Table of Contents

Advertisement

Quick Links

© ALSTOM 2014. All rights reserved. Information contained in this document is indicative only. No representation or warranty is given or should be relied on that it is

complete or correct or will apply to any particular project. This will depend on the technical and commercial circumstances. It is provided without liability and is subject

to change without notice. Reproduction, use or disclosure to third parties, without express written authority, is strictly prohibited.

Reason RPV311

Technical Manual

Distributed Multifunction Fault Recorder

Platform Hardware Version: C

Platform Software Version: 13

Publication Reference: RPV311-TM-EN-6

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Alstom Reason RPV311

- Page 1 Publication Reference: RPV311-TM-EN-6 © ALSTOM 2014. All rights reserved. Information contained in this document is indicative only. No representation or warranty is given or should be relied on that it is complete or correct or will apply to any particular project. This will depend on the technical and commercial circumstances. It is provided without liability and is subject...

-

Page 3: Table Of Contents

Contents Chapter 1 Introduction Chapter Overview Foreword Target Audience Nomenclature Acronyms and Abbreviations Product Scope Unpacking External Indication RPV311 Nameplate RA331, RA332, and RA333 Nameplate Key Features Compliance Functional Overview Programs Under the GPL 2 License Ordering Options 10.1 RPV311 10.2 RA331 10.3... - Page 4 Mechanical Implementation RPV311 RA331 RA332 RA333 Chapter 4 Configuration Chapter Overview Accessing the Equipment Configuration Configuration History Equipment Identification Synchronization Communications Acquisition with remote acquisition modules Acquisition with Sampled Values Access Control User Record Management Auto Upload Voltage Circuit Current Circuits Power Circuit Digital Channels DC Channels...

- Page 5 15.2 Relays 2, 3, and 4 16.1 Data 16.2 Communication MODBUS DNP3 18.1 Configuring the DNP3 function 18.2 DNP3 configuration example Chapter 5 Operation Chapter Overview Local Interface Status Indicators Menu Navigation Local Interface Menus Monitoring Web Interface Accessing the Monitoring Web Interface Navigating Status Manual Trigger...

- Page 6 Average Series Harmonics Flicker SOE - Sequence of Events Records Record Format and Naming, and Mass Storage Capacity Record Format Record Naming Mass Storage Capacity Record Management and Access Chapter 7 TW Fault Locator Chapter Overview TWFL Overview TW Fault Location Information Maximum Number of Lines Monitored by the TW Fault Locator Accuracy and TWFL with CVTs Underground and Overhead Cables...

- Page 7 Chapter Overview Description Software – RPV Tools Chapter 12 Chapter Overview RPV Tools Description RPV Tools Installation Scanner Configuration Tool TW Fault Locator GOOSE Configurator Software – RPV Manager Chapter 13 Chapter Overview Requirements Software Description RPV Manager Main Window RPV Manager Settings Automatic TW Faul Location Polling and Refresh...

- Page 8 RPV311 Mechanical Installation RA331, RA332 and RA333 Mechanical Installation Cables and Connectors Power Supply Connections RPV311 AC and DC Power Connection RA331, RA332 and RA333 AC and DC Power Connection Powering Up Earth Connnection Connection Between RPV311 and RA331, RA332 or RA333 Analog Voltage Inputs (50/60 Hz) High-speed Analog Voltage Inputs (TW) Analog Current Inputs...

- Page 9 Chapter 17 Technical Specifications Chapter Overview RPV311 Specifications Electrical Ethernet Port Optical Ethernet Port (optional) Modem Serial Port TTL IRIG Input Optical IRIG-Input (optional) Dry-contact Relay Outputs Fiber-optic Links Power Supply Environmental Conditions 2.10 Type Tests RPV311 2.11 Safety Tests 2.12 Environmental tests 2.13...

- Page 10 TABLE OF FIGURES Figure 1: Functional design overview Figure 2: RA333, RA332, RA333 and RPV311 Figure 3: Front View of the RPV311 Figure 4: Back view of the RPV311 Figure 5: Front and back views of the RA331 Figure 6: Front and back views of the RA332 Figure 7: Front and back views of the RA333 Figure 8: Initial configuration screen Figure 9: Equipment identification configuration section...

- Page 11 Figure 33: Disturbance recorder – trigger’d recording configuration Figure 34: Disturbance recorder – continuous recording configuration section Figure 35: Traveling waves recorder – trigger’d recording configuration section Figure 36: Steady-state recorder – average series configuration section Figure 37: Steady-state recorder – harmonics configuration section Figure 38: Steady-state recorder –...

- Page 12 Figure 70: Concatenation event example Figure 71: Example of an event without concatenation Figure 72 – TW Fault Locator architecture overview Figure 73 - Typical Circuit Three-Terminal Application Figure 74 – Three terminal line application Figure 75 – TW Fault Location example 1 Figure 76 - TW Fault Location example 2 Figure 77: Directory of the records received of the equipment Figure 78: Configuration Tool main screen...

- Page 13 Figure 105: AC/DC power connection Figure 106: AC/DC power connection Figure 107: RPV311 Grounding Figure 108: RA33X Grounding Figure 109: RPV311 Fiber Optic Connectors Figure 110: RA331, RA332 and RA333 fiber optic connectors Figure 111: Connection between RPV311 and the RA331, RA332 or RA333 Figure 112: Screws of the Back Panel Figure 113: Analog input terminals Figure 114: Screws of the Back Panel...

- Page 14 Figure 141: RPV311 Dimensions Figure 142: RA331, RA332 and RA333 dimensions Figure 143: AEMC / MN312 (PN 2468) current clamps...

-

Page 15: Chapter 1 Introduction

INTRODUCTION CHAPTER 1... -

Page 16: Chapter Overview

Chapter 1 – Introduction RPV311 CHAPTER OVERVIEW This chapter provides some general information about the technical manual and an introduction to the device(s) described in this technical manual. THIS CHAPTER CONTAINS THE FOLLOWING SECTIONS: Foreword Product Scope Features and Functions Unpacking External Indication Key Features... -

Page 17: Foreword

Some of these terms are well-known industry-specific terms while others may be special product-specific terms used by Alstom Grid. The first instance of any acronym or term used in a particular chapter is explained. In addition, a separate glossary is available on the Alstom website, or from the Alstom contact centre. - Page 18 Chapter 1 – Introduction RPV311 DFR - DataFlex file extension; EMC - Electromagnetic Compatibility; FRQ - Frequency; FUT - Firmware Upgrade Tool; GOOSE - Generic Object Oriented Substation Events; GPS - Global Positioning System; HDD - Hard disk drive; HTML - HyperText Markup Language; IMB - Imbalance;...

- Page 19 Chapter 1 – Introduction RPV311 SQL - Structured Query Language; SSD - Solid-state Drive; TCP - Transmission Control Protocol; THD - Total harmonic distortion; TTL - Time to Live; TW - Travelling Wave; UDP - User Datagram Protocol; UTC - Coordinated Universal Time; VLAN - Virtual Local Area Network;...

-

Page 20: Product Scope

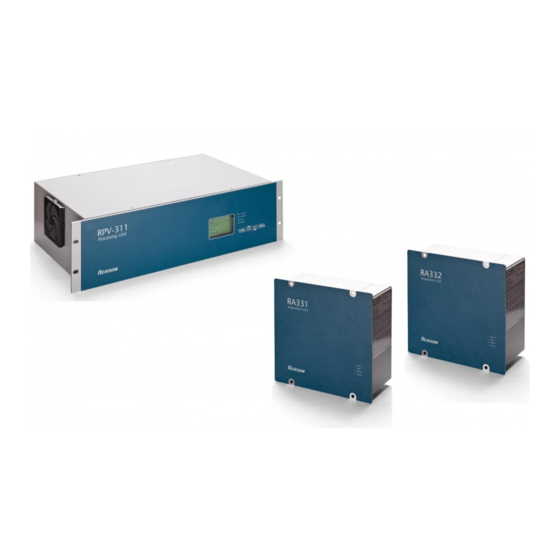

Chapter 1 – Introduction RPV311 PRODUCT SCOPE The processing unit RPV311 and the acquisition modules RA331, RA332, and RA333 offer a distributed solution for Multifunction Digital Recording. The solution is designed for the acquisition, monitoring and recording of electrical quantities normally associated with electrical power generation, transmission or distribution equipment. -

Page 21: Unpacking

Unpack the equipment carefully and make sure that all accessories and cables are put away so they will not be lost. Check the contents against the packing list. If any of the contents listed is missing, please contact Alstom immediately (see contact information at the beginning of this manual). -

Page 22: External Indication

Chapter 1 – Introduction RPV311 EXTERNAL INDICATION RPV311 NAMEPLATE Information about the company, power supply and the serial number and part number is shown on a small nameplate affixed to the rear of the equipment, as shown in Figure Figure 1: Location of Serial Number, Part Number and specifications RA331, RA332, AND RA333 NAMEPLATE Information about the company, power supply, the serial number and part number and specifications about the equipment are shown on a small nameplate affixed to the side of the equipment, as shown in... - Page 23 Chapter 1 – Introduction RPV311 Figure 2: Location of Serial Number, Part Number and specifications RPV311-TM-EN-6...

