Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Volvo Penta TAD734GE

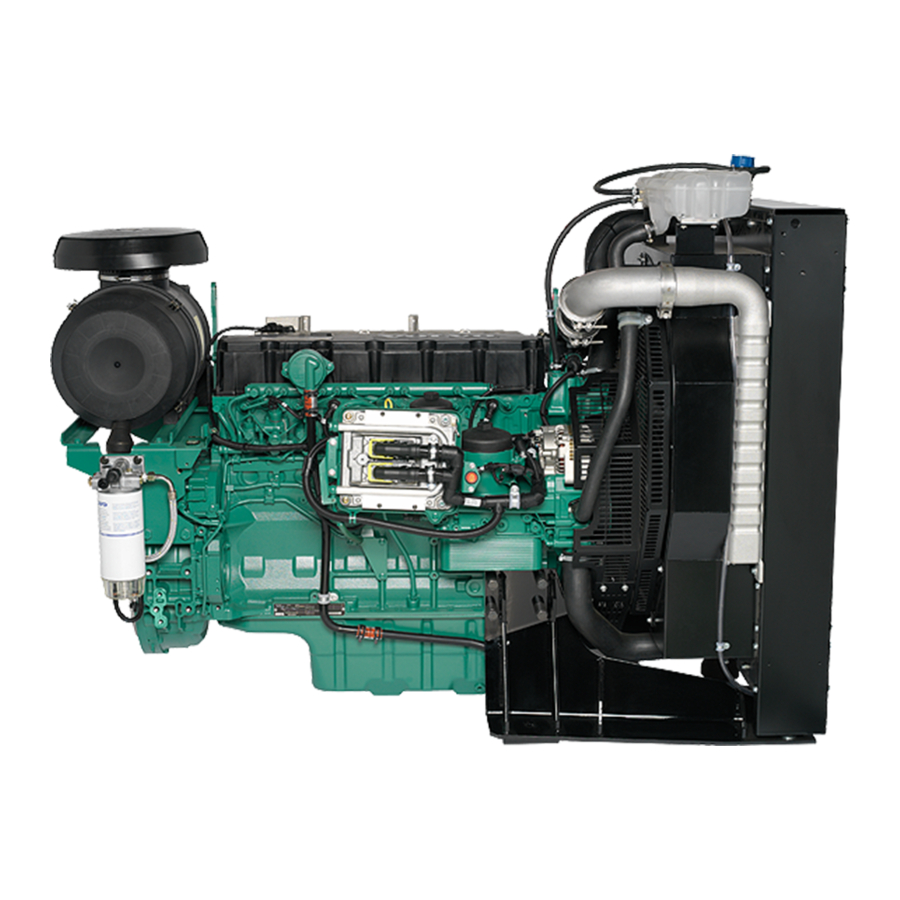

- Page 1 Installation EMS 2 1(1) Industrial engines TAD734GE...

-

Page 3: Table Of Contents

Fault codes ............34 Instruments, Easy Link (optional) ....... 17 Instruments, analogue (optional) ......18 References to service bulletins ......43 Other matters ............. 19 © 2009 AB VOLVO PENTA We reserve the right to changes or modifications. Printed on environmentally compatible paper. -

Page 4: Safety Regulations

Ask your Volvo Penta dealer for help if there is any- IMPORTANT! Used to draw your attention to thing in this instruction manual that you do not under- something that can cause damage or malfunc- stand or are uncertain about. - Page 5 Safety regulations Never work on an engine that is hanging from Make sure that the positive (+) and negative (-) lifting gear (a crane or similar). battery cables are correctly connected to the corresponding battery terminals. You can cause serious damage to the electrical equipment if The engine shall not be operated in areas where the cables are mixed up.

-

Page 6: Special Tools

Special Tools Special Tools 9510060 3838619 3838619 VODIA, complete with cable harness. 9510060-8 Multimeter Refer to the VODIA operators manual when ordering separate parts. - Page 7 The tools below are intended for work on the engine cable harness. The tools are not part of Volvo Pentas assort- ment, but must be ordered from AMP or Deutsch dealers. Contact Volvo Penta Quality Action Center if you have trouble finding a dealer.

