Ricoh Pro L5160 Operating Instructions Manual

Hide thumbs

Also See for Pro L5160:

- Care and maintenance (64 pages) ,

- Solutions manual (58 pages) ,

- Rip settings manual (44 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Maintenance and Care

Advertisement

Table of Contents

Summary of Contents for Ricoh Pro L5160

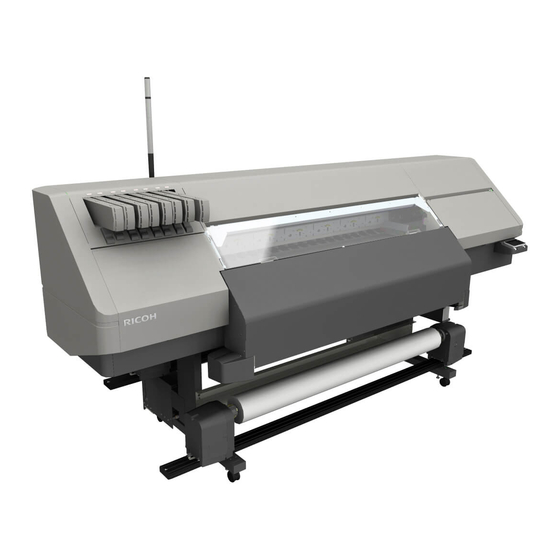

- Page 1 Operating Instructions For safe and correct use, be sure to read the Safety Information in "Read This First" before using the machine.

-

Page 3: Table Of Contents

TABLE OF CONTENTS 1. Getting Started Before You Start..............................7 How to Read the Manuals..........................7 Model-Specific Information...........................8 About Operating Environments........................10 Conditions for Installation Locations......................10 Space Required for Installation........................11 About Moving the Machine........................11 About Long Term Storage of the Machine....................11 Confirming Accessories........................... 13 List of Included Items............................13 Guide to Names and Functions of Components....................15 Front View..............................15... - Page 4 Setting Ethernet Speed..........................36 About Ink................................38 Supported Ink...............................38 Setting Order of Ink Cartridges........................38 How to Store Ink Cartridges........................39 Precautions for Handling Ink Cartridges....................40 About Media..............................42 Supported Media............................42 How to Store Media............................45 Precautions for Handling Media........................ 45 2.

- Page 5 Before Print Start............................101 Start Printing............................... 101 Interrupt or Abort Printing......................... 102 Cutting Media..............................104 3. Convenient Usage Configuring the Margin Settings........................105 Performing the Connection Methods......................107 Performing the Connection Method for the Print Heads Automatically..........108 Performing the Connection Method for the Print Heads Manually............109 Performing the Connection Method for the Media Feed...............

- Page 6 [Maintenance] Screen..........................143 [Print Adjustment] Screen.......................... 146 [Heater Settings] Screen........................... 149 [Origin Setting] Screen..........................151 Initializing Setting Items..........................153 Setting Items for Initialization........................153 Initializing Settings.............................154 Using Web Image Monitor...........................155 Displaying Top Page..........................156 About Guest Mode and Administrator Mode..................157 Access in the Administrator Mode......................158 Confirming the Machine Status........................

- Page 7 When There Is a Strange Odor........................201 When the Heater Temperature Does Not Rise..................202 When the Media Cannot Be Set......................203 When the Media Cannot Be Cut......................205 Other Printing Problems..........................206 When Messages Appear..........................210 Precautions for Removing Jammed Media / Performing Maintenance............224 Clearing Misfeeds............................

- Page 8 7. Appendix Trademarks..............................257...

-

Page 9: Getting Started

1. Getting Started This chapter describes how to read the manuals supplied with the machine, names and functions of components, and supported ink and media, etc. Before You Start How to Read the Manuals Symbols used in the manuals This manual uses the following symbols: Indicates points to pay attention to when using the machine, and explanations of likely causes of media misfeeds, damage to media, or loss of data. -

Page 10: Model-Specific Information

1. Getting Started Notes Contents of this manual are subject to change without prior notice. Some illustrations in this manual might be slightly different from the machine. Certain options might not be available in some countries. For details, please contact your local dealer. Depending on which country you are in, certain units may be optional. - Page 11 Before You Start • 208–240 V • Dimensions in this manual are given in two measurement units: metric and imperial. If your machine is a Region A model, refer to the metric units. If your machine is a Region B model, refer to the imperial units.

-

Page 12: About Operating Environments

1. Getting Started About Operating Environments Conditions for Installation Locations • Keep the machine away from humidity and dust. Otherwise a fire or an electric shock might occur. • Do not place the machine on an unstable or tilted surface. If it topples over, an injury might occur. -

Page 13: Space Required For Installation

About Operating Environments Chlorine or mineral components atomized by an ultrasonic-type humidifier may adhere to the electronic components inside the product, causing it to malfunction. Space Required for Installation Ensure enough space around the machine for installation. The space shown below is necessary for operating the machine and for work done by a service engineer. - Page 14 1. Getting Started properly, problems, such as nozzle clogging due to a dried-out print head and white ink precipitation may occur, causing a malfunction. • If you do not use the machine for a long period of time, always check if the nozzles are clogged by printing a nozzle check pattern.

-

Page 15: Confirming Accessories

Confirming Accessories Confirming Accessories The main accessories included with the machine are shown below. Contact your service representative if any accessories are missing or damaged. • When cleaning the ink-station or the heads, or replacing the cleaning cartridge, make sure to wear the attached goggles. - Page 16 1. Getting Started Operating Instructions Describes detailed information about how to use the machine. The contents are shown below: • Getting Started • Basic Operations • Convenient Usage • Configuring and Managing the Machine • Troubleshooting • Maintenance and Specifications Requests for Daily Care and Maintenance Describes periodical maintenance procedures for the machine.

-

Page 17: Guide To Names And Functions Of Components

Guide to Names and Functions of Components Guide to Names and Functions of Components This section describes the names and functions of the machine's components. • Do not obstruct the machine's vents. Doing so risks fire caused by overheated internal components. - Page 18 1. Getting Started 4. Media holding lever (front) A lever to hold media on the feeding surface. Use this lever when setting media or dealing with media misfeeds, etc. The media holding lever (front) and media holding lever (back) work in conjunction with each other.

-

Page 19: Rear/Side View

Guide to Names and Functions of Components Rear/Side View DWT107 1. Vents Prevents overheating. 2. Ethernet port Port for connecting an Ethernet interface cable. 3. Pre-heater cover Open this cover when setting media or cleaning the pre-heater. There are media input locations and a media sensor inside of this cover. -

Page 20: Inside View

1. Getting Started 8. Media holding lever (back) A lever to hold media on the feeding surface. Use this lever when setting media, dealing with media misfeeds, etc. The media holding lever (front) and media holding lever (back) work in conjunction with each other. 9. -

Page 21: Symbols For Power Switch

Guide to Names and Functions of Components 1. Cleaning cartridge A maintenance cartridge that is made up of a wiper and flushing pad. Use this cartridge when performing head cleaning. To replace the cleaning cartridge, see page 238 "Replacing a Cleaning Cartridge". 2. - Page 22 1. Getting Started • The media feeding surface is hot while the heater is heated. When opening the center cover or replacing media, lower the temperature of the heater and make sure the temperature of the media feeding surface has lowered sufficiently before working. •...

-

Page 23: Guide To Functions Of The Attention Light

Guide to Names and Functions of Components Guide to Functions of the Attention Light • Do not push or pull the attention light when it is installed to the machine. Doing so may result in damage or malfunction of the attention light or the machine. CUV121 The attention light notifies the user by light when there is a media jam or no media is left. - Page 24 1. Getting Started Lamp Status The top lamp flashes yellow. Warning (Example) • Ink has nearly run out. • Waste ink bottle is nearly full. Read the message on the display panel, and then take appropriate action. For details, see page 210 "When Messages Appear".