-

Page 24: Key Features

Chapter 1 – Introduction RPV311 KEY FEATURES The RPV311 plus RA33x acquisition modules solution presents the following key features: Acquisition system: 16-bit opto-isolated analog-to-digital converters, independent for each channel (50/60 Hz channels); 256 points-per-cycle sampling rate (50/60 Hz channels); Frequency response of DC to 3.0 kHz;... - Page 25 Chapter 1 – Introduction RPV311 RS232 serial port for modem connection; Support for IEC 61850: Up to 320 binary inputs related to IEC 61850-8-1 GOOSE messages (optional); Two Ethernet ports for redundant connection (optional); One Ethernet port for Process Bus (IEC 61850-9-2LE Sampled Values) connection (optional).

-

Page 26: Compliance

Chapter 1 – Introduction RPV311 COMPLIANCE The device has undergone a range of extensive testing and certification processes to ensure and prove compatibility with all target markets. A detailed description of these criteria can be found in the Technical Specifications chapter. RPV311-TM-EN-6... -

Page 27: Functional Overview

Chapter 1 – Introduction RPV311 FUNCTIONAL OVERVIEW The processing unit RPV311 and the acquisition modules RA331, RA332, and RA333 offer a distributed solution for Multifunction Digital Recording. The solution is designed for the acquisition, monitoring and recording of electrical quantities normally associated with electrical power generation, transmission or distribution equipment. -

Page 28: Programs Under The Gpl 2 License

Chapter 1 – Introduction RPV311 PROGRAMS UNDER THE GPL 2 LICENSE The RPV311 uses GPL 2 licenses in its implementation. In case the user wants get ahold of the source code, please contact out contact centre. RPV311-TM-EN-6... -

Page 29: Ordering Options

Chapter 1 – Introduction RPV311 ORDERING OPTIONS 10.1 RPV311 Variants Order Number 7 8 9-11 12 13-14 15 Model Type RPV311 Multifunction Recorder IED RPV311 Power Supply 24-48 Vdc 100-250 Vdc / 110-240 Vac Network Interface Two RJ45 copper 100BASE-TX Ethernet interfaces Two RJ45 copper or duplex ST-type connector 100BASE-X Ethernet interfaces Functions and Protocols Fault Recorder... -

Page 30: Ra331

Chapter 1 – Introduction RPV311 10.2 RA331 Variants Order Number 6 7 8 9 10 11 12 Model Type RA331 Acquisition Module for RPV311 RA331 Power Supply 24-48 Vdc 100-250 Vdc / 110-240 Vac Analogue Inputs 1 to 4 Voltage inputs 115 V / Current inputs 1 A; full-scale 20 A (Ith = 32 A) Voltage inputs 115 V / Current inputs 5 A;... -

Page 31: Ra332

Chapter 1 – Introduction RPV311 10.3 RA332 Variants Order Number 6 7 8 9 Model Type RA33 RA332 Acquisition Module for RPV311 Power Supply 24-48 Vdc 100-250 Vdc / 110-240 Vac Analogue Inputs 1 to 4 Voltage inputs 115 V / Current inputs 1 A; full-scale 20 A (Ith = 32 A) Voltage inputs 115 V / Current inputs 5 A;... - Page 32 Chapter 1 – Introduction RPV311 250 V Not installed Digital Inputs 17 to 32 24 V / 48 V 125 V 250 V Not installed Customization / Regionalisation Default Reason branding Hardware Design Suffix Third version Issue B RPV311-TM-EN-6...

-

Page 33: Ra333

Chapter 1 – Introduction RPV311 10.4 RA333 Variants Order Number 6 7 8 9 10 11 12 13 Model Type RA333 Travelling Wave and DFR Acquisition Module for RPV311 RA333 Power Supply 24-48 Vdc 100-250 Vdc / 110-240 Vac Analogue Inputs 1 to 4 Voltage inputs 115 V / Current inputs 1 A;... -

Page 34: Chapter 2 Safety Information

SAFETY INFORMATION CHAPTER 2... -

Page 35: Chapter Overview

Chapter 2 – Safety Information RPV311 CHAPTER OVERVIEW This chapter provides information about the safe handling of the equipment. The equipment must be properly installed and handled in order to maintain it in a safe condition and to keep personnel safe at all times. You must be familiar with information contained in this chapter before unpacking, installing, commissioning, or servicing the equipment. -

Page 36: Health And Safety

Chapter 2 – Safety Information RPV311 HEALTH AND SAFETY Personnel associated with the equipment must be familiar with the contents of this Safety Information. When electrical equipment is in operation, dangerous voltages are present in certain parts of the equipment. Improper use of the equipment and failure to observe warning notices will endanger personnel. -

Page 37: Symbols

Chapter 2 – Safety Information RPV311 SYMBOLS Throughout this manual you will come across the following symbols. You will also see these symbols on parts of the equipment. Caution: Refer to equipment documentation. Failure to do so could result in damage to the equipment Risk of electric shock Ground terminal. -

Page 38: Installation, Commissioning And Servicing

Chapter 2 – Safety Information RPV311 INSTALLATION, COMMISSIONING AND SERVICING LIFTING HAZARDS Many injuries are caused by: Lifting heavy objects Lifting things incorrectly Pushing or pulling heavy objects Using the same muscles repetitively Plan carefully, identify any possible hazards and determine how best to move the product. Look at other ways of moving the load to avoid manual handling. -

Page 39: Fusing Requirements

Chapter 2 – Safety Information RPV311 Testing may leave capacitors charged to dangerous voltage levels. Discharge capacitors by reducing test voltages to zero before disconnecting test leads. If the equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired. -

Page 40: Equipment Connections

Chapter 2 – Safety Information RPV311 Reason devices contain an internal fuse for the power supply which is only accessed by opening the product. This does not remove the requirement for external fusing or use of an MCB as previously mentioned. The ratings of the internal fuses are: RPV unit: 5 Amp, type T, 250V rating RA units: 2 Amp, type T, 250V rating CTs must NOT be fused since open circuiting them may produce lethal hazardous voltages. -

Page 41: Pre-Energisation Checklist

Chapter 2 – Safety Information RPV311 The PCT connection must have low-inductance and be as short as possible. For best EMC performance, ground the unit using a 10 mm (0.4 inch) wide braided grounding strap. All connections to the equipment must have a defined potential. Connections that are pre- wired, but not used, should be earthed, or connected to a common grouped potential. -

Page 42: Upgrading/Servicing

Chapter 2 – Safety Information RPV311 Operation of computers and equipment connected to RPV311 and RA33x under environmental conditions such as temperature and humidity that exceed the conditions specified in their respective manuals can cause malfunctioning or even irreversible damage to them or the nearby installation. -

Page 43: Decommissioning And Disposal

Chapter 2 – Safety Information RPV311 DECOMMISSIONING AND DISPOSAL Before decommissioning, completely isolate the equipment power supplies (both poles of any dc supply). The auxiliary supply input may have capacitors in parallel, which may still be charged. To avoid electric shock, discharge the capacitors using the external terminals before decommissioning. -

Page 44: Standards Compliance

Chapter 2 – Safety Information RPV311 STANDARDS COMPLIANCE Compliance with the European Commission Directive on EMC and LVD is demonstrated using a Technical File. EMC COMPLIANCE: Compliance with IEC 60255-26:2013 was used to establish conformity. PRODUCT SAFETY: 2006/95/EC Compliance with IEC 61010-1:2010 was used to establish conformity. PROTECTIVE CLASS Protective Class 1. -

Page 45: Chapter 3 Hardware Design

HARDWARE DESIGN CHAPTER 3... -

Page 46: Chapter Overview

Chapter 3 – Hardware Design RPV311 CHAPTER OVERVIEW This chapter provides information about the product's hardware design. THIS CHAPTER CONTAINS THE FOLLOWING SECTIONS: Hardware Architecture Mechanical Implementation RPV311-TM-EN-6... -

Page 47: Hardware Architecture

Chapter 3 – Hardware Design RPV311 HARDWARE ARCHITECTURE The RPV311 is a multifunction processing unit and has an acquisition system with 16-bit A/D D converters that provide an acquisition rate of 256 points-per-cycle synchronized by the IRIG-B signal. It has a high processing capability, which allows the acquisition of up to 64 analog channels and 256 digital channels divided in up to 8 acquisition modules connected by fiber-optic links. - Page 48 Chapter 3 – Hardware Design RPV311 Device Logic Demand (slots) RA331 RA332 RA333 DFR RA333 TW The user can combine the RA units as long as the logical sum of the slots value of each RA do not exceed the maximum number of 12. Note: Differently from the RA331/332 the RA333 has two link: One for the DFR functionality and another for the TW functionality.

