Summary of Contents for SATO Argox I4 Series

- Page 1 I4 Series Printer User Manual http://www.argox.com Version: 1.3 service@argox.com Date: May 23, 2019...

- Page 2 Liability Disclaimer Argox Corporation takes steps to assure that the company’s published engineering specifications and manuals are correct; however, errors do occur. Argox reserves the right to correct any such errors and disclaims any resulting liability. In no event shall Argox or anyone else involved in the creation, production, or delivery of the accompanying product (including hardware and software) be liable for any damages whatsoever (including, without limitation, damages for loss of business profits, business...

- Page 3 This is a Grade A product. In living environment, the product may cause interference to radio communications. In this case, the user is encouraged to try to correct the interference by effective measures. Caution Any changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate the equipment.

-

Page 4: Table Of Contents

Contents Introduction ......................1 Features ....................... 1 Unpacking ....................2 Understand your printer ................3 1.3.1 Perspective view ................3 1.3.2 Back view ..................4 1.3.3 Interior view ................... 5 Printer control panel ................... 6 1.4.1 Status lights ..................6 1.4.2 Buttons ................... - Page 5 Maintenance ......................71 Cleaning ..................... 72 4.1.1 Printhead ..................72 4.1.2 Platen Roller ................. 73 RTC Battery Replacement ................74 Troubleshooting ....................75 Printer issues ..................... 75 Media issues ....................76 Ribbon issues..................... 77 Other issues ....................78 Specifications ....................... 79 Printer......................

-

Page 6: Introduction

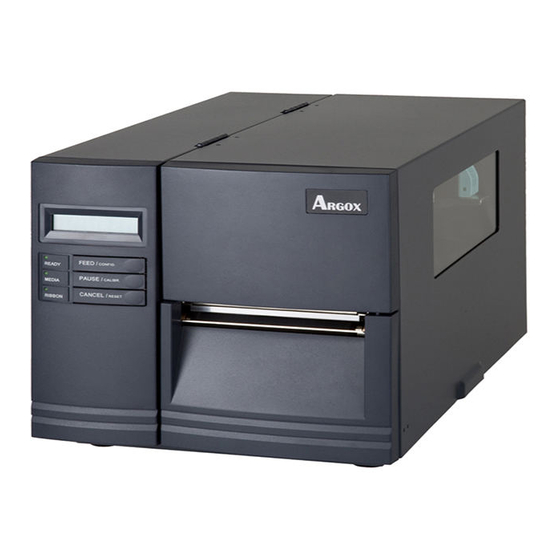

1 Introduction Features 1 Introduction Thank you for purchasing an Argox I4 Series industrial barcode printer. This manual provides information about how to set up and operate your printer, load media, ribbon and solve common problems. Illustrations are provided to help you quickly become familiar with the printer. -

Page 7: Unpacking

1 Introduction Unpacking 1.2 Unpacking Make sure all of the following items are included in your package. Quick Installation Printer Guide AC Power Cord USB Cable 1” ID Core for Ribbon When you receive the printer, open the package immediately and inspect for shipping damage. -

Page 8: Understand Your Printer

1 Introduction Understand your printer 1.3 Understand your printer 1.3.1 Perspective view Control panel Top Access Door Front Access Door... -

Page 9: Back View

1 Introduction Understand your printer 1.3.2 Back view Standard Ethernet USB Type A USB Type B RS232 Serial Power switch AC power connector Optional WIFI Parallel port GPIO... -

Page 10: Interior View

1 Introduction Understand your printer 1.3.3 Interior view Internal Parts and Features Ribbon Supply Spindle Ribbon Pick-up Spindle Media Supply Spindle Feed Slot Bracket Open Bracket Head Latch Thermal Print Paper Sensor Paper Roller... -

Page 11: Printer Control Panel

1 Introduction Printer lights 1.4 Printer control panel There are three lights on the front panel - READY, MEDIA and RIBBON. These indicators display operation status of the printer. Three Buttons – FEED, PAUSE, CANCEL can control printer simple function. 1.4.1 Status lights Status lights help you check printer’s condition. - Page 12 1 Introduction Printer lights LCD Display READY MEDIA RIBBON Description CLEAR FLASH Blinking ON Clear flash memory. CUTTER Blinking ON Cutter has failed, or there is paper FAILED jam inside the cutter. MEMORY FULL Blinking ON Printer buffer is full caused by the loaded soft fonts, graphics or forms.

