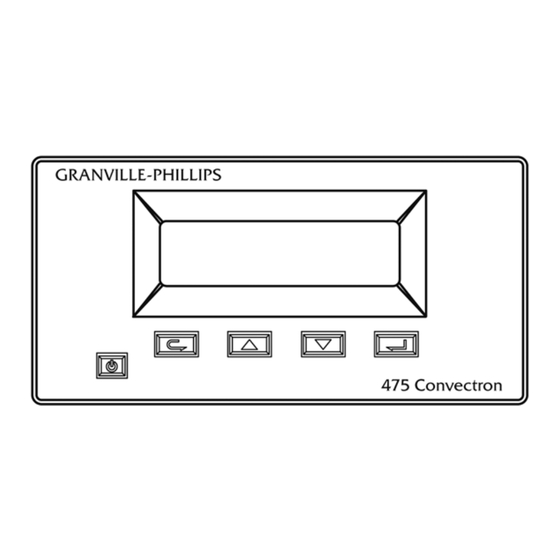

Granville-Phillips 475 Series Manuals

Manuals and User Guides for Granville-Phillips 475 Series. We have 1 Granville-Phillips 475 Series manual available for free PDF download: Instruction Manual

Granville-Phillips 475 Series Instruction Manual (108 pages)

Convectron Vacuum Measurement Controller; 275 Series Convectron Gauge

Brand: Granville-Phillips

|

Category: Controller

|

Size: 2 MB

Table of Contents

Advertisement