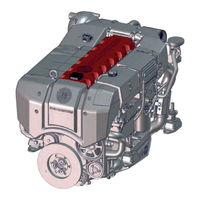

STEYR MOTORS SE236E40 Manuals

Manuals and User Guides for STEYR MOTORS SE236E40. We have 4 STEYR MOTORS SE236E40 manuals available for free PDF download: Service Manual, Installation Manual, Operation, Maintenance And Warranty Manual

STEYR MOTORS SE236E40 Service Manual (274 pages)

Brand: STEYR MOTORS

|

Category: Engine

|

Size: 16 MB

Table of Contents

Advertisement

STEYR MOTORS SE236E40 Installation Manual (224 pages)

4 Cylinder / 6 Cylinder

Brand: STEYR MOTORS

|

Category: Engine

|

Size: 11 MB

Table of Contents

STEYR MOTORS SE236E40 Operation, Maintenance And Warranty Manual (134 pages)

4 + 6 Cylinders

Brand: STEYR MOTORS

|

Category: Engine

|

Size: 24 MB

Table of Contents

Advertisement

STEYR MOTORS SE236E40 Operation, Maintenance And Warranty Manual (120 pages)

Brand: STEYR MOTORS

|

Category: Engine

|

Size: 11 MB

Table of Contents

Advertisement