Carrier WEATHERMAKER 8000 58ZAV Installation And Operating Instructions Manual

Downflow/horizontal induced-combustion furnaces

Hide thumbs

Also See for WEATHERMAKER 8000 58ZAV:

Table of Contents

Advertisement

Visit www.carrier.com

Installation, Start-Up, and Operating Instructions

NOTE: Read the entire instruction manual before starting the

installation.

This symbol → indicates a change since the last issue.

Index

SAFETY CONSIDERATIONS .....................................................1

PROCEDURE ...........................................................................2

INTRODUCTION.......................................................................3-4

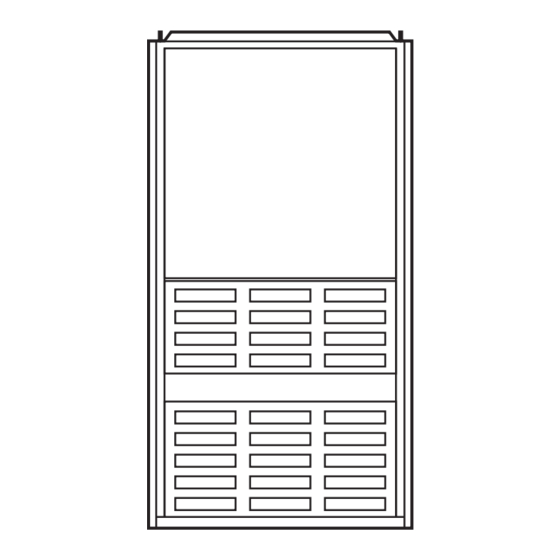

Dimensional Drawing ...............................................................2

Clearances From Combustible Materials .................................3

LOCATION....................................................................................4

General ......................................................................................4

Location Relative to Cooling Equipment ................................4

Hazardous Locations.................................................................4

AIR FOR COMBUSTION AND VENTILATION...................4-5

Unconfined Space..................................................................4-5

Confined Space .........................................................................5

AIR DUCTS................................................................................5-6

General Requirements...............................................................5

Ductwork Acoustical Treatment...............................................5

Supply-Air Connections............................................................6

Return-Air Connections ............................................................6

DOWNFLOW INSTALLATION ..................................................7

HORIZONTAL ATTIC INSTALLATION...................................9

Construct a Working Platform .................................................9

Install Furnace...........................................................................9

HORIZONTAL CRAWLSPACE INSTALLATION....................9

FILTER ARRANGEMENT...........................................................9

GAS PIPING ..................................................................................9

ELECTRICAL CONNECTIONS...........................................10-12

115-v Wiring...........................................................................10

24-v Wiring.............................................................................11

Accessories ........................................................................11-12

VENTING ....................................................................................12

START-UP, ADJUSTMENT, AND SAFETY CHECK.......12-21

General ....................................................................................12

Sequence Of Operation...........................................................13

Heating Mode..........................................................................12

Cooling Mode .........................................................................15

Continuous Blower Mode.......................................................15

Heat Pump Mode ....................................................................15

Start-up Procedures.................................................................15

Adjustments .......................................................................15-21

Set Gas Input Rate..................................................................15

Set Temperature Rise..............................................................19

Set Thermostat Heat Anticipator............................................20

Check Safety Controls ............................................................20

Checklist..................................................................................21

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

PC 101

Catalog No. 535-768

Tab 6a 8a

Downflow/Horizontal Induced-Combustion Furnaces

Sizes 050-135, Series 151 and 161

Page

Printed in U.S.A.

WeatherMaker 8000™

REGISTERED QUALITY SYSTEM

SAFETY CONSIDERATIONS

Installing and servicing heating equipment can be hazardous due to

gas and electrical components. Only trained and qualified person-

nel should install, repair, or service heating equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning and replacing air filters. All other operations must

be performed by trained service personnel. When working on

heating equipment, observe precautions in the literature, on tags,

and on labels attached to or shipped with the unit and other safety

precautions that may apply.

