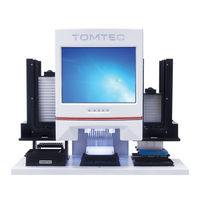

TomTec QUADRA 4 Automated Liquid Handling Manuals

Manuals and User Guides for TomTec QUADRA 4 Automated Liquid Handling. We have 1 TomTec QUADRA 4 Automated Liquid Handling manual available for free PDF download: Operator's Manual

TomTec QUADRA 4 Operator's Manual (217 pages)

Brand: TomTec

|

Category: Laboratory Equipment

|

Size: 5 MB

Table of Contents

-

Preface9

-

-

Introduction25

-

What's New25

-

-

Main Screen34

-

Menu Bar40

-

File Menu40

-

Edit Menu41

-

System Menu42

-

Tools Menu43

-

Options Menu44

-

View Menu45

-

Reports Menu45

-

Help Menu46

-

-

Alert Timer48

-

Empty Sample56

-

GOTO Program60

-

Load Tips61

-

Loop62

-

MIX Sample64

-

Move Arm66

-

Move Shuttle67

-

Move Stage68

-

Nitrogen Dry69

-

Pause70

-

Program Note71

-

Quit72

-

Shaker Nest75

-

Shuck Tips77

-

Wash87

-

Dip Tips90

-

Touch off93

-

-

Options99

-

Default Plates101

-

Configure Model103

-

Logging Options108

-

View Preferences110

-

Utility111

-

Shuttle/Stacker111

-

Stage112

-

Pinch Tubes114

-

Pump115

-

System116

-

Trap Operations116

-

Miscellaneous118

-

Arm - Vacuum Box119

-

Status120

-

-

Tools125

-

Technical Tips129

-

Introduction129

-

Pre-Planning129

-

Labware129

-

Labware Location129

-

-

File Management141

-

-

System Security149

-

Why Use CFR11150

-

Installation151

-

Overview154

-

Installation154

-

Configuration155

-

Usage156

-

OS Requirements157

-

Quick Start158

-

-

-

Quadra Shuttle172

-

Stackers172

-

Quadra Stage173

-

-

Aspirating175

-

Dispensing176

-

Mixing176

-

Titration176

-

Bubbling177

-

Injection177

-

-

-

-

Shaker Nest185

-

Peltier Nest186

-

SPE Vacuum Box186

-

-

-

Weighing Vessels191

-

Evaporation193

-

Setup Procedure194

-

Points194

-

-

Definitions201

-

Advertisement

Advertisement