Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for York OPTIVIEW YIA D

- Page 1 SINGLE STAGE YIA ABSORPTION CHILLERS WITH OPTIVIEW CONTROL CENTER OPERATION MANUAL Supersedes: Form 155.21-O1 (410) Form 155.21-O1 (615) YIA MOD D SINGLE STAGE STEAM / HOT WATER WITH OPTIVIEW CONTROL CENTER LD13714 1A1 through 14F3 Issue Date: June 12, 2015...

- Page 2 All wiring must be in accordance with YORK’s published specifications and must be performed ONLY by qualified Johnson Controls personnel. Johnson Controls will not be responsible for damages/problems resulting from improper connections to the controls or application of improper control signals.

- Page 3 YORK/ equipment has been modified and if current literature Johnson Controls Service Office.

-

Page 4: Table Of Contents

FORM 155.21-O1 (615) TABLE OF CONTENTS SECTION DESCRIPTION OF SYSTEM AND FUNDAMENTALS OF OPERATION .. 5 SECTION OPTIVIEW CONTROL CENTER ............ 11 Setpoints and Configuration ....................12 Unit Operation ........................12 Unit Operation Under Power Failure Condition ..............19 OptiView Control Center....................20 Interface Conventions .......................21 Navigation ........................22 Languages... -

Page 5: Section 1 Description Of System And Fundamentals Of Operation

FORM 155.21-O1 (615) SECTION 1 DESCRIPTION OF SYSTEM AND FUNDAMENTALS OF OPERATION FIGURE 1 – MODEL YIA ABSORPTION CHILLER LD14498 water (the refrigerant) to boil at a temperature below that GENERAL INFORMATION of the liquid being chilled. Chilled liquid entering the evaporator can be cooled for air conditioning or process The chiller is controlled by a modern state of the art Microcomputer Control Center that monitors its op-... - Page 6 Description of System and Fundamentals of Operation FORM 155.21-O1 (615) Absorber Solution Pump The concentrated solution coming back from the genera- A hermetically sealed, centrifugal pump located under tor is partially mixed with solution from the absorber the absorber. It receives diluted lithium bromide solu- section then pumped to a solution spray header where tion from the absorber shell and circulates it through a it is sprayed over the tubes in the absorber.

- Page 7 FORM 155.21-O1 (615) Power Panel Rupture Disk The power panel serves as single-point wiring location Although IsoFlow™ absorption units operate at less than for the unit’s incoming power wiring. It houses all the atmospheric pressure (a vacuum), if certain safeties fail unit pump contactors and overloads, as well as fuses and and/or incorrect valves are closed, the unit could experi- terminal lugs for ease of serviceability.

- Page 8 Description of System and Fundamentals of Operation FORM 155.21-O1 (615) Condenser (Tower) Water 2SOL (Stabilizer refrigerant solenoid valve) The external water loop which is used to remove heat from the unit. This water passes first through the Ab- This solenoid valve is located on a separate line that goes sorber, then the Condenser.

-

Page 9: Figure 2 - Flow Diagram

FORM 155.21-O1 (615) CONDENSER CONCENTRATED SOLUTION (LiBr) TOWER WATER VR40 DILUTE SOLUTION OUTLET (LiBr) INTERMEDIATE SOLUTION (LiBr) VP10 CHILLED LIQUID PURGE TOWER STEAM OR HOT WATER WATER TANK CONTROL VALVE REFRIGERANT LIQUID LOW TEMPERATURE HOT WATER OR REFRIGERANT LIQUID STEAM HIGH TEMPERATURE **PT2 GENERATOR... - Page 10 OptiView Control Center FORM 155.21-O1 (615) THIS PAGE INTENTIONALLY LEFT BLANK JOHNSON CONTROLS...