-

Page 49: Mechanical Implementation

Chapter 3 – Hardware Design RPV311 MECHANICAL IMPLEMENTATION RPV311 3.1.1 MAIN FEATURES Fan-less and no rotating part design Trigger waveform recorder at 256, 128, or 64 points-per-cycle; Continuous waveform recorder at 16 points-per-cycle; Continuous disturbance recorder and trigger recorder (optional); ... -

Page 50: Figure 3: Front View Of The Rpv311

Chapter 3 – Hardware Design RPV311 3.1.2 COMPONENTES Front view of the RPV311, showing all the main components on the front panel. Figure 3: Front View of the RPV311 Indicators of the state of the equipment: Alarm: Lights up when the equipment requires attention of the operator. Trigger: Flashes when a threshold has been triggered;... -

Page 51: Ra331

2 electrical Ethernet interfaces for the communication between the equipment. 1 electrical Ethernet interface for the Process Bus communication. Double internal converter for optical Ethernet interface. Serial port RS323 for modem connection. Maintenance ports for exclusive use by Alstom's technical support personnel. RA331 3.2.1 MAIN FEATURES ... -

Page 52: Ra332

Chapter 3 – Hardware Design RPV311 Figure 5: Front and back views of the RA331 AC or DC power input. Mains and Ready back panel indicators: The Mains is lit when the module is powered. Ready indicator lights up after the module self-test is completed. Up to 8 analog inputs for voltage, current, or DC transducers, identified as 101 to 108. -

Page 53: Figure 6: Front And Back Views Of The Ra332

Chapter 3 – Hardware Design RPV311 Figure 6: Front and back views of the RA332 AC or DC power input. Mains and Ready back panel indicators: Mains is lit when the module is powered-up. Ready indicator lights up after the module self-test is completed. Up to 16 analog inputs for voltage, current, or DC transducers, identified as 101 to 116. -

Page 54: Ra333

Chapter 3 – Hardware Design RPV311 RA333 3.4.1 KEY FEATURES 3 high-speed analog inputs with 5 MHz; Up to 8 analog inputs with 50/60 Hz (voltage, current, DC transducers); Up to 32 digital inputs; 16-bit analog-to-digital converters, 256 points-per-cycle sampling rate for 50/60 Hz acquisition; ... - Page 55 Chapter 3 – Hardware Design RPV311 The Ready indicator lights up after the module's self-test is completed; The Mains indicator lights up when the module is powered; The PPS indicator flashes signaling that the timing signal of the processing module is detected; The Busy indicator lights up when a traveling wave signal is detected and the RA333 is transmitting the data for processing module.

-

Page 57: Chapter 4 Configuration

CONFIGURATION CHAPTER 4... -

Page 58: Chapter Overview

Chapter 4 – Configuration RPV311 CHAPTER OVERVIEW This chapter includes concise instructions of how to configure all available features in the device. THIS CHAPTER CONTAINS THE FOLLOWING SECTIONS: Accessing the Equipment Configuration Equipment Voltage Circuit Power Circuit Digital Channels DC Channels Threshold Fault Records Disturbance Recorder... -

Page 59: Accessing The Equipment Configuration

Chapter 4 – Configuration RPV311 ACCESSING THE EQUIPMENT CONFIGURATION Access to the equipment's configuration is provided by the Web Interface. When the equipment is accessed, a copy of the current configuration is maintained on the equipment until a new configuration is sent. To enter the configuration interface, click on the <C >... -

Page 60: Configuration History

Chapter 4 – Configuration RPV311 D To send the changes to the equipment, click on the <T > button. Before sending the configuration RANSMIT to the equipment, the user must define the changes to be included in the configuration history. By clicking the <O >... -

Page 61: Equipment

Chapter 4 – Configuration RPV311 EQUIPMENT IDENTIFICATION On this screen, shown below, it is possible to configure the equipment identifier, location and owner. These three fields make up the equipment file name pursuant to the COMNAME rule. The equipment identification will appear in the name of the records; therefore, it is very important that it be properly identified. -

Page 62: Synchronization

Chapter 4 – Configuration RPV311 SYNCHRONIZATION If the IRIG-B signal has the CF extensions (IEEE1344), timing information as date, hour, year, time zone and daylight saving time can be provided by the signal. Time zone and daylight saving time information can also be manually set via the Web Interface, overriding the information of the IRIG-B signal. -

Page 63: Communications

Chapter 4 – Configuration RPV311 COMMUNICATIONS The RPV311 communication may be via Ethernet and serial ports. The equipment may also operate as a gateway over a local subnet. Optionally the user can choose between two types of Ethernet, optical and electrical. Gateway setup will enable the RPV311 to communicate with other equipment connected over a local subnetwork. -

Page 64: Figure 11: Equipment Serial Port Configuration Section

Chapter 4 – Configuration RPV311 The RPV311 allows point-to-point communication with a conventional modem, cellular phone, GPRS and radio links. The Serial Port can be configured by accessing the section shown in Figure Figure 11: Equipment serial port configuration section A The B scroll box allows user to select the data bits (7 or 8), parity (none, even or odd) and stop PARITY... -

Page 65: Acquisition With Remote Acquisition Modules

Chapter 4 – Configuration RPV311 ACQUISITION WITH REMOTE ACQUISITION MODULES The RPV311 data acquisition can be performed by the RA331, RA332 and RA333 remote acquisition modules. The RA333 module consists of two different acquisition systems. One, called DFR, is used for analog data acquisition of 50/60 Hz of voltage, current, or DC. -

Page 66: Figure 12: Links Between Rpv And Acquisition Modules Configuration Section

Chapter 4 – Configuration RPV311 Figure 12: Links between RPV and acquisition modules configuration section A The Position represents the position where the acquisition module is physically connected to the RPV311. Positions A to L. B The Module scroll box allows user to select the acquisition module used in the link and its characteristics based on the Part Number of the module. -

Page 67: Acquisition With Sampled Values

Chapter 4 – Configuration RPV311 To improve the accuracy of the measurement, a correction factor can be manually provided. Inputs without the correction factor have accuracy better than 1%. The digital channels do not have type selection. Figure 13: Analog inputs configuration section A The P indicates the position of each analog input on the back panel of the module. -

Page 68: Figure 14: Sampled Values Subscriptions Links Configuration Section

Chapter 4 – Configuration RPV311 The RPV311 processing module can be configured with up to 8 Subscription links. To configure the links, access the S section, shown in Figure AMPLED VALUES SUBSCRIPTIONS Figure 14: Sampled Values subscriptions links configuration section A The E check box allows user to enable the Subscription link feature. -

Page 69: Access Control

Chapter 4 – Configuration RPV311 Figure 15: Analog inputs configuration section for Sampled Values channels A The P indicates the position of each analog input according to the Sampled Value message. OSITION B The I scroll box allows user to select the type of the signal to be received as Sampled Values. NPUT C The A text field allows user to enter a correction factor to adjust the accuracy of the... -

Page 70: User

Chapter 4 – Configuration RPV311 Figure 16: Equipment access control configuration section A The U check box enables use of password to access equipment SE PASSWORD FOR ALL ACCESS LEVELS operation and configuration via Web Interface. B The F text field allows user to enter an independent password to update the IRMWARE UPDATE PASSWORD firmware for the equipment. -

Page 71: Figure 17: Adding New User Section

Chapter 4 – Configuration RPV311 Figure 17: Adding new user section A The U text field allows entering a user identification (maximum 8 characters). No editing is allowed. B The N text field allows user to enter a new password to access the Web Interface (maximum ASSWORD 8 characters). -

Page 72: Record Management

Chapter 4 – Configuration RPV311 Figure 18: Changing the administrator password section: Changing the administrator password section A The O text field allows user to enter an old password. ASSWORD B The N text field allows user to enter a new password to access the Web Interface (maximum ASSWORD 8 characters). -

Page 73: Auto Upload

Chapter 4 – Configuration RPV311 Figure 19: Record management configuration section A Selecting the A check box, erases older record automatically if memory capacity exceeds 90%. UTO ERASE B The E scroll box allows user to choose a type of record (fault, disturbance, steady-state and SOE) RASE ALL to be removed. -

Page 74: Figure 20: Auto Upload Configuration Section

Chapter 4 – Configuration RPV311 Figure 20: Auto upload configuration section A The D check box allows user to select a record destination IP address previously entered. ESTINATION B Selecting the F SOE check boxes, these records AULT ISTURBANCE TEADY TATE RAVELING AVE OR... -

Page 75: Figure 21: Email/Fax Configuration

Chapter 4 – Configuration RPV311 Figure 21: Email/Fax configuration RPV311-TM-EN-6... -

Page 76: Voltage Circuit

Chapter 4 – Configuration RPV311 VOLTAGE CIRCUIT Considering the input type configurations, it is possible to create voltage circuits with 1, 2, 3, or 4 elements. For details about each circuit type, see Chapter 14. The circuit sequences supported by the equipment are ABC, BCA, CAB, CBA, BAC, and CBA and may be customized by the user in the equipment setup. -

Page 77: Figure 22: Adding And Editing Voltage Circuits

Chapter 4 – Configuration RPV311 Figure 22: Adding and editing voltage circuits RPV311-TM-EN-6... -

Page 78: Current Circuits

Chapter 4 – Configuration RPV311 CURRENT CIRCUITS Considering the input type configurations, it is possible to create current circuits with 1, 2, 3, or 4 elements. For details about the each circuit type, see Chapter 14 Installation. The phase sequences of the circuits supported by the equipment are ABC, BCA, CAB, CBA, BAC, and CBA and may be customized by the user in the Equipment Setup, shown in Section 3.9. -

Page 79: Figure 23: Adding And Editing Current Circuits

Chapter 4 – Configuration RPV311 Figure 23: Adding and editing current circuits A The <R > button allows user to rename the circuit. ENAME B The <R > button allows user to delete the circuit. EMOVE RPV311-TM-EN-6... -

Page 80: Power Circuit

Chapter 4 – Configuration RPV311 POWER CIRCUIT Power circuits can be created of circuit voltage and current. To add a new power circuit select the P section and fill in the following: OWER IRCUITS The I text field allows user to enter a single code for the circuit being defined (maximum 12 DENTIFIER characters). -

Page 81: Digital Channels

Chapter 4 – Configuration RPV311 DIGITAL CHANNELS The acquisition is simultaneous and synchronized with a time resolution of 65.104 ��s at 60 Hz or 78.125 ��s at 50 Hz. The polarity is user-programmable (active high, active low). Digital channels can be associated with physical electrical digital inputs or associated with the detection of IEC61850 GOOSE messages. -