-

Page 8: General Information

General information General information EMS 2 – Engine Management System (engine control system) EMS 2 is an electronic system with CAN communication (Controller Area Network) for controlling diesel engines. The system has been developed by Volvo and includes fuel regulation and diagnostic functions. The system comprises a control unit, six injectors, a number of sensors that supply the control unit with values and connectors for diagnostics and functional checks. - Page 9 General information DCU (Display Control Unit) The DCU is a digital instrument panel that communi- cates with the engine control unit via the CAN link. The DCU has several functions, such as: Engine control – Start, stop, engine speed regulation, pre-heating, etc.

- Page 10 Fault codes can also be read off by Volvos VODIA channel. In this state, no fuel is injected into the cylin- tool at authorized Volvo Penta workshops. ders. If a serious fault occurs, the engine may be shut down...

-

Page 11: Component Location

General information Component Location NOTE: Locations can vary, depending on the engine model. 1. Solenoid proportional valve, high pres- sure pump – fuel (MPROP) 2. Coolant temperature 3. Water in fuel (mounted on primary fuel filter). 4. Charge air pressure and temperature 5. -

Page 12: Power Supply 24 V

General information Power supply 24 V The positive and negative cables from the batteries Battery cable cross-sectional area must be connected to the starter motor terminals. The battery positive cable shall be connected via a The total length (L) of the positive and negative ca- main switch to terminal 30 on the starter motor. -

Page 13: Wiring Diagram Ems 2, Engine Cable Harness

General information Wiring diagram EMS 2, engine cable harness... -

Page 14: Wiring Diagram, Ciu

Alarm, low coolant level RPM-potentiometer Fuel alarm Tachometer (code 14) Diagnostic lamp Oil pressure, instrument Indicator, engine overspeed Oil temperature, instrument (Does not apply for TAD734GE) Running lamp Coolant temperature, instrument Pre-heater indicator Instrument lighting Pre-heating contact Idle contact, two-way... -

Page 15: Wiring Diagram Dcu

General information Wiring diagram DCU Cable colors BL = Blue Light blue BN = Brown Light brown GN = Green GR = Gray OR = Orange Pink SB = Black VO = Violet White Yellow Cable cross section = 0.75 mm 1. -

Page 16: Ciu

Connectors, analogue i n s t r u m e n t s (optional) 3-pin Deutsch connec- tor, Easy Link instru- ments 8-pin Deutsch connector from Connecting cable cable harness on Connecting, see section engine Instruments 8-pin Deutsch connectors Extension cables are available in the follo- wing lengths: 3, 5, 7, 9 and 11 m General The installation must be well prerared and performed... -

Page 17: Connection

Connecting the CIU This function allows a change of frequency from 50 to Engine control 60 Hz. See wiring diagram. Contact type two position. NO = Normally open NC = Normally closed Idle contact Contact type two position. Ignition key (system voltage OFF/ON) Closed contact provides idling speed (900 rpm). -

Page 18: Warning And Indication Lamps

Warning and indication lamps The warning and indication lamps listed below are av- ailable. Specs for all lamps: Max. load 3 W Voltage 24 V See Electrical diagram CIU • Alarm, low oil pressure • Alarm, high oil temperature • Alarm, high coolant temperature •... -

Page 19: Instruments, Easy Link (Optional)

Instruments, Easy Link (optional) See wiring diagram For parallel connection of up to 20 extra VDO-instru- ments. The instruments automatically find their respective pa- rameter group in the data bus. Max length of Easy- Link wiring is 3 m (10 ft). The following instruments are available: - Tachometer/operating hours - Coolant temp... -

Page 20: Instruments, Analogue (Optional)

