Summary of Contents for Bosch Hagglunds CB

- Page 1 Hägglunds CB Radial piston hydraulic motor Replaces: Installation and maintenance RE 15302-WA/10.2015 manual RE 15302-WA/05.2019 English...

- Page 2 Rexroth representative. The cover shows an example configuration. The product supplied may therefore differ from the figure shown. The original operating instructions were pre- pared in English. Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019...

-

Page 3: Table Of Contents

Unpacking Installation conditions 7.2.1 Spline shaft end 7.2.2 Plain shaft end Required tools 7.3.1 Assembly tool for coupling adapter CB 1120 7.3.2 Assembly tool for CB motor RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB... - Page 4 11.4 Preparing the components for storage or further use Disposal 12.1 Environmental protection Extension and conversion Troubleshooting Technical data 15.1 Technical data, Hägglunds CB 15.1.1 Hydraulic fluids Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019...

-

Page 5: This Documentation

The described danger prevention measures must be observed. RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB... -

Page 6: Symbols

Numbered operating instruction: The numbers indicate the actions follow one another in sequence Center of gravity Markings on packaging to indicate where the center of gravitiy are. Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019... -

Page 7: Safety Instructions

Bosch Rexroth must be approved by contact at Bosch Rexroth. • Extension or conversion is not permissible and has to be approved by contact at Bosch Rexroth. RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB... -

Page 8: Personnel Qualifications

• Use only genuine Bosch Rexroth spare parts to avoid the risk of personal injury through using unsuitable parts. • Comply with the technical data and ambient conditions stated in the product documentation. -

Page 9: Product-Specific Safety Instructions

(operating safety). • You may only commission the product if it has been determined that the end product (e.g. machinery or a system) into which the Bosch Rexroth products are installed complies with the country-specific provisions, safety regulations and standards of the application. -

Page 10: Personal Protective Equipment (Ppe)

PPE is the responsibility of the user of the Hägglunds motors. Observe the safety regulations and provisions of your country. All components of the PPE must be intact. Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019... -

Page 11: General Instructions On Material Damage And Product Damage

▶ Remove any sensitive electronic equipment before performing any electro- welding on the machine RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB... - Page 12 The warranty applies only to the delivered configuration. The entitlement to warranty cover will be rendered void if the product is incorrectly installed, commissioned or operated, or if it is used or handled improperly. Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019...

-

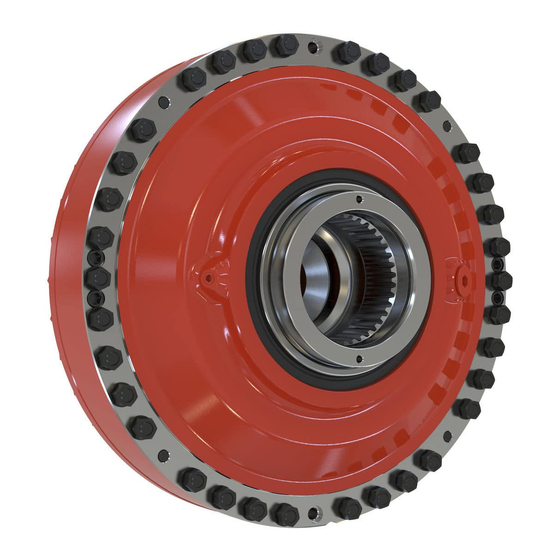

Page 13: Delivery Contents

9. Connection housing 10. Distributor 11. Combined axial and radial bearing 12. Wear ring Fig. 1: The CB radial piston motor RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB... -

Page 14: Product Identification

14/68 Delivery contents 5.3 Product identification DD00099509 1 Type of product 2 Serial number 3 Weight 4 Manufacturer 5 Max pressure Fig. 2: Plate on motor Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019... -

Page 15: Transport And Storage

Mounting alternative shaft Measure A 2.83 CB 280 3.94 4.92 CB 400 6.14 -0.39 CB 560 1.18 1.89 CB 840 3.39 S inkl coupling adapter 0.08 CB 1120 5.67 RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB... -

Page 16: Lifting Motors And Accessories

Motor type Ibf⋅ft CB 280 to CB 1120 6.1.2 Lifting motors and accessories DD00059090 CB 280 to CB 1120 Fig. 5: Lifting motor with shaft in vertical plane Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019... - Page 17 CB 280 to CB 400 CB 560 to CB 1120 Fig. 6: Lifting motor with shaft in horizontal plane DD00100400 DD00100399 Fig. 7: Lifting motor mounted to single/double ended torque arm RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB...

