Mitsubishi Electric PEFY-WP20VMA-E Technical & Service Manual

Hide thumbs

Also See for PEFY-WP20VMA-E:

- Operation manual (204 pages) ,

- Data book (28 pages) ,

- Technical & service manual (38 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Operating Manual

Advertisement

Table of Contents

Summary of Contents for Mitsubishi Electric PEFY-WP20VMA-E

- Page 1 AIR CONDITIONERS 2012 TECHNICAL & SERVICE MANUAL Model name PEFY-WP20VMA-E PEFY-WP25VMA-E PEFY-WP32VMA-E PEFY-WP40VMA-E PEFY-WP50VMA-E...

-

Page 3: Safety Precautions

It may also be in violation of applicable laws. Only use accessories (i.e., air cleaners, humidifiers, electric MITSUBISHI ELECTRIC CORPORATION cannot be held heaters) recommended by Mitsubishi Electric. responsible for malfunctions or accidents resulting from the use of the wrong type of refrigerant. - Page 4 Mitsubishi Electric may result in smoke, fire, or explosion. Only use the type of water that is indicated on the unit when installing or relocating the unit.

-

Page 5: Table Of Contents

CONTENTS I Features [1] Features............................ 1 II Components and Functions [1] Components and Functions...................... 2 III Specifications [1] Specifications..........................4 1.Specifications.......................... 4 2.Electrical component specifications..................6 IV Outlines and Dimensions [1] Outlines and Dimensions......................7 V Wiring Diagram [1] Wiring Diagram ......................... 8 VI Refrigerant System Diagram [1] Refrigerant system diagram.................... - Page 6 HWE1114A...

-

Page 7: I Features [1] Features

[ I Features ] I Features [1] Features Model Cooling capacity/Heating capacity PEFY-WP20VMA-E 2.2/2.5 PEFY-WP25VMA-E 2.8/3.2 PEFY-WP32VMA-E 3.6/4.0 PEFY-WP40VMA-E 4.5/5.0 PEFY-WP50VMA-E 5.6/6.3 HWE1114A - 1 -... -

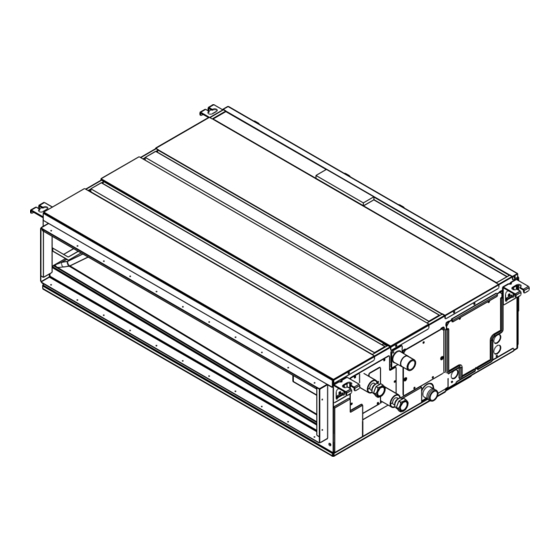

Page 8: Components And Functions

[ II Components and Functions ] II Components and Functions [1] Components and Functions 1. Indoor (Main) Unit (1) In case of rear inlet (2) In case of bottom inlet Air inlet Air inlet Air outlet Air outlet 2. Remote Controller [PAR-21MAA] Once the operation mode is selected, the unit will remain in the selected mode until changed. - Page 9 [ II Components and Functions ] (2) Remote Controller Display Current time/Timer time Louver swing Centralized control indicator Ventilation Timer OFF indicator Filter sign Timer mode indicator Sensor position Operation mode display: COOL, DRY, AUTO, Room temperature FAN, HEAT Function mode indicator Vane setting Preset temperature Fan speed...