0–2600 rpm. Set code 14. See Installation instructions . TACHO METER R/SB GR/SB Oil pressure instrument Use Volvo Penta oil pressure instrument, graduated 0–10 bar (0–145 psi). R/SB OIL PRESSURE INSTRUMENT R/BL Oil temperature instrument Use Volvo Penta oil temperature instrument, gradua- ted 40–150°C (104–302°F). -

Page 21: Other Matters

VODIA tool, as shown below, when this system is SPEED CONTROL (GN/SB) used. ON SWITCH (R/BL 1.5) NOTE! The interface module EAM122 is not sold by Volvo Penta. Contact the local representative for GAC (Governors of America Corporation). Nominal rpm + 120 rpm Nominal rpm... -

Page 22: Dcu

General Installation must be planned very carefully and per- Avoid having to make splices in the system wiring, if formed with great care. at all possible. The cables and any splices must be accessible for inspection and service. Fix the connecting cable between the engine and in- strument panel with clamps. -

Page 23: Connection

Connecting DCU DCU (Display Control Unit) RPM-potentiometer The DCU is connected via the 8-pin databus connec- Max. potentiometer value: 0-10 V (preset value 9 V) tor block. Refer to “Wiring diagram DCU”. Min. potentiometer value 0-10 V (preset value 1 V) The signal can be inverted, refer to diagram below. -

Page 24: Parameter Settings

Parameter settings Parameter settings Connecting the VODIA parameter tool Function, VODIA By using the VODIA tool (3838619) in position “Pa- rameters, reprogramming” you can read off and adjust the parameters stated below. The VODIA tool is con- nected to the diagnostics connector (6-pin connector block) located beneath the “cable cover”... -

Page 25: Adjustable Parameters

Parameter settings Adjustable parameters NOTE: VODIA is used to adjust parameters in CIU and EMS2. Some parameters require special authori- zation. Functions Connected to system voltage during running/stop, CIU Primary control mode Stops input data to the CIU unit connected to system Selects which regulator is to be used when there is no voltage at “run”... -

Page 26: Engine Protector

Parameter settings Engine protector Engine protector coolant Engine protection, charge air temperature pressure Determines if engine protection shall be activated in Determines if engine protection shall be activated in response to high coolant temperature. response to high charge air pressure. A fault code is registered and the engine is shut down. -

Page 27: Engine Speed Regulator, Adjustment

Engine speed regulator, adjustment The regulator has a factory setting that has been optimized to suit the most common generator set applications. Use the VODIA tool (including EMS software), to read and adjust the P, I and D sections of the engine speed regu- lator. - Page 28 D-value compensates (Derivative). Reacts to fast changes of engine speed/load. A reduced value (Fig 4.) gives a greater sensitivity to fast changes of engine speed/load. Reduce the D-value Fig 4. I-value too high or D-value too low to reduce oscillations caused by fast changes. An increased value (Fig.

- Page 29 4. Select “High” or “Low”. High: when one is far from the nominal engine speed, i.e. to improve load response. Low: when one is close to the nominal engine speed point, i.e. to increase stability. 5. Run the engine at the working speed and working temperature.

- Page 30 7. Adjust the P and I sections again as above, if nec- essary. 8. Check engine response as fig. 6. 9. Repeat the procedure in the other position, “High”/ “Low” if necessary. 10. To reset to factory settings, use the reset button above the PID settings.

-

Page 31: Frequency Change, Ems 2

Routine, with system voltage applied: The routine for altering the engine speed on the TAD734GE is not the same as for, i.e. D12. There is 1. Send a stop request in a VP_STATUS-message. no system reset on the EMS 2 unit, and the routine is 2. -

Page 32: Troubleshooting

A number of symptoms and possible causes of engine malfunctions are described in the table below. Always con- tact your Volvo Penta dealer if any problems occur that you cannot solve yourself. WARNING! Read through the safety instructions for care and service in chapter “Safety information” before you start working. -

Page 33: Diagnostic Functions

Diagnostic function Diagnostic function The diagnostic function monitors and checks that the EMS 2 system functions normally. The diagnostic function has the following tasks: • Detect and locate functional faults • Inform that a functional fault has been detected • Give guidance during fault tracing Fault code If the diagnostic function discovers a fault in the EMS... - Page 34 Diagnostic function Function Read off the fault codes via DU (Display When a functional fault has occurred and the diagnos- Unit) tics system has created one or more fault codes, then these can be read off in different ways depending on Depending on how serious the fault is, one of the fol- which equipment is used.