- Page 18 18/68 Transport and storage DD00100401 DD00100403 Fig. 8: Lifting single ended torque arm Fig. 9: Lifting coupling adapter Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019...

-

Page 19: Product Storage

Fig. 10. DD00100066 DD00100065 A) Standing with B) Standing with shaft horizontal shaft vertical Support Fig. 10: CB motor standing on a flat surface (example) RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB... -

Page 20: Storing For Extended Periods Or In Uncontrolled Environment

Table 6: Motor case oil volume Motor size Motor case oil volume including channels Litre US gallon CB 280 CB 400 CB 560 CB 800 CB 1120 Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019... -

Page 21: Storing During Maintenance

3 Remove the packaging from the Hägglunds motor. 4 Check the Hägglunds motor for transport damage and completeness, see chapter 4. 5 Dispose of the packaging according to the environmental regulations of your country. RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB... -

Page 22: Installation Conditions

For further information see data sheet RE 15302 Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019... -

Page 23: Required Tools

1 Lifting eye 4 Dismantling tool 2 Adapter shaft 5 Nut 3 Shrink disc 6 Washer 7 Screw 8 Carriage beam 9 Adapter M20 to M16 RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB... -

Page 24: Assembly Tool For Cb Motor

Assembly tool Assembly tool motor 1 Tie rod 2 O-ring 3 Washer 4 Nut DD00100406 Fig. 13: Mounting CB motor with assembly tool Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019... -

Page 25: Product Installation

6. Tighten the screws (1) to the torque stated in Table DD00100408 Fig. 14: Mounting single ended torque arm TC A 0400 for CB 280 to CB 400 RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB... - Page 26 M20x180/300 10.9 DTCB 0400 TC A 0840 CB 560/840 DTCB 1120 M24x80 10.9 TC A 1120 CB 1120 DTCB 1120 Notice! Use torque wrench and oiled screws! Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019...

-

Page 27: Single Ended Torque Arm Installation

TC A 0840 CB 560 to CB 840 1 500 59.06 21.46 TC A 1120 CB 1120 2 000 78.74 21.46 ) Single ended torque arm with articulated connection. RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB... - Page 28 If hot work (e.g. welding) is done on the product, protective breathing equipment must be used. ▶ Never use motor as grounding point. Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019...

- Page 29 TC A 1120 CB 1120 1120 235 200 52 875.06 214 792 48 287.16 1) The force Fr is calculated including the weight of spline motor and torque arm. RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB...

- Page 30 Fig. 23: Electrical isolated articulated connection TC A Description Linkage part Fastening support Bolt Supporting disc Circlip Spherical plain bearing Split pin Washer (electrical isolated) Bushing (electrical isolated) Washer (electrical isolated) Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019...

- Page 31 Fig. 24: Heavy duty articulated connection TC A Description Linkage part Fastening support Shaft Supporting disc Circlip Spherical plain bearing Sleeve Set of wedge lock washers Screw Washers RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB...

-

Page 32: Double Ended Torque Arm Installation

Table 10: Dimensions torque arm DTCB Torque arm Weight DTCB 0400 2120 83.46 35.43 1102 DTCB 1120 3000 118.11 35.43 1102 ) Double ended torque arm with articulated connection and hydraulic cylinder Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019... - Page 33 Fig. 29: Hole pattern articulated connection and hydraulic cylinder for DTCB Table 11: Hole pattern dimensions for articulated connection and hydraulic cylinder DTCB Torque arm DTCB 5.43 3.74 5.98 7.72 0.98 RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB...