-

Page 13: Buttons

1 Introduction Printer lights LCD Display READY MEDIA RIBBON Description MEDIA OUT Blinking Blinking Media is not installed or used up. Printer fails to detect the media gap. The media sensor is out of range during calibration. The label has run out. The last label has been issued normally and the label has run out. -

Page 14: Get Started

2 Get started Attach the power cord 2 Get started This chapter describes how to set up your printer. 2.1 Attach the power cord 1. Make sure the power switch is set to the OFF position. 2. Place the printer within cable distance of the host and printer (USB or Serial cable.) 3. -

Page 15: Turn On/Off Your Printer

2 Get started Turn on/off the printer 2.2 Turn on/off your printer When your printer is connected to a host (a computer), it is good to turn on the printer before turning on the host, and turn off the host before turning off the printer. -

Page 16: Turn Off Your Printer

2 Get started Turn on/off the printer 2.2.2 Turn off your printer 1. Make sure READY、MEDIA、RIBBON are solid green before turning off the printer. 2. To turn off your printer, turn off the Power Switch as below. The “O” is the OFF position. -

Page 17: Load Media

2 Get started Load media 2.3 Load media The I4 Series printers offer three different loading modes: standard, peel-off, or with a cutter. Standard mode allows you to collect each label freely. • Peel-off mode peels backing material away from the label as it prints. After •... -

Page 18: Prepare Media

2 Get started Load media 2.3.1 Prepare media The inside wound and outside wound media roll can be loaded into the printer the same way. In case the media roll is dirty during shipping, handling or storage, remove the outside length of the media. It helps avoid dragging adhesive and dirty media between the printhead and platen roller. -

Page 19: Placing Media Roll

2 Get started Load media 2.3.2 Placing media roll Load Media In Standard Mode Lift the top cover and front access door to expose the media compartment. Door Insert the media roll into the media supply spindle and move the media guide to the inside. - Page 20 2 Get started Load media Turn the head latch counter-clockwise and open the bracket. Turn the outside media guide counter-clockwise for media insert. Head Latch Outside Media Guide Bracket 4. Lead the media through the print head module, under the paper sensor guide and over the roller.

- Page 21 2 Get started Load media 5. Return the outside media guide, close the bracket, and hook the head latch. Head Latch Outside Media Guide Bracket 6. Close the front access door and the top cover.

- Page 22 2 Get started Load media 7. Press the FEED button if the printer is already on. Important After the media is loaded, please perform media calibration to calibrate the label sensor before printing. Note Make sure the die-cut media’s label length is at least 25mm or longer, for direct thermal printing in tear-off mode with perforation.

- Page 23 2 Get started Load media Load Media In Peel Off Mode Steps 1 to 3 are the similar with “Standard Mode”. 1. Lift the top cover and front access door to expose the media compartment. 2. Insert the media roll into the media supply spindle and move the media guide to the inside.

- Page 24 2 Get started Load media Push down the peel-off mechanism release lever and lead the media under the peeler module. Dispenser Module Peel Lever Media Return the outside media guide, close the bracket, and hook the head latch. Close the peeler module using the peel-off mechanism release lever. Peel Lever Dispenser Module...

- Page 25 2 Get started Load media Close the top access door and turn on the printer or press the FEED button if the printer is already on. Important After the media is loaded, please perform media calibration to calibrate the label sensor before printing.

- Page 26 2 Get started Load media Load Media In Rotary Cutter Mode Steps 1 to 3 are the similar with “Standard Mode”. Lift the top cover to expose the media compartment. Insert the media roll into the media supply spindle and move the media guide to the inside.

- Page 27 2 Get started Load media Return the outside media guide, close the bracket, and hook the head latch. Head Latch Outside Media Guide Bracket Close the top access door and turn on the printer or press the FEED button if the printer is already on.

