Stober EZ Manuals

Manuals and User Guides for Stober EZ. We have 3 Stober EZ manuals available for free PDF download: Manual, Operating Manual, Connection Manual

Stober EZ Manual (460 pages)

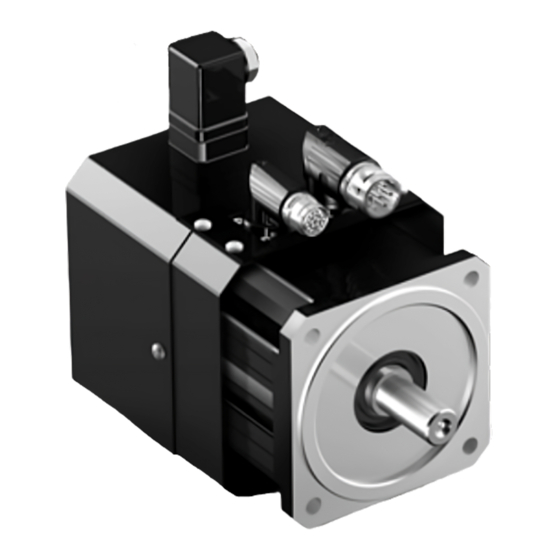

Synchronous servo geared motors with redundant brake

Brand: Stober

|

Category: Industrial Equipment

|

Size: 16 MB

Table of Contents

Advertisement

Stober EZ Operating Manual (7 pages)

synchronous servo motors, synchronous servo motors for screw drive

Brand: Stober

|

Category: Servo Drives

|

Size: 0 MB

Table of Contents

Stober EZ Connection Manual (2 pages)

Synchronous servo motor EZ to B&R ACOPOS (EZ_HQ)_Customer KRONES

Advertisement

Advertisement