Summary of Contents for Duplo DF-520

- Page 1 Duplo Folder Instruction Manual [230V] Please let our service people install the machine.

- Page 2 FEATURES OF DUPLO FOLDER 1. Easy to Use 4. Standard Folding of Non-standard size Paper Can be Carried Out Easily • Automatic detection of paper size (A3 to B6). by Inputting Their Size on the • A one touch function automatically returns the folding Keypad.

-

Page 3: Table Of Contents

INTRODUCTION Thank you for your purchase. To ensure correct usage, please read this instruction manual thoroughly, especially the section Safety Precautions. After reading, please store this instruction manual in a safe place for future reference. CONTENTS 1. SAFETY PRECAUTIONS ...... 2 9. -

Page 4: Safety Precautions

1. SAFETY PRECAUTIONS Always observe the cautions and warnings explained below to prevent personal injury or property damage. The degree of danger and damage that could occur is indicated in two levels by the following marks. WARNING: Ignoring this mark could result in the possibility of serious injury or even death. - Page 5 Do not use flammable sprays inside or near the unit (e.g. when cleaning the unit). Such flammable gas can be ignited and cause a fire or combustion. Make sure that the current consumption listed on the main nameplate does not exceed capacity rating of the power outlet and do not connect other equipment to this same power outlet.

-

Page 6: Usage Precautions

2. USAGE PRECAUTIONS 2-1. POWER SUPPLY Make sure the power supply used is always within the following range. + 6% 230V AC , 50Hz -10% Plug the power cord plug directly into a wall power outlet. 2-2. OPERATING ENVIRONMENT Operate this unit in the following environment. •... -

Page 7: Installing The Unit

3. INSTALLING THE UNIT The customer should never install the machine. Please be sure to ask your dealer for installation. 3-1. BEFORE INSTALLATION • Turn the power of this unit off, and disconnect the power cord from the power outlet. •... -

Page 8: Component Parts

3. INSTALLING THE UNIT 3-4. COMPONENT PARTS After checking that you have following parts, attach them to the unit. Duplo Folder Instruction Manual Please let our service people install the machine. DUPLO CORPORATION Name Qty. Name Qty. Cross folding lever... -

Page 9: Removing The Press Release Lever

3. INSTALLING THE UNIT 3-5. REMOVING THE PRESS RELEASE LEVER This press release level is attached to the unit at shipment to prevent the rubber roll from becoming distorted. Be sure to remove it when installing the unit. Take note that the unit will be damaged if it is used without removing the lever. Remember to remove it in the following order when installing the unit. -

Page 10: Attaching The Parts

3. INSTALLING THE UNIT 3-6. ATTACHING THE PARTS First, attach the second folding plate. • Before starting, push the lock lever at the side of Lock lever the folding plate to “UNLOCK”. • Next, insert the folding plate into the unit. •... - Page 11 3. INSTALLING THE UNIT Attach the cross folding lever at its proper place. Cross folding lever <Parts Used> Cross folding lever ..........1 Note: • The unit has a built-in battery to protect the different types of data memorized. • This battery must be charged when installing the unit for the first time.

-

Page 12: Names Of The Parts

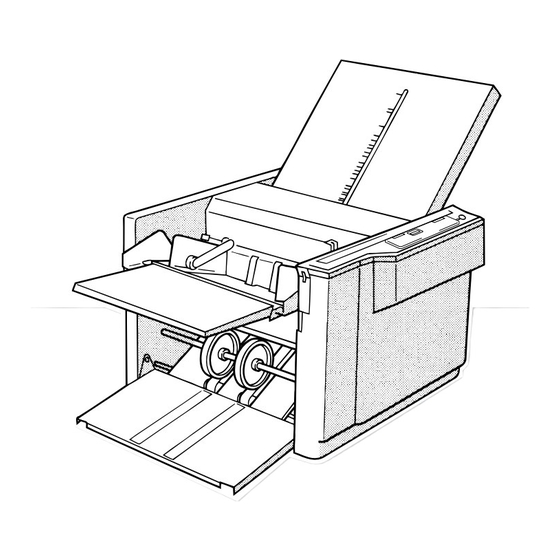

4. NAMES OF THE PARTS Jam correction handle Rubber roll Paper feed ring (For moving) Set knob First folding plate Top cove Control panel Paper feed tray Cross folding lever Paper feed pressure adjustment lever Guide Second folding plate Auxiliary paper feed plate Stacker roller Power switch... -

Page 13: Names And Functions Of The Control Panel Parts

5. NAMES AND FUNCTIONS OF THE CONTROL PANEL PARTS bo bn blbk 4 3 2 Name Function Start/stop button Starts/stops folding. Each time this button is pressed, start/stop is repeated alternately. Test button Each time this button is pressed, the unit folds two sheets of paper and stops. Number of sheets/ Sets the number of sheets to be folded and switches the input of the paper length. - Page 14 5. NAMES AND FUNCTIONS OF THE CONTROL PANEL PARTS Name Function Custom folding This button is used to memorize the position where the folding stopper and stacker preset button stop. When moved in custom folding modes such as cross folding, non-standard folding, etc.

