Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Garmin GRS 77

- Page 1 GRS 77/GMU 44 Installation Manual 190-00303-10 March, 2010 Revision L...

- Page 2 Garmin. Garmin hereby grants permission to download a single copy of this manual and of any revision to this manual onto a hard drive or other electronic storage medium to be viewed and...

- Page 3 Section 2 2-1 – 2-8 Section 3 3-1 – 3-6 Section 4 4-1 – 4-6 Section 5 5-1 – 5-18 Appendix A A-1 – A-12 Appendix B B-1 – B-4 GRS 77/GMU 44 Installation Manual Page i 190-00303-10 Revision L...

- Page 4 NOTE Throughout this document references made to GRS 77 shall equally apply to the GRS 77 and GRS 77H (011-00868-20) except where specifically noted. Page ii GRS 77/GMU 44 Installation Manual Revision L 190-00303-10...

-

Page 5: Table Of Contents

INSTALLATION OVERVIEW ......................2-1 2.1 Introduction............................2-1 2.2 Installation Approval Considerations for Pressurized Aircraft............2-3 2.3 Wiring ..............................2-4 2.4 Cooling Air ............................2-4 2.5 Aircraft Mounting Requirements for GRS 77/GMU 44 ..............2-4 INSTALLATION PROCEDURE......................3-1 3.1 Unpacking Unit..........................3-1 3.2 Electrical Connections ........................3-1 3.3 Backshell Assembly...........................3-2 3.4 GRS 77/GMU 44 Interconnect Harness Fabrication Instructions .............3-3... -

Page 6: Paragraph Page

5.7 Calibration Procedure D: Engine Run-Up Vibration Test ...............5-11 5.8 Calibration Procedure E: Magnetometer Interference Test .............5-13 5.9 Site Evaluation of Magnetic Disturbances for Magnetometer Calibration Procedure.....5-17 APPENDIX A OUTLINE AND INSTALLATION DRAWINGS APPENDIX B INTERCONNECT DRAWINGS Page iv GRS 77/GMU 44 Installation Manual Revision L 190-00303-10... - Page 7 LIST OF ILLUSTRATIONS FIGURE PAGE 2-1 GRS 77 and Mounting Rack......................2-5 3-1 Measuring GRS 77 to Mounting Rack with Feeler Gauge ..............3-5 4-1 Rear Connector J771..........................4-1 4-2 Pigtail Connector J441........................4-3 5-1 Fixed-wing and Helicopter position examples ..................5-7 A-1 GRS 77 Outline Drawing With Mounting Rack................A-1 A-2 GMU 44 Mounting Rack (Sheet 1 of 2) ...................

- Page 8 GRS 77/GMU 44 HARDWARE MOD LEVEL HISTORY The following table identifies hardware modification (Mod) Levels for the GRS 77 AHRS and GMU 44 Magnetometer. Mod Levels are listed with the associated service bulletin number, service bulletin date, and the purpose of the modification. The table is current at the time of publication of this manual (see date on front cover) and is subject to change without notice.

- Page 9 NUMBER DATE This modification improves the reliability of certain GMU 44 LRUs. GMU 44 P/N 011-00870-10 HARDWARE MOD LEVEL HISTORY SERVICE SERVICE BULLETIN BULLETIN PURPOSE OF MODIFICATION LEVEL NUMBER DATE GRS 77/GMU 44 Installation Manual Page vii 190-00303-10 Revision L...

- Page 10 This page intentionally left blank Page viii GRS 77/GMU 44 Installation Manual Revision L 190-00303-10...

-

Page 11: General Description

The GMU 44 magnetometer provides magnetic information to support the function of the GRS 77. Operating voltage range of the GRS 77 AHRS is from 10 to 33 volts DC. The GRS 77 provides operating voltage to the GMU 44 Magnetometer. -

Page 12: Interface Summary

6) South of 55° South latitude between longitude 120° E and 165° E. (Region south of Australia and New Zealand) Interface Summary The following is an interface summary for the GRS 77 and GMU 44. See Section 4 and Appendix B for connection details. •... - Page 13 In the case of a single power source, where typically only one of the power pins would be used, both pins should be connected to this wire to get A4. The splice must be in the backshell of the GRS 77. Generally every installation should do this unless it is known that A3 on the power pins will suffice.

