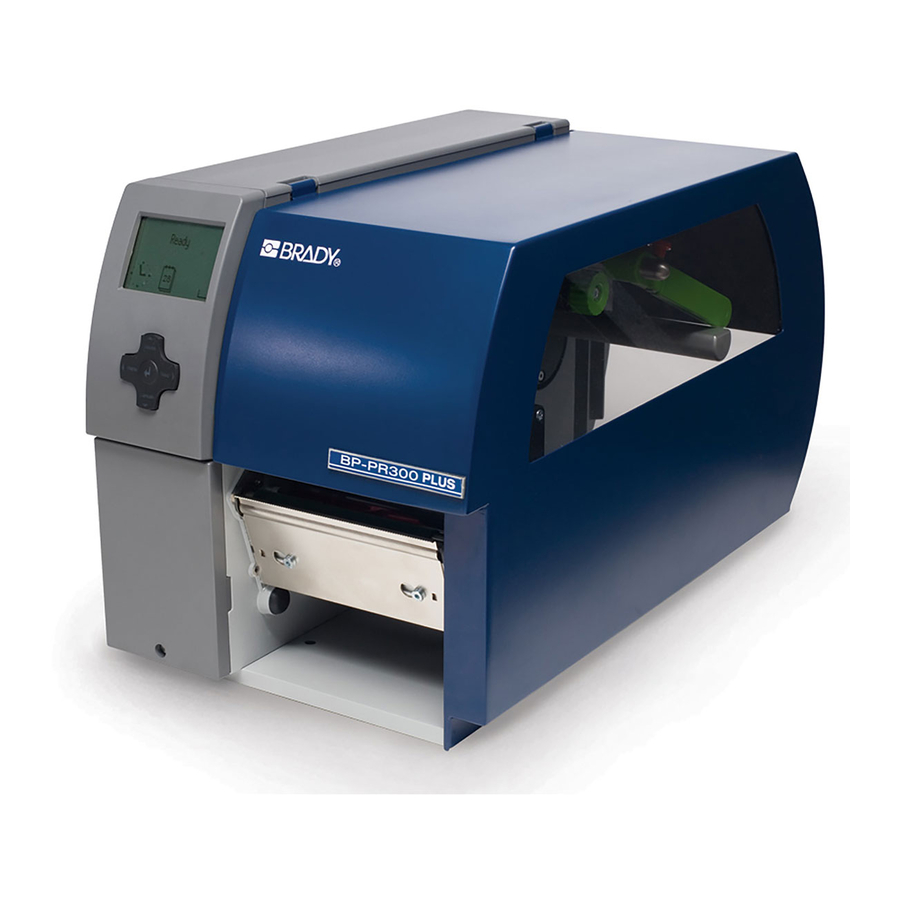

Brady BP-PR PLUS Series Quick Operator's Manual

Transfer printer

Hide thumbs

Also See for BP-PR PLUS Series:

- Operator's manual (27 pages) ,

- Quick start manual (20 pages) ,

- Configuration instructions (66 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Brady BP-PR PLUS Series

- Page 1 Transfer Printer BP-PR PLUS series Quick Operator’s Guide Edition 7/06...

- Page 2 BP-PR PLUS series Information on the scope of delivery, appearance, performance, dimensions and weight reflect our knowledge at the time of printing. We reserve the right to make modifications. All rights, including those regarding the translation, are reserved. Approval The transfer printers comply with the following safety guidelines:...

-

Page 3: Notes On The Documentation

BP-PR PLUS series Notes on the documentation Notes on the documentation The documentation for the BP-PR PLUS series transfer printers is comprised of the following parts: • Operating Instructions • Configuration Instructions • Service Instructions Additional documentation • Spare parts lists •... -

Page 4: Safety Notes

Safety and the environment Safety notes • The transfer printer is designed for power supply systems from 100 V AC to 240 V AC. Connect the transfer printer only to electrical outlets with a ground contact. • Couple the transfer printer to devices using extra low voltage only. -

Page 5: Installation

Setting up the transfer printer CAUTION! The device and the print media can be damaged by moisture and water. ⇒ The transfer printer may only be set up in a dry place protected from sprayed water. Fig. 1: Removing the transportation safeguards Edition 7/06 •... -

Page 6: Connecting To The Power Supply

Connecting to the power supply The printer is equipped with a versatile power supply unit. The device may be operated with a mains voltage of 230 V AC/ 50 Hz or 115 V AC/60 Hz without any adjustments or modifications. -

Page 7: Layout Of The Operating Panel

The symbol indicators shown in the following table can appear on the status line of the screen, depend- ing on the configuration of the printer. They inform you of the current status of the printer at a glance. For configuration of the status line, see the “Configuration Instructions“. -