-

Page 15: Precautions Before Use

6. PRECAUTIONS BEFORE USE 6-1. PAPER TO BE USED • Straighten folded or curled paper before use. • Make sure that the ink on the paper has dried up properly before use. If the ink has not dried properly, it may dirty the machine, and cause other problems such as dirtying the folded surface with ink, etc. - Page 16 6. PRECAUTIONS BEFORE USE • If the paper is not stacked properly lengthwise, mis-feed or chain feed may occur. • When stacking just a few sheets of paper on the paper Guide plate Paper feed tray, lower the paper set lever while pressing the back edge of the paper.

-

Page 17: Operation Procedures

7. OPERATION PROCEDURES 7-1. STANDARD FOLDING OF STANDARD SIZE PAPER Start the various standard folding operations for standard size paper as follows. Insert the power cord in the electrical outlet and turn on the power. • Press “I” to turn on the power. •... - Page 18 7. OPERATION PROCEDURES Press the “folding mode select” button and select the desired fold mode. • When the right “folding mode select” button is pressed, the lamp on the right of that currently lit will light up. • When the left one is pressed, the lamp on the left of that currently lit will light up.

- Page 19 7. OPERATION PROCEDURES Adjust the paper feed pressure Paper feed pressure adjustment lever adjustment lever to “0”. • If the paper slips and no paper is fed, raise the paper feed pressure one level from 0 to 1. • If several sheets of paper are fed at one time, lower the paper feed pressure one level from 0 to –1.

- Page 20 7. OPERATION PROCEDURES Press the “test” button and perform test folding. • Two sheets of paper will be folded. Even after two folded sheets of paper have been ejected, the machine will not stop working when the stop button is pressed until the buzzer sounds and the motor inside stops completely.

- Page 21 7. OPERATION PROCEDURES Check the folded paper for testing. • Proceed onto the next step if the sheets of paper have been folded satisfactorily. Check the second ejected paper to confirm that folding is performed correctly. Paper for testing folding •...

- Page 22 7. OPERATION PROCEDURES Input the number of sheets to be folded on the number buttons. • Press the number buttons and input/set the number of sheets to be processed. • When this is input, the counter decrease. • If this is not input, the counter increases. After completing all preparations, start operation.

-

Page 23: Single Folding Thick Paper

7. OPERATION PROCEDURES 7-2. SINGLE FOLDING THICK PAPER When single folding cardboard paper and Corner fine quality thick paper (157 g/m ), the corners and center of the folded part of the paper may bend due to conditions such as the using environment (terperature, humidity), paper size, fiber direction of the paper, etc. -

Page 24: Double Folding Thick Paper

7. OPERATION PROCEDURES 7-3. DOUBLE FOLDING THICK PAPER • When thick paper (above 105 g/m ) such as fine quality paper, double folding, its thickness may cause its folds to open when it is ejected to the stacker. As a result, the paper will not be able to pass through the stacker rolls and paper jam will occur. - Page 25 7. OPERATION PROCEDURES • While lifting up the stacker rolls with your hand, Stacer roller pull the levers (left and right) attached to the Lever Stacer lever stacker lever in the direction of the arrow, and adjust so that the stacker rolls are above the belt. Belt Set the folding mode to “Double fold”.

- Page 26 7. OPERATION PROCEDURES If there is folding slippage, adjust the stopping position of the folding stopper with the adjustment button of folding plate 1 or 2. After completing all adjustments, press “custom folding” preset 1 or 2 and memorize this custom folding method. Note : If a custom folding method had been memorized before, memorize the new method will erase the previous data.