Page 82: Figure 25: Adding And Editing Digital Channels

Chapter 4 – Configuration RPV311 Figure 25: Adding and editing digital channels The <R > button allows user to rename the digital channel. ENAME The <R > button allows user to delete the digital channel. EMOVE RPV311-TM-EN-6... -

Page 83: Dc Channels

Chapter 4 – Configuration RPV311 DC CHANNELS The signal of the transducer (±10 V or 0-20 mA) is converted in to the desired physical measurement using a first order transfer function with the parameters of gain (��) and offset (��) defined by the user: ��... -

Page 84: Figure 26: Adding And Editing Dc Channels

Chapter 4 – Configuration RPV311 Figure 26: Adding and editing DC channels The <R > button allows user to rename the DC channel. ENAME The <R > button allows user to delete the DC channel. EMOVE RPV311-TM-EN-6... -

Page 85: Thresholds

Chapter 4 – Configuration RPV311 THRESHOLDS Measured values are continuously monitored and may be tested once every cycle of the nominal frequency of the system, against lower and upper thresholds and range rates involving: Magnitude; Frequency; Active, Reactive, and Apparent Powers; Positive and Negative Sequences;... -

Page 86: Adding New Voltage Thresholds

Chapter 4 – Configuration RPV311 DC Transducers: upper and lower limits; Digital channels: "L" to "H" transition, "H" to "L" transition, "H" and "L" level.; Following parameters can be set for every defined threshold: Parameters set for every defined threshold 0 …... -

Page 87: Adding New Current Thresholds

Chapter 4 – Configuration RPV311 The O scroll box allows user to select greater than or less than for analog magnitude; PERATOR The V text field allows user to enter the magnitude value associated with greater than or less than ALUE operator;... - Page 88 Chapter 4 – Configuration RPV311 The S scroll box allows user to define a code of a current circuit used. No editing allowed; OURCE The Q scroll box allows user to select the associated magnitude to be monitored. For current circuits: UANTITY ABC and N - magnitude or effective value;...

-

Page 89: Adding New Power Thresholds

Chapter 4 – Configuration RPV311 Figure 28: Adding and editing a current threshold A The <A > button allows user to apply the hold time or the hysteresis for all thresholds. PPLY ALL B The <R > button allows user to delete the threshold. EMOVE ADDING NEW POWER THRESHOLDS To add a power threshold, fill in the following:... -

Page 90: Figure 29: Adding And Editing A Power Threshold

Chapter 4 – Configuration RPV311 The O scroll box allows user to select greater than or less than for analog magnitude. PERATOR The V text field allows user to enter the magnitude value associated with greater than or less ALUE than operator. - Page 91 Chapter 4 – Configuration RPV311 Power Swing,Voltage Oscillation and Frequency Oscillation The parameters that are configurable in Power Swing,Voltage Oscillation and Frequency Oscillation threshold are: Oscillation magnitude (in MVA, PU and Hz), Oscillation time (in seconds) and Hysteresis (in percentage).

-

Page 92: Adding New Digital Thresholds

Chapter 4 – Configuration RPV311 ADDING NEW DIGITAL THRESHOLDS To add a digital threshold, fill in the following: The S scroll box allows user to define a code of a digital channel used. No editing allowed; OURCE The C scroll box allows user to select the threshold condition: ONDITION (blank) -

Page 93: Figure 30: Adding And Editing A Dc Threshold

Chapter 4 – Configuration RPV311 Figure 30: Adding and editing a DC threshold A The <A > button allows user to apply the hold time or the hysteresis for all threshold. PPLY ALL B The <R > button allows user to delete the threshold. EMOVE RPV311-TM-EN-6... -

Page 94: Fault Recorder

Chapter 4 – Configuration RPV311 FAULT RECORDER The RPV311 allows user to register triggered and continuous fault recorder. TRIGGER’D RECORDING 10.1 In this section, shown in Figure 31, it is possible to configure the equipment's fault triggered recorder. Figure 31: Fault recorder – triggered recording configuration section A The E check box allows user to enable the fault recorder feature. -

Page 95: Continuous Recording

Chapter 4 – Configuration RPV311 C The T field contains all the thresholds created. The logic equation uses AND and OR logic RIGGER LOGIC operators over previously defined thresholds. Initially, all preset thresholds are displayed as implicit OR operators, one per line. To enable thresholds individually, click on the threshold and select E NABLE To disable discarded thresholds individually, click on the threshold and select D... - Page 96 Chapter 4 – Configuration RPV311 A The E check box allows user to enable the continuous fault recording feature. NABLED B The Q scroll box allows user to select the derived quantity of continuous disturbance records. UANTITY C The <D >...

-

Page 97: Disturbance Recorder

Chapter 4 – Configuration RPV311 DISTURBANCE RECORDER The RPV311 allows user to configure triggered and continuous disturbance recording. 11.1 TRIGGER'D RECORDING In this section, shown in Figure it is possible to configure the equipment disturbance triggered recorder. Figure 33: Disturbance recorder – trigger’d recording configuration A The E check box allows user to enable the disturbance triggered recorder feature. -

Page 98: Continuous Recording

Chapter 4 – Configuration RPV311 To enable thresholds individually, click on the threshold and select E NABLE To disable discarded thresholds individually, click on the threshold and select D ISABLE To break or remove complex thresholds, click on the threshold and select C UT LAST ... - Page 99 Chapter 4 – Configuration RPV311 A The E check box allows user to enable the continuous disturbance reordering feature. NABLED B The D scroll box allows user to select the derived quantity of continuous disturbance ERIVED QUANTITY records. C The <D >...

-

Page 100: Traveling Waves Recorder

Chapter 4 – Configuration RPV311 TRAVELING WAVES RECORDER The RPV311 allows user to configure a traveling wave recorder for fault location, by trigger. To start the configuration, it is necessary add a new recorder in accordance with the position of selected links in equipment. -

Page 101: Recommended Sources Of Trigger

Chapter 4 – Configuration RPV311 Click on the threshold to which is desired to add the previously selected threshold and then select the threshold to be added. D Selecting the R or S check box enables ECEIVE THERNET CROSS TRIGGER THERNET CROSS TRIGGER these features. -

Page 102: Steady-State

Chapter 4 – Configuration RPV311 STEADY-STATE RPV311 allows user to register average series, harmonics, and flicker in the steady-state recorder. 13.1 AVERAGE SERIES In this section, shown in Figure 36, it is possible to configure the equipment's average series recorder. The average series the following voltage and current circuits quantities: magnitude or effective value, neutral magnitude or effective value, frequency, unbalance and total harmonic distortion. -

Page 103: Flicker

Chapter 4 – Configuration RPV311 Figure 37: Steady-state recorder – harmonics configuration section A The I field shows all the circuits previously configured. DENTIFIER B The T field shows the circuit type. C The check box allows the selection of preset circuits for the steady-state record formation. In the harmonics recorder, only 2 circuits can be selected at the same time. -

Page 104: Figure 38: Steady-State Recorder - Flicker Configuration Section

Chapter 4 – Configuration RPV311 Figure 38: Steady-state recorder – flicker configuration section A The I field shows all the voltage circuits previously configured. DENTIFIER B The T field shows the circuit type. C The check box allows the selection of circuits to be included in the steady-state record. In the flicker recorder, up to 6 circuits can be selected at the same time. -

Page 105: Groups

Chapter 4 – Configuration RPV311 GROUPS Group setup allows the user to monitor voltage and current circuit information via local interface or the Monitoring screen at the web interface operation. It is not possible to monitor circuits that are not included in either group. To add new groups fill in the following: ... -

Page 106: Relays

Chapter 4 – Configuration RPV311 RELAYS Relays indicate events or state transitions and set off the alarm on the equipment. RPV311 provides four relays: three relays set by the user and one factory default relay, which signals internal equipment failure. 15.1 ON TIME In this section, shown in... -

Page 107: Figure 41: Relay Signaling Events Configuration Section

Chapter 4 – Configuration RPV311 Figure 41: Relay signaling events configuration section A The L events text field allows user to enter a code used for signaling events. Refer to Chapter 5 for log references. Signaling is only during the time set in the previous section. B The W check box allows user to select the following events for signaling: ARNINGS... -

Page 108: Pmu

Chapter 4 – Configuration RPV311 Synchrophasors are measured and broadcast according to the specifications contained in IEEE C37.118, Standard for Synchrophasors for Power Systems. For further information about the PMU, see Chapter 8. The PMU functionality is able to send up to 4 streams of data and the configuration is divided in two sub menus.: Data;... - Page 109 Chapter 4 – Configuration RPV311 In Spontaneous mode the RPV sends the PMU data automatically up to 4 different socket addresses (IP + port number). The 4 streams of data can be sent using unicast or multicast transmission. The parameters of the Communication screen are listed below: <C >...

-

Page 110: Modbus

Chapter 4 – Configuration RPV311 MODBUS Status, analog and digital data are available in MODBUS registers. Access to SCADA integration is provided over the Ethernet interface. Up to 8 simultaneous connections are allowed a maximum rate of 60 accesses per second. For further information about MODBUS, see Chapter 9 Each register reports 16-bit data. - Page 111 Chapter 4 – Configuration RPV311 A The E check box allows user to enable recording. NABLE B The A field allows user to select a derived quantity and insert a decimal correction factor of an NALOG DATA analog input. C The D field allows user to select a block of a digital input.

