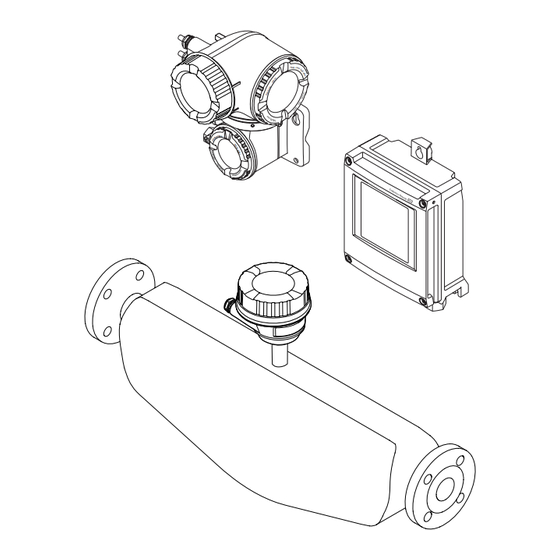

Endress+Hauser Proline Promass S 500 Manuals

Manuals and User Guides for Endress+Hauser Proline Promass S 500. We have 2 Endress+Hauser Proline Promass S 500 manuals available for free PDF download: Operating Instructions Manual

Endress+Hauser Proline Promass S 500 Operating Instructions Manual (314 pages)

Coriolis Flowmeter PROFINET over Ethernet-APL

Brand: Endress+Hauser

|

Category: Measuring Instruments

|

Size: 9 MB

Table of Contents

-

Symbols6

-

Security10

-

Proline 50013

-

Installation21

-

Requirements57

-

Relay Output60

-

Status Input60

-

Display Area70

-

Editing View73

-

Text Editor73

-

Requirements81

-

Logging on84

-

Function Row85

-

Logging out86

-

Fieldcare90

-

Devicecare91

-

Simatic Pdm92

-

Data Structure104

-

Status Coding105

-

Factory Setting106

-

Commissioning108

-

Endress+Hauser153

-

Simulation164

-

Operation171

-

Totalizer174

-

Output Values176

-

Transmitter188

-

Diagnostics List265

-

Maintenance271

-

Maintenance Work271

-

Repair272

-

General Notes272

-

Spare Parts272

-

Return272

-

Disposal273

-

Accessories274

-

For the Sensor275

-

Technical Data278

-

Application278

-

Input279

-

Output281

-

Output Signal281

-

Local Display285

-

Web Browser285

-

Power Supply287

-

Flow Values289

-

Mounting292

-

Environment292

-

Process294

-

Display Elements299

-

Index308

Advertisement

Endress+Hauser Proline Promass S 500 Operating Instructions Manual (282 pages)

PROFINET Coriolis flowmeter

Brand: Endress+Hauser

|

Category: Measuring Instruments

|

Size: 12 MB

Table of Contents

-

Symbols6

-

IT Security12

-

Proline 50015

-

Installation23

-

Requirements58

-

Editing View74

-

Code80

-

Logging on85

-

Logging out88

-

Fieldcare92

-

Devicecare93

-

Status Coding104

-

Factory Setting105

-

Commissioning108

-

Function Check108

-

Interface114

-

Switch Output120

-

Detection133

-

Simulation147

-

Access150

-

Switch151

-

Operation154

-

Totalizer156

-

Output Values158

-

Conditions160

-

Diodes169

-

Transmitter169

-

Diagnostic List232

-

Maintenance239

-

Repair240

-

General Notes240

-

Spare Parts240

-

Return240

-

Disposal240

-

Accessories242

-

For the Sensor243

-

Technical Data246

-

Application246

-

Input247

-

Output249

-

Power Supply254

-

Installation259

-

Environment259

-

Process260

-

Index275

Advertisement

Related Products

- Endress+Hauser Cerabar S PMP75

- Endress+Hauser Cerabar S PMP7

- Endress+Hauser Smartec S CLD132

- Endress+Hauser Proline Promass S 300

- Endress+Hauser SpectraSensors SS2100r

- Endress+Hauser SpectraSensors SS2100

- Endress+Hauser Liquiphant S FDL61

- Endress+Hauser SS500

- Endress+Hauser SS2000XP

- Endress+Hauser SS3000