-

Page 11: Section 2 Optiview Control Center

INTRODUCTION of remote control and communications. By providing a common networking protocol through E-Link Gateway, The YORK OptiView™ Control Center is a micropro- cessor based control system for YORK chillers. YORK Chillers not only work well individually, but also as a team. -

Page 12: Setpoints And Configuration

OptiView Control Center FORM 155.21-O1 (615) Software versions (C.OPT.15.xx.yzz) are alpha-numeric If the unit is equipped with Franklin Pumps, the steam/ codes that represent the application, language package hot water shut-off valves are energized and the refrigerant and revision levels per below. Each time the controls pump and generator pump (50 Hz Models YIA-10E3 - portion or language section is revised, the respective YIA-14F3) are started. - Page 13 FORM 155.21-O1 (615) setpoint. This allows the chiller to remain running while Strong Solution Concentration (SSC) Control adjusting LCHLT to a new setpoint. If a setpoint change The "Strong Solution Concentration Control" is a fuzzy is entered more than once within 5 minutes of the first logic control;...

- Page 14 OptiView Control Center FORM 155.21-O1 (615) During normal operation where at least medium load Dilution Cycle Operation prevails, Lithium Bromide in the refrigerant circuit is A dilution cycle is performed every time the chiller is NOT required. The YIA unit provides means for Lithium cycled off or shutdown.

- Page 15 FORM 155.21-O1 (615) Manual Dilution Cycle – is only available in the “Sys- System Details Condition tems” screen when the panel is set to “Service” access Display Message level. The manual dilution key will NOT show in the Chilled liquid flow opens Dilution cycle interrupted “View”...

- Page 16 OptiView Control Center FORM 155.21-O1 (615) Limited Dilution Cycle – A limited dilution cycle was The mode determines how to clear the purge tank. created for power failure situations when the unit is • Auto-purge mode enables the unit able to clear the connected to a stand-by generator.

- Page 17 FORM 155.21-O1 (615) • Purge trending transducer (PT3) must be equal to or less than 15mm Hg Abs. If not, the purge pump will continue to run for • Post purge "Oil Clean-up" an additional minute. If during this additional minute, the pressure at PT3 reaches 15mm Hg Abs or less, purge The logic to control the YIA auto-purge is ONLY avail- tank solenoid (7SOL) will open.

- Page 18 OptiView Control Center FORM 155.21-O1 (615) When the post purge cleaning process finishes, the Once the purge tank pressure transducer (PT4) reads 30 purge pump is turned off and the last 7 days manual mm Hg Abs, both 7SOL and 8SOL will close. The purge purge counter and the total manual purge counter is pump will continue to run for another 10 minutes for a increased by 1.

-

Page 19: Unit Operation Under Power Failure Condition

FORM 155.21-O1 (615) Purge Mode Changes Limited Auto-decrystallization When the purge mode is changed, 7SOL and 8SOL are The limited auto-decrystallization process is triggered closed. If NOT closed the purge pump will continue to when the temperature sensed by RT2 is greater than run an additional 65 seconds, if it was running. -

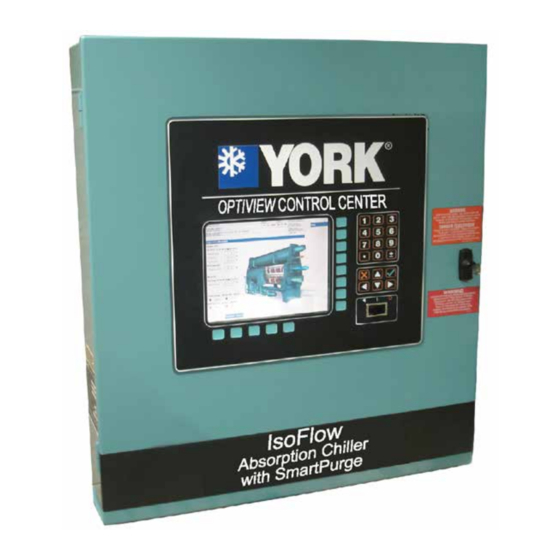

Page 20: Optiview Control Center

OptiView Control Center FORM 155.21-O1 (615) OPTIVIEW CONTROL CENTER The Start/Stop control is operated via a three-position rocker/rotary switch. When toggled all the way to the right, it is considered in the STOP/RESET position. The OptiView™ Control Center display is highlighted When in the middle position, this is considered the by a full screen graphics display. -