-

Page 112: Dnp3

Chapter 4 – Configuration RPV311 DNP3 The DNP3 functionality is fully associated with the MODBUS functionality in the RPV311. To use the DNP3 protocol, it is necessary to insert a configuration key at the equipment to unlock the MODBUS and DNP3 functionalities. - Page 113 Chapter 4 – Configuration RPV311 Channel name RA33x input Channel type DNP3 Database associated number A201 Physical A217 Physical C201 Physical D_Linha2 B201 Physical D_Linha3 B202 Physical GOOSE GOOSE A210 Physical A211 Physical A212 Physical 18.2.2 ADDING ANALOG CHANNELS The analog data possibilites for the DNP3 communication procol are the same as for MODBUS. The MODBUS analog data are shown in section 2.3.

-

Page 114: Figure 44: Analog Channels Selected

Chapter 4 – Configuration RPV311 Figure 44: Analog channels selected A The field is only used for analog quantities with DNP3; B Used to configure the digital inputs that will be sent. RPV311-TM-EN-6... - Page 115 Chapter 4 – Configuration RPV311 Data name MODBUS DNP3 Database Data type register associated number number Alarms: bit 0: Equipment NOK bit 1: Primary power failure bit 2: Not used bit 3: Not used bit 4: Equipment not synchronized bit 5: Fault recorder low memory bit 6: Disturbance recorder low memory bit 7: Steady-state recorder low memory bit 8: SOE recorder lack of memory...

- Page 116 Chapter 4 – Configuration RPV311 Note: The phase angles are sent in degrees for the MODBUS and radian for DNP3 RPV311-TM-EN-6...

-

Page 117: Chapter 5 Operation

OPERATION CHAPTER 5... -

Page 118: Chapter Overview

Chapter 5 – Operation RPV311 CHAPTER OVERVIEW This chapter provides information on possible ways to access and operate the device. . THIS CHAPTER CONTAINS THE FOLLOWING SECTIONS: Local Interface Monitoring Web Interface RPV311-TM-EN-6... -

Page 119: Local Interface

Chapter 5 – Operation RPV311 LOCAL INTERFACE The RPV311 has a local interface for human-machine interaction, composed of a display, navigation buttons, and status indicators, as shown in the figure below. Figure 45: Local interface of the RPV311 STATUS INDICATORS The local interface has 4 status indicators: ... - Page 120 Chapter 5 – Operation RPV311 Date and time; If the equipment is in normal operation; If the equipment is using the IRIG-B timing and the signal quality; Internal temperature; Date and time since last power up; ...

-

Page 121: Figure 46: Status Monitoring Sequence

Chapter 5 – Operation RPV311 Figure 46: Status monitoring sequence RPV311-TM-EN-6... - Page 122 Chapter 5 – Operation RPV311 2.3.2 MONITORING It is possible to locally monitor the analog quantities measured by the RPV311. Quantities are separated by the name of the circuit and the data is updated once per second. To view the values related to quantities associated with a circuit, select the circuit group, choose the circuit type (voltage, current, or power) and then select the name of the circuit to be monitored.

-

Page 123: Figure 47: Monitoring Sequence

Chapter 5 – Operation RPV311 Figure 47: Monitoring sequence RPV311-TM-EN-6... - Page 124 Chapter 5 – Operation RPV311 2.3.3 RECORDS This menu shows the list of records provided by the equipment in decreasing chronological order (of the latest to the oldest). To view a record, select the type of the record (Waveform, Synchrophasors, Steady-state, TW or SOE), and then select the date and the time of the record to be viewed.

-

Page 125: Figure 48: Records Monitoring Sequence: Fault Disturbance, Tw And Average Series

Chapter 5 – Operation RPV311 Figure 48: Records monitoring sequence: Fault disturbance, TW and average series RPV311-TM-EN-6... -

Page 126: Figure 49: Records Monitoring Sequence: Harmonics, Flicker And Soe

Chapter 5 – Operation RPV311 Figure 49: Records monitoring sequence: harmonics, flicker and SOE RPV311-TM-EN-6... - Page 127 Chapter 5 – Operation RPV311 2.3.4 SETTINGS Shows the RPV311 configuration, related to: Equipment identification; Synchronization information; Communication settings (gateway, serial port and Ethernet); Information about voltage, current and power circuits and digital channels; Relay configuration. To access the Setting items, use the sequence shown in Figures 51 to 53.

-

Page 128: Figure 50: Equipment Settings Monitoring Sequence

Chapter 5 – Operation RPV311 Figure 50: Equipment settings monitoring sequence RPV311-TM-EN-6... -

Page 129: Figure 51: Circuit And Channel Settings Monitoring Sequence

Chapter 5 – Operation RPV311 Figure 51: Circuit and channel settings monitoring sequence RPV311-TM-EN-6... -

Page 130: Figure 52: Relays, Pmu And Modbus Settings Monitoring Sequence

Chapter 5 – Operation RPV311 Figure 52: Relays, PMU and MODBUS settings monitoring sequence RPV311-TM-EN-6... - Page 131 Chapter 5 – Operation RPV311 2.3.5 GENERAL INFORMATION Shows general information about the equipment, such as: Equipment model; Processor; Module identification; Frequency; Type of sequence; Key (to enable the equipment functions); Features (features enabled). To access the items of General Information, use the sequence shown in Figure 53.

-

Page 132: Figure 53: General Information Monitoring Sequence

Chapter 5 – Operation RPV311 Figure 53: General information monitoring sequence RPV311-TM-EN-6... -

Page 133: Monitoring Web Interface

Chapter 5 – Operation RPV311 MONITORING WEB INTERFACE ACCESSING THE MONITORING WEB INTERFACE The equipment’s monitoring interface allows access to the equipment and link status, event log, manual trigger, records, monitoring of magnitudes, configuration history, and general information about the equipment. - Page 134 Chapter 5 – Operation RPV311 in order to verify the support applications and the minimum requirements needed to access all the RPV311 Web Interface features. To access the monitoring interface, enter the equipment's Ethernet IP in a web browser. If the Flash Player 9.0 (or higher) plug-in is not already installed on the computer, it will be automatically installed by the operating system.

-

Page 135: Navigating

Chapter 5 – Operation RPV311 If the equipment is not fond with the default IP settings, refer to Chapter 5 in order to be able to verify the current IP address. NAVIGATING The default screen of the Web Interface is shown in Figure 54. -

Page 136: Status

Chapter 5 – Operation RPV311 To finish the session, click on the <L > button. A confirmation box will appear. Click Yes to confirm or OGOUT No to keep logged in. If the screen is closed before pressing the logout button, the user will remain connected until a time delay expires (1 minute). -

Page 137: Figure 56: Link Status Screen

Chapter 5 – Operation RPV311 Memory usage: indicates the memory usage related to the fault, disturbance, TW, steady-state and SOE records and log; Last power-up: indicates the date and time since the last power up. B The <R >... -

Page 138: Log

Chapter 5 – Operation RPV311 The Log screen, shown in Figure 57, displays a history of equipment event logs. Figure 57: Log screen A The Search box allows user to choose the period of time of the oldest to the latest to display. B The Codes box allows user to search for specific logs or time intervals. -

Page 139: Records

Chapter 5 – Operation RPV311 The Manual Trigger screen, shown in Figure 58, allows the user to trigger the equipment manually even if no threshold was exceeded. Figure 58: Manual Trigger screen A By selecting this box, a fault recording is triggered. B By selecting this box, a disturbance recording is triggered. -

Page 140: Figure 59: Fault Recorder Screen

Chapter 5 – Operation RPV311 Figure 59: Fault recorder screen A The Search box allows user to choose the period of time of the oldest to the latest to display. B The Manual Filter box allows user to filter the records manually, according to their selection. C The Trigger and the Continuous boxes allow user to select either or both types of record present on the list. -

Page 141: Figure 60: Fault Recorder Screen

Chapter 5 – Operation RPV311 3.6.1 DISTURBANCE RECORDER The Disturbance recorder screen, shown in Figure 60, displays a history of equipment disturbance records. Figure 60: Fault recorder screen A The Search box allows user to choose the period of time of the oldest to the latest, in order to display it in the interface. -

Page 142: Figure 61: Traveling Wave Recorder Screen

Chapter 5 – Operation RPV311 G The <C > button allows download of record, line per line, and saving it in the COMTRADE format, OMTRADE and compression as .zic file. H The <C > button allows user to close the section. LOSE 3.6.2 TRAVELING WAVE RECORDER... -

Page 143: Figure 62: Steady-State Recorder Screen

Chapter 5 – Operation RPV311 E The <D > button allows user to view information about the record. This information is also included in ETAILS the .HDR file. F The <C > button allows download of record, line per line, and saving it in the COMTRADE format, OMTRADE and compression as .zic file. -

Page 144: Figure 63: Soe Recorder Screen

Chapter 5 – Operation RPV311 Time stamp: indicates the date and time of event log (yyyymm-dd hh:mm:ss[.uuuuuu] ± 0000 (UTC time offset); Cause: indicates threshold exceeded; Duration: record length in seconds. F The <C > button allows download of record, line per line, and saving it in the Comtrade format, OMTRADE and compression as .zic file. -

Page 145: Monitoring

Chapter 5 – Operation RPV311 D SOE records listed, with the following information: Time stamp: indicates the date and time of event log (yyyymm-dd hh:mm:ss[.uuuuuu] ± 0000 (UTC time offset); Cause: indicates threshold exceeded; Duration: record length in seconds. E The <C >... - Page 146 Chapter 5 – Operation RPV311 ¹ Is not calculated for circuits of 1 element without 3-phase synthesis. ² Is not calculated for neutral circuits. The fundamental frequency of the input signal must be within a range of ± 6 Hz of the nominal frequency of the electrical system.