- Page 34 DTCB_ 1120 11 CB 1120 1120 163 226 36 694.66 67 033 15 069.62 1) The force Fr is calculated included the weight of splines motor and torque arm. Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019...

- Page 35 Pins Circlips Hydraulic cylinder Air bleeding G ¼" (opposite side of connections) Attachment brackets Screw M24-8.8 665 Nm / 490 lbf ft 8 (Not included in delivery) RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB...

- Page 36 Make sure to follow the installation instructions regarding hydraulic connections The cylinders should be vented from air during commisioning by using the air bleeding screws on the cylinder, see Fig. 31 Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019...

-

Page 37: Mounting Of Motor And Coupling Adapter

If nescesary separate the clamping ring for easier mounting. 5. Absolutely no grease on the surfaces between driven shaft and hollow shaft. Clean the driven shaft and the inside of the hollow shaft RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB... - Page 38 When a motor has been in for overhaul or service and shall be reassembled it may be necessary to relubricate those surfaces with Molykote G-Rapid plus paste again but only on the specified surfaces. Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019...

- Page 39 DD00058276, DD00080049 Driven shaft Coupling adapter Fig. 35: Mounting the coupling adapter on the driven shaft with the assembly tool. Assembly tool 1 Nut 2 Carriage beam RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB...

- Page 40 Fig. 37: Driven shaft with stress relieving groove Table 14: Clamping length Lenght B Motor CB 280 4.17 CB 400 4.61 CB 560 to CB 1120 6.02 Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019...

- Page 41 DD00079284 Keep the coupling adapter or coupling motor in level with driven shaft! Fig. 38: Gap between the clamping rings RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB...

- Page 42 This torque is always to be used. ▶ Tightening torque value is critical. Use calibrated torque wrench. ▶ Uncoated screws shall be greased with Molykote G-Rapid plus paste. Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019...

- Page 43 Tie rod Driven shaft O-ring Washer Key grip 3. Bearing retainer 2. Plug G 1˝ 1. End cover Fig. 40: Mounting of coupling motor with assembly tool RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB...

- Page 44 Litre US gallon Litre US gallon CB 280 0.22 0.58 CB 400 0.45 1.14 CB 560 0.45 1.14 CB 840 0.71 1.82 CB 1120 0.98 2.48 Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019...

- Page 45 Oil filling of spline (delivered with motor) 10 mm Axial clearance Spacer Spacer Screw 5. Screw M20 Fig. 42: Fix the spline motor with the mounting kit, horizontal mounting RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB...

- Page 46 Mounting the motor onto the driven shaft using the assembly tool see : Mounting the coupling motor to the driven shaft page 43. Note! If splines motor is to be used, contact your Bosch Rexroth representative. DD00100627 Fig. 43: Vertical mounting of coupling motor...

- Page 47 US gallon Litre US gallon CB 280 0.34 0.98 CB 400 0.55 1.57 CB 560 0.74 1.98 CB 840 1.00 10.2 2.68 CB 1120 1.27 12.9 3.40 RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB...

-

Page 48: Draining And Venting The Motor

Drain line connection Flushing flow inlet Alternative flushing flow inlet for flange mounted motors. DD00087718 Fig. 45: Horizontal mounting Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019... - Page 49 D1, D2, D4 Drain line Drain line connection connection Low pressure Flushing flow inlet D1, D2, D4 A) Shaft side upwards B) Shaft side downwards Fig. 46: Vertical mounting RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB...