- Page 28 2 Get started Load media...

- Page 29 2 Get started Load media Load Media In Guillotine Cutter Mode Steps 1 to 3 are the similar with “Standard Mode”. Lift the top cover to expose the media compartment. Insert the media roll into the media supply spindle and move the media guide to the inside.

- Page 30 2 Get started Load media Push back Guillotine Cutter and return the outside media guide, close the bracket, and hook the head latch. Head Latch Outside Media Guide Bracket Close the top access door and turn on the printer or press the FEED button if the printer is already on.

-

Page 31: Media Types

2 Get started Load media 2.3.3 Media types Your printer supports various media types, including non-continuous media, continuous media, and fanfold media. The following table provides details about them. Media Type Looks Like Description Non-Continuous Non-continuous media is the typical media for Media bar code printing. - Page 32 2 Get started Load media Media Type Looks Like Description Continuous Continuous media does not have gaps, holes, Media notches or black marks. It allows you to print data anywhere on the media. A cutter may be used for splitting labels. Mostly it is used for direct thermal printing.

-

Page 33: Load Ribbon

2 Get started Loading Ribbon 2.4 Load Ribbon The following steps only apply to thermal transfer printing mode. Direct thermal does not need ribbon to be installed. I4 Series printers apply to both Inside wound ribbon and Outside wound ribbon. Printers can switch automatically. -

Page 34: Placing Ribbon Roll

2 Get started Loading Ribbon 2.4.1 Placing Ribbon Roll 1. Lift the top cover and front access door to expose the media compartment. Door 2. Turn the head latch counter-clockwise and open the bracket. Head latch Bracket... - Page 35 2 Get started Loading Ribbon 3. Unwrap the ribbon and separate the ribbon roll from the bare core. Insert the ribbon roll onto the ribbon supply spindle. Ribbon Supply Spindle 4. Lead the ribbon through the print head module. Attach the edge of the ribbon onto the bare core and wind it a bit onto the core.

- Page 36 2 Get started Loading Ribbon 5. Insert the core onto the ribbon pick-up spindle. Turn the pick-up spindle to ensure the ribbon is tightly wound. Ribbon Pick-up spindle 6. Close the top cover and the front access door and turn on the printer.

-

Page 37: Printer Operation

3 Printer operation Front Panel 3 Printer operation This chapter provides more specific information about printer operation. 3.1 Front Panel Change settings via buttons on panel: Buttons Function PAUSE+CANCEL Press to enter setting mode. Press again to exit setting mode and return to normal mode. FEED Press to show next parameter. -

Page 38: Lcd Function Setting Procedure

3 Printer operation Front Panel 3.1.1 LCD Function Setting Procedure The following procedure is an example of setting procedure to direct thermal printing mode: READY (203, AUTO) Press both PAUSE + CANCEL buttons. Then release the buttons to enter settings. PRINT MODE Function which has “*”... - Page 39 3 Printer operation Front Panel Press over 5 seconds to set different languages. PAUSE + CANCEL Item Range Factory Default LANGUAGE ENGLISH, ENGLISH FRENCH, GERMAN, ITALIAN, SPANISH, PORTUGUESE, Press less than 1 second to set printer function. PAUSE + CANCEL Item Range Factory...

- Page 40 3 Printer operation Front Panel TPH VER OFFSET -009~009 mm 000 mm To adjust offset of vertical print position. RECOVER ENABLE, ENABLE Will not reprint after recovering from media-out or ribbon-out errors. PRINT DISABLE CUTTER (Restart printer after change setting) INSTALLED PEELER INSTALLED...

- Page 41 3 Printer operation Front Panel BAUD RATE 2400/ 4800 / 9600 Should be as same as setting of host. 9600 / 19200 / (Restart printer after change setting) 38400 / 57600 / 115200 PARITY (RS232) NONE NONE Should be as same as setting of host. (Restart printer after change setting) EVEN LENGTH (RS232) 8 DATA BITS...

