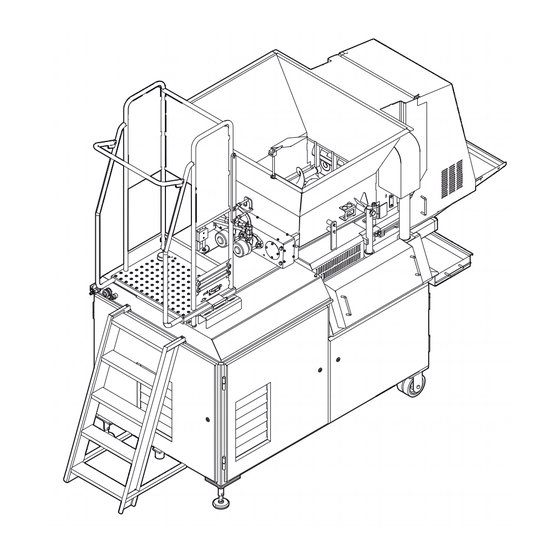

GEA MultiFormer 600 Manuals

Manuals and User Guides for GEA MultiFormer 600. We have 1 GEA MultiFormer 600 manual available for free PDF download: Original Operating Instructions

GEA MultiFormer 600 Original Operating Instructions (94 pages)

Forming machine

Brand: GEA

|

Category: Commercial Food Equipment

|

Size: 5 MB

Table of Contents

Advertisement

Advertisement