-

Page 25: Guide To The Names And Functions Of The Machine's Control Panel

Guide to the Names and Functions of the Machine's Control Panel Guide to the Names and Functions of the Machine's Control Panel This section explains the names and functions of the machine’s control panel. DWU100 1. Display panel Displays the machine conditions, setting items, and errors. See page 24 "How to Use the Home Screen". 2. -

Page 26: How To Use The Home Screen

1. Getting Started 10. [Maintenance] key Press to change and check the settings about each item of the [Maintenance] screen. See page 143 "[Maintenance] Screen". 11. [Standard Procedure] key Press to change and check the settings about each item of the [Print Adjustment] screen. See page 146 "[Print Adjustment] Screen". -

Page 27: Adjusting The Angle Of The Control Panel

Guide to the Names and Functions of the Machine's Control Panel 6. [Heater Setting] Changes whether the heater is enabled/disabled as well as the temperature of the heater. See page 81 "Adjusting the Heater Temperature". 7. [Origin Setting/Cut] Sets the printing origin and cuts media. During printing, it switches to [Job Status]. See page 79 "Changing Print Origin", page 104 "Cutting Media". -

Page 28: Changing The Display Language

1. Getting Started Hold the control panel by both the left and right sides and tilt it at an appropriate angle. DWT111 • You can tilt the control panel from 12 to 90 degrees. Changing the Display Language You can switch the language to be displayed on the control panel. The available languages are Japanese, English, French, German, Italian, Spanish, Dutch, Portuguese, and Russian. -

Page 29: About The Auto-Reset Function

Guide to the Names and Functions of the Machine's Control Panel About the Auto-Reset Function If the control panel is not used for a specific period of time, the current operation will automatically be canceled, and the screen will return to the home screen. The operation must be restarted from the beginning. -

Page 30: Connecting The Cable

1. Getting Started Connecting the Cable This section explains how to connect an Ethernet interface cable and power cord. Connecting to the Ethernet Interface This section describes how to connect an Ethernet interface cable to the Ethernet port. If you use an Ethernet interface cable that supports 1000BASE-T, set [Ethernet Speed] to [Auto selection] in [Network Settings] on the [Initial Setting] screen. -

Page 31: Connecting The Power Cord

Connecting the Cable 2. Indicator (both orange and green) When 1000BASE-T is operating, both LEDs are lit. • For details about how to turn on and off the power, see page 32 "Turning On/Off the Power". Connecting the Power Cord •... - Page 32 1. Getting Started • Be sure to disconnect the plug from the wall outlet at least once a year and check for the following: • There are burn marks on the plug. • The prongs on the plug are deformed. •...

- Page 33 Connecting the Cable • The main power switch must only be turned on by personnel with sufficient knowledge about how to use this machine. Confirm that the power of the machine is off. Insert the connector of the power cord into the power socket of the machine. Insert the power cord plug into the wall outlet.

-

Page 34: Turning On/Off The Power

1. Getting Started Turning On/Off the Power • Do not disconnect the power cord plug. If the machine is not going to be used for several days or longer, contact your service representative. The main power switch is on the left rear of the machine. When this switch is turned on, the main power turns on and the main power indicator on the right side of the control panel lights up. -

Page 35: Turning Off The Power

Turning On/Off the Power Turning Off the Power • Do not turn off the power while the machine is in operation. Doing so may result in nozzle clogging due to dried head, leading to malfunctions. • Do not hold down the main power switch while turning off the power of the machine. Doing so forcibly turns off the machine's main power switch and may cause a malfunction. - Page 36 1. Getting Started • Press one of the keys on the control panel. • Touch the display panel. • Raise the media holding lever. • In Sleep mode, the [Energy Saver] key flashes slowly. • The machine does not enter Sleep mode in the following cases: •...

-

Page 37: Ethernet Configuration

Ethernet Configuration Ethernet Configuration Configure the machine for the network using the control panel. • For details about the setting items and default values, see page 140 "Network Settings". • You can also use Web Image Monitor to configure the IP address-related settings. For details, see page 159 "Configuring the Machine Settings". -

Page 38: Receiving An Ip Address Automatically (Dhcp)

1. Getting Started Receiving an IP Address Automatically (DHCP) Follow the procedure below to set the machine to receive an IP address automatically using DHCP. The DHCP feature is active by default, so this procedure is only required if you have changed the default settings. - Page 39 Ethernet Configuration Press the [User Tools] key. DWU101 Press [Network Settings]. Press [ ]. Press [Ethernet Speed]. Select an Ethernet speed from [Auto selection], [100 Mbps Full Duplex], [100 Mbps Half Duplex], or [1 Gbps Full Duplex]. Press [Close]. Press [End].

-

Page 40: About Ink

1. Getting Started About Ink This section describes supported ink, and how to store and handle ink cartridges. Supported Ink The ink combinations that can be used with this machine are as follows: • 4C: Cyan, magenta, yellow, and black ink cartridges × 2 of each •... -

Page 41: How To Store Ink Cartridges

About Ink Set the ink cartridges in accordance with the labels on the cartridges. When changing the configuration of the ink, contact your service representative. Follow the table below and set the ink cartridges in order from the left side of the machine. Model type Ink configuration 4C+W... -

Page 42: Precautions For Handling Ink Cartridges

1. Getting Started • Keep ink, flushing liquid, displacement liquid, the nozzle cleaning cartridge, the waste ink bottle and the maintenance kit out of reach of children. • When storing ink cartridges, the following precautions should always be followed: • Do not store ink cartridges where they will be exposed to direct sunlight. Store ink cartridges where the temperature is 40°C (104°F) or less and the humidity is 35 to 80%. - Page 43 About Ink • The supplied gloves are consumables. If they are damaged or lost, use polythene gloves instead. • Use up an ink cartridge within 3 months after unsealing it. In addition, do not use an ink cartridge if its expiration date has expired. •...

-

Page 44: About Media

Supported media are shown below. Roll media and leaf media can be used with this machine. Types of recommended media PVC/Tarpaulin/PET/PP/Coated Paper/Plain Paper/Soft Signage (Fabric)/Wallpaper/Canvas Media width • RICOH Pro L5130 297 – 1,371 mm (approx. 11.7 – 53.98 inches) • RICOH Pro L5160 297 – 1,625 mm (approx. 11.7 – 63.98 inches) - Page 45 About Media Media thickness Value/Range Media Thickness (mainly Europe and Asia) 0.05-0.1mm (mainly North America) 0.002-0.004 inches (mainly Europe and Asia) 0.1-0.15mm (mainly North America) 0.004-0.006 inches" Default (mainly Europe and Asia) 0.15-0.2mm (mainly North America) 0.006-0.008 inches (mainly Europe and Asia) 0.2-0.3mm (mainly North America) 0.008-0.012 inches...

- Page 46 0.15 inches Maximum print area • RICOH Pro L5130 Width: 1,361 mm (approx. 53.58 inches) Length: 300,000 mm (approx. 11,811.02 inches) • RICOH Pro L5160 Width: 1,615 mm (approx. 63.58 inches) Length: 300,000 mm (approx. 11,811.02 inches) Roll media Outside diameter A diameter of 250 mm (9.84 inches) or less...

-

Page 47: How To Store Media

Precautions for Handling Media Take the following precautions when handling media: • Use media recommended by RICOH to ensure reliable, high-quality printing. • Set the heater temperature to meet the characteristics of the media. Set the temperature of the pre-heater, print heater, post-heater, and cure heater according to the type and characteristics of the media used. - Page 48 1. Getting Started • Pay attention to the expansion and contraction of the media. Do not use media immediately after unpacking. The media can be affected by the room temperature and humidity, and thus it may expand and contract. The media have to be left in the atmosphere in which they are to be used for 30 minutes or more after unpacked.

- Page 49 About Media • Dust included in the packaging of roll media may have accumulated in the side of the roll. If the roll media is used in this state, it may cause nozzle clogging, etc. Remove dust affixed in the side of the roll before setting the media.

- Page 50 1. Getting Started...

-

Page 51: Basic Operations

2. Basic Operations This chapter explains the procedures for preparing media and ink, printing data, and how to configure these settings. Procedure to Print Use the following procedure to print on media: Set the media. See page 50 "Setting Media". Change the print origin. -

Page 52: Setting Media

2. Basic Operations Setting Media This section explains how to set media. Roll media and leaf media are supported. For details about supported media or precautions for handling media, see page 42 "About Media". Precautions for Setting Media Make sure to understand the following precautions before setting media: •... - Page 53 Setting Media • Skewing may occur because of uneven stretching of the media at its edges, so do not try to align the media to "0" on the scale forcefully. Scale on the post-heater DWT081 Scale on the pre-heater DWT080 If it is -4 on the pre-heater scale DWT084...

-

Page 54: Setting Roll Media

2. Basic Operations DWT085 1. Media 2. Post-heater 3. Pre-heater 4. Adjust according to the pre-heater scale. 5. The value when placed in a straight line. Do not try to adjust the media to zero by force. When setting roll media The scale on the pre-heater can be used for checking the misalignment at the edge of the media when loading the media. - Page 55 Setting Media • Do not set media on the outside of the left and right media guides. If media is skewed, this may cause the media to rise and the print heads to be damaged. • When the edges of roll media are not aligned with the roll core, make sure to align them before setting media.