- Page 35 Diagnostic function Reading off the fault code via the Reading off a fault code via Easy Link diagnostics lamp on the instrument instruments (only with CIU) panel, CIU When the system has detected a functional fault, this When the system has detected a functional fault, the will be reported by the diagnostics lamp flashing.

-

Page 36: Fault Codes

Fault codes Fault codes WARNING! Read the safety instructions for handling and service in chapter “Safety information” before starting work. NOTE: Reading the fault codes below, such as Code 2.1, PID /SPN 97, where 2.1 is a flash code indicated by a flashing diagnostic lamp. - Page 37 Fault codes Code 2.5, SID 21 / SPN 636 Code 2.9, PID / SPN 97 Engine speed sensor, camshaft Indicator for water in fuel Reason: Reason: • No signal. • Short circuit. • Abnormal frequency. • Open circuit. • Fault in sensor. •...

- Page 38 Fault codes Code 3.3, PID / SPN 110 Code 3.6, PID / SPN 94. Fuel pressure sensor Coolant temperature sensor Reason: Reason: • Short circuit to positive (+) or earth (ground) (-). • Short circuit to positive (+) or earth (ground) (-). •...

- Page 39 Fault codes Code 4.6, PPID 3 / SID 39 / SPN 677 Code 5.3, PPID 6 / SPN 520195. Stop input CIU Start output / Starter motor relay Reason: Reason: • Short circuit to negative (-). • Short circuit to positive (+) or earth (ground) (-). •...

- Page 40 Fault codes Code 6.5, SID 231 / SPN 639/2017 / PSID 201 Code 6.1, PID / SPN 110. Coolant temperature Data link (CAN), EMS 2 Reason: Reason: • Coolant temperature is too high. • Internal fault in control module. Reaction: Reaction: •...

- Page 41 Fault codes Code 7.1, SID 1 / SPN 651 Code 7.3, SID 3 / SPN 653 Injector, cylinder #1 Injector, cylinder #3 Reason: Reason: • Electrical fault. • Electrical fault. • Faulty compression or injector. • Faulty compression or injector. Reaction: Reaction: •...

- Page 42 Engine control unit reduces engine power. • Reduced performance. Action: Action: • Please contact an authorized Volvo Penta work- shop. • Check that the unit injector cables are not dam- aged. Code 8.3, PSID 96 / SPN 1239 Pressure in Common Rail •...

- Page 43 Fault codes Code 9.3, SID 232/221 / SPN 620/1079/1080 Code 8.3, PID / SPN 164. Injection pressure Voltage supply to sensor Reason: Reason: • Fault in fuel supply. • Short circuit. • Faulty fuel pump. • Fault in one of the sensors. •...

- Page 44 Fault codes Code 9.9, SID 240 / SPN 639. Memory fault in Reason: • Memory fault in engine management system (EMS). Reaction: • Engine might not start. Action: • Re-program the unit. Code 9.9, SID 254 / SPN 629. Control unit EMS Reason: •...

-

Page 45: References To Service Bulletins

References to Service bulletins Group Date Concerning .......................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................... - Page 46 Notes ................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................

- Page 47 From: ....................................................................Refers to publication: ............................. Publication no: ............... Date of issue: ..............Suggestion/Motivation: ................................................................................................................................................................................................................................................................................................................... Date: ..............Name: ............... AB Volvo Penta Teknisk Information Avd. 42200 SE-405 08 Göteborg Sweden...