- Page 42 3 Printer operation Front Panel LOAD DEFAULTS LAST SAVED LAST SAVED LAST SAVED: FACTORY NO.1~15, NO.17, NO.22, NO.24~25 and language will be loaded. NETWORK FACTORY: NO.1, NO6, NO9, NO11, NO14~15, NO17, NO.27~30 will be loaded. NETWORK: NO. 27~30 will be loaded. (Restart printer after change setting)

- Page 43 3 Printer operation Front Panel Ethernet settings and parameters Item Range Factory Default Remarks DHCP DISABLE If printer has been connected to a router, IP address will be assigned automatically by DHCP server after power on. ENABLE If printer is not connected to a router, with DHCP disabled, settings of IP ADDRESS, SUBNET MASK, and DEFAULT GATEWAY settings will be available on LCD.

- Page 44 3 Printer operation Front Panel To have more information on Ethernet settings, please refer to Ethernet User’s Guide. WiFi module (Option) Item Range Remarks WIFI SSID Read only WIFI module is an option for I4 Series. Connect printer to WIFI IP PC and use print tool to set WIFI module.

-

Page 45: Printing Media Calibration & Configuration

3 Printer Operation Printing Media Calibration & Configuration 3.2 Printing Media Calibration & Configuration Before calibration, be sure media and ribbon (for thermal transfer printing) have been loaded correctly. The label sensor needs to locate properly to index labels’ gaps/ notches/ holes. After the media is loaded, please perform media calibration to calibrate the label sensor in advance. -

Page 46: Printing A Configuration Report

3 Printer Operation Printing Media Calibration & Configuration 3.3 Printing a Configuration Report To perform a self-test and print a configuration report, helping to check printer’s print quality and internal settings. Steps as below: 1. Turn off the printer. 2. Load media and ribbon. 3. - Page 47 3 Printer Operation Printing Media Calibration & Configuration ■ PPLB...

- Page 48 3 Printer Operation Printing Media Calibration & Configuration 1. Version Information The firmware version and its build date. 2. Standard RAM Total SDRAM size. 3. Available RAM RAM is able to be used. 4. Flash Type The flash memory type and size. 5.

- Page 49 3 Printer Operation Printing Media Calibration & Configuration For non-continues media, it is the length between the tops of two labels. 16. Speed The speed of printing. The unit is inch per second (ips). 17. Darkness The current darkness. 18. Print Method It is either thermal transfer (TT) or direct thermal (DT) printing.

- Page 50 3 Printer Operation Printing Media Calibration & Configuration 26. Cutter Enabled/Disabled Enable or disable the cutter during the printing process. 27. Dispenser Enabled/Disabled Enable or disable the dispenser during the printing process. 28. Cutter/Dispenser Offset Move the cutting line or the peeling position forward or backward. The value in the angle brackets is the offset unit.

- Page 51 3 Printer Operation Printing Media Calibration & Configuration 40. IPv6 Type It is the IPv6 address type of your printer. There are four types: NONE, NORMAL, EUI and ANY. 41. IPv6 Address The static IPv6 address of your printer. 42. Link Local The IPv6 address that used in a network segment.

- Page 52 3 Printer Operation Printing Media Calibration & Configuration If your printer has a Wi-Fi module, your PPLB configuration label will contain the following entries: 1. FW Version WLAN board firmware version. 2. Date WLAN board firmware version date. 3. IP Address The IP address of your printer.

- Page 53 3 Printer Operation Printing Media Calibration & Configuration 10. SSID Short for service set identifier. It is the name of a wireless local area network. 11. Mode There are ad-hoc and infrastructure mode. Refer to Print Tool Network type description from Technical manual. 12.

- Page 54 3 Printer Operation Printing Media Calibration & Configuration ■ PPLA...

- Page 55 3 Printer Operation Printing Media Calibration & Configuration ■ PPLZ...