- Page 56 2. Basic Operations When using media whose printing surface is rolled up on the inside DWT123 Release the roll holder's holding lever on the left side of the back of the machine. DWT124 Move the position of the roll holder to match the roll core size of the set media. There are two types of inner diameter for the roll core of the roll media: 2 inches and 3 inches.

- Page 57 Setting Media DWT126 If the roll holder's lock is weak and the media moves, hold the media while attaching it. Release the roll holder's holding lever on the right side of the back of the machine. When the roll holder is located further inside than the set media, move the roll holder so that it is located outside the media.

- Page 58 2. Basic Operations Lock the roll holder's holding lever. DWT129 Lock the holding lever with the roll holder pressed thoroughly into the roll core. If the amount of force used to press the roll holder into the roll core is insufficient, the media may hang down and touch the floor.

- Page 59 Setting Media Insert the tip of the media between the feed rollers and pinch rollers. DWT132 • If the media is difficult to insert because the edges of the media are getting caught, diagonally insert the media between the rollers, so that one corner gets inserted first. Ensure the media is inserted evenly, and begin feeding.

- Page 60 2. Basic Operations • If the edge of the media is out of the range of the pre-heater's scale, release the roll holder's holding lever, and then adjust the roll holder's position. • Align the edge of the media, and then load the media while adjusting media position by hand so that it is stretched evenly.

- Page 61 Setting Media DWT135 Holding it at the center, pull the media evenly out of the paper exit. Align the edge of the media to the post-heater's scale so that it matches the value on the pre- heater's scale. While holding down the center of the media, lower the media holding lever (front). The pinch rollers lower and the media is fixed.

- Page 62 2. Basic Operations DWT136 Close the center cover. When media is set correctly, a confirmation screen is displayed on the control panel. Set the roll-up switch to the off position (middle). DWT138 Move to the rear of the printer and check for warping in the media. If the roll media is slack, rotate it to take up the slack.

- Page 63 Setting Media EDP011 If the media's slack is uneven, return to Step 11 and try loading the media again. Insert an empty roll core onto the roll core holder on the right side of the front of the machine. Insert the roll core as far as possible so that it does not move. DWT139 Release the roll core holder's holding lever on the left side of the front of the machine.

- Page 64 2. Basic Operations DWT141 Lock the roll core holder's holding lever. DWT142 Press [Yes] on the confirmation screen for media replacement. If the media is not going to be replaced and it is not necessary to change the media settings, press [No] and proceed to Step 41.

- Page 65 Setting Media Press [Remaining Media]. When [Display Remaining Media] is set to [On] in [Media Display Settings] on the [Initial Setting] screen, the input screen for the remaining amount of media is displayed after detecting the media width. For details, see page 131 "Registering the Remaining Amount of Media". Enter the length of the set media using the number keys, and then press [Set].

- Page 66 2. Basic Operations • When you load the media, if the arm near the media cutter is positioned behind the media, you cannot cut the media correctly. Correct DWT074 Incorrect DWT075...

- Page 67 Setting Media DWT076 1. arm If you touch the cutter part, the arm near the cutter may close. If this happens, move the media to a position unreachable by the cutter, and then execute [Origin Setting / Cut] to cut. When using thick or hard media, hold the tip of the media at the center and cut the left and right sides at equal angles.

- Page 68 2. Basic Operations DWT144 When placing the printing surface on the outside and rolling up media Roll the media from the front of the roll core to the inside to fix it. DWT145 When placing the printing surface on the inside and rolling up media Roll the media from the back of the roll core to the front to fix it.

- Page 69 Setting Media Set the roll-up switch to the on position. When placing the printing surface on the outside and rolling up media Lower the roll-up switch (normal rotation). DWT147 When placing the printing surface on the inside and rolling up media Raise the roll-up switch (reverse rotation).

-

Page 70: Changing Roll Media

2. Basic Operations • If the message "Cannot detect the media." appears, operate the media holder lever to display the media replacement menu. Changing Roll Media This section explains how to remove and change roll media. Change the roll media with the machine turned on. - Page 71 Setting Media Release the roll core holder's holding lever on the left side of the front of the machine. DWT150 Move the roll core holder to the left to remove the roll core. Hold the roll core while removing it so that it does not fall down. DWT151 Remove the roll core from the roll core holder on the right side of the front of the machine.

- Page 72 2. Basic Operations DWT139 Move the roll core holder on the left side of the front of the machine to the right to insert the empty roll core. Insert the roll core as far as possible so that it does not move. DWT141 Lock the roll core holder's holding lever.

- Page 73 Setting Media DWT153 While holding down the center of the media, roll up the remaining media. DWT154 Return the pre-heater cover to its original position. Grab the handle on the back of the machine to pull out the roll feed unit. DWT155...

- Page 74 2. Basic Operations Release the roll holder's holding lever on the right side of the back of the machine. DWT156 Move the roll holder to the right to remove the roll media. Hold the roll media while removing it so that it does not fall down. DWT157 Remove the roll media from the roll holder on the left side of the back of the machine.

-

Page 75: Setting Leaf Media

Setting Media Return the roll feed unit to its original position. DWT159 Set new media. For details about how to set media, see page 52 "Setting Roll Media". Setting Leaf Media This section explains how to set leaf media. • If media is not on the rear media sensor, it cannot be detected correctly. Leaf media should have a length of over 1,000 mm (approx. - Page 76 2. Basic Operations Raise the media holding lever (back). DWT168 Place the printing surface upward and insert leaf media between the feed rollers and pinch rollers. • Insert the media with both hands so that it does not slant. • If there is no media on the sensor, the machine cannot detect media successfully. Set media so that it covers the media sensor on the left side of the feeding surface.

- Page 77 Setting Media Return the pre-heater cover to its original position. • After returning the pre-heater cover to its original position, press its ends to make sure that it is not bulging. • If you operate the device with a bulge in the pre-heater cover, the cover may come open during operation or printing.

- Page 78 2. Basic Operations DWT164 While holding down the center of the media, lower the media holding lever (front). The pinch rollers lower and the media is fixed. DWT137 Move the left and right media guides to match the media width. •...

- Page 79 Setting Media Close the center cover. When the media has set correctly, a confirmation screen appears on the control panel. Press [Yes] on the confirmation screen for media replacement. If you do not need to change the media settings, press [No] to proceed to Step 25. Select [Leaf], and then press [Next].

- Page 80 2. Basic Operations Press [Completed]. Wait until "Ready" is displayed on the home screen. • If an unsupported media is set, "Cannot detect the media." appears. Set supported media again. For details about supported media, see page 42 "Supported Media". •...

-

Page 81: Changing Print Origin

Changing Print Origin Changing Print Origin This section explains how to change the position of the print origin. You cannot change the origin when a misfeed error occurs or during maintenance. • The carriage moves when setting the horizontal origin. A buzzer sounds after 10 minutes or more have elapsed since the carriage moved. - Page 82 2. Basic Operations • Fed media does not return to its original position even when pressing [Cancel] while configuring the origin settings.

-

Page 83: Adjusting The Heater Temperature

Adjusting the Heater Temperature Adjusting the Heater Temperature • Set the heater temperature to meet the characteristics of the media. Set the temperature of the pre-heater, print heater, post-heater, and cure heater according to the type and characteristics of the media used. Automatic temperature setting can be made on the operation panel by setting the profile on the dedicated RIP. - Page 84 2. Basic Operations • Press [ All +5°C] or [ All -5°C] to change the temperature of the pre-heater, print heater, post-heater, and cure heater collectively. The temperature of each heater can be set between 20 to 70°C or 20 to 95°C. (mainly North America) •...

-

Page 85: Test Feeding

Test Feeding Test Feeding Perform test feeding to check whether the temperature settings of each heater are appropriate for the media to be used. Press the [Standard Procedure] key. DWU103 Press [ ]. Press [Test Feed]. Press [Yes] when you rewind the media to its original position after performing test feeding. - Page 86 2. Basic Operations • Depending on the media to be used, the media may ripple as the heater becomes hot. If the media ripples when feeding, see page 196 "When Media Curls While Feeding".