In the United States, follow all safety codes including the National

Fuel Gas Code (NFGC) NFPA 54-1999/ANSI Z223.1-1999 and

the Installation Standards, Warm Air Heating and Air Condition-

ing Systems (NFPA 90B) ANSI/NFPA 90B.

In Canada, refer to the CAN/CGA-B149.1- and .2-M95 National

Standard of Canada, Natural Gas and Propane Installation Codes

(NSCNGPIC).

Wear safety glasses and work gloves. Have fire extinguisher

available during start-up and adjustment procedures and service

calls.

Recognize safety information. This is the safety-alert symbol

When you see this symbol on the furnace and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, CAUTION,

and NOTE. These words are used with the safety-alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies a hazard

which could result in personal injury or death. CAUTION is used

to identify unsafe practices which would result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability,

or operation.

These instructions cover minimum requirements and conform to

existing national standards and safety codes. In some instances,

these instructions exceed certain local codes and ordinances,

especially those that may not have kept up with changing residen-

tial construction practices. We require these instructions as a

minimum for a safe installation.

Form 58ZAV-12SI

Pg 1

58ZAV

ama

CERTIFIED

10-00

Replaces: 58ZAV-10SI

®

.

Advertisement

Table of Contents

Summary of Contents for Carrier WEATHERMAKER 8000 58ZAV

-

Page 1: Table Of Contents

Recognize safety information. This is the safety-alert symbol When you see this symbol on the furnace and in instructions or manuals, be alert to the potential for personal injury. Understand the signal words DANGER, WARNING, CAUTION, and NOTE. -

Page 2: Electrostatic Discharge (Esd) Precautions Procedure

LOCATED IN THE TOP PLATE AND BOTTOM PLATE NOTE: Minimum return-air openings at furnace, based on metal duct. If flex duct is used, see flex duct manufacturer's recommendations for equivalent diameters. a. For 800 CFM–16-in. round or 14 b. For 1200 CFM–20-in. round or 14 c. -

Page 3: Introduction

The furnace is factory- shipped for use with natural gas. A factory accessory gas conver- sion kit, as listed on the furnace rating plate is required to convert furnace for use with propane gas. These furnaces SHALL NOT be installed directly on carpeting, tile, or any other combustible material other than wood flooring. -

Page 4: Location

This furnace must be installed so the electrical components are protected from water. Locate the furnace as close to the chimney/vent and as near the center of the air distribution system as possible. The furnace should be installed as level as possible. -

Page 5: Confined Space

The duct system should be sized to handle the required system design CFM at the design static pressure. When a furnace is installed so that the supply ducts carry air to areas outside the space containing the furnace, the return air must also be handled by a duct(s) sealed to the furnace casing and terminating outside the space containing the furnace. -

Page 6: Supply-Air Connections

ONLY be con- nected to an accessory subbase or factory approved air condition- ing coil casing. DO NOT cut main furnace casing to attach supply side air duct, humidifier, or other accessories. All accessories MUST be connected external to furnace main casing. -

Page 7: Downflow Installation

→ Do not install furnace on its back. Safety control operation will be adversely affected. Never connect return-air ducts to back of furnace. Failure to follow this warning could result in fire, personal injury, or death. Step 5—Downflow Installation NOTE: This furnace is approved for use on combustible materials or wood flooring. - Page 8 OPENING Fig. 6—Furnace, Plenum, and Subbase Installed on a Combustible Floor LINE CONTACT ONLY PERMISSIBLE BETWEEN LINES FORMED BY INTERSECTIONS OF THE TOP AND TWO SIDES OF THE FURNACE JACKET AND BUILDING JOISTS, STUDS, OR FRAMING. MANUAL SHUTOFF GAS VALVE...