Page 8: Power Save Mode

BP-PR PLUS series Operating panel 4.2.2 Power-Save mode If the printer is not used for some time, it switches to Power-Save mode automatically. The display shows the To exit Power-Save mode: ⇒ Press any button on the navigator pad. 4.2.3... -

Page 9: Device Types

BP-PR PLUS series Device types Device types Standard device The standard device is used for printing labels or continuous media on rolls or fanfolded media. In Tear-Off mode, labels are removed by hand. The labels can be cut off automatically with the 'cutter' accessory. For details, see the Operating Instruc- tions for the 'cutter' accessory. -

Page 10: Loading Media

BP-PR PLUS series Loading media Loading media For adjustments and simple installation work, use the accompanying hexagonal wrench located in the bottom section of the print unit. See Fig. 5, Item 8. No other tools are required for the work described here. -

Page 11: Positioning The Label Roll On The Roll Retainer

BP-PR PLUS series Loading media 6.1.2 Positioning the label roll on the roll retainer Fig. 5: Loading labels from a roll 1. Open cover (10). 2. Loosen knurled screw (1) and swivel guide (2) upward and push it all the way out. -

Page 12: Setting The Label Sensor

BP-PR PLUS series Loading media 6.1.4 Setting the label sensor Fig. 6: Setting the label sensor The label sensor (2) can be shifted perpendicular to the direction of paper flow for adaptation to the label medium. The sensor unit (1) of the label sensor is visible from the front through the print unit and is marked with a indentation in the label sensor retainer. -

Page 13: Winding Up The Label Strip In Rewind Mode

BP-PR PLUS series Loading media 6.1.5 Winding up the label strip in Rewind mode Fig. 7: Guiding the label strip in Rewind mode In Rewind mode, the labels are wound up internally after printing for later use. 1. Remove the locking system for Rewind mode if necessary (see ”6.5” on page 18) and install rewind guide plate (see ”6.4”... - Page 14 BP-PR PLUS series Loading media 6.1.6 Winding up the liner in Peel-Off mode Fig. 8: Guidance of the liner in Peel-Off mode In Peel-Off mode, the labels are removed after printing, and only the liner is wound up internally. 1. Lift the pinch roller (4) off the rewind assist roller (5).

-

Page 15: Setting The Head Locking System

BP-PR PLUS series Loading media 6.1.7 Setting the head locking system The printhead is pushed on via two plungers. The location of the outer plunger must be set to the width of the label medium used so as to •... -

Page 16: Loading Transfer Ribbon

BP-PR PLUS series Loading media Loading transfer ribbon With direct thermal printing, do not load a transfer ribbon; if one has already been loaded, remove it. Fig. 10: Feed path of the transfer ribbon Quick Operator’s Guide 1. Clean printhead before loading the transfer ribbon (see ”8.3”... -

Page 17: Setting The Feed Path Of The Transfer Ribbon

Removing and installing the rewind guide plate, dispense plate or tear-off plate To convert the printer for use in another operating mode, a rewind guide plate, a dispense plate or a tear- off plate may need to be installed. For printer versions with a locking system on the rewind assist roller, the locking system on the rewind assist roller must be removed (see ”6.5”... -

Page 18: Removing And Installing The Locking System

Removing and installing the locking system Fig. 13: Removing the locking system Removing the locking system 1. Position printer at edge of table so that the oblong hole is accessible from below. 2. Screw out screws (1) (2) and remove them. -

Page 19: Tear-Off Mode

⇒ Print at the lowest possible printhead temperature. Synchronization The printer is ready for operation when all connections have been made, the labels and, if necessary the transfer ribbon, have been loaded and the printhead is locked. For details on printer configuration, see the “Configuration Instructions“. -

Page 20: Cleaning And Basic Maintenance

Cleaning and basic maintenance Cleaning and basic maintenance DANGER! Risk of death via electric shock! ⇒ Disconnect the printer from the power supply before performing any maintenance work. General cleaning When: as necessary. CAUTION! Abrasive cleaning agents can damage the printer! ⇒... -

Page 21: Cleaning The Label Sensor

BP-PR PLUS series Cleaning and basic maintenance Cleaning the label sensor When: when the label roll is changed CAUTION! Label sensor can be damaged! ⇒ Do not use sharp or hard objects or solvents to clean the label sensor. The label sensor can become dirtied with paper dust. This can adversely affect label detection. -

Page 22: Ec Declaration Of Conformity

BP-PR PLUS series EC Declaration of Conformity EC Declaration of Conformity We declare herewith that as a result of the manner in which the machine designated below was designed, the type of construction and the machines which, as a result have been brought on to the general market comply with the relevant fundamental regulations of the EU Rules for Safety and Health.