAUSE SOLUTION System will not run or Air pressure or air Increase air pressure. Check air compressor and air supply filters stops while running. volume is too low. regulator, lubricator valves and other components for blockages and restrictions. If this is a new system, be sure that air supply components have been sized properly. -

Page 16: Service

Service 4. With the bleeder type main air valve turned off (1), Required Tools remove the thumb screws (14) and the two guards Set of large adjustable wrenches (15) from the sides of the proportioner. Set of metric sockets or wrenches 5. -

Page 17: Reconnecting The Displacement Pump

Torque to 196–210 N.m ft-lb). service and reference. 7. Fill the wet cup (18) 1/3 full with Graco Throat Seal Lubricant or compatible solvent. Reconnecting the Air Motor 8. -

Page 18: Replacing The Bearings

(11). Run the pump of the shaft ends. slowly at first to ensure proper operation. 7. Replace the bearings only with identical Graco replacement parts. Pack the bearings in Industrial Grade 1, Heavy Duty, Extreme Pressure, Lithium Soap Grease, Graco Part Number 110-293 or equivalent. -

Page 19: Dimensions

Dimensions (A) Height.......... 66.0 inch 1676 mm) (B) Length ..........31.5 inch (800 mm) (C) Width..........33.0 inch (838 mm) (D) Air Inlet............3/4 npt(f) (E) Fluid Inlets..........Two, 2” npt(f) (G) Fluid Outlet ..........Two 1/2” npt(f) (H) Relief Valve Outlets ......Two, 1/4 npt(m) Net Weight ........ - Page 20 NOTES 684-026...

-

Page 21: Technical Data

Technical Data Air motor effective diameter..................Premier 12.64” (321 mm) ..........................King 10.00” (254 mm) Air motor stroke ........................4.75” (120 mm) Operating air pressure range..............20 to 100 psi (1.4 to 7 bar) Premier 20 to 90 psi (1.4 to 6.2 bar) King Recommended pump speed ................. -

Page 22: Graco Phone Numbers

Graco distributor to the original purchaser for use. As purchaser’s sole remedy for breach of this warranty, Graco will, for a period of twelve months or two thousand hours of operation from time of sale, repair or replace any part of the equipment proven defective.