-

Page 147: Figure 64: Monitoring With Plots

Chapter 5 – Operation RPV311 Figure 64: Monitoring with plots A The Fault Recorder or Disturbance Recorder check boxes allows user to select which type of recording to trigger. B The <T > button allows user to trigger the selected record. RIGGER C Quantities selected to be monitored. -

Page 148: Figure 65: Monitoring Circuit Quantities Via Web Interface

Chapter 5 – Operation RPV311 Figure 65: Monitoring circuit quantities via Web interface A Phasor angle for each phase of the selected circuit. B Selected circuit to be monitored. C Quantities related to the circuits being monitored. Phasor angles measured and displayed are absolute angles referenced to the PPS signal provided by the synchronization. -

Page 149: Figure 66: Monitoring The Status Of Digital Channels

Chapter 5 – Operation RPV311 3.7.4 DIGITAL CHANNELS The status of each digital channel can be monitored via Web Interface, as shown inFigure 66. Access: > D ONITORING IGITAL HANNELS It is possible to monitor the status of up to 64 digital channels per page and up to six pages. The data is updated every 2 seconds. -

Page 150: Configuration History

Chapter 5 – Operation RPV311 CONFIGURATION HISTORY The Configuration History screen, shown in Figure 67, displays the history of changes made in the equipment configuration and its corresponding revision number. Figure 67: Configuration History screen A Configuration history, with the following information: ... -

Page 151: Figure 68: General Information Screen

Chapter 5 – Operation RPV311 The General Information screen, shown in Figure 68, displays general information about the equipment, such as: Figure 68: General Information screen A General information about the equipment, such as: Equipment model: model of RPV; ... -

Page 152: Figure 69: Setup Screen

When contacting our support personnel, it is necessary to inform the equipment serial number and part number. Alstom's support personnel will send an email with the new key. In order to enable the new key, please follow the instructions below:... - Page 153 Chapter 5 – Operation RPV311 1. Click on the <S > button to enter the new key. A new window will open, enter the username and ETUP password (username and password for Web Interface configuration). 2. Another window will open indicating that all open Web Interface windows should be closed (except the key window).

-

Page 154: Comtrade Files Download

Chapter 5 – Operation RPV311 COMTRADE FILES DOWNLOAD There are four different ways to get the COMTRADE files from the RPV311 to a computer, one manual way and three automatic way. The manual method uses the web interface and is described in the item 3.6 Records in Chapter 5 The three ways automatic ways listed below: Scanner software (RPVTools.Chapter 12): Simple platform that download specific types of files (fault, disturbance, SOE, TW...) from specific IP address with pre set time intervals. -

Page 155: Chapter 6 Records

RECORDS CHAPTER 6... -

Page 156: Chapter Overview

Chapter 6 – Records RPV311 CHAPTER OVERVIEW This chapter details all types of registers created by the RPV311. THIS CHAPTER CONTAINS THE FOLLOWING SECTIONS: Continuous and Triggered Fault Records Continuous and Triggered Disturbance Records Traveling wave Fault Records Steady-State Records SOE –... -

Page 157: Continuous And Triggered Fault Records

Chapter 6 – Records RPV311 CONTINUOUS AND TRIGGERED FAULT RECORDS Fault records can be created in the following ways: Continuously: Measurements are continuously recorded. A new record is available each 10 minutes. The record size depends on the number of derived measurements selected by the user (limited to 16). ... -

Page 158: Recording Times By Trigger

Chapter 6 – Records RPV311 RECORDING TIMES BY TRIGGER Once triggered, the following parameters are considered by the fault recorder: Parameter Allowed values Increment 0 … 5 s 0.1 s Pre-fault time (�� 0 … 60 s Post-fault time (�� 0.1 s 1 …... -

Page 159: Trigger Burst Limiter

Chapter 6 – Records RPV311 Figure 70: Concatenation event example If the pre-fault time of the second register does not overlap the post-fault time of the first records, then the RPV311 creates two separate COMTRADE files. In the figure below, if T ≥ pre-fault time + post-fault time, then the RPV311 creates two separate COMTRADE files. - Page 160 Chapter 6 – Records RPV311 There is an user-configurable trigger burst limiter for the fault recorder. The burst limiter is based on the number of triggers time interval (both parameters are user-configurable). When the limit is exceeded, recording will be disabled for a period of time defined by the user. Parameter Allowed values Increment...

-

Page 161: Continuous And Trigger'd Disturbance Records

Chapter 6 – Records RPV311 CONTINUOUS AND TRIGGER'D DISTURBANCE RECORDS Disturbance records can be created in the following ways: Continuously: Derived measurements are continuously recorded. A new record is created at each hour rollover. The record size depends on the number of derived measurements selected by the user (limited to 64). ... -

Page 162: Sampling Rate

Chapter 6 – Records RPV311 Parameter Allowed values Increment 0 … 5 min Pre-fault time (�� 0.1 min 0 … 20 min Post-fault time (�� 0.1 min 1 … 20 min Maximum Record time (�� 0.1 s The Maximum Record time configures the maximum duration that the register can reach. If consecutive retriggers or a sustained fault happens, the Maximum Record time establishes the limit of time that the COMTRADE file will register. -

Page 163: Traveling Wave Fault Records

Chapter 6 – Records RPV311 TRAVELING WAVE FAULT RECORDS Faults in a transmission line cause transients traveling along the line as waves composed of by a frequencies ranging of a few kilohertz to several megahertz. These traveling waves have a wave front with a very fast rise time and a down time which is relatively slow. The waves move at speeds near that of light, away of the fault point toward the end points of the line. - Page 164 Chapter 6 – Records RPV311 The recording parameters are fixed and the record has 100 ms before the violation of the limit and one cycle after, approximately 117 ms at 60Hz and 120 ms at 50 Hz. The duration of recording may vary slightly but this does not cause in implications for fault location.

-

Page 165: Steady-State Records

Chapter 6 – Records RPV311 STEADY-STATE RECORDS Steady-state records can be created by the following means: Average Series; Harmonics; Flicker. AVERAGE SERIES The equipment continuously records averaged values of Values of average series recorder RMS (voltage) Simple average RMS (current) Simple average Voltage imbalance... - Page 166 Chapter 6 – Records RPV311 ��ℎ A Fourier transform is used to obtain all frequency components of the input signal up to the 50 order. The values obtained at every measuring window are aggregated over �� = 3 s. Values resulting of the �� = 3 s aggregation are aggregated a second time over ��...

-

Page 167: Soe - Sequence Of Events Records

Chapter 6 – Records RPV311 SOE - SEQUENCE OF EVENTS RECORDS All variations of the equipment inputs occurred are recorded on this record. It generates one record per day. RPV311-TM-EN-6... -

Page 168: Record Format And Naming, And Mass Storage Capacity

The ".inf" files have the groups and the power lines parameters. The data are formatted according to the requirements of Alstom's Analise software. The ".tri" files have the sequence of digital events. The data was formatted according to the requirements of Alstom's Analise software. -

Page 169: Mass Storage Capacity

Chapter 6 – Records RPV311 Parameter Format Description Record’s start date STARTDATE yymmdd (year, mounth, day) Record’s start time STARTTIME hhmmssuuuuuu (hour, minutes, seconds, microsseconds) TIMECODE soohmm Indication of timezone offset (the last three characters are included only when fractional hours are in use) STATIONID Location of the equipment, configurable in: >... - Page 170 Chapter 6 – Records RPV311 Memory type HDD Capacity SSD Capacity Fault 27 GB 22 GB 1 GB 1 GB Disturbance 9 GB 9 GB Steady-state 1 GB 1 GB 500 MB 500 MB SSD or HDD mass storage devices are available. Check the order code to identify the mass storage device installed in the processing module.

-

Page 171: Record Management And Access

Chapter 6 – Records RPV311 RECORD MANAGEMENT AND ACCESS Records can be accessed in three ways: Through the Web Interface, see further information in Chapter 5; Through the Scanner which is part of the RPVTools package, see further information in Chapter 12; ... -

Page 173: Chapter 7 Tw Fault Locator

TW FAULT LOCATOR CHAPTER 7... -

Page 174: Chapter Overview

Chapter 9 – TW Fault Locator RPV311 CHAPTER OVERVIEW This chapter provides information regarding the architecture and the proper use of the Reason Traveling Wave Fault Location. THIS CHAPTER CONTAINS THE FOLLOWING SECTIONS: TWFL Overview Three-Terminal-Traveling Wave How to Test the TW Fault Location in Lab Three Terminal Line Application RPV311-TM-EN-6... -

Page 175: Twfl Overview

Chapter 9 – TW Fault Locator RPV311 TWFL OVERVIEW The figure below shows an overview of the Traveling Wave Fault Location architecture. Figure 72 – TW Fault Locator architecture overview Each terminal of the line has to have a set of RPV311 processing unit+RA333 acquisition unit ; and each RPV311 has to be synchronized with a GPS Clock as accurate as possible. - Page 176 Chapter 9 – TW Fault Locator RPV311 Where: fault distance from terminal A; length of the line; constant of the line attenuation of the speed of the wave; speed of light time which the traveling wave gets to terminal A time which the traveling wave gets to terminal B The means to get the COMTRADE files from the RPV311 to the computer where the fault location will be performed are described in Chapter 5, item 4 - COMTRADE files download.