-

Page 50: Flushing

Connect the input flushing line at the lowest drain port, D1 to D4 at opposite side compared to the drain outlet in order to obtain a cross flushing flow through the motor, see Fig. 45 and Fig. 46. Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019... -

Page 51: Hydraulic Connections

G 1/2" For flushing of axial bearing and motor case. *SAE flange J 518 , code 62, 420 bar (6000 psi). All connections are normally plugged at delivery. RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB... -

Page 52: Direction Of Rotation Of Motor Shaft

Do not touch rotating parts or be in the zone of rotating parts. DD00100623 Rotating part Fig. 48: Rotating part, motor with coupling adapter DD00100622 DD00100624 Rotating part Rotating part Fig. 49: Rotating part, spline motor and coupling motor Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019... - Page 53 With the inlet flow connected to C port, the motor shaft rotates clockwise viewed from shaft side of the motor. RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB...

-

Page 54: Commissioning

2. Check the drain line to ensure that excessive pressure does not build up in the motor case; see chapter 7.2 and 7.4.5 3. Check that the motor is protected from overloads, see chapter Motor data in data sheet 15302. Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019... -

Page 55: Start Of The Hydraulic Supply

Use the product only within the performance range provided in the technical data. The machine/system manufacturer is responsible for the proper project-planning of the hydraulic system and its control. RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB... -

Page 56: Maintenance And Repair

The disadvantage with this method is that you only get the contamination level in the oil. Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019... - Page 57 Connect the hoses according to the particle counters manual. To get a true value the contamination readings have to be stable about 10 min before you stop to measure. RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB...

-

Page 58: Maintenance Plan

After the first 100 hours After 3 months or 500 hours Once every 2 weeks Once every 6 months Once every 12 months R = Replacement, I = Inspection Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019... -

Page 59: Maintenance

Degree of contamination Heavy contamination of the oil causes increased wear of the components in hydraulic system. The cause of the contamination must be immediatly investigated and remedied. RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB... -

Page 60: Repair

Make sure that the relevant system components are not under pressure or voltage. 2. Protect the complete system against being energized. 3. Remove the hoses, cables and pipelines from the motor. Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019... -

Page 61: Removing Motor And Coupling Adapter

Use an oil binding agent if hydraulic fluid is spilled. ▶ Observe the information in the safety data sheet for the hydraulic fluid and the specifications provided by the system manufacturer. RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB... - Page 62 10. Pull the motor off the shaft by turning the nut on the assembly tool. DD00100628 Tie rod Driven shaft O-ring Washer Bearing retainer Plug G 1˝ End cover Fig. 51: Assembly tool for removing the CB spline motor Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019...

- Page 63 8. Untighten the screws on the shrink disc gradually, appr. a quarter turn each. Keep doing this until all screws are loosened. 9. Pull the motor off the shaft by turning the nut on the assembly tool. RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB...

-

Page 64: Preparing The Components For Storage Or Further Use

4. Washer 5. Screw 6. Carriage beam 7. Adapter M20 to M16 11.4 Preparing the components for storage or further use Proceed as described in chapter 6.2. Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019... -

Page 65: Disposal

Dispose material in accordance with the national regulations in your country. 13 Extension and conversion Do not modify Hägglunds products. Please contact your Bosch Rexroth representative for extension or conversion. RE 15302-WA/05.2019, Hägglunds CB, Installation and maintenance manual , Bosch Rexroth Mellansel AB... -

Page 66: Troubleshooting

The radial lip seals or other seals is worn or External oil leakage on the motor. Replace the damaged seals. damaged. Bosch Rexroth Mellansel AB, Installation and maintenance manual , Hägglunds CB, RE 15302-WA/05.2019... -

Page 67: Technical Data

RE 15302 , chapter Recommended charge pressure. ▶ Changes to the factory settings must only be made by Bosch Rexroth specialist personnel. 15.1.1 Hydraulic fluids The hydraulic CB motor is primarily designed for operation with hydraulic fluids according to ISO 11158 HM. - Page 68 Bosch Rexroth AB SE-895 80 Mellansel Sweden Tel. +46 (0) 660 870 00 Fax +46 (0) 660 871 60 hagglunds@boschrexroth.com www.boschrexroth.com/hagglunds Your local contact can be found at: www.boschrexroth.com/adresses We reserve the right to make changes Printed in Sweden RE 15302-WA/05.2019...