Page 21: Interface Conventions

FORM 155.21-O1 (615) INTERFACE CONVENTIONS this point, the user will be prompted to enter a User ID and the corresponding Password. By default, the User ID is zero (0). In order to gain standard OPERATOR Overview level access, the Password would be entered as 9 6 7 5, The new graphical display on each control panel allows using the numeric keypad. -

Page 22: Navigation

OptiView Control Center FORM 155.21-O1 (615) 3. Press the "" (Enter) key. NAVIGATION If the value is within range, it is accepted and the In order to maximize the amount of values which the dialog box disappears. The chiller will begin to op- panel can display to the user, and in order to place those erate based on the new programmed value. -

Page 23: Figure 4 - Yia Optiview Navigation

FORM 155.21-O1 (615) YIA OptiView Navigation Gen / Cond Screen (page 30) Evap / Absorb Screen (page 28) System Screen (page 32) Purge Screen (page 34) Evap / Absorb Screen (page 28) Gen / Cond Screen (page 30) System Screen (page 32) Purge Screen (page 34) Solution System Screen (page 32) -

Page 24: Analog Input Ranges

OptiView Control Center FORM 155.21-O1 (615) ANALOG INPUT RANGES The following table indicates the valid display range for each of the analog input values. In the event that the input sensor is reading a value outside of these ranges, the < or >... - Page 25 FORM 155.21-O1 (615) THIS PAGE INTENTIONALLY LEFT BLANK JOHNSON CONTROLS...

-

Page 26: Home Screen

OptiView Control Center FORM 155.21-O1 (615) LD13812 FIGURE 5 - HOME SCREEN HOME SCREEN Programmable Overview Login When the chiller system is powered on, the above default Access Level Required: VIEW display appears. The primary values which must be moni- The OptiView Panel restricts certain operations based on tored and controlled are shown on this screen. - Page 27 FORM 155.21-O1 (615) Login System Access level required: View Causes an instant return to a detailed view of the status This key is displayed when the user is NOT logged in. of System Pumps, Liquid Flow details, Solenoid Valves, and Level Switches. Manual operation of these devices Pressing the login key will bring up a login screen, al- lowing OPERATOR and SERVICE access level.

-

Page 28: Evaporator / Absorber Screen

OptiView Control Center FORM 155.21-O1 (615) FIGURE 6 - EVAPORATOR / ABSORBER SCREEN LD13813 EVAPORATOR / ABSORBER SCREEN Programmable Overview Leaving Chilled Liquid Temperature Setpoint This screen displays a cutaway view of the chiller Access Level Required: OPERATOR evaporator and absorber. All setpoints relating to the This value allows the user to define the Leaving Chilled evaporator side of the chiller are maintained on this Liquid Temperature that is to be maintained by the chill-... - Page 29 FORM 155.21-O1 (615) Navigation Home Causes an instant return to the Home Screen. Gen/Conden Causes an instant return to the Generator/Condenser Screen. System Causes an instant return to the System Screen. Purge Causes an instant return to the Purge System Screen. JOHNSON CONTROLS...

-

Page 30: Generator / Condenser Screen

OptiView Control Center FORM 155.21-O1 (615) FIGURE 7 - GENERATOR / CONDENSER SCREEN LD13814 GENERATOR / CONDENSER SCREEN Condenser Displays the leaving cooling liquid temperature and re- frigerant temperature from the Condenser. Overview This screen displays a cutaway view of the chiller gen- Programmable erator and condenser. - Page 31 FORM 155.21-O1 (615) Navigation Home Causes an instant return to the Home Screen. Evaporator / Absorber Causes an instant return to the Evaporator / Absorber Screen. System Causes an instant return to the System Screen. Purge Causes an instant return to the Purge Screen. JOHNSON CONTROLS...