-

Page 27: Custom Folding Of Standard Size Paper

7. OPERATION PROCEDURES After the operations have completed, be Stacker rollers Lever sure to lower the left and right levers Belts attached to the stacker lever in the direction of the arrow. If the stacker rolls are left lifted up, Stacker lever problems will occur when “folding mode”... - Page 28 7. OPERATION PROCEDURES For measurement A, press “first folding stopper” adjustment button and move the folding stopper of the first folding plate corresponding position. • For measurement B, press the “second folding stopper” adjustment button and move the folding stopper of the second folding plate to the corresponding position.

- Page 29 7. OPERATION PROCEDURES Number Length of Paper Fold Folding Mode 40—91 mm B6: Single Fold, Double Fold, Letter Fold, Accordion Fold, Irregular Accordion Fold, Letter Fold A5: Double Fold, Letter Fold, Accordion Fold B5: Double Fold, Letter Fold, Accordion Fold A4: Double Fold B4: Double Fold 91—105 mm...

- Page 30 7. OPERATION PROCEDURES If there is folding slippage, adjust the stop position of the folding stopper. • Press either the “first folding stopper adjustment” or “second folding stopper adjustment” button to adjust the stop position of the folding stopper. If the paper is not ejected smoothly, adjust the stopping position of the stacker rollers properly.

- Page 31 7. OPERATION PROCEDURES After completing all adjustments, press “custom folding” preset 1 or 2 button. • When preset button 1 is pressed, the folding method will be memorized in custom folding mode • When preset button 2 is pressed, the felding made it will be memorized in custom folding mode •...

-

Page 32: Calling The Memory

7. OPERATION PROCEDURES 7-5. CALLING THE MEMORY • When folding is to be carried out using the data that was memorized during the custom folding process, press the “folding mode select” button and select the memorized custom folding mode, 1 or 2. •... - Page 33 7. OPERATION PROCEDURES 2 Measure the length of the paper to be used, and input its length using the number buttons. • If the measurements previously registered and currently being displayed are not to be used, press the “clear” button, erase these measurements, and input the desired measurements.

-

Page 34: Folding Adjustments And Memorize Corrections

8. FOLDING ADJUSTMENTS AND MEMORIZE CORRECTIONS 8-1. ADJUSTING THE FOLDING SLIPPAGE IN THE VERTICAL DIRECTION To adjust the folding slippage in the vertical direction, press the “folding stopper adjustment” button. Folding Plate 1 Folding Style Fold Surface A Adjustment Adjustment Button When A Press the left button is longer... - Page 35 8. FOLDING ADJUSTMENTS AND MEMORIZE CORRECTIONS Folding Plate 2 Folding Style Fold Surface B Adjustment Adjustment Button When B Press the left button is longer Double Fold When B Press the right button is shorter When B Press the left button is longer Irregular Accordion Fold...

-

Page 36: Memorize The Folding Stopper Correction

8. FOLDING ADJUSTMENTS AND MEMORIZE CORRECTIONS 8-2. MEMORIZE THE FOLDING STOPPER CORRECTION Use this correction memory function to memorize the position of the folding stopper after adjusting the folding slippage in the vertical direction. This function is extremely useful when folding the same type of paper (size, type, thickness) at the same folding speed. - Page 37 8. FOLDING ADJUSTMENTS AND MEMORIZE CORRECTIONS After adjusting folding slippage, continue pressing the “standard folding adjustment” button until the buzzer (pi, pi, pi) sounds. • When the value of the folding stopper correction is memorized, the display lamp of the specified folding mode will start blinking.

-

Page 38: Adjustment The Folding Slippage In The Horizontal Direction

8. FOLDING ADJUSTMENTS AND REGISTERING CORRECTIONS 8-3. ADJUSTING THE FOLDING SLIPPAGE IN THE HORIZONTAL DIRECTION • If folding slips as shown in the figure because the paper is not cut straight, rotate the “slant correction” knob to adjust the folding slippage. Rotate the “slant adjustment”... -

Page 39: Using Art/Coated Paper

9. USING ART/COATED PAPER • Art/coated paper are difficult to fold as their printed surfaces tend to stick together easily and cause double feeding. • When folding such a kind of paper, observe the following precautions before starting folding operations. 9-1. -

Page 40: Operating Precautions

9. USING ART/COATED PAPER 9-2. OPERATING PRECAUTIONS If double-feed occurs frequently and Guide Paper cannot be corrected, reduce the amount of paper on the paper feed tray until the middle of the guide (approx. 25mm) As the specific gravity of this type of paper is higher than that of normal paper, they tend to stick together, causing double-feeding to occur frequently. - Page 41 9. USING ART/COATED PAPER If the paper is not folded properly, adjust the speed control to a slower speed. When paper is folded at a high speed, as the front edges of the paper cannot reach the folding stopper due to various conditions such as environmental conditions (temperature, humidity), paper size, thickness of paper, paper couch conditions, and printed surface...