-

Page 9: Horizontal Attic Installation

An accessible manual shutoff valve MUST be installed upstream of the furnace gas controls and within 72 in. of the furnace. A 1/8-in. NPT plugged tapping, accessible for test gage connection, MUST be installed immediately upstream of the gas supply... -

Page 10: Electrical Connections

& WASHER (4) REQD PER ROD NOTES: 1. A 1 In. clearance minimum between top of furnace and combustible material. 2. The entire length of furnace must be supported when furnace is used in horizontal position. Step 10—Electrical Connections 115-V WIRING Refer to the unit rating plate or Table 6 for equipment electrical requirements. -

Page 11: 24-V Wiring

AIRFLOW INSTALLATION POSITION OF FILTERS RETURN-AIR PLENUM ACCESS DOOR Fig. 12—Downflow Filter Arrangement Table 5—Maximum Capacity of Gas Pipe * NOMINAL IRON INTERNAL LENGTH OF PIPE (FT) PIPE SIZE DIAMETER (IN.) (IN.) 0.622 0.824 1.049 1-1/4 1.380 1400 1-1/2 1.610 2100 1460 1180 990 900 * Cubic ft of gas per hr for gas pressures of 0.5 psig (14-in. -

Page 12: Venting

Proper polarity must be maintained for correct operation. Thermostat wire connections at R, W, C, and Y must be made at the furnace 24-v terminal block on the control board. The gas service pressure must not exceed 0.5 psig (14-in. wc), but must be no less than 0.16 psig (4.5-in. -

Page 13: Furnace Control Overview

CONDENSING UNIT WIRE NOTES: Connect Y-terminal in furnace as shown for proper blower operation. Some thermostats require a "C" terminal connection as shown. If any of the original wire, as supplied, must be replaced, use same type or equivalent wire. - Page 14 TRAN...

-

Page 15: Cooling Mode

1. Set gas input rate Furnace gas input rate on rating plate is for installations at altitudes up to 2000 ft. Furnace input rate must be within ±2 percent of input on furnace rating plate. a. Determine natural gas orifice size and manifold pressure for correct input. - Page 16 →Table 7—Model 58ZAV Orifice Size† and Manifold Pressure for Correct Input (Tabulated Data Based on 23,000 BTUH Per Burner, Derated 4 Percent per 1000 Ft Above Sea Level)* AVG GAS ALTITUDE HEAT VALUE RANGE AT ALTITUDE Orifice (FT) (BTU/CU FT) 1000 2000 1025...

- Page 17 →Table 7—Model 58ZAV Orifice Size† and Manifold Pressure for Correct Input (Tabulated Data Based on 23,000 BTUH Per Burner, Derated 4 percent per 1000 Ft Above Sea Level)* AVG GAS ALTITUDE HEAT VALUE RANGE AT ALTITUDE Orifice (FT) (BTU/CU FT) 5001 6000 1000...

- Page 18 92,000 Canada A93059 At installation altitudes from 2000 to 4500 ft, this furnace must be derated 10 percent by an authorized Gas Conversion Station. To determine correct input rate for altitude, see example above and use 0.90 as derate multiplier factor.

-

Page 19: Set Temperature Rise

Gas rate = 88 cu ft/hr (from Table 9) Btu heating input = 88 X 1050 = 92,400 Btuh In this example, the orifice size and manifold pressure adjustment is within ±2 percent of the furnace input rate. 2. Set temperature rise. SIZE OF TEST DIAL... -

Page 20: Set Thermostat Heat Anticipator

The preferred method of checking the limit control is to gradually block off the return air after the furnace has been operating for a period of at least 5 minutes. As soon as the limit has shut off the burners, the return-air opening should be unblocked. -

Page 21: Checklist

Disconnect red motor lead at blower speed selector. Mark terminal for proper reconnection. d. Replace blower access door. e. Turn on 115-v power to furnace. Be sure room thermostat is calling for heat. f. Allow furnace to operate until auxiliary limit activates, but DO NOT operate furnace longer than 4 minutes. - Page 22 LOAD CALCULATION ____________ Heating Load (Btuh) ____________ Cooling Load (Btuh) ____________ Furnace Model Selection AIR FOR COMBUSTION AND VENTILATION ____________ Unconfined Space ____________ Confined Space VENTING ____________ NFGC (United States) ____________ NSCNGPIC (Canada) ____________ Local Codes ____________ 1/4-in. Upward Slope...

- Page 24 [ ] Packaged Service Training [ ] Classroom Service Training Copyright 2000 CARRIER Corp. • 7310 W. Morris St. • Indianapolis, IN 46231 Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.