-

Page 87: Test Printing

Test Printing Test Printing Print a nozzle check pattern and check whether there are discharge defects such as nozzle clogging (blurring or drop-out of printing). You cannot print a test pattern on narrow media. When performing test printing, use media that has a width of 420 mm (approx. -

Page 88: How To Read The Printing Result

2. Basic Operations • If there are abnormalities, perform head cleaning. For details about head cleaning, see page 89 "Cleaning Print Head Nozzles". Press [End]. • It is not reflected in the result of the test print even when [Nozzle Recovery] is set to [On]. When checking the print result in which the clogged nozzle is recovered, print a recovery check pattern by using the RIP software. - Page 89 Test Printing Normal printing result CFT168 When there are discharge defects in the heads DVB195 1. Nozzle clogging has occurred. 2. The nozzle check pattern is wave-like. 3. The nozzle check pattern is intermittent. 4. The intervals in the nozzle check pattern are not equal. (Bending lines have occurred.) Check the clogged nozzle number.

- Page 90 2. Basic Operations DWT216...

-

Page 91: Cleaning Print Head Nozzles

Cleaning Print Head Nozzles Cleaning Print Head Nozzles This section explains how to handle print heads. • Head cleaning consumes ink. Perform this function only when necessary. • Perform no other operations during head cleaning. • Cleaning may be incomplete if ink in a cartridge gets too low or runs out during cleaning. •... -

Page 92: Performing Head Cleaning

2. Basic Operations Performing Head Cleaning Press the [Maintenance] key. DWU102 Press [Nozzle Cleaning]. Press [Nozzle Cleaning: Low] or [Nozzle Cleaning: High]. Select which print heads to clean from [Head 1], [Head 2], or [Head 3], and then press [Execute]. You can select multiple print heads simultaneously. -

Page 93: Adjusting The Media Feed Quantity

Adjusting the Media Feed Quantity Adjusting the Media Feed Quantity • Never open the center cover or raise the lever during printing. Opening the cover or raising the lever will abort printing. This section explains how to adjust the media feed quantity if image quality defects such as horizontal misalignments or image surface irregularities occur. -

Page 94: Adjusting The Media Feed Quantity Automatically

2. Basic Operations • The machine cannot adjust the media feed quantity automatically for transparent or colored media. Adjust the media feed quantity manually. For details, see page 92 "Adjusting the Media Feed Quantity Manually". Adjusting the Media Feed Quantity Automatically The machine prints the test pattern of the media feed adjustment, and then adjusts the media feed quantity automatically. - Page 95 Adjusting the Media Feed Quantity Press the [Standard Procedure] key. DWU103 Press [Media Feed Adjustment]. Press [Manual]. Press [Execute]. Select a print mode from [6 Pass] or [8 Pass / 12 Pass / 16 Pass / 32 Pass]. If using the machine with white ink, select a print mode from [6 Pass], [8 Pass / 12 Pass / 16 Pass], or [32 Pass / 12 Pass (White)].

- Page 96 2. Basic Operations EDP012 1. If the horizontal line for "+10" is the straightest, the adjustment value is +10. EDP017 If the lines for "0" and "+10" are oblique contrariwise, the adjustment value is between 0 and +10. 2. If the obliqueness of "+10" and "0" is the same, the adjustment value is +5. EDP018 3.

- Page 97 Adjusting the Media Feed Quantity Press [Adjustment Amount Entry]. Enter the adjustment value that you checked in Step 9 using the number keys, and then press [Set]. Press [Close]. Press [Confirm]. Press [End].

-

Page 98: Adjusting The Drop Position

2. Basic Operations Adjusting the Drop Position • Never open the center cover or raise the lever during printing. Opening the cover or raising the lever will abort printing. This section explains how to correct misalignment of the ink dropping position. You can reduce misaligned verticals or blurred colors. -

Page 99: Adjusting The Drop Position Automatically

Adjusting the Drop Position Adjusting the Drop Position Automatically This function corrects the misalignment of the ink dropping position automatically so that it reduces image quality defects. You cannot print a test pattern on narrow media. When adjusting the drop position automatically, use media that has a width of 297 mm (approx. - Page 100 2. Basic Operations Press the [Standard Procedure] key. DWU103 Press [Drop Position Adjustment]. Press [Manual]. Select a print mode from [6 Pass / 8 Pass], [12 Pass], [16 Pass], or [32 Pass]. If the ink configuration used for the machine is 4C+W, you can select [12 Pass (White)]. Press [Execute].

- Page 101 Adjusting the Drop Position Select [Base line position on the media guide], and press [Cut]. The media is cut at the reference line on the media guide. Check the optimal adjustment value based on the printing result of the test pattern of the drop position adjustment.

- Page 102 2. Basic Operations Press [Completed]. Press [Completed]. As required, press [Back] and return to Step 13. Press [End]. • If the control panel is not used for 30 minutes, the adjustment value entry menu is canceled and the Home screen returns. If this happens, carry out the adjustment procedure again from the beginning. •...

-

Page 103: Printing Data

Printing Data Printing Data Before Print Start Check the state of the ink cartridges, cleaning cartridge, flushing cartridge, and waste ink bottle before printing. For details about how to check the conditions, see page 166 "Checking Machine Status and Settings". For details about replacing consumables, see page 233 "Replacing Consumables". -

Page 104: Interrupt Or Abort Printing

2. Basic Operations media using the [Origin Setting] menu, eliminate the ripples, and then send the RIP data to start printing. Set media. For details, see page 50 "Setting Media". Check the heater temperature on the display panel. Press [Heater Setting] to adjust the temperature as required. For details about adjusting the heater temperature, see page 81 "Adjusting the Heater Temperature". - Page 105 Printing Data Press the [Off Line/On Line] key during printing. DWU105 Printing is interrupted. Press [Resume] to resume printing or [Abort] to abort printing. When pressing [Resume], the machine starts printing from the interrupted state. • For details about operations for interrupting, resuming, and stopping using a computer, see "Functions on the Main Menu", RIP Settings Guide.

-

Page 106: Cutting Media

2. Basic Operations Cutting Media This section explains how to cut roll media. Roll up cut media with the roll-up unit so that the printing surface of the media does not touch the floor or the printing surface of another piece of media. Press [Origin Setting/Cut] on the bottom right of the screen. -

Page 107: Convenient Usage

3. Convenient Usage This chapter explains operating procedures for using this machine more usefully and procedures for each setting. Configuring the Margin Settings Set the right and left margins for media. (mainly Europe and Asia) The margin settings can be changed in increments of 1 mm with a range of -10 to +85 from the reference value of 15 mm. - Page 108 3. Convenient Usage Press [Right Side Margin]. Enter the adjustment value of the right side margin using the number keys, and then press [Set]. Press [+/-] to change between "+" and "-". Press [Close]. Press [End].

-

Page 109: Performing The Connection Methods

Performing the Connection Methods Performing the Connection Methods • Never open the center cover or raise the lever during printing. Opening the cover or raising the lever will abort printing. This section explains procedures for connection methods to reduce image quality defects such as black lines and white lines as well as variation in concentration. -

Page 110: Performing The Connection Method For The Print Heads Automatically

3. Convenient Usage Performing the Connection Method for the Print Heads Automatically Performs image processing automatically in the connection parts between each head. Performing the connection method for the print heads can reduce image quality defects if the defects appear in the connection parts between each head. -

Page 111: Performing The Connection Method For The Print Heads Manually

Performing the Connection Methods Performing the Connection Method for the Print Heads Manually If image quality defects cannot be reduced even after performing the connection method for the print heads automatically or you want to adjust visually, perform the connection method for the print heads manually. -

Page 112: Performing The Connection Method For The Media Feed

3. Convenient Usage 1. Test pattern for mode A When printing by mixing the upper nozzles and lower nozzles 2. Test pattern for mode B When printing by using only the upper nozzles 3. Test pattern for mode C When printing by using only the lower nozzles Select the optimal mode that you checked in Step 6 from [A], [B], or [C]. -

Page 113: Configuring Print-Head Alignment For Media Feed Correction

Performing the Connection Methods Press [Selected Setting for Head Alignment]. Press [Media Feed Correction]. Press [Media Feed Correction]. Press [On]. Press [Close] twice. Press [End]. The connection method for the print heads will be applied to the first printing job after these settings are configured. - Page 114 3. Convenient Usage (If the ink combinations are 4C+W) Press the [Standard Procedure] key. DWU103 Press [Selected Setting for Head Alignment]. Press [Media Feed Correction]. Press [Level Setting]. Select the print layer to change the media feed correction level to [4 color], [white], [4 color ->...