-

Page 56: Resetting To Factory Default Settings

3 Printer Operation Printing Media Calibration & Configuration 3.4 Resetting to Factory Default Settings Be cautioned that this will reset all printer settings back to defaults; if possible, print the configuration label in advance before reset. All settings stored in FLASH memory are retained even after turning off the printer. -

Page 57: Media Sensing

3 Printer operation Media sensing 3.5 Media sensing Printer offer two types of media sensor: transmissive and reflective. They are used for detecting specific media types. Both sensor types are installed together as a movable module. 3.5.1 Transmissive sensor The transmissive sensor is used for detecting gaps across the entire width of the label. -

Page 58: Reflective Sensor

3 Printer operation Media sensing 3.5.2 Reflective sensor The reflective sensor detects gaps, notches and black marks. Multi Columns Notch Black Mark Flip the media so the black-mark side is facing down to align with the sensor. 3.5.3 Adjust Position of Label Sensor... - Page 59 3 Printer operation Media sensing Function of the label sensor is to detect the gap, notch, or holes of labels, to help the printer for accurate print positions and label length. For labels with gaps, label sensor can be positioned wherever media locates. If labels with notches or holes are in use, follow the steps below to check position of the label sensor: Unlatch the Print head Latch.

- Page 60 3 Printer operation Media sensing Paper Sensor Position Lever Make sure the Media sensor position mark locates right on notch or hole of labels. Check below.

-

Page 61: Communications

3 Printer operation Communications 3.6 Communications 3.6.1 Interfaces and Requirements This printer comes with USB type A and type B interface, a nine-pin Electronics Industries Association (EIA) RS-232 serial data interface, a standard Centronics parallel interface(Option), GPIO interface(Option), . USB Interface Requirements The Universal Serial Bus (USB) interface is compatible with your existing PC hardware. - Page 62 3 Printer operation Communications General-purpose input/output (GPIO) Pins depend on usage and the signal is user selectable. The function is diversity. For general-purpose, I/O signals programmed as inputs can cause CPU interrupted. For more information, contact local dealer. Ethernet Module Status Indicators The indicators with two different colors help users understand status of Ethernet: Description Status...

-

Page 63: Driver Installation

3 Printer operation Driver installation 3.7 Driver installation The bundled printer driver can be applied to all applications under Windows XP/ Vista/ Windows 7/ Windows 8/ Windows 10, supporting 32-bit/ 64-bit operation systems. With this driver you can operate any popular Windows software applications including Argox Bartender UL label editing software or MS Word, etc., to print to this printer. -

Page 64: Installing A Plug And Play Printer Driver (For Usb Only)

3 Printer operation Driver installation 3.7.1 Installing a Plug and Play printer driver (for USB only) Note: We strongly recommend that you use the Seagull Driver Wizard instead of the Microsoft Windows Add Printer Wizard when installing and updating your Drivers by Seagull. (Even though the "Add Printer Wizard"... - Page 65 3 Printer operation Driver installation 3. Run the driver from Argox website. On the prompt, Windows Printer Driver, select “I accept…” and click "Next". 4. Assign the directory to keep Seagull driver, (for example: C:\Seagull) and click "Next".

- Page 66 3 Printer operation Driver installation 5. Click "Finish". 6. Select Install printer drivers and Click "Next"...

- Page 67 3 Printer operation Driver installation 7. On the Seagull Driver Wizard prompt, select the first radio button to “Install a driver for a Plug and Play printer” Then click “Next.” 8. Enter Printer name (i.e. Argox I4-250 PPLB) and select "do not share this printer”, and click "Next"...

- Page 68 3 Printer operation Driver installation 9. Check all the data on the showing screen, if it is correct, click "Finish". 10. After the related files have been copied to your system, click "Finish".

- Page 69 3 Printer operation Driver installation 11. After driver installation is complete, click "Close". The driver should now be installed.

-

Page 70: Installing A Printer Driver (For Other Interfaces Except Usb)

3 Printer operation Driver installation 3.7.2 Installing a Printer Driver (for other interfaces except USB) 1. Turn off the printer. Plug the power cable into the power socket on the wall, and then connect the other end of the cable to printer's power socket. Connect the Parallel cable, Serial cable, or Ethernet cable to the proper port on the printer and on your computer. - Page 71 3 Printer operation Driver installation 3. Assign the directory to keep Seagull driver, (for example: C:\Seagull) and click "Next". 4. Click "Finish".