-

Page 10: Specifications

[ III Specifications ] III Specifications [1] Specifications 1. Specifications Model PEFY-WP20VMA-E PEFY-WP25VMA-E Power supply Voltage 1-phase 220-230-240 Frequency 50/60 Cooling capacity Heating capacity Power consumption Cooling 0.07 0.09 Heating 0.05 0.07 Current consumption Cooling 0.55 0.64 Heating 0.44 0.53... - Page 11 [ III Specifications ] Model PEFY- PEFY- PEFY- WP32VMA-E WP40VMA-E WP50VMA-E Power supply Voltage 1-phase 220-230-240 Frequency 50/60 Cooling capacity Heating capacity Power consumption Cooling 0.11 0.14 0.14 Heating 0.09 0.12 0.12 Current consumption Cooling 0.74 1.15 1.15 Heating 0.63 1.04 1.04 External finish...

-

Page 12: Electrical Component Specifications

[ III Specifications ] 2. Electrical component specifications Component Sym- PEFY-WP20VMA-E Room temperature TH21 Resistance 0°C/15kŸ, 10°C/9.6kŸ, 20°C/6.3kŸ, 25°C/5.4kŸ, 30°C/4.3kŸ, 40°C/3.0kŸ thermistor Water inlet pipe TH22 Resistance 0°C/15kŸ, 10°C/9.6kŸ, 20°C/6.3kŸ, 25°C/5.4kŸ, 30°C/4.3kŸ, 40°C/3.0kŸ thermistor Water outlet pipe TH23 Resistance 0°C/15kŸ, 10°C/9.6kŸ, 20°C/6.3kŸ, 25°C/5.4kŸ, 30°C/4.3kŸ, 40°C/3.0kŸ... -

Page 13: Outlines And Dimensions

[ IV Outlines and Dimensions ] IV Outlines and Dimensions [1] Outlines and Dimensions 1. PEFY-WP20, 25, 32, 40, 50VMA-E Space required for service and maintenance. Provide an access door for maintenance at the bottom. Note 1 Use M10 suspension bolts. (not supplied) 2 Provide an access door for maintenance at the bottom. -

Page 14: Wiring Diagram

[ V Wiring Diagram ] V Wiring Diagram [1] Wiring Diagram 1. PEFY-WP20, 25, 32, 40, 50VMA-E HWE1114A - 8 -... - Page 15 [ V Wiring Diagram ] Table.1 SYMBOL EXPLANATION SYM- NAME SYM- NAME SYM- NAME I.B. Indoor controller board CN32 Connector (Remote switch) Switch (for capacity code) (I.B.) P.B. Power supply board CN41 Connector (HA terminal-A) Switch (for mode selection) (I.B.) Power source terminal block CN51 Connector (Centrally control)

-

Page 16: Refrigerant System Diagram

[ VI Refrigerant System Diagram ] VI Refrigerant System Diagram [1] Refrigerant system diagram Water outlet thermistor TH23 Water outlet Water inlet Screw connections Water inlet thermistor TH22 Heat exchanger Manual air purge valve Room temperature thermistor TH21 Capacity PEFY-WP20, 25, 32, 40, 50VMA-E Water outlet Rc3/4 screw Water inlet... -

Page 17: Troubleshooting

[ VII Troubleshooting ] VII Troubleshooting [1] Troubleshooting 1. Check methods 1. Component and check points (1) Thermistor ŒRoom temperature thermistor (TH21) ŒWater inlet thermistor (TH22) ŒWater outlet thermistor (TH23) Disconnect the connector and measure the resistance between terminals with a volt meter. (Ambient temperature 10°C - 30°C) Normal Abnormal... - Page 18 [ VII Troubleshooting ] (4) Drain float switch (CN4F) Disconnect the connector, and measure the resistance between terminals with a volt meter. Moving part Switch Magnet Position of the moving part Normal Abnormal Short (any position but short) Down Open (any position but open) HWE1114A - 12 -...