-

Page 115: Using The Auto Maintenance Function

Using the Auto Maintenance Function Using the Auto Maintenance Function You can prevent nozzle clogging by performing auto maintenance periodically. The auto maintenance function has the following items. The frequency of maintenance will differ depending on each maintenance item. Set the maintenance frequency in accordance with the usage of this machine. Flushing Interval Set the frequency for discharging ink that accumulates in the print heads. -

Page 116: Configuring Auto Maintenance Interval

3. Convenient Usage • If the waste ink bottle is full, a message will appear on the control panel and auto maintenance will not be executed. If the message appears, replace the waste ink bottle. For details, see page 243 "Replacing a Waste Ink Bottle". -

Page 117: Recovering The Clogged Nozzle By Compensating With Another Nozzle

Recovering the Clogged Nozzle by Compensating with Another Nozzle Recovering the Clogged Nozzle by Compensating with Another Nozzle Register a clogged nozzle and compensate it with another nozzle. Perform this function when nozzle clogging is not resolved even after performing head cleaning and corrective measures for nozzle clogging. -

Page 118: Compensating The Clogged Nozzle Manually

3. Convenient Usage Press the [Maintenance] key. DWU102 Press [ ]. Press [Clogged Nozzle Settings]. Press [Auto Nozzle Check]. Press [Execute]. The nozzle check pattern is printed, and the clogged nozzle is detected. Press [Confirm]. The clogged nozzle is registered. Press [Nozzle Recovery]. - Page 119 Recovering the Clogged Nozzle by Compensating with Another Nozzle Cut the nozzle check pattern. For details about how to cut media, see page 104 "Cutting Media". Check for clogged nozzles based on the printing result of the nozzle check pattern. For details about how to check the print head, nozzle column, and nozzle number, see page 86 "How to Read the Printing Result ".

-

Page 120: Deleting The Registered Clogged Nozzle

3. Convenient Usage Enter the number of the clogged nozzle that you checked in Step 3 using the number keys, and then press [Set]. The clogged nozzle is registered. Press [Close] 3 times. Press [Nozzle Recovery]. Press [On]. The clogged nozzle is compensated with another nozzle. Prints with the compensated nozzle from the first printing job after these settings are configured. - Page 121 Recovering the Clogged Nozzle by Compensating with Another Nozzle Press the [Maintenance] key. DWU102 Press [ ]. Press [Clogged Nozzle Settings]. Press [Registering Clogged Nozzle]. Select the print head to be deleted. Select the nozzle column to be deleted. If you want to delete registration of nozzle A column of Head 1, select [H1-A Delete All]. Confirm the message on the control panel, and then press [Execute].

-

Page 122: Using The Displacement Liquid Instead Of White Ink

3. Convenient Usage Using the Displacement Liquid Instead of White As white ink settles easily, we recommend replacing it with the displacement liquid when it has not been used continuously for a month or more. Using white ink again after replacement consumes a lot of ink. Do not use the displacement liquid when using white ink regularly. -

Page 123: Replacing White Ink With The Displacement Liquid

Using the Displacement Liquid Instead of White Ink • When removing jammed media, replacing media, or performing maintenance on the machine, avoid getting ink, flushing liquid, and displacement liquid on your skin. If ink, flushing liquid, and displacement liquid come into contact with your skin, wash the affected area thoroughly with soap and water. - Page 124 3. Convenient Usage Press [White Ink Displacement]. Confirm the message on the control panel, and then press [Execute]. Slide down all lock levers for the white ink cartridges to unlock the cartridges. DWT172 Take out all white ink cartridges. DWT173 Fully insert the displacement cartridge into its cartridge holder until it stops.

-

Page 125: Replacing The Displacement Liquid With White Ink

Using the Displacement Liquid Instead of White Ink Slide up the lock lever to lock the displacement cartridge. DWT175 Press [Execute]. Press [Confirm]. Press [Close]. Press [End]. The white ink icon is replaced by the displacement liquid icon displayed on the home screen. •... - Page 126 3. Convenient Usage • When replacing white ink with displacement liquid, all 4 corresponding cartridges must be replaced. The displacement process cannot be performed if only a portion of the cartridges are replaced. • If the display panel is idle for 30 minutes or more, maintenance work will be canceled, and the panel will return to the home screen.

- Page 127 Using the Displacement Liquid Instead of White Ink Take out all displacement cartridges. DWT173 With the connecting parts of the white ink cartridge facing upwards, hold a dry cloth on the ink supply port and lightly shake the cartridge up and down. •...

- Page 128 3. Convenient Usage Slide up the lock lever to lock the white ink cartridge. DWT175 Confirm the message on the control panel, and then press [Execute]. Slide down all lock levers, including those of inapplicable color cartridges, to unlock the ink cartridges.

- Page 129 Using the Displacement Liquid Instead of White Ink Slide up all lock levers to lock the cartridges. Make sure to lock the other empty cartridge holders. Press [Execute]. The displacement liquid is discharged. Wait until a message appears on the control panel. Confirm the message on the control panel, and then slide down all lock levers to unlock the cartridges.

-

Page 130: Using The Timer Settings

3. Convenient Usage Using the Timer Settings This section explains the settings for energy saving and the timer function. Configuring Sleep Mode Transition Time After a specified period has passed, the machine enters Sleep mode in order to conserve energy. Specify the time to elapse before entering Sleep mode. - Page 131 Using the Timer Settings configured temperature can reduce power consumption. Also, Cooling mode keeps the temperature of the heaters stable so that it can shorten the standby time that occurs before printing. Press the [User Tools] key. DWU101 Press [Time and Timer Settings]. Press [Cooling Mode].

- Page 132 3. Convenient Usage Press [End].

-

Page 133: Changing The Machine Settings

Changing the Machine Settings Changing the Machine Settings This section explains the settings for items displayed on the control panel and the buzzer sound. Registering the Remaining Amount of Media When you enable [Display Remaining Media], you can check the remaining amount of roll media on the home screen or the [Check Status] screen. -

Page 134: Changing The Buzzer Setting

3. Convenient Usage • The machine detects media width automatically and displays it on the control panel. Changing the Buzzer Setting You can specify whether to make a buzzer sound from the control panel when the operation keys are pressed or an error occurs. Press the [User Tools] key. -

Page 135: Switching The Indication Unit

Changing the Machine Settings Press the [User Tools] key. DWU101 Press [Time and Timer Settings]. Press [Time]. Enter the time to be displayed using the number keys, and then press [Set]. To change between hours, minutes, and seconds, press [ ] or [ ]. Press [Close]. - Page 136 3. Convenient Usage Press [Close]. Press [End].

-

Page 137: Configuring And Managing The Machine

4. Configuring and Managing the Machine This chapter explains how to configure and manage the machine using the control panel and Web Image Monitor. Changing Setting Items You can change the setting items from the following 5 setting screens. • [Initial Setting] screen Press the [User Tools] key on the control panel to display it. - Page 138 4. Configuring and Managing the Machine Press the [User Tools] key. DWU101 Select an item to be set. Press [ ] or [ ] to switch the screen to be displayed. Follow the instructions on the screen to change the setting value. Press the [User Tools] key.

-

Page 139: List Of Setting Items

List of Setting Items List of Setting Items This section explains the setting items and default values on each setting screen. • Some of the setting items shown below are the same as the RIP software. The setting values in the RIP software take priority. - Page 140 4. Configuring and Managing the Machine Default: [On] Language Select the display language on the control panel. Depending on the destination, the default value is changed. The following languages can be set: [Japanese], [English], [French], [German], [Italian], [Spanish], [Dutch], [Portuguese], and [Russian] Media Display Settings You can specify and display the remaining amount of media.

- Page 141 List of Setting Items the configured temperature can reduce power consumption. Also, Cooling mode keeps the temperature of the heaters stable so that it can shorten the standby time that occurs before printing. • Cooling Mode Setting Specify whether to enable Cooling mode. •...

- Page 142 4. Configuring and Managing the Machine Time Set the time for the machine's internal clock using the number keys. To change between hours, minutes, and seconds, press [ ] or [ ]. Network Settings Specify each network setting. IPv4 Specify the machine's IPv4 network address, subnet mask, and IPv4 gateway address. When you select [Specify], enter the IPv4 address and subnet mask as "xxx.xxx.xxx.xxx".

- Page 143 List of Setting Items • Off Default: [On] Valid Protocol Select protocols to use in the network. • IPv4: Active/Inactive • IPv6: Active/Inactive Default: • IPv4: [Active] • IPv6: [Inactive] Make settings for the DNS server. Enter the DNS Server IPv4 address as "xxx.xxx.xxx.xxx" ("x" indicates a number). •...

- Page 144 Communication Test You can make a test call to the RICOH @Remote center. This function is available only if the RICOH @Remote service is enabled and active. Machine Information Notification You can send notification of the machine's status to the RICOH @Remote center.

