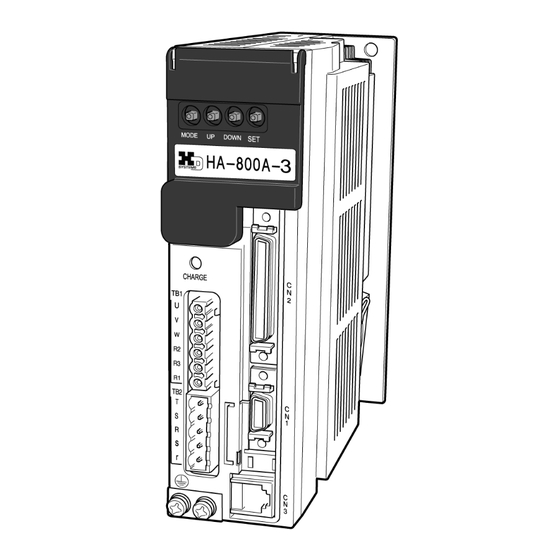

User Manuals: HarmonicDrive H A - 800A Servo Drives

Manuals and User Guides for HarmonicDrive H A - 800A Servo Drives. We have 1 HarmonicDrive H A - 800A Servo Drives manual available for free PDF download: Manual

HarmonicDrive H A - 800A Manual (314 pages)

HA-800A series AC Servo Driver

Brand: HarmonicDrive

|

Category: Servo Drives

|

Size: 10 MB

Table of Contents

-

-

-

-

-

Features91

-

Startup93

-

Data Output96

-

-

-

Features102

-

Startup104

-

Origin Setting105

-

Data Output106

-

-

Startup114

-

-

-

-

I/O Signal List118

-

Monitor Output145

-

-

-

-

Alarm Mode176

-

Alarm Display176

-

-

Alarm List177

-

Tune Mode179

-

-

-

-

SP52: Zero Clamp198

-

-

Test Mode207

-

-

T09: Auto-Tuning218

-

-

-

Overview224

-

Setup224

-

Initial Screen227

-

Status Display230

-

-

Auto-Tuning232

-

Test Operation245

-

IO Monitor248

-

Alarms252

-

-

-

Extension Cables272

-

Option272

-

-

Advertisement

Advertisement