-

Page 14: Certification

The article may be installed only if performed under 14 CFR part 43 or the applicable airworthiness requirements. At the time of publication, installation of this TSO approved article is only approved when installed in an aircraft as part of a Garmin Integrated Flight Deck. - Page 15 1.5.3 TSO/ETSO Deviations The following table provides a list of applicable TSO and SAE deviations for the GRS 77, GRS 77H, and the GMU 44. Deviation TSO-C3d 1. Garmin was granted a deviation from TSO-C3d to use RTCA DO-160D instead of...

-

Page 16: Reference Publications

Reference Publications The following publications are sources of additional information for installing the GRS 77 and GMU 44. Before installing the unit, the technician should read all referenced materials along with this manual. Part Number Document 190-00303-00 G1000 System Installation Manual... -

Page 17: Aviation Limited Warranty

Garmin in lieu of repair. Within the applicable period, Garmin will, at its sole option, repair or replace any components that fail in normal use. Such repairs or replacement will be made at no charge to the customer for parts or labor, provided that the customer shall be responsible for any transportation cost. - Page 18 This page intentionally left blank Page 1-8 GRS 77/GMU 44 Installation Manual Revision L 190-00303-10...

-

Page 19: Installation Overview

INSTALLATION OVERVIEW Introduction This section provides hardware equipment information for installing the GRS 77 AHRS and GMU 44 Magnetometer. Installation of the GRS 77/GMU 44 must follow the aircraft TC or STC requirements. Cabling is fabricated by the installing agency to fit each particular aircraft. The guidance of FAA advisory circulars AC 43.13-1B and AC 43.13-2B, where applicable, may be found useful for making... - Page 20 *Garmin recommends the GMU 44 (011-00870-10) with Installation Rack (115-00481-10) for new TC/STC approvals. Garmin does not recommend the GMU 44 (011-00870-00) for new TC/STC approvals. The GMU 44 (011-00870-10) maintains the same form, fit, and function as the original GMU 44 (011-00870-00).

-

Page 21: Installation Approval Considerations For Pressurized Aircraft

2.1.2 Accessories NOTE The following GRS 77 Connector kits are based on airframe and TC/STC requirements. Item Garmin P/N Sub Assy, Connector Kit, GRS 77 w/Spider 011-00869-00 Sub Assy, Connector Kit, GRS 77 w/Shield Block 011-00869-01* Installation Rack, GRS 77... -

Page 22: Wiring

Cooling Air No cooling air is needed for either the GRS 77 or the GMU 44. Refer to the G1000 System Installation Manual, Garmin part number 190-00303-00, for information on G1000 system cooling requirements. Aircraft Mounting Requirements for GRS 77/GMU 44 The following guidelines describe proper mechanical installation of the Garmin GRS 77 AHRS and GMU 44 Magnetometer. - Page 23 The GRS 77 mounting rack should be leveled to within 3.0° of the aircraft level reference, and an aircraft leveling and offset setting procedure carried out prior to flight. (This procedure is described in Section 5.) Alternatively, if the mounting rack can be guaranteed level to within 0.25°...

- Page 24 Align the GMU 44 mounting rack to within 3.0° of the aircraft level reference in pitch and roll. Page 2-6 GRS 77/GMU 44 Installation Manual Revision L 190-00303-10...

- Page 25 GMU 44. Electrically isolating the light assembly should not be used as an alternative to item 1 above, unless the isolated light assembly has been analyzed for adequate protection against direct attachment of lightning. GRS 77/GMU 44 Installation Manual Page 2-7 190-00303-10...

- Page 26 This page intentionally left blank Page 2-8 GRS 77/GMU 44 Installation Manual Revision L 190-00303-10...