-

Page 19: Dc Fan Motor (Fan Motor/Indoor Control Board)

[ VII Troubleshooting ] 2. DC fan motor (fan motor/indoor control board) 1. CAUTION ŒA high voltage is applied to the connector for connection to the fan motor (CNMF). ŒDo not unplug the connector CNMF with the unit energized to avoid damage to the indoor control board and fan motor. 2. -

Page 20: Address Switch Setting

[ VII Troubleshooting ] 3. Address switch setting Make sure that power to the unit is turned off. Indoor unit control board Factory setting (all models) 1. When using an ME remote controller, set the address with the rotary switches (SW11, SW12). ŒAddress setting is not required when the unit remote controller is used. -

Page 21: Voltage Test Points On The Control Board

[ VII Troubleshooting ] 4. Voltage test points on the control board 1. PEFY-WP20, 25, 32, 40, 50VMA-E Fuse(AC 250V 6.3A) Power supply voltage (220 - CN2M 240VAC) CN2M For M-NET transmission cable connection (24 - 30VDC) Emergency operation Capacity setting CN41 CN3A Function setting... -

Page 22: Dipswitch Setting (Factory Setting)

[ VII Troubleshooting ] 5. Dipswitch setting (Factory setting) 1. Function setting (1) SW1 Switch position Function Switch setting Active Thermistor (Intake air Built-in thermistor on the remote Indoor unit thermistor) controller Filter clogging detection Available Unavailable Filter life 2500 hr 100 hr Outdoor air intake Enabled... - Page 23 2. Capacity code setting (1) SW2 1) Indoor control board Dipswitch settings must be made while the unit is stopped. Factory setting The switches are set to correspond to the unit capacity. PEFY-WP20VMA-E PEFY-WP25VMA-E PEFY-WP32VMA-E PEFY-WP40VMA-E PEFY-WP50VMA-E 3. Model setting...

- Page 24 [ VII Troubleshooting ] 5. External static pressure (1) SWA, SWC 1) Indoor control board All models Factory 35Pa 50Pa 70Pa 100Pa 150Pa setting SWA SWC Note: Changes that are made to the dipswitches SWA and SWC immediately become effective regardless of the unit's operation status (RUN/STOP) or the remote controller status (ON/OFF).

-

Page 25: Disassembly Procedure

[ VIII Disassembly Procedure ] VIII Disassembly Procedure [1] Disassembly Procedure 1. Control box Exercise caution when removing heavy parts. 1. Removing the control box cover (1) Remove the three fixing screws on the cover (A) to re- move it. Fig.1 Fig.2 HWE1114A... -

Page 26: Thermistor (Intake Air)

[ VIII Disassembly Procedure ] 2. Thermistor (Intake air) Exercise caution when removing heavy parts. 1. Remove the control box cover according to the procedure in section 1. 2. Remove the thermistor. (1) Pull out the thermistor holder (B) and thermistor (C) on the control box. -

Page 27: Drainpan

[ VIII Disassembly Procedure ] 3. Drainpan Exercise caution when removing heavy parts. 1. Removing the filter and the bottom plate (1) Push down the tab on the filter, and pull out the filter in the direction of the arrow 1. (2) Remove the fixing screws on the bottom plate (D), (E) to remove it. -

Page 28: Thermistor (Water Outlet) (Water Inlet)

[ VIII Disassembly Procedure ] 4. Thermistor (Water outlet) (Water inlet) Exercise caution when removing heavy parts. 1. Remove the drain pan according to the procedure in sec- tion 3. 2. Removing the Heat exchanger cover (1) Remove the four fixing screws on the heat exchanger cov- er (F) to remove it. -

Page 29: Fan And Fan Motor

[ VIII Disassembly Procedure ] 5. Fan and fan motor Exercise caution when removing heavy parts. 1. Removing the filter and the bottom plate (1) Push down the tab on the filter, and pull out the filter in the direction of the arrow 1. (2) Remove the fixing screws on the bottom plate (J) to re- move it. -

Page 30: Heat Exchanger

[ VIII Disassembly Procedure ] 6. Heat exchanger Exercise caution when removing heavy parts. 1. Remove the drain pan according to the procedure in section 2. Remove the heat exchanger cover according to the proce- dure in section 4. 2. 3. - Page 32 New publication effective Mar. 2012 Specifications subject to change without notice HWE1114A...

Need help?

Do you have a question about the PEFY-WP20VMA-E and is the answer not in the manual?

Questions and answers