-

Page 32: System Screen

OptiView Control Center FORM 155.21-O1 (615) FIGURE 8 - SYSTEM SCREEN LD13815 SYSTEM SCREEN Programmable Overview Solution Access Level required: SERVICE This screen gives an overview of system mechanical This key selects the solution pump for manipulation to equipment status for both shells. Auto or Manual. - Page 33 FORM 155.21-O1 (615) Chilled Navigation Access Level required: SERVICE This key selects the Chilled liquid pump run contacts Home for manipulation to Auto or Manual. To switch the pump Causes an instant return to the Home Screen. run contacts "ON" (closed) or "OFF" (open) use the soft keys located at the bottom of the display.

-

Page 34: Purge Screen

OptiView Control Center FORM 155.21-O1 (615) LD13816 FIGURE 9 - PURGE SYSTEM SCREEN PURGE SYSTEM SCREEN Autopurge Total Counter Displays the total number of Autopurges performed. Overview Manual Purge Total Counter Displays the total number of Manual purges per- This screen gives an overview of parameters for the formed. - Page 35 FORM 155.21-O1 (615) Programmable Navigation Purge Pump Home Access level required: SERVICE Causes an instant return to the Home Screen. This key selects the purge pump for manipulation, to turn it "ON" or "OFF" in "REPAIR" mode with the soft Evaporator / Absorber keys located at the bottom of the display.

-

Page 36: Purge Trend Screen

OptiView Control Center FORM 155.21-O1 (615) FIGURE 10 - PURGE TREND SCREEN LD14068 PURGE TREND SCREEN Start Access Level required: OPERATOR Overview This key allows the user to begin the trending of the Purge Tank Pressure. This screen gives a graphical chart tracking the Purge Tank pressure over a selected time period for trouble- Stop Access Level required: OPERATOR... -

Page 37: Control Valve Screen

FORM 155.21-O1 (615) LD13817 FIGURE 11 - CONTROL VALVE SCREEN CONTROL VALVE SCREEN Programmable Overview This screen gives an overview of setup parameters for Navigation the Control Valve. Home Display Only Causes an instant return to the Home Screen. Valve Part Number Displays the part number for the current control valve, as entered from the SALES ORDER screen, and the CONFIGURE screen in SERVICE access. -

Page 38: Setpoints Screen

OptiView Control Center FORM 155.21-O1 (615) FIGURE 12 - SETPOINTS SCREEN LD13818 SETPOINTS SCREEN the 2SOL valve to dilute the solution. When the value is set to ON considers the strong solution concentration to Overview define the length of the dilution cycle and also opens the 2SOL valve to help shorten the dilution cycle. - Page 39 FORM 155.21-O1 (615) Automatic Restart After Power Failure Maximum Purge / Week Access Level required: OPERATOR Access Level required: OPERATOR This function defines how the unit will react to a power This setpoint warns the operator regarding non condens- failure. If the setpoint is enabled and the unit was run- able gases in the unit.

- Page 40 The default value should be used unless directed other- that allows refrigerant level switch 3F to open, and it wise by YORK/Johnson Controls Service. remains open continuously for the duration of the pro- grammed timer, the refrigerant pump will be shutdown after this setpoint time delay has elapsed.

- Page 41 FORM 155.21-O1 (615) Schedule Setpoints Pulldown Loading Stop Setpoint Access Level required: OPERATOR This setpoint defines the control valve open position limit at the end of the pulldown process. Pulldown Setpoints RANGE: 20% - 100% DEFAULT: 10% Ramp Down Interval Timer (Soft Shutdown) Current Valve Opening = [(Pulldown loading stop Access Level required: OPERATOR setpoint - Pulldown loading start setpoint)*(Time...