- Page 72 3 Printer operation Driver installation 5. Select Install printer drivers and Click "Next" 6. Make sure printer is connected to PC, select “Other” and click “Next”:...

- Page 73 3 Printer operation Driver installation 7. Select model & emulation - the following examples are based on model I4-250 PPLB: 8. Select the port of the printer and click "Next".

- Page 74 3 Printer operation Driver installation 9. Enter Printer name (i.e. Argox I4-250 PPLB) and select "do not share this printer”, and click "Next". 10. Check all the data on the showing screen, if it is correct, click "Finish".

- Page 75 3 Printer operation Driver installation 11. After the related files have been copied to your system, click "Finish". 12. After driver installation is complete, click "Close". The driver should now be installed.

-

Page 76: Maintenance

4 Maintenance Cleaning 4 Maintenance Vertical streaks in the printout usually indicate a dirty or faulty print head. (Refer to the following examples.) Clean the print head. If the problem persists, replace the print head. For unstable ribbon roll rotation, check the label path and make sure the head latch is securely closed. -

Page 77: Cleaning

4 Maintenance Cleaning 4.1 Cleaning To maintain print quality and prolong the printer’s life, you need to perform some routine maintenance. Daily maintenance should be done for high volume printing, and weekly for low volume printing. Warning Always turn off the printer before cleaning. 4.1.1 Printhead It is essential to keep printhead clean if you want the best print quality. -

Page 78: Platen Roller

4 Maintenance Cleaning 4.1.2 Platen Roller The platen roller is also important for print quality. Dirty platen roller may damage the printhead. Clean the platen roller right away if the adhesive, dirt or dust accumulates on it. 1. Moisten a soft cloth with absolute ethyl alcohol. 2. -

Page 79: Rtc Battery Replacement

4 Maintenance RTC Battery Replacement 4.2 RTC Battery Replacement RTC stands for real-time clock. It is a battery powered clock that keep track of the current date and time. If your printer has a built-in RTC, you’ll find the RTC battery on the main board. -

Page 80: Troubleshooting

5 Troubleshooting Printer issues 5 Troubleshooting This chapter provides the information about printer problems and solutions. 5.1 Printer issues The printer won’t turn on ■ Did you attach the AC power cord? ■ Check the power connection from the wall socket to the printer. Test the power cord and the socket with other electrical devices. -

Page 81: Media Issues

5 Troubleshooting Media issues 5.2 Media issues The media is out ■ Load a new media roll. The paper is jammed ■ Open the printer and clear the jammed paper. ■ Make sure the paper is held properly by the Media Guides. The printing position is not correct ■... -

Page 82: Ribbon Issues

5 Troubleshooting Ribbon issues 5.3 Ribbon issues The ribbon is out ■ Load a new ribbon roll. The ribbon is broken ■ Check the print darkness and adjust it if it is too high, and take the following steps to fix the broken ribbon: Unload the ribbon supply roll and take-up roll from the printer. -

Page 83: Other Issues

5 Troubleshooting Other issues 5.4 Other issues There are broken lines in the printed label ■ The printhead is dirty. Clean the printhead. The printhead temperature is extremely high ■ The printhead temperature is controlled by the printer. If it is extremely high, the printer will stop printing automatically, until the printhead is cool down. -

Page 84: Specifications

6 Specifications Printer 6 Specifications This chapter provides specifications for the printer. 6.1 Printer Model I4-240 I4-250 I4-350 Print method Direct Thermal & Thermal Transfer 300 dpi (12 Resolution 203 dpi (8 dots/mm) dots/mm) Standard: Continuous mode, Tear-off mode Operation Mode Optional: Cutter mode, Peeler mode Media Reflective sensor x 1 (movable) &... - Page 85 6 Specifications Printer Model I4-240 I4-250 I4-350 Software--- Utility Printer Tool Agency Listing CE, FCC, CB/LVD, cULus, ICES, Energy Star Note Print quality and speed is based on 15% print coverage.