-

Page 145: [Maintenance] Screen

List of Setting Items Reset Return the set values to the factory-set values. For details, see page 153 "Initializing Setting Items". [Maintenance] Screen This section explains the setting items and default values on the [Maintenance] screen. Nozzle Cleaning Select and execute the type of head cleaning that you want to perform. Nozzle Cleaning: Low Select a print head to be cleaned. - Page 146 4. Configuring and Managing the Machine Waste Ink Level Specify the remaining amount of ink in the waste ink bottle. Enter 0 after disposing of waste ink. Default: [0%] The remaining amount of ink in the waste ink bottle can be set from 0 to 100%, using the number keys. Clogged Nozzle Settings Specify the settings for compensating, detecting, registering, and deleting clogged nozzles.

- Page 147 List of Setting Items • Level 1 (Lo) • Level 2 • Level 3 (Hi) Default: [Level 1 (Lo)] Cleaning (White) Interval Set the cleaning frequency to prevent white ink from clogging. • Level 1 (Lo) • Level 2 • Level 3 (Hi) Default: [Level 1 (Lo)] Ink Circulation Interval Set the circulation frequency to avoid white ink from settling in the ink supply route.

-

Page 148: [Print Adjustment] Screen

4. Configuring and Managing the Machine The immersion time can be set from 1 to 90 minutes, using the number keys. White Ink Displacement Perform ink replacement using the displacement liquid and white ink. Ink Circulation Circulate white ink to prevent white ink from settling in the ink supply route. Ink Refreshing Select a print head and discharge ink from the ink supply route. - Page 149 List of Setting Items • 6 Pass • 8 Pass / 12 Pass / 16 Pass • 32 Pass / 12 Pass (White) Drop Position Adjustment Adjust the drop position automatically or manually to reduce image quality defects. Auto Select a print mode, and then adjust the drop position automatically. •...

- Page 150 4. Configuring and Managing the Machine • Right Side Margin (mainly Europe and Asia) Default: [0] (15 mm) The margin settings can be changed in increments of 1 mm with a range of -10 to +85 from the reference value of 15 mm using the number keys. For example, if you want to set 25 mm, enter "+10". Press [+/-] to change between "+"...

-

Page 151: [Heater Settings] Screen

List of Setting Items Default: [2] The vacuum level can be set from 1 to 9, using the number keys. Test Feed Perform test feeding to check whether the configured heater temperature is appropriate for the media to be used. Rewind or not? (after test feeding) •... - Page 152 4. Configuring and Managing the Machine Default: [140°F] When you select the [On] check box, the temperature can be set from 68 to 158°F, using [ ] or [ ]. Print Specify whether to enable the print heater. When selecting the [On] check box, the heater is enabled and the image quality can be improved.

-

Page 153: [Origin Setting] Screen

List of Setting Items When set to [All On], you can change the temperature in increments of 5°C within a 20 to 70°C or 20 to 95°C range by pressing [ All +5°C] or [ All -5°C]. (mainly North America) When set to [All On], you can change the temperature in increments of 9°F within a 68 to 158°F or 68 to 203°F range by pressing [ All +9°F] or [ All -9°F]. - Page 154 4. Configuring and Managing the Machine • Base line position on the media guide...

-

Page 155: Initializing Setting Items

Initializing Setting Items Initializing Setting Items Return the set values to the factory-set values. Setting Items for Initialization Setting items for initialization are shown below: Initial Setting • General Settings • Buzzer • Media Display Settings • Display Remaining Media •... -

Page 156: Initializing Settings

4. Configuring and Managing the Machine Initializing Settings Press the [User Tools] key. DWU101 Press [ ]. Press [Reset]. Press [Execute]. Press [Confirm]. The set values are returned to the factory-set values. Press [End]. -

Page 157: Using Web Image Monitor

Using Web Image Monitor Using Web Image Monitor Using Web Image Monitor, you can check the machine status and change settings. Available operations The following operations can be remotely performed using Web Image Monitor from a client computer. • Displaying machine status or settings •... -

Page 158: Displaying Top Page

4. Configuring and Managing the Machine • When using a host name under Windows Server 2008/2008 R2/2012/2012 R2/2016 with IPv6 protocol, perform host name resolution using an external DNS server. The host file cannot be used. • If you are using Internet Explorer 7.0/8.0 under an IPv6 environment, enter the machine's host name, not the IP address, in the browser's address bar. -

Page 159: About Guest Mode And Administrator Mode

Using Web Image Monitor DWU108 1. Menu area If you select a menu item, its content will be shown. 2. Header area The available languages menu is displayed. This area also displays [Login] and [Logout], which allows you to switch between the administrator and guest mode. -

Page 160: Access In The Administrator Mode

4. Configuring and Managing the Machine Access in the Administrator Mode On Top Page, click [Login]. The window for entering a login password appears. Enter your login password, and then click [Login]. For details about the login password, consult your administrator. Depending on the configuration of your web browser, the login password might be saved. -

Page 161: Configuring The Machine Settings

Using Web Image Monitor Media Item Description Roll/Leaf The media type is displayed. When using leaf media, displays whether the media has been set. Remaining Enter the remaining amount of roll media. Select a unit from m, inch, or feet. Supplies Item Description... - Page 162 4. Configuring and Managing the Machine Machine Administrator Settings Item Description New Password Enter the new administrator password. Can contain up to 32 characters. New Password (Confirmation) Enter the same password again, to confirm. Interface Interface Settings • Ethernet Item Description MAC Address Displays the MAC address of the machine.

- Page 163 Using Web Image Monitor Item Description DHCP Specify whether the machine should receive a dynamic IPv4 address automatically by using DHCP. To use DHCP, select [Active]. The IP address, Subnet Mask, and Default Gateway cannot be set when DHCP is active. IPv4 Address Enter the IPv4 address for the machine.

- Page 164 4. Configuring and Managing the Machine Item Description Stateless Address 1-3 Displays the stateless address. DHCPv6 Sets whether the machine receives its IPv6 address from a DHCP server automatically. DHCPv6 Address Displays the IPv6 address obtained from a DHCP server when [DHCPv6] is [Active].

- Page 165 Using Web Image Monitor Item Description Local Hostname Displays the local hostname. • Details Item Description Computer Name Displays the computer name. Security SSL/TLS Settings • TLS Version Item Description TLS1.2 Specify whether to enable or disable TLS1.2. TLS1.1 Specify whether to enable or disable TLS1.1. TLS1.0 Specify whether to enable or disable TLS1.0.

- Page 166 4. Configuring and Managing the Machine RC Gate Setup Item Description Status Displays the inquiry or registration status. Request No. Enter the request number, and then click [Confirm]. RC Gate Proxy Server • Remote Communication Gate Proxy Item Description Proxy Server When using the proxy server, specify [Active].

-

Page 167: Troubleshooting

5. Troubleshooting This chapter provides solutions to common problems and it also explains how to correct unwanted print results. When the Machine Makes a Beeping Sound The following table describes the meaning of the various beep patterns that the machine produces. Beep pattern Meaning Cause... -

Page 168: Checking Machine Status And Settings

5. Troubleshooting Checking Machine Status and Settings You can check the machine status and the settings by pressing the [Check Status] key. DWU104 The items that you can check on the [Check Status] screen are as follows: Machine Status You can check messages relating to the machine status. For details, see page 168 "When the Indicator Lamp for the [Check Status] Key Is Lit". - Page 169 Checking Machine Status and Settings • Media Thickness The thickness of the set media is displayed. • For details about how to check media jams and remove jammed media, see page 227 "Clearing Misfeeds".

-

Page 170: When The Indicator Lamp For The [Check Status] Key Is Lit

5. Troubleshooting When the Indicator Lamp for the [Check Status] Key Is Lit If the indicator lamp for the [Check Status] key lights up, press the [Check Status] key to display on the [Check Status] screen. Check the status of each function in the [Check Status] screen. [Check Status] screen DWU109 1. -

Page 171: When A Status Icon Is Displayed

When the Indicator Lamp for the [Check Status] Key Is Lit Problem Cause Solution The machine is unable to A network error has • Check that the Ethernet interface connect to the network. occurred. cable is correctly connected to the machine and that the machine is set correctly. - Page 172 5. Troubleshooting Status icon Status : Waste Ink Bottle Full icon Appears when the waste ink bottle is full. For details about how to change the waste ink bottle, see page 243 "Replacing a Waste Ink Bottle". : Service Call icon Appears when the machine is malfunctioning or requires maintenance.