-

Page 42: Diagnostics Screen

OptiView Control Center FORM 155.21-O1 (615) FIGURE 13 - DIAGNOSTICS SCREEN LD14069 DIAGNOSTICS SCREEN Overview This screen shows details of the Software Version the Absorption chiller is currently running. Display Only Software Version States the Software Version the OptiView Control center is currently running. -

Page 43: Sales Order Screen

These values should never be changed or entered by System Information anyone other than a qualified Service Technician. The remainder of the values are entered at the YORK Factory Factory defined conditions for which the chiller was originally rated and sold. -

Page 44: History Screen

OptiView Control Center FORM 155.21-O1 (615) FIGURE 15 - HISTORY SCREEN LD13820 HISTORY SCREEN Start Inhibit History File This window displays the date and time and a descrip- Overview tion of the condition that would not allow the unit to be started. - Page 45 FORM 155.21-O1 (615) PROGRAMMABLE Inhibit This soft key activates the Start Inhibit History File to be accessed. Warnings NAVIGATION This soft key activates the Warnings History File to be accessed. Home Causes an instant return to the Home Screen. Last Normal Stop This soft key activates a pop-up window with the pa- Trending rameter values at the time of the last normal chiller stop...

-

Page 46: Trend Screen

OptiView Control Center FORM 155.21-O1 (615) FIGURE 16 - TREND SCREEN LD14070 TREND SCREEN • Steam Pressure • Steam in Temperature Overview • Generature Pressure • Refrigerant Temperature This screen allows the user to select up to 6 different • Total Operating Hours trends for tracking system operating conditions. - Page 47 FORM 155.21-O1 (615) Access Level required: OPERATOR This key allows the operator to to set the minimum value on the trending chart. Access Level required: OPERATOR This key allows the operator to set the maximum value trending chart. Navigation Home Causes an instant return to the Home Screen.

-

Page 48: Trend Setup Screen

OptiView Control Center FORM 155.21-O1 (615) FIGURE 17 - TREND SETUP SCREEN LD14071 TREND SETUP SCREEN Navigation Overview Home Causes an instant return to the Home Screen. This screen allows the operator to configure the trend- ing Data Chart. Trending Causes an instant return to the Trending Screen. -

Page 49: Triggers Screen

FORM 155.21-O1 (615) FIGURE 18 - TRIGGERS SCREEN LD14072 TRIGGERS SCREEN If Primary Trigger Is Primary Operator Primary Test Trend Setup Screen Overview Primary to Secondary Operator This screen allows the Operator to select desired data collection start/stop triggers. The trend data collection Secondary Trigger can be set to start or stop based upon the status of up to Is Secondary Operator Secondary Test... - Page 50 OptiView Control Center FORM 155.21-O1 (615) Programmable Data collection will start/stop (as selected with Trigger Action) when: Pri Trig • If AND selected: Both Primary AND Secondary are Access Level required: OPERATOR true. This key allows the Operator to select the first parameter •...

-

Page 51: Display Messages

FORM 155.21-O1 (615) DISPLAY MESSAGES Run Messages The Status Bar of the Display contains a Status Line ADC in progress - load Limit to 50% and, beneath it a Details Line. The Status Line contains The auto-decrystallization process is triggered when a message describing the operating state of the chiller;... - Page 52 OptiView Control Center FORM 155.21-O1 (615) Manual Dilution Cycle is in progress While the “Secondary ADC” is in effect, the stabi- lizer refrigerant solenoid valve (2SOL) is not energized A dilution cycle was initiated manually in SERVICE (opened) and the steam/hot water valve is driven to access and is in progress.

