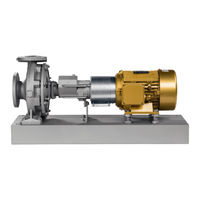

KSB Etanorm SYT Manuals

Manuals and User Guides for KSB Etanorm SYT. We have 3 KSB Etanorm SYT manuals available for free PDF download: Installation & Operating Manual, Manual

KSB Etanorm SYT Installation & Operating Manual (84 pages)

Thermal Oil / Hot Water Pump

Brand: KSB

|

Category: Water Pump

|

Size: 9 MB

Table of Contents

Advertisement

KSB Etanorm SYT Installation & Operating Manual (66 pages)

Thermal Oil / Hot Water Pump

Brand: KSB

|

Category: Water Pump

|

Size: 2 MB

Table of Contents

KSB Etanorm SYT Manual (32 pages)

Thermal Oil / Hot Water Pump

Brand: KSB

|

Category: Water Pump

|

Size: 6 MB

Table of Contents

Advertisement

Advertisement