-

Page 27: Installation Procedure

If the unit is damaged, notify the carrier and file a claim. To justify a claim, save the original shipping container and all packing materials. Do not return the unit to Garmin until the carrier has authorized the claim. -

Page 28: Backshell Assembly

Backshell Assembly The GRS 77 connector kit includes a Garmin backshell assembly. The backshell assembly houses the configuration module. Garmin’s backshell connectors give the installer the ability to quickly and easily terminate shield grounds at the backshell housing using one of two methods available. To assemble the backshell and grounding system, refer to instructions provided in the SPIDER Installation Instructions (190-00313-03) or Shield Block Installation Instructions (190-00313-09). -

Page 29: Grs 77/Gmu 44 Interconnect Harness Fabrication Instructions

GRS 77/GMU 44 Interconnect Harness Fabrication Instructions Table 3-3 lists parts needed for the GMU 44 interconnect harness. Some of the parts for installation are included in the GMU 44 Connector Installation Kit. Other parts are provided by the installer. Reference numbers refer to item bubble numbers shown in Figure A-5. -

Page 30: Grs 77 And Gmu 44 Mounting Instructions

291-00023-02, or equivalent. Important: Mounting screws must be brass. GRS 77 Rack to Unit Flatness Check While installing the GRS 77 unit on its rack, a flatness check is required to ensure that the unit’s base is properly preloaded after installation. -

Page 31: Post Installation Inspection

The rack is fastened down to a surface that is not sufficiently flat b) The rack is warped or damaged c) The GRS 77 has a center baseplate external shim that is damaged or has been removed d) The GRS 77 baseplate has been warped or damaged In the event of a failed test (gap on unfastened end of unit not within the range of 0.010 inch to 0.070... - Page 32 This page intentionally left blank Page 3-6 GRS 77/GMU 44 Installation Manual Revision L 190-00303-10...

-

Page 33: System Interconnects

ARINC 429 OUT 3 B (CDU 2, high-speed) AIRCRAFT POWER 2 GPS 2 RS-232 OUT POWER GROUND An asterisk (*) following a signal name denotes that the signal is an Active Low, requiring a ground to activate. GRS 77/GMU 44 Installation Manual Page 4-1 190-00303-10 Revision L... - Page 34 SIGNAL GROUND (CDU 1) SIGNAL GROUND (AFCS) SIGNAL GROUND (AIR DATA) An asterisk (*) following a signal name denotes that the signal is an Active Low, requiring a ground to activate. Page 4-2 GRS 77/GMU 44 Installation Manual Revision L 190-00303-10...

-

Page 35: Power Function

1 and B-2 in Appendix B for power connections and Section 1.4.4 for lightning level note. Table 4-3. Aircraft Power Pin Assignments, P771 and P441 Pin Name Description P771-18 AIRCRAFT POWER 1, GRS 77 Unit Power P771-20 AIRCRAFT POWER 2, GRS 77 Unit Power... -

Page 36: Serial Data Electrical Characteristics

Data In P771-39 MAGNETOMETER RS-485 IN B Data In P771-25 MAGNETOMETER RS-485 IN A P771-40 MAGNETOMETER GROUND Ground P441-4 RS-485 OUT A Data Out P441-2 RS-485 OUT B Data Out Page 4-4 GRS 77/GMU 44 Installation Manual Revision L 190-00303-10... - Page 37 The configuration module, mounted in the unit connector backshell, contains an EEPROM. Table 4-7. Configuration Module Connections, P771 Pin Name Description CONFIG MODULE GROUND Ground CONFIG MODULE DATA Data In /Out CONFIG MODULE POWER OUT Power CONFIG MODULE CLOCK Clock Output GRS 77/GMU 44 Installation Manual Page 4-5 190-00303-10 Revision L...

- Page 38 ARINC 429 output messages/labels. The System ID may be used to uniquely distinguish the source of the GDC 74A ARINC 429 labels in a system with more than one GRS 77. The GRS 77 System ID can be set to All Call, #1, #2, or #3 for such purposes. Table 4-8 identifies which pins on connector P741 are used to select the desired System ID.

-

Page 39: Post Installation Configuration And Checkout Procedure

There are no operating controls or displays on the GRS 77/GMU 44. Post-Installation Calibration Procedures After mechanical and electrical installation of the GRS 77 AHRS and GMU 44 magnetometer have been completed, prior to operation, a set of post-installation calibration procedures must be carried out. - Page 40 G1000 system. If removal and replacement of a GRS 77 or GMU 44 unit is required after post-installation calibration has been completed, the unit mounting racks must not be moved. If the mounting bolts that secure the...