-

Page 42: Using Non-Standard Paper Size

10. USING NON-STANDARD PAPER SIZE 10-1. STANDARD FOLDING PROCEDURE Start standard folding operations for non-standard size paper according to the following procedure. Press the “Number of sheets/paper length” button and set the paper length input mode. • When the paper length input mode is set, the “paper size”... - Page 43 10. USING NON-STANDARD PAPER SIZE Memorize the paper length input. • Continue pressing the “Number of sheets/paper length” button until the buzzer sounds. • The “paper size” and “Number of sheets/paper length” display windows will switch to the paper length folding mode display shown in the figure. The paper length memorized will be kept even after the power is turned off.

-

Page 44: Custom Folding Procedures

10. CUSTOM FOLDING PROCEDURES 10-2. CUSTOM FOLDING PROCEDURES Press the “Number of sheets/paper length” button and set the paper length input mode. • When the paper length input mode is set, the “paper size” and “Number of sheets/paper length” display windows will display as shown in the figure. - Page 45 10. CUSTOM FOLDING PROCEDURES Fold the paper as desired and measure the folded paper. Adjust the Accordion fold position of the folding stopper of the folding plate accordingly. • The figure on the right shows an example of an accordion fold. •...

- Page 46 10. CUSTOM FOLDING PROCEDURES • The stop position of the stacker rollers depends on the length of the paper fold. Refer to the following table “Stacker Roller Positions” when pressing the keys on the number buttons. Stacker roller Number Length of Paper Fold Folding Mode 40—91 mm B6: Single Fold, Double Fold, Letter Fold, Accordion Fold, Irregular...

- Page 47 10. CUSTOM FOLDING PROCEDURES Press the “test” button and carry out test folding. • Check the fold of the paper. If there is folding slippage, adjust the stop position of the folding stopper. • Press either the “first folding” or “second folding” Folding stopper adjustment button adjustment button to adjust the stop position of the folding stopper.

- Page 48 10. CUSTOM FOLDING PROCEDURES After completing all adjustments, continue pressing “custom folding” preset 1 or 2 button until the buzzer (pi, pi, pi) sounds. • This completes the memory of custom folding. Once the values have been memorized, they will be kept even after the power is turned off.

-

Page 49: Cross Folding

11. CROSS FOLDING • As shown in the figure, cross folding Folded Cross single means folding paper already folded into folding two parts into twos again, threes, or in other ways. Cross letter • Paper can be cross folded into various folding shapes depending on use. -

Page 50: Cross Folding Standard Size Paper

11. CROSS FOLDING 11-2. CROSS FOLDING STANDARD SIZE PAPER • The following describes the cross folding shown in the figure and the procedures for it. • Start cross folding according to the following procedures. Set the “single fold” mode first and fold the paper into two. - Page 51 11. CROSS FOLDING Open the top cover and move the Paper feed ring(For moving) paper feed ring at the far end to the folded edge of the paper. • Loosen the set screw and move the paper feed ring. • After moving the paper feed ring, tighten the set screw properly.

-

Page 52: Cross Folding Non-Standard Paper Size

11. CROSS FOLDING Adjust the paper feed pressure Paper feed pressure adjustment lever adjusting lever to “3”. • When the paper slips or non-feed occurs, raise the paper feed pressure one level at a time until the optimum paper feed pressure is obtained. Set the paper feed pressure within the range of 3 to 6. - Page 53 11. CROSS FOLDING Next, set the single fold mode and perform test folding. • Make sure that the paper has been folded properly. Press the number buttons to input the number of sheets to be folded, and start single folding. If the number of sheets to be folded is 520 sheets for example, press the number buttons to input this value.

- Page 54 11. CROSS FOLDING Measure the length of the paper that has been folded into two, and input this value again. If the length is 180mm for example, input this value on the number buttons. Memorize the paper length input. • Continue pressing the “Number of sheets/paper length”...