-

Page 177: Tw Fault Location Information

Chapter 9 – TW Fault Locator RPV311 TW FAULT LOCATION INFORMATION MAXIMUM NUMBER OF LINES MONITORED BY THE TW FAULT LOCATOR If the voltage is sourced from a bus VT you only need one RA333 to capture TWs from all the lines connected to that bus, however simultaneous or consecutive faults (less than 2 minutes apart) on lines connected to that bus will not be captured.. -

Page 178: Automatic Fault Location

Chapter 9 – TW Fault Locator RPV311 AUTOMATIC FAULT LOCATION The RPV Manager software is a tool design for management of COMTRADE files, configuration and fault location. One of its features is the automatic TW fault location. The RPV Manager download the COMTRADE files from both terminals of the line, performs the fault location calculations, displays the fault location results in its interface and sends the location via MODBUS to the supervisory system. -

Page 179: How To Test The Tw Fault Location In Lab

Chapter 9 – TW Fault Locator RPV311 HOW TO TEST THE TW FAULT LOCATION IN LAB The most complete test would be using two sets of RPV311+RA333: 1. Make sure that both RPV311 are properly time synced. For conditions that are more realistic, the sync sources could be independent;... -

Page 180: Three Terminal Line Application

Chapter 9 – TW Fault Locator RPV311 THREE TERMINAL LINE APPLICATION The figure below shows a line of three-terminal. The Terminal A, B and C (sources X, Y and Z respectively). Figure 73 - Typical Circuit Three-Terminal Application To use TWFL in the case above 3 sets of equipment are necessary: 3(RPV311 + RA333). One set for each terminal (Figure 74). -

Page 181: Examples

Chapter 9 – TW Fault Locator RPV311 L1=(L1’ + L1’’) L1’ L1’’ Figure 74 – Three terminal line application EXAMPLES Consider the TAP point located at 50% of line A-B and 50% of line C-B. Consider the names and topology of Figure Example 1: If the result of the fault location of the line A-B returns more than 50% of the length of the line and the result... -

Page 182: Figure 75 - Tw Fault Location Example 1

Chapter 9 – TW Fault Locator RPV311 Figure 75 – TW Fault Location example 1 Figure 76 - TW Fault Location example 2 RPV311-TM-EN-6... -

Page 183: Chapter 8 Pmu

CHAPTER 8... -

Page 184: Chapter Overview

Chapter 8 – PMU RPV311 CHAPTER OVERVIEW This chapter provides detailed information about the PMU feature. THIS CHAPTER CONTAINS THE FOLLOWING SECTIONS: Synchrophasor Measurement and Broadcast RPV311-TM-EN-6... -

Page 185: Synchrophasor Measurement And Broadcast

Chapter 8 – PMU RPV311 SYNCHROPHASOR MEASUREMENT AND BROADCAST Synchrophasors are measured and broadcast according to the specifications contained in IEEE C37.118, Standard for Synchrophasors for Power Systems. REPORTED VALUES The reported values are user-selectable of the list below. Reported values user-selectable Phasors Voltage synchrophasors (any phase) Current synchrophasors (any phase) -

Page 186: Accuracy Limits

Chapter 8 – PMU RPV311 ACCURACY LIMITS The Total Vector Error defined through (�� (��) − �� + (�� (��) − �� �� �� �� �� TVE = √ �� + �� �� �� Represents the magnitude of the error vector, obtained by subtracting the measured synchrophasor of the theoretical value. -

Page 187: Timestamp

Chapter 8 – PMU RPV311 Stream of data Port number 4713 4714 4715 4716 The transmission rate options at 60Hz are: 10, 12, 15, 20, 30, or 60 frames per second At 50Hz the rates are: 10, 25, or 50 frames per second. TIMESTAMP The reported timestamp is synchronized to the UTC second rollover and refers to the middle of the sampling window. -

Page 188: Wmu - Waveform Measurement Unit

Chapter 8 – PMU RPV311 WMU – WAVEFORM MEASUREMENT UNIT The WMU transmits Ethernet messages that are analogue signals calculated and sent within a PMU frame with a transmission rate equal to 4 times the system nominal frequency. The analog signal sent is a representation of a three-phase signal that is used to evaluate wide-area subcyclic oscillations. -

Page 189: Chapter 9 Modbus

MODBUS CHAPTER 9... -

Page 190: Chapter Overview

Chapter 9 – MODBUS RPV311 CHAPTER OVERVIEW This chapter provides detailed information about the MODBUS feature. .THIS CHAPTER CONTAINS THE FOLLOWING SECTIONS: Description RPV311-TM-EN-6... -

Page 191: Description

Chapter 9 – MODBUS RPV311 DESCRIPTION Status, analog and digital data are available in MODBUS registers. Access to SCADA integration is provided over Ethernet interface. Up to 8 simultaneous connections are allowed at a maximum rate of 60 accesses per second. REGISTER TYPES Each register reports 16-bit data. -

Page 192: Analog Data

Chapter 9 – MODBUS RPV311 ANALOG DATA The user must manually associate analog data to a register number. The following analog data can be selected: RMS value of voltage and current circuits (any phase); Voltage and current synchrophasors (any phase, angles are sent in degrees units); ... -

Page 193: Chapter 10 Dnp3

DNP3 CHAPTER 10... -

Page 194: Chapter Overview

Chapter 10 – DNP3 RPV311 CHAPTER OVERVIEW This chapter provides detailed information about the DNP3 feature. THIS CHAPTER CONTAINS THE FOLLOWING SECTIONS: Description RPV311-TM-EN-6... -

Page 195: Description

Chapter 10 – DNP3 RPV311 DESCRIPTION Status, analog and digital data are available in DNP3 registers. Access to SCADA integration is provided via Ethernet interface. The DNP3 functionality is fully dependent on the MODBUS functionality. To use DNP3, it is necessary for a configuration key to unlock the MODBUS functionality. Each register reports 16-bit data. -

Page 197: Chapter 11 Goose Message Detection

GOOSE MESSAGE DETECTION CHAPTER 11... -

Page 198: Chapter Overview

Chapter 11 – GOOSE Message Detection RPV311 CHAPTER OVERVIEW This chapter provides detailed information about the GOOSE message detection functionality. THIS CHAPTER CONTAINS THE FOLLOWING SECTIONS: Description RPV311-TM-EN-6... -

Page 199: Description

Chapter 11 – GOOSE Message Detection RPV311 DESCRIPTION Digital channels can be associated with physical electrical digital inputs or associated to the detection of IEC61850, GOOSE messages. GOOSE messages are captured and filtered by one of the Ethernet interfaces installed at the communications module. -

Page 201: Chapter 12 Software - Rpv Tools

SOFTWARE – RPV TOOLS CHAPTER 12... -

Page 202: Chapter Overview

Chapter 12 – RPV Tools RPV311 CHAPTER OVERVIEW This chapter provides detailed information about the features, configuration and usage of the RPV Manager software. THIS CHAPTER CONTAINS THE FOLLOWING SECTIONS: RPV Tools Description RPV311-TM-EN-6... -

Page 203: Rpv Tools Description

Chapter 12 – RPV Tools RPV311 RPV TOOLS DESCRIPTION The RPV Tools are a suite of applications to be installed on the PC and allow the communication and the transfer of records between several pieces of equipment and a PC. It also allows user to receive, manage, edit, and transmit configurations of different pieces of equipment. -

Page 204: Scanner

Chapter 12 – RPV Tools RPV311 Only the administrator of the system can install the RPV Tools. To check if the user is the administrator click > S > C > U . The computer administrator information will show TART ETTINGS ONTROL ANEL... - Page 205 Chapter 12 – RPV Tools RPV311 Scanner is accessed through an xml configuration file, where it is possible to configure a list of pieces of equipment to be scanned in each cycle, the configuration file can be saved either in a standard file (C:\RPV\scanner\conf\conf.xml) or in an alternative file, which in turn can be indicated by command line.

- Page 206 Chapter 12 – RPV Tools RPV311 Example of a configuration file with RPV: Below is the configuration of the xml file with an interval of 300 seconds between the cycles. First RPV: activated scanning, RPV 192.168.0.195, waiting time for connection of 60 seconds, scanning fault, disturbance, steady state and SOE records, no baud rate limit, automatic deletion of records, activated modem, telephone number for connection to the modem 21080 300;...

- Page 207 Chapter 12 – RPV Tools RPV311 <bandwidth>0</bandwidth> <delete>yes</delete> <modem enabled="no"> </modem> </equipment> </list> </scanner> RPV311-TM-EN-6...

- Page 208 Chapter 12 – RPV Tools RPV311 2.2.4 STARTING SCANNER There are 2 possible ways to start the Scanner: 1. Double click on the Scanner icon on the Desktop; 2. Click on Start > Programs > RPV > Scanner. The Windows security alert window may appear during the first cycle of the Scanning. Click on the <U >...