-

Page 86: Media & Ribbon

6 Specifications Media 6.2 Media & Ribbon Properties Description Media Size Max. width:4.4” (112mm). Min. width: 1” (25.4 mm). Thickness:0.0025”~0.01” (0.0635mm~0.254mm) 8”(203mm) OD on a 3”(76mm) ID core. 7”(177.8mm) OD on a 1.5”(38mm) ID core. Min. width 2.3” (58mm)for partial cutter options. Min. -

Page 87: Fonts, Barcodes, And Graphics Specification

6 Specifications Electrical and operating 6.1 Fonts, Barcodes, and Graphics Specification The specifications of fonts, bar codes and graphics depends on the printer emulation. The emulations PPLA, PPLB, and PPLZ are printer programming languages, through which the host can communicate with your printer. Printer Programming Language PPLA Programming Language PPLA... - Page 88 6 Specifications Electrical and operating Printer Programming Language PPLB Programming Language PPLB Internal fonts 5 fonts with different point size 8 bits code page : 437, 850, 852, 860, 863, 865, 857, 861, 862, 855, 866, 737, 851, 869, 1252, 1250, 1251, 1253, 1254, 1255 Symbol sets 7 bits code page: USA, BRITISH, GERMAN,...

- Page 89 6 Specifications Electrical and operating Printer Programming Language PPLZ Programming Language PPLZ 8 (A~H) fonts with different point size. 8 AGFA fonts: 7 (P~V) fonts with fixed different Internal fonts point size (not scalable). 1 (0) font with scaling point size. USA1, USA2, UK, HOLLAND, DENMARK/NORWAY, SWEDEN/FINLAND, GERMAN, FRANCE1, FRANCE2, ITALY,...

-

Page 90: Electrical And Operating Environment

6 Specifications Electrical and operating 6.3 Electrical and operating environment Properties Description Power Supply Voltage: AC 100 V ~ 240 V ± 10 % (full range) Frequency: 50 Hz - 60 Hz ± 5 % Temperature Operating: 40°F~104°F (4°C~40°C) Storage: -4°F~122°F (-20°C~50°C) Humidity Operating: 25 %RH ~ 85 %RH (non-condensing) Storage: 10 %RH ~ 90 %RH (non-condensing) - Page 91 6 Specifications Electrical and operating Properties Wireless LAN I/F Speed/Modulation 2 Mbps: DQPSK 1 Mbps: DBPSK IEEE Transmission Conforming to IEEE 802.11g Method 802.11g OFDM method DSSS method Channel Depending on the country Data Transmission 54/48 Mbps: 64 QAM Speed/Modulation 36/24 Mbps: 16 QAM 18/12 Mbps: QPSK 9/6 Mbps: BPSK...

- Page 92 6 Specifications Electrical and operating Properties Wireless LAN I/F Parameter Setting and Status Monitor Note The specifications may be changed at any time without prior notice. For more information about the new specifications, visit Argox website or contact your dealer.

-

Page 93: Interfaces

6 Specifications Interfaces 6.6 Interfaces This section provides information about IO port specifications for the printer. 6.6.1 USB There are two common USB connectors. Typically, type A is found on hosts and hubs; type B is found on devices. The figure below shows their pinouts. Type A Type B Signal... -

Page 94: Rs-232C

6 Specifications Interfaces 6.6.2 RS-232C The RS-232C on the printer is DB9 female. It transmits data bit by bit in asynchronous start-stop mode. The figure below shows its pinout. Signal Description No Function Transmit Receive No Function Ground No Function Clear to Send Request to Send No Connection... -

Page 95: Centronics

6 Specifications Interfaces 6.6.3 Centronics The 36-pin Centronics on the printer uses parallel communication, and complies with IEEE 1284 compatibility mode (also called SPP, Standard Parallel Port). The figure below shows its pinout. Signal Signal Signal Signal Direction Direction To Printer /STROBE S-GND Signal-GND... -

Page 96: Ethernet

6 Specifications Interfaces 6.6.4 Ethernet The Ethernet uses RJ-45 cable, which is 8P8C (8-Position 8-Contact). The figure below shows its pinout. 1 2 3 4 5 6 7 8 Signal Transmit+ Transmit- Receive+ Reserved Reserved Receive- Reserved Reserved...