-

Page 55: Troubleshooting

12. TROUBLESHOOTING Press the number buttons to input the number of sheets to be folded. Next start folding operations. • Paper will be folded according to the procedures described above. For details of other procedures, refer to “Operation Procedures” on page 15. When using standard size paper, press the “Number of sheets/paper length”... -

Page 56: Paper Is Slipped Near The Paper Feed Section

12. TROUBLESHOOTING 12-2. PAPER IS SLIPPED NEAR THE PAPER FEED SECTION The “Number of sheets/paper length” display window will show “ ”. Increase the paper feed pressure. Paper feed pressure adjusting lever • Raise the paper feed pressure adjusting lever one level at a time. -

Page 57: Paper Is Jammed At The First Folding Plate

12. TROUBLESHOOTING 12-4. PAPER IS JAMMED AT THE FIRST FOLDING PLATE The “Number of sheets/paper length” display window will show “ ”. Turn off the power and disconnect control cord 1. Control cord 1 Be sure to turn off the power first when inserting and disconnecting the control cord or the unit will be damaged. -

Page 58: Paper Is Jammed At The Second Folding Plate

12. TROUBLESHOOTING After removing the paper, return the folding plate and top cover to the unit. Lock lever Lock the folding plate and insert control cord 1. Top cover Check that the folding plate has been set correctly. Always remove and return folding plates with First both hands. - Page 59 12. TROUBLESHOOTING Pull the jammed paper towards you to remove. After completing operations, slide the Slider Control cord 2 folding plate along the slider and return it to its original position. Lock lever Make sure that the folding plate has been set correctly.

-

Page 60: Paper Is Jammed Near The Stacker

12. TROUBLESHOOTING 12-6. PAPER IS JAMMED NEAR THE STACKER The “Number of sheets/paper length” display window will show “ ”. Pull the jammed paper in the stacker section towards you to remove. Paper receiving tray... -

Page 61: Emergency Stops

13. EMERGENCY STOPS An emergency stop device to ensure safety has been, or first folding plates and second forlding plates installed to the top cover of this unit. Take note that this emergency stop device will function as follows. If the top cover is open while the unit Top cover is operating, the “Number of sheets/ paper length”... -

Page 62: Error Messages

14. ERROR MESSAGES • This unit has a self-diagnosing function which will display the following error messages when problems arise while the unit is operating. • When error messages are displayed, refer to the following countermeasures. Display Check Correct No paper on the paper feed tray. Set a sheets. - Page 63 14. ERROR MESSAGES Display Check Correct Turn off the power and correct the First folding plate motor has cause of the lock. locked due to overload. Contact your serviceman. Isn't the control cord for first Turn OFF the power and insert the control cord in the connector.

-

Page 64: Trouble Shooting Guide

15. TROUBLE SHOOTING GUIDE Problem Check Correct (1) The unit does not start when 1 Is there paper on the paper • Set a sheets. feed plate? the start button is pressed. 2 Does the paper feed plate • Lower the paper set lever and face down? set the paper feed plate so that it faces up. - Page 65 15. TROUBLE SHOOTING GUIDE Problem Check Correct 1 Is the paper feed pressure too • Lower the paper feed pressure (5) Double feed occurs frequently. high? gradually until the optimum pressure is obtained. 2 Is the separator pressure too • Raise the separator pressure low? gradually until the optimum...

- Page 66 15. TROUBLE SHOOTING GUIDE Problem Check Correct (8) When paper slips in the • Adjust each folding stopper vertical direction. finely. 1 Was the speed changed • Use the original speed. halfway? Adjust each folding stopper finely again. 2 Was the paper type (quality, •...

-

Page 67: Cleaning The Unit

16. CLEANING THE UNIT • As paper shreds, ink of printed paper on the rubber roll and paper feed ring will cause problems, clean these parts according to the following procedures. • To ensure safety, always turn off the power of the unit first before cleaning. 16-1. -

Page 68: Cleaning The Paper Feed Ring

16. CLEANING THE UNIT 16-2. CLEANING THE PAPER FEED RING Open the top cover. Top cover While rotating the paper feed ring in the direction of the arrow with your hand, clean it with a cloth moistened Paper feed ring with neutral detergent or alcohol, etc. -

Page 69: Specifications

17. SPECIFICATIONS Model Type Office use, desktop Max. 297 (W) x 432 (L) mm Paper size that can be folded Min. 128 (W) x 182 (L) mm Rough paper, fine quality paper, stencil paper, recycled paper, Paper quality drawing paper, thick paper art/coated paper Single fold, double fold, irregular accordion fold, letter fold, accordion fold, brochure fold, special cross fold (paper thickness: Folding mode... - Page 70 96V-92014-98110025S-1 This manual is printed on recycled paper to help protect the environment.

Need help?

Do you have a question about the DF-520 and is the answer not in the manual?

Questions and answers