-

Page 209: Figure 77: Directory Of The Records Received Of The Equipment

Chapter 12 – RPV Tools RPV311 Figure 77: Directory of the records received of the equipment 2.2.7 LOGGING The Scanner generates a log file with all the information about the ongoing process. The log messages are available in the directory C:\RPV\scanner\log\scanner.log 2.2.8 TROUBLESHOOTING Problem... -

Page 210: Configuration Tool

Chapter 12 – RPV Tools RPV311 CONFIGURATION TOOL 2.3.1 DESCRIPTION The Configuration Tool allows creation of offline equipment configuration and sending of it to several RPV's. With this tool it is possible to make a safety backup of all the equipment configurations and either export them to a file server or keep them locally on the user's PC. - Page 211 Chapter 12 – RPV Tools RPV311 A Shows the identification and the version of the RPV Tools. B List of equipment configurations stored locally: Equipment configurations Name Configuration name defined by the user Location Shows location of the equipment. The location of the equipment is defined in the RPV configuration.

- Page 212 Chapter 12 – RPV Tools RPV311 To remove a plug-in, go to Start > Control Panel > Add or remove programs. Select the plug-in file to be removed and click on the <Remove> button. The uninstall process takes about 1 minute. 2.3.3 HOW TO USE IT To open the Configuration Tool, double click on the Conftool icon and wait while default Web browser is...

- Page 213 Chapter 12 – RPV Tools RPV311 2.3.6 IMPORTING EQUIPMENT CONFIGURATION It is possible to import a configuration previous saved on the computer. To import a configuration, the exported configuration XML file has to be first stored in the folder C:\RPV\conftool\conf and then proceed as follows: Double click Conftool icon.

-

Page 214: Tw Fault Locator

Chapter 12 – RPV Tools RPV311 Select the name of the stored configuration to be deleted and click on the <R > button; EPORT An HTML Web page will open with a list of all configuration parameters. The report consists of a header with the following information: owner, identifier, and location of the equipment, revision number, date and time of the last configuration change. - Page 215 Chapter 12 – RPV Tools RPV311 2.4.2 THE POWER LINE CONFIGURATION Before running the fault locator algorithm, it is necessary to establish the power line configuration. The basic information related to the power line must be described in an XML file with the following fields: RPV311-TM-EN-6...

- Page 216 Chapter 12 – RPV Tools RPV311 Power line file configuration <length>nnn</length> Nominal length of the line as the owner of the line claims (in kilometers) <k1>nnn<k1> Is the coefficient related to the length of the line, represents the actual length of the cable of the line.

- Page 217 Chapter 12 – RPV Tools RPV311 <terminal _ b>LOCATION,IDENTIFIER,LINE</terminal _ b> </line> Make a copy of the file and edit it with the parameters related to the power line to be monitored. Below is an example of the power line configuration: <?xml version"1.0"...

-

Page 218: Figure 79: Fault Locator Interface

Chapter 12 – RPV Tools RPV311 2.4.3 THE TRAVELING WAVE FAULT LOCATION The graphical interface must be open, double click the Fault Locator icon on the desktop. The Fault Locator interface is shown in Figure 79. Figure 79: Fault Locator Interface A Selection of the power line to be checked. - Page 219 Chapter 12 – RPV Tools RPV311 The <L > button allows user to run the fault location algorithm; OCATE The <V > button allows user to open the manual graphical tool to locate the time of the wave fronts in IEWER each terminal;...

-

Page 220: Figure 80: Graphical Tool Of Fault Locator Interface

Chapter 12 – RPV Tools RPV311 Figure 80: Graphical tool of Fault Locator interface To move the cursor with the keyboard, first click on the corresponding graph with the left mouse button and navigate the graph, as follows: Right mouse button position the cursor on the local clicked; <... -

Page 221: Goose Configurator

Chapter 12 – RPV Tools RPV311 TW Fault Locator software’s buttons The <H > button displays the graphic in the format of the initial display The <B > and <F > allow the zoom graph to navigate the front and rear positions ORWARD The <P >... -

Page 222: Figure 81: Initial Screen Of The Goose Configurator

Chapter 12 – RPV Tools RPV311 > P > A > C 1. Click S TART ROGRAMS CCESSORIES OMMAND ROMPT 2. At Prompt, access C:\RPV\ GOOSEMON CONFIG RESOURCES 3. Run the G file and the application will open. OOSEMON ONFIG The initial screen of the GOOSE Configurator application is shown in Figure 81 and has the following... - Page 223 Chapter 12 – RPV Tools RPV311 Starting a Configuration To perform a configuration, it is possible to either edit a pre-existing configuration on the equipment, create a new configuration,or open a file containing a pre-existing configuration. Receiving an equipment configuration >...

-

Page 224: Figure 82: Screen To Configuration On The Scl File

Chapter 12 – RPV Tools RPV311 Figure 82: Screen to configuration on the SCL file The <O > button is to confirm the changes in the files list. The <C > button is to cancel the changes. ANCEL The <A >... -

Page 225: Figure 83: Association Of A Goose Control Block With A Digital Input

Chapter 12 – RPV Tools RPV311 Figure 83: Association of a GOOSE Control Block with a digital input Filter parameters > F To edit the filter parameters, access T . A screen will open and show the OOLS ILTER ARAMETERS parameters that can be changed, shown in Figure 84. -

Page 226: Figure 84: Filter Parameters

Chapter 12 – RPV Tools RPV311 Figure 84: Filter parameters Transmission of the Configuration Transmitting the configuration > T To transmit the configuration to the RPV access C . A window will open for user to OMMUNICATION RANSMIT enter the RPV IP address, and then click on the <O >... - Page 227 Chapter 12 – RPV Tools RPV311 Bit set to an unknown SCL file; Item that must be selected or not; Line that contains the original SCL filename View the Configuration Files > V To view the contents of the configuration file to be sent to the equipment, access T OOLS IEW THE .

-

Page 229: Chapter 13 Software - Rpv Manager

SOFTWARE – RPV MANAGER CHAPTER 13... -

Page 230: Chapter Overview

Chapter 13 – RPV Manager RPV311 CHAPTER OVERVIEW The RPV Manager is a tool that allows data management of the equipment. THIS CHAPTER CONTAINS THE FOLLOWING SECTIONS: Requirements Software Description RPV311-TM-EN-6... -

Page 231: Requirements

Chapter 13 – RPV Manager RPV311 REQUIREMENTS The RPV Manager Installer works on Microsoft Windows and needs .NET 4 (client profile) to run. It also depends on a database engine, Sql Compact Edition 3.5. The user must have administrative rights to install the software. -

Page 232: Software Description

Chapter 13 – RPV Manager RPV311 SOFTWARE DESCRIPTION RPV MANAGER MAIN WINDOW 3.1.1 SYSTEM MONITOR Figure 85 - RPV Manager main window The software main tab is called System Monitor. All the substation and RPV311 configured in the software are listed in a tree menu on the left corner of the window. The top level of the tree shows the user created facilities and the equipment installation on the second level. -

Page 233: Figure 87: Alarms Tab

Chapter 13 – RPV Manager RPV311 The records highlighted yellow are stored only in equipment memory which can be seen each time Refresh occurs. Green highlight represents the records that have already been downloaded and then saved in the database in the respective directory including data of the equipment within the COMTRADE directory. -

Page 234: Figure 88: Configuration Tab

Chapter 13 – RPV Manager RPV311 3.1.3 CONFIGURATION The Configuration tab shows all registered equipment with their local (downloaded to the PC) and remote (loaded in the RPV311) configuration versions. Figure 88: Configuration tab The user can perform a backup or upload a saved configuration by right clicking the mouse. The background colour of each row represents different situations of settings: Red: Communication error with the equipment. -

Page 235: Rpv Manager Settings

Chapter 13 – RPV Manager RPV311 Auto Polling The procedure to activate the can be seen in the Settings Menu 3.2.2. Manual Download: Selected records Select the records required, and click the button “Get Selected”; All records Click "Get All". - Page 236 Generally, User name and Password are not required to download DFR registers. If required for the application, then type Users name and password for administrator user of the equipment (Alstom's default, user name is admin and password is 1234). The figure below shows the Device configuration window.

-

Page 237: Figure 89: Device Window

Chapter 13 – RPV Manager RPV311 Figure 89: Device window There are two parameters to be configured by the user: Enable Auto COMTRADE Download: When enabled, the unit will be part of the Auto Polling process, where records not yet saved are automatically downloaded. Enable Auto Refreshing: When enabled, the unit will be part of the process of Auto Refresh, where the equipment state will be updated automatically during the process. -

Page 238: Figure 90: Current Circuit Name

Chapter 13 – RPV Manager RPV311 In order to add and edit a transmission line, the user must: 1. Select the installation A at one terminal of the line; 2. Select the device A that is monitoring the line in installation A; 3. -

Page 239: Figure 91: Terminal Name Configuration

Chapter 13 – RPV Manager RPV311 Figure 91: Terminal name configuration 8. Finally, enter the name of the transmission line. Contacts This menu configures the contacts to which the RPV can send emails notifications. On this window the user can view the list of registered contacts, add, edit, or remove any contact. During the removal of any contact, if any association with any warning, a confirmation message will be displayed to the user. - Page 240 Chapter 13 – RPV Manager RPV311 In the automatic mode, the software will download the registers and refresh the COMTRADE list automatically according the parameters set on the Configuration>Polling menu. Also, each device has to have those option enabled on the Settings>Device menu. 3.2.4 TOOLS MENU In the Tools menu, the user can:...

- Page 241 Chapter 13 – RPV Manager RPV311 In this option user can use filters to search for specific downloaded records of a selected DFR. The search can be made taking into account: Selection of one or more equipment; Period start and/or end of the occurrence of the registry; ...

-

Page 242: Figure 92: Percentage Of Records Chart