- Page 41 GRS 77 mounting racks are loosened for any reason, a new post-installation calibration procedure, A-1, B and D (plus C if required initially) must be carried out before the aircraft can be returned to service. Any GMU 44 removal and replacement requires repeating the magnetometer calibration, and if applicable, the heading offset compensation.

-

Page 42: Calibration Procedure A-1: Pitch/Roll Offset Compensation By Aircraft Leveling

12 6. Press in the FMS small knob to highlight GRS 77 #1. The FMS small knob can now be turned to select either GRS 77 #1 or GRS 77 #2 for calibration. Press the ENTER key after selecting which GRS 77 unit to calibrate. -

Page 43: Calibration Procedure A-2: Zero Pitch/Roll Offsets By Manual Entry

11 softkey 12 3. Press the FMS small knob to highlight GRS 77 #1. The FMS small knob can now be turned to select either GRS 77 #1 or GRS 77 #2 for calibration. Press the ENTER key after selecting which GRS 77 unit to calibrate. - Page 44 14. Press the ENTER key on the PFD to conclude this procedure. Page 5-6 GRS 77/GMU 44 Installation Manual Revision L 190-00303-10...

-

Page 45: Calibration Procedure B: Magnetometer Calibration

Figure 5-1. Fixed-wing and Helicopter position examples With the aircraft stationary, initiate the GRS 77 AHRS magnetometer calibration procedure as follows: 1. If the MFD and PFD(s) are not both in configuration mode, proceed with Steps 2 through 4. If the MFD and PFD(s) are already in configuration mode, skip ahead to Step 5. - Page 46 12 6. Press the FMS small knob to highlight GRS 77 #1. The FMS small knob can now be turned to select either GRS 77 #1 or GRS 77 #2 for calibration. Press the ENTER key after selecting the desired GRS 77 unit to calibrate.

- Page 47 STATIONS.” 12. Repeat the turn-and-stop process until the PFD instructs the operator that a successful calibration is complete. 13. Press the ENTER key on the PFD to conclude this procedure. GRS 77/GMU 44 Installation Manual Page 5-9 190-00303-10 Revision L...

-

Page 48: Calibration Procedure C: Heading Offset Compensation

3. The operator must confirm each aircraft heading. Press the ENTER key to confirm. The CONFIRM HEADING field stops blinking. 4. The PFD informs the operator of the calibration results. Press the ENTER key on the PFD to conclude this procedure. Page 5-10 GRS 77/GMU 44 Installation Manual Revision L 190-00303-10... -

Page 49: Calibration Procedure D: Engine Run-Up Vibration Test

Vibrational motion of GRS 77 and/or GMU 44 caused by neighboring equipment and/or supports. c) Mounting of GRS 77 at a location that is subject to severe vibrations (example; close to an engine mount.) GRS 77/GMU 44 Installation Manual... - Page 50 Mounting screws and other hardware for GRS 77 and/or GMU 44 not firmly attached. e) Absence of mounting supports recommended by the aircraft manufacturer. f) GRS 77 connector not firmly attached to unit. g) Cabling leading to GRS 77 or GMU 44 not firmly secured to supporting structure.

-

Page 51: Calibration Procedure E: Magnetometer Interference Test

GMU 44 magnetometer which directly impacts the determination of attitude and heading by the GRS 77 AHRS. Calibration Procedures A-1 through D are not required prior to this execution of this procedure. - Page 52 (typically will include navigation lights, recognition lights and strobe) 4:10 Turn off all wing-tip lights simultaneously 4:20 Beacon on 4:30 Beacon off 4:40 Pitot heat on 4:50 Pitot heat off 5:00 End of test Page 5-14 GRS 77/GMU 44 Installation Manual Revision L 190-00303-10...

- Page 53 It is important that the “time equals zero” moment corresponds with the moment the PFD first displays the blinking TEST COMPLETE message. 2. The operator should carry out the actions called for in the prepared test sequence. GRS 77/GMU 44 Installation Manual Page 5-15 190-00303-10...

- Page 54 5.0 milliGauss in either the X or Y axes, or greater than 8.0 milligauss in the Z axis indicates a problem that must be resolved. Compare the corresponding timestamps with the prepared test sequence to identify which action produced the problem. Contact Garmin for assistance in resolving the problem.