-

Page 173: If You Cannot Turn On The Power

If You Cannot Turn On the Power If You Cannot Turn On the Power If you cannot turn on the power of the machine, check the power supply. Main causes and solutions are shown below. Cause Solution The power cord is not connected to the machine Make sure to connect the power cord firmly to the and the power source. -

Page 174: When You Cannot Print

5. Troubleshooting When You Cannot Print Problem Cause Solution The machine is unable to The Ethernet interface cable is Check that the Ethernet interface connect to the network. not connected correctly. cable is correctly connected to the machine and that the machine is set correctly. - Page 175 When You Cannot Print Problem Cause Solution Printing does not start. As the machine is not Perform either of the following: connected to the computer • Check if the machine is firmly properly, a printing error has connected to the computer by occurred in the RIP software.

- Page 176 5. Troubleshooting Problem Cause Solution An error message is An error where the machine Check the displayed error message displayed on the control cannot be operated has and take the appropriate action. For panel, and printing is not occurred. details, see page 210 "When possible.

-

Page 177: When There Is A Problem Connecting To Web Image Monitor

When There Is a Problem Connecting to Web Image Monitor When There Is a Problem Connecting to Web Image Monitor Cause Solution The Ethernet interface cable is not Check that the Ethernet interface cable is correctly connected correctly. connected to the machine and that the machine is set correctly. -

Page 178: When You Cannot Print As Expected

5. Troubleshooting When You Cannot Print as Expected When the Printed Media Becomes Dirty Problem Cause Solution The reverse side of printed The media guides or platen Perform the following: media becomes dirty. is dirty. 1. Clean the media guides. For details about how to clean the media guides, see "Cleaning the Media Guides", Requests for... -

Page 179: When Print Quality Is Not Satisfactory

When You Cannot Print as Expected Problem Cause Solution Ink adheres to the media or • The print head nozzle Perform the following: media guides. faces are dirty. 1. Clean the area around the cap • The cap is dirty. and print-head nozzles. - Page 180 5. Troubleshooting Problem Cause Solution Horizontal white lines and • The ink may be dry or Perform the following: thick lines appear. the nozzles of the print 1. Perform head cleaning. For heads may be details about head cleaning, see clogged, preventing page 89 "Cleaning Print Head effective discharge.

- Page 181 When You Cannot Print as Expected Problem Cause Solution The entire printed image is • The ink may be dry or Perform the following: faint or the color is the nozzles of the print 1. Perform head cleaning. For inconsistent. heads may be details about head cleaning, see clogged, preventing...

- Page 182 5. Troubleshooting Problem Cause Solution The printed image is There are marks where ink Perform head cleaning. For details smudged. has dropped on the printed about head cleaning, see page 89 image. "Cleaning Print Head Nozzles". Uneven density or black The media feed quantity Adjust the media feed quantity streaks occur on the printed...

- Page 183 When You Cannot Print as Expected Problem Cause Solution To make further adjustment, carry out the following procedure: 1. Press the [Standard Procedure] key. 2. Press [Media Feed Adjustment]. 3. Press [Micro Setting]. 4. To reduce uneven density, enter a negative value.

- Page 184 5. Troubleshooting Problem Cause Solution • If you perform [Media Feed Adjustment] and black streaks occur on the printed image when resolving uneven density, perform [Media Feed Correction] in the following procedure. 1. Press the [Standard Procedure] key. 2. Press [Selected Setting for Head Alignment].

- Page 185 When You Cannot Print as Expected Problem Cause Solution • To adjust further, change the media feed correction level using the following procedure: 1. Press the [Standard Procedure] key. 2. Press [Selected Setting for Head Alignment]. 3. Press [Media Feed Correction].

-

Page 186: When You Want To Clear Nozzle Clogging

5. Troubleshooting Problem Cause Solution If the problem persists despite executing the abovementioned solutions, perform media feed adjustment again. If the problem still persists, increase the print resolution or select unidirectional printing. When You Want to Clear Nozzle Clogging This section explains how to recover the machine when nozzle defects are not resolved after head cleaning is performed. - Page 187 When You Cannot Print as Expected Clean the nozzle faces. • Clean the nozzle faces of the print heads. See "Cleaning the Nozzle Faces of the Print Heads", Requests for Daily Care and Maintenance. • After cleaning, print nozzle check pattern. For details, see page 85 "Test Printing".

- Page 188 5. Troubleshooting Press the [Maintenance] key. DWU102 Press [ ]. Press [Special Maintenance]. Check the nozzle immersion time to be displayed on the control panel. If you do not change the nozzle immersion time, proceed to Step 6. Press [Nozzle Immersion Time]. Enter the immersion time to immerse print heads into caps using the number keys, and then press [Set].

- Page 189 When You Cannot Print as Expected Confirm a message on the control panel, and then open the right cover. DWT183 Pour the included cleaning liquid into all caps. Fill the caps up with the cleaning liquid by using a dropper. DWT184 Raise the lock lever located inside of the right cover on the left, and then close the right cover.

- Page 190 5. Troubleshooting Perform this function when nozzle defects are not resolved after head cleaning and nozzle maintenance are performed. • As ink refreshing discharges ink in the ink supply route, it consumes a lot of ink. Make sure that there is enough space in the waste ink bottle before performing ink refreshing. Press the [Maintenance] key.

-

Page 191: When You Want To Clear Ink Mixes

When You Cannot Print as Expected When You Want to Clear Ink Mixes Air purging discharges unnecessary ink and air mixed inside the print heads from the air purge ports of the carriage. Perform air purge if: • Nozzle clogging is not resolved after cleaning the machine and the print heads. •... - Page 192 5. Troubleshooting • The supplied gloves are consumables. If they are damaged or lost, use polythene gloves instead. • If the display panel is idle for 30 minutes or more, maintenance work will be canceled, and the panel will return to the home screen. If this occurs, the process will need to be performed again from the beginning.

- Page 193 When You Cannot Print as Expected Remove the two lower screws that secure the carriage cover. Use the removed screws when reattaching. Be sure to store them in a safe place. DWT185 Loosen the two upper screws, and then remove the carriage cover. Use the removed cover when reattaching.

- Page 194 5. Troubleshooting DWT187 1. The port cover for print head 1 2. The port cover for print head 2 3. The port cover for print head 3 Hook the air purge tool over the front of the carriage. Check that the air purge tool is correctly set on the edge of the front of the carriage. DWT188 Raise the lock lever located inside of the right cover on the left, and then close the right cover.

- Page 195 When You Cannot Print as Expected If ink drips from the ports, wipe it off using a dry cloth. DWT189 Attach the port cover, and then secure it with the screw. DWT190 Remove the air purge tool from the carriage. Be careful not to spill ink.

- Page 196 5. Troubleshooting Pour the ink from the air purge tool into the ink receiver. DWT192 Attach the carriage cover. DWT193 Secure the carriage cover with four screws. DWT194 Raise the lock lever located inside of the right cover on the left, and then close the right cover.

-

Page 197: If The Density Of White Ink Is Uneven

When You Cannot Print as Expected • When the air purge tool is removed, ink may leak. Place a paper towel near the port before the work. • Air purging is performed for one print head. You cannot perform air purging for multiple print heads. -

Page 198: When Media Is Not Fed Properly

5. Troubleshooting When Media Is Not Fed Properly When Media Curls While Feeding Cause Solution Media has not been set straight into the When the media is skewed, see page 197 "When media input location. Media Skews While Feeding". The media guides have been removed. Set the media guides correctly. -

Page 199: When Media Skews While Feeding

When Media Is Not Fed Properly Cause Solution The machine moves or the roll-up unit is not When the machine moves and work to make it level is aligned. required, or when the roll-up unit is not correctly aligned, contact your service representative. The drying temperature is too high. -

Page 200: When Roll Media Hangs Down And Makes Contact With The Floor

5. Troubleshooting When Roll Media Hangs Down and Makes Contact with the Floor Cause Solution • Media has not been set firmly to the roll • Release the lever that secures the right roll holder on the rear of the machine. holder. -

Page 201: When A Media Misfeed Occurs

When Media Is Not Fed Properly When a Media Misfeed Occurs Problem Cause Solution • The media has not been • The vacuuming level of the • Lower the vacuum level. fed and does not come out media is too strong. For details about changing from the media output the vacuum level, see... - Page 202 5. Troubleshooting Problem Cause Solution Misfeeds occur. • A media jam has occurred. • Open the center cover and check the state of the • The media is dirty. media. For details about • The media is floating. solving media jams, see page 227 "Clearing Misfeeds".