-

Page 53: Start Inhibit Messages

FORM 155.21-O1 (615) Start Inhibit Messages Steam Valve Loaded > 10% close to < 9% to restart Auxiliary Safety Shutdown This message is displayed when the Steam Control Valve position is greater than 10% and the unit is OFF. This When "Auxiliary Safety Shutdown"... - Page 54 OptiView Control Center FORM 155.21-O1 (615) Faulty Strong Solution Temp Sensor RT3 • Hot water supply temperature is less than 266°F (130°C) , unit is hot water high temp; releases the This message occurs when the strong solution temper- warning, but it is required to press the WARNING (32.7°C) ature is less than or equal to 91°F and the...

- Page 55 FORM 155.21-O1 (615) Low Ref Temp in Evap RT8 < 34.0°F (1.1°C) - Possible Crystallization RT2 > 160ºF (71.1ºC) Soln Pump is off Temperature on the automatic decrystallization line The evaporator refrigerant temperature is less than (RT2) exceeded 160 ºF (71.1ºC) during operation. Au- tomatic decrystallization process started.

- Page 56 OptiView Control Center FORM 155.21-O1 (615) Recovery Condition Purge Pump Overload Contacts are in conflict This message occurs when purge pump overload con- • Purge tank pressure is less than 100mmHg; it tacts change from closed to open and the pump is not releases this warning but is required to press the running.

-

Page 57: Routine Shutdown Messages

FORM 155.21-O1 (615) Refrigerant Pump Overload Contacts are in Routine Shutdown Messages conflict This shutdown occurs when the refrigerant pump over- Local Stop load contacts open when the refrigerant pump is OFF. A local shutdown command has been recieved as Soft If the unit is NOT running, the unit will be set in a stand Shutdown or by placing the Keypad Start-Run-Stop/ by safety shutdown condition. -

Page 58: Safety Shutdown Messages

OptiView Control Center FORM 155.21-O1 (615) Low Leaving Chilled Liquid Temperature Safety Shutdown Messages The unit executes a cycling shutdown when LCHLT is less than (LCHLT setpoint - LCHLT offset setpoint). If Auxiliary Safety Shutdown the LOCAL entered LCHLT setpoint was changed in the The auxiliary safety shutdown contacts connected be- past 30 minutes, this cycling shutdown is NOT initiated tween I/O board TB4-1 and TB4-31 are open. - Page 59 FORM 155.21-O1 (615) Condenser Liquid Flow Switch Opened Dilution Cycle Interrupted - Switch 3F Opened The condenser liquid flow switch has been opened This shutdown occurs when 3F is open at least for continuously for 30 seconds. If the chiller was in RUN "Chiller Refrigerant level shutdown delay setpoint"...

- Page 60 OptiView Control Center FORM 155.21-O1 (615) Generator Hi-Press Digital Switch HP1 Opened High Hot Water Supply Temp RT7 > %XXX.XX°F The generator high pressure digital safety switch opened The unit is hot water fed and the hot water temperature (Shutdown = 710 mmHg Abs). If the chiller was in RUN less than or equal to 255°F (123°C) and the generator status, the chiller initiates a dilution cycle.

- Page 61 FORM 155.21-O1 (615) Recovery Conditions MCFL Switch Opened, LDC Interrupted - Chk Cryst • If the chiller was in RUN status at the time of the This shutdown occurs when the motor coolant float event, then when the refrigerant temperature at RT8 switch opens when the unit is performing a limited is greater than or equal to 37ºF (2.7°C) and the unit dilution cycle (only applicable to units equipped with...

- Page 62 OptiView Control Center FORM 155.21-O1 (615) Recovery Condition Refrigerant Pump Level Switch 3F Failure The chiller shutdown because the refrigerant pump has • After it has been determined that crystallization has been stopped for the duration of the Chiller Refrigerant not occurred, the unit can be restarted.