-

Page 55: Site Evaluation Of Magnetic Disturbances For Magnetometer Calibration Procedure

If, upon completion of the Magnetometer Calibration Procedure in either of the two directions, the PFD displays either the “MAG FIELD AT SITE NOT UNIFORM”, or “MAG FIELD AT SITE DIFFERS FROM IGRF MODEL” message, then the site contains magnetic disturbances that are too large. GRS 77/GMU 44 Installation Manual Page 5-17 190-00303-10... - Page 56 A site that is used repeatedly to perform the Magnetometer Calibration Procedure should be re-evaluated every 12 months, and after any significant construction or placement of magnetic objects (above or below ground) within 50 meters of the location. Page 5-18 GRS 77/GMU 44 Installation Manual Revision L 190-00303-10...

-

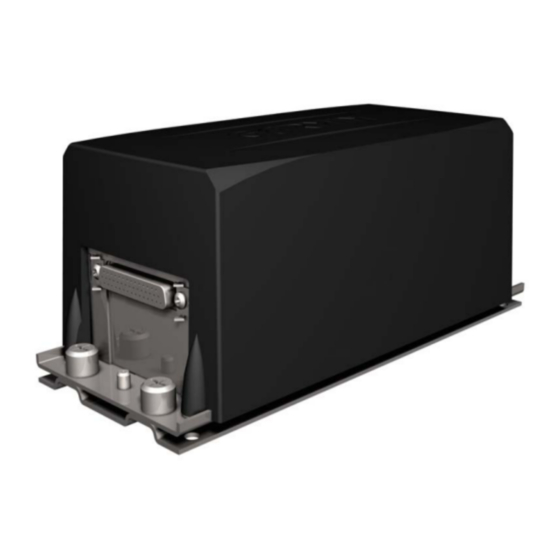

Page 57: Appendix Aoutline And Installation Drawings

APPENDIX A OUTLINE AND INSTALLATION DRAWINGS Figure A-1. GRS 77 Outline Drawing With Mounting Rack GRS 77/GMU 44 Installation Manual Page A-1 (Page A-2 blank) 190-00303-10 Revision L... - Page 58 APPENDIX A OUTLINE AND INSTALLATION DRAWINGS Figure A-2. GMU 44 Mounting Rack (Sheet 1 of 2) GRS 77/GMU 44 Installation Manual Page A-3 (Page A-4 blank) 190-00303-10 Revision L...

- Page 59 APPENDIX A OUTLINE AND INSTALLATION DRAWINGS Figure A-2. GMU 44 Mounting Rack (Sheet 2 of 2) GRS 77/GMU 44 Installation Manual Page A-5 (Page A-6 blank) 190-00303-10 Revision L...

- Page 60 APPENDIX A OUTLINE AND INSTALLATION DRAWINGS Figure A-3. GMU 44 Top Mounted Installation GRS 77/GMU 44 Installation Manual Page A-7 (Page A-8 blank) 190-00303-10 Revision L...

- Page 61 APPENDIX A OUTLINE AND INSTALLATION DRAWINGS Figure A-4. GMU 44 Bottom Mounted Installation GRS 77/GMU 44 Installation Manual Page A-9 (Page A-10 blank) 190-00303-10 Revision L...

- Page 62 APPENDIX A OUTLINE AND INSTALLATION DRAWINGS Figure A-5. GMU 44 Wiring Detail GRS 77/GMU 44 Installation Manual Page A-11 (Page A-12 blank) 190-00303-10 Revision L...

- Page 63 APPENDIX B INTERCONNECT DRAWINGS Figure B-1. Typical GRS 77/GMU 44 Interconnect Wiring Diagram GRS 77/GMU 44 Installation Manual Page B-1 (Page B-2 blank) 190-00303-10 Revision L...

- Page 64 APPENDIX B INTERCONNECT DRAWINGS Figure B-2. Simplified GRS 77/GMU 44 Installation, Interconnect Wiring Diagram GRS 77/GMU 44 Installation Manual Page B-3 (Page B-4 blank) 190-00303-10 Revision L...