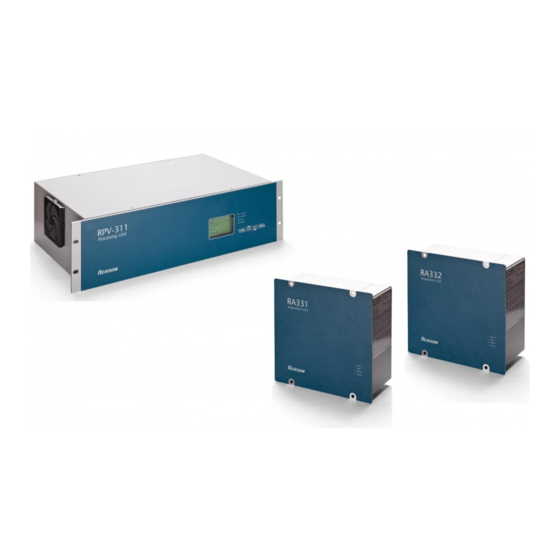

Alstom Reason RPV311 Manuals

Manuals and User Guides for Alstom Reason RPV311. We have 1 Alstom Reason RPV311 manual available for free PDF download: Technical Manual

Alstom Reason RPV311 Technical Manual (350 pages)

Distributed Multifunction Fault Recorder

Brand: Alstom

|

Category: Voice Recorder

|

Size: 8 MB

Table of Contents

-

Foreword

17 -

Unpacking

21 -

Key Features

24 -

Compliance

26 -

Symbols

37 -

Equipment

61-

User70

-

Auto Upload73

-

DC Channels

83 -

Thresholds

85-

Threshold85

-

-

Steady-State

102 -

Groups

105 -

Relays

106 -

Pmu

108-

Data108

-

Communication108

-

-

Modbus

110 -

Dnp3

112 -

-

Chapter Overview118

-

-

Local Interface

119-

Menu Navigation119

-

-

Navigating135

-

Status136

-

Log138

-

Manual Trigger138

-

Records139

-

Monitoring145

-

-

Chapter Overview156

-

-

-

Record Format168

-

Record Naming168

-

-

Chapter Overview

174 -

TWFL Overview

175 -

Chapter 8 PMU

183 -

Chapter Overview

184 -

-

Reported Values185

-

Accuracy Limits186

-

Timestamp187

-

Configuration187

-

-

Chapter 9 MODBUS

189 -

Chapter Overview

190 -

Description

191-

Register Types191

-

Status191

-

Analog Data192

-

Digital Channels192

-

Configuration192

-

-

Chapter 10 DNP3

193 -

Chapter Overview

194 -

Description

195 -

Chapter Overview

198 -

Description

199 -

Chapter Overview

202 -

-

Scanner204

-

TW Fault Locator214

-

Chapter Overview

230 -

Requirements

231 -

-

Chapter Overview

250 -

Chapter Overview

262 -

-

-

Powering up270

-

Current Clamps288

-

Digital Inputs289

-

Case Dimensions

293 -

-

Chapter Overview300

-

-

Maintenance

301 -

Equipment Return

308 -

-

Chapter Overview311

-

-

-

TTL IRIG Input313

-

Power Supply315

-

Safety Tests318

-

Dimensions319

-

-

Voltage Inputs321

-

Current Inputs322

-

Digital Inputs323

-

Type Tests Ra33X325

-

Safety Tests327

-

Dimensions328

-

Current Clamps330

-

-

Chapter Overview332

-

-

Appendix A

340 -

Equipment Log

341

Advertisement