-

Page 203: When You Have Problems Operating The Machine

When You Have Problems Operating the Machine When You Have Problems Operating the Machine When There Is a Strange Odor • If the machine emits smoke or odours, or if it behaves unusually, you must turn off its power immediately. After turning off the power, be sure to disconnect the power cord plug from the wall outlet. -

Page 204: When The Heater Temperature Does Not Rise

5. Troubleshooting • To check that the heater temperature set in RIP data is suitable for the media, perform a test feed. For details, see page 83 "Test Feeding". When the Heater Temperature Does Not Rise When the heater temperature does not rise as you expect, perform the following solutions. Cause Solution The power has not been turned on. -

Page 205: When The Media Cannot Be Set

When You Have Problems Operating the Machine Cause Solution The machine is not used in the recommended Check whether the machine is used in the environments. recommended environments. For details about installation environments, see page 10 "Conditions for Installation Locations". If turning on the power again fails to eliminate the problem, contact your service representative. - Page 206 5. Troubleshooting Problem Cause Solution "The width of the media is not The setting position of the media • When setting media, check detected. Reload the media." is is misaligned. how well its edge (home displayed on the control panel. position side) is aligned with the position below.

-

Page 207: When The Media Cannot Be Cut

When You Have Problems Operating the Machine When the Media Cannot Be Cut If the message "Check the cutter and then open and close the center cover." appears on the control panel and you cannot cut the media, or if the cutter is operating normally but you cannot cut the media, check the problem as follows: Feed the media to move the cut position, and then check whether you can cut it or not. -

Page 208: Other Printing Problems

5. Troubleshooting Other Printing Problems Problem Solution The printing speed is slow. Check that the computer being used fulfills the recommend performance specifications. Use a computer that fulfills the recommended performance specifications. The printing speed is slow. • For the Ethernet cable, use a cable that supports 1000BASE-T or 100BASE-TX. - Page 209 When You Have Problems Operating the Machine Problem Solution An error occurs when reading the sensor during • When white lines appear due to nozzle auto adjustment of the media feed quantity. clogging, clean the print heads. For details about head cleaning, see page 89 "Cleaning Print Head Nozzles".

- Page 210 5. Troubleshooting Problem Solution The test pattern of the drop position adjustment Perform the following procedures: cannot be printed successfully. 1. Check that media is correctly set in the media output location and the roll-up unit. 2. When the media set at an angle, reset the media.

- Page 211 When You Have Problems Operating the Machine Problem Solution When manually performing drop position Check the width of the loaded media. This adjustment and carrying out a test print, the function works only if the width of the loaded message "Failed to print." appears and printing media is at least 420 mm (approx.

-

Page 212: When Messages Appear

5. Troubleshooting When Messages Appear • The contact information and machine number are displayed in the service call message ( ). Check them and contact your sales representative. If the contact information is blank, contact the store where you purchased it. •... - Page 213 When Messages Appear Message Cause Solution "The following unit(s) is not set • The ink cartridge of the • Set the ink cartridge of the correctly. Please reset it displayed color is not set displayed color correctly. correctly. correctly. • Check that the ink Ink Cartridge (Name)"...

- Page 214 5. Troubleshooting Message Cause Solution "The following unit(s) is not set • The cleaning cartridge is • Check that the cleaning correctly. Please reset it not set correctly. cartridge is set correctly. correctly. • A cartridge other than the • Replace the cleaning Cleaning Cartridge"...

- Page 215 When Messages Appear Message Cause Solution "The flushing cartridge is The flushing cartridge is running Replace the flushing cartridge. depleted. Replace the flushing low. For details about how to cartridge." replace the cartridge, see page 242 "Replacing a Flushing Cartridge". "The cleaning cartridge is The flushing pad of the cleaning Replace the cleaning cartridge.

- Page 216 5. Troubleshooting Message Cause Solution "White ink has settled. Please If white ink cartridges are not After removing the white ink shake the white ink cartridge." used for a fixed time or longer, cartridge, with the connecting the ink may clog in the supply parts of the white ink cartridge path due to settled ink facing upwards, hold a dry...

- Page 217 When Messages Appear Message Cause Solution "The width of the media is not • The media setting position Perform the following: detected. Reload the media." is misaligned. • When setting media, check • Media with a width that how well its edge (home cannot be detected has position side) is aligned been set.

- Page 218 5. Troubleshooting Message Cause Solution "The media is depleted. Reload The roll media set in the roll Set new roll media. the media." holder is depleted. For details about changing media, see page 68 "Changing Roll Media". "The machine's internal •...

- Page 219 When Messages Appear Message Cause Solution "Printing was cancelled because Both the computer and the Check the following, and then of a communication timeout." machine cannot connect to the resend the RIP data from the network during printing, or you computer.

- Page 220 5. Troubleshooting Message Cause Solution "Adjustment has failed. Please A sensor scanning error • Perform media feed refer to Troubleshooting." occurred during drop position adjustment. For details adjustment. about how to do this, see page 91 "Adjusting the Media Feed Quantity". •...

- Page 221 When Messages Appear Message Cause Solution "Adjustment has failed. Please A sensor scanning error The solution depends on the refer to Troubleshooting." occurred after auto-adjustment. type of auto-adjustment executed. General Solutions • If streaks appear because of nozzle clogging, perform head cleaning. For the head cleaning procedure, see page 89 "Cleaning Print Head...

- Page 222 5. Troubleshooting Message Cause Solution Media Feed Adjustment • If the media feed quantity is substantially out of alignment, auto-adjustment may fail. If auto-adjustment fails, perform the adjustment manually. For the adjustment procedure, see page 92 "Adjusting the Media Feed Quantity Manually".

- Page 223 When Messages Appear Message Cause Solution • Detection may fail if the height of the head does not match the paper thickness. Check whether the height of the head is sufficient. • The degree of sensor misdetection is approximately 0.1%. If you notice a problem with the printed image, perform the detection manually.

- Page 224 5. Troubleshooting Message Cause Solution Selecting Auto or Manual Print Head Alignment • Depending on the media, detection may not be executed correctly. If this happens, perform this alignment manually. For manual alignment, see page 109 "Performing the Connection Method for the Print Heads Manually".

- Page 225 When Messages Appear Message Cause Solution "Maintenance has failed. Please Ink refreshing or ink • When performing ink refer to Troubleshooting." replacement has failed. refreshing Check that the waste ink level is less than 50%. If the level is more than 50%, dispose of the waste ink.

-

Page 226: Precautions For Removing Jammed Media / Performing Maintenance

5. Troubleshooting Precautions for Removing Jammed Media / Performing Maintenance • When you remove jammed media or perform maintenance, do not touch the sensors, connectors, LEDs, or other fragile parts that are shown in this manual. Touching these parts may cause malfunctions. - Page 227 Precautions for Removing Jammed Media / Performing Maintenance Location of the LEDs 1–6 DWT206 Location of the sensors DWT221 8, 9 DWT207...

- Page 228 5. Troubleshooting DWT208 DWT209 DWT210...

-

Page 229: Clearing Misfeeds

Clearing Misfeeds Clearing Misfeeds • Do not remove any covers or screws other than those explicitly mentioned in this manual. Inside this machine are high voltage components that are an electric shock hazard. Contact your sales or service representative if any of the machine's internal components require maintenance, adjustment, or repair. -

Page 230: Removing Jammed Media Inside The Center Cover

5. Troubleshooting If the actions recommended in this manual cannot resolve the problem, contact your service representative. • If the error message remains displayed even after you remove jammed media, fully open the center cover and right cover, and then close them. •... - Page 231 Clearing Misfeeds DWT211 Slowly move the carriage in the direction from which it comes. DWT212 Raise the media holding lever (front). The pinch rollers rise and the media is unfixed. DWT135 Remove jammed or torn media. Remove torn scraps of media carefully to prevent them from tearing.

- Page 232 5. Troubleshooting DWT213 While holding down the center of the media, pull the media straight out to the media output location. While holding down the center of the media, lower the media holding lever (front). The pinch rollers lower and the media is fixed. DWT137 Move the left and right media guides to match the media width.

-

Page 233: Removing Jammed Media In The Cutter Unit

Clearing Misfeeds Perform [Nozzle Cleaning: High]. • If ink adheres on the internal components of the machine while removing jammed media, the back side of media may get dirty. If the back side of media gets dirty after the jammed media is removed, clean the platen. - Page 234 5. Troubleshooting...

-

Page 235: Maintenance And Specifications