-

Page 63: Equipment Status Messages

FORM 155.21-O1 (615) Solution Pump Overloads Opened Equipment Status Messages Solution pump motor protector overload or thermal switch contacts opened and the pump was running. Chilled Liquid Pump has been stopped after 2 hours of Operation Recovery Conditions The chilled liquid pump was manually started with the chiller not running and the 2 hour run limiting timer has •... - Page 64 OptiView Control Center FORM 155.21-O1 (615) Manual Purge Started Service Access Level is needed to A manual purge was initiated by an operator from the Reset the Unit panel. This message resides for 60 seconds after the The chiller can not be reset at this time because SER- command is issued.

-

Page 65: Section 3 Printers

FORM 155.21-O1 (615) SECTION 3 PRINTERS 00085VIP SEIKO DPU-414 FIGURE 19 – PRINTERS A printer or laptop can be connected to the Control PRINTERS Center’s Microboard to print the following reports. The The following Printer can be used. Printer must be screen from which each report can be generated is listed equipped with an RS-232 Serial interface. -

Page 66: Printer Setup

Printers FORM 155.21-O1 (615) The Control Center provides the required formatting con- Printer Setup trol codes for the printers above when the printer is se- The printer must be configured as follows. Refer to lected on the PRINTER Screen in the instructions below. manual provided by Printer manufacturer with respec- These codes are transmitted through the serial interface tive Printer. -

Page 67: Control Center Setup

FORM 155.21-O1 (615) Control Center Setup YORK A JOHNSON CONTROLS COMPANY Printer Setup UNIT MODEL < > SERIAL NUMBER < > Access Level Required: OPERATOR <DATE>, <HOUR> Using the COMMS Screen, the Control Center must be TOTAL OPERATING HOURS < > [HOURS] LATEST RUN TIME <... -

Page 68: Figure 21 - Sample Printout (Last Normal Stop)

Printers FORM 155.21-O1 (615) YORK A JOHNSON CONTROLS COMPANY YORK A JOHNSON CONTROLS COMPANY UNIT MODEL < > SERIAL NUMBER < > UNIT MODEL < > SERIAL NUMBER < > <DATE>, <HOUR> <DATE>, <HOUR> TOTAL OPERATING HOURS < > [HOURS] TOTAL OPERATING HOURS <... -

Page 69: Figure 23 - Sample Printout (History)

FORM 155.21-O1 (615) YORK A JOHNSON CONTROLS COMPANY YORK A JOHNSON CONTROLS COMPANY UNIT MODEL < > SERIAL NUMBER < > UNIT MODEL < > SERIAL NUMBER < > <DATE>, <HOUR> <DATE>, <HOUR> TOTAL OPERATING HOURS < > [HOURS] TOTAL OPERATING HOURS < > [HOURS] LATEST RUN TIME <... -

Page 70: Figure 25 - Sample Printout (Setpoints)

Printers FORM 155.21-O1 (615) YORK A JOHNSON CONTROLS COMPANY UNIT MODEL < > SERIAL NUMBER < > <DATE>, <HOUR> TOTAL OPERATING HOURS < > [HOURS] LATEST RUN TIME < > [DAYS, HOURS, MINUTES] SOFTWARE VERSION < > SETPOINT VALUE DEFAULT LEAVING CHILLED LIQUID TEMP <... -

Page 71: Downloading Histories To A Laptop

FORM 155.21-O1 (615) DOWNLOADING SYSTEM HISTORIES TO 4. Press the the Print Screen key on the appropriate A LAPTOP FROM AN OPTIVIEW CONTROL screen to be captured. The HyperTerminal will dis- PANEL play the printed information and the information will be recorded as a .txt file. -

Page 72: Figure 26 - Communications Block Diagram

To convert a temperature range (i.e., 10°F or 12°F chilled water range) from Fahrenheit to Celsius, multiply by 5/9 or 0.5556. P.O. Box 1592, York, Pennsylvania USA 17405-1592 800-861-1001 Subject to change without notice. Printed in USA Copyright © by Johnson Controls 2015 www.johnsoncontrols.com...