Table of Contents

Advertisement

Quick Links

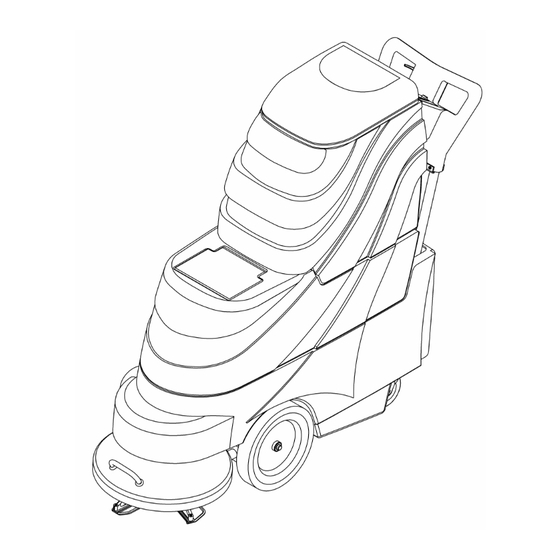

Express Multi Surface

Carpet and Upholstery Cleaner

Model No.:

Operator and Parts Manual

100-041-017

12 gal Multi Surface Cleaner

CLEANMASTER

TH

11015 47

AVENUE WEST

MUKILTEO WA 98275 U.S.A.

FAX: 1-800-426-4225

MNL50005

Website: http://www.cleanmaster.com

CUSTOMER SERVICE: 1-425-775-7276

Rev. 00 (02-03)

Advertisement

Table of Contents

Summary of Contents for CleanMaster 100-041-017

- Page 1 Express Multi Surface Carpet and Upholstery Cleaner Model No.: Operator and Parts Manual 100-041-017 12 gal Multi Surface Cleaner CLEANMASTER 11015 47 AVENUE WEST MUKILTEO WA 98275 U.S.A. FAX: 1-800-426-4225 MNL50005 Website: http://www.cleanmaster.com CUSTOMER SERVICE: 1-425-775-7276 Rev. 00 (02-03)

-

Page 2: Table Of Contents

© CleanMaster Printed in U.S.A. distributor. CleanMaster is a registered United States trademark This machine will provide excellent service. However, the best results will be obtained at minimum costs if: BEFORE STARTING The machine is operated with reasonable care. -

Page 3: Safety Precautions

OPERATION 4. Before leaving or servicing machine: SAFETY PRECAUTIONS Turn off machine. – Unplug cord from wall outlet. – 5. When servicing machine: This machine is intended for commercial use. It is designed to wet clean carpet and upholstery in an –... -

Page 4: Machine Components

OPERATION MACHINE COMPONENTS 1. Recovery Tank 6. Power Cord Connector 2. Solution Tank 7. Solution Tank Coupler to Base 3. Recovery Tank Lid 8. Squeegee connection loop 4. Solution Tank Lid 9. Recove ry Tank Drain 5. Star Assembly 10. Solution Hose Connector MACHINE SETUP 1. -

Page 5: Machine Operation

OPERATION ATTENTION: If using powdered cleaning CLEANING CARPETS WITH WAND chemicals, mix prior to adding to solution tank. 1. Turn on the vacuum switch. Next, activate the NOTE: Prespraying carpet prior to cleaning will pump by turning on the “Continuous Spray” enhance the overall cleaning results. - Page 6 OPERATION MACHINE OPERATION - ROTARY CONTROLS There are three switches installed in the dash panel located on the main handle assembly. Place vacuum switch in the on position. Next, turn on “Power Head”. For solution output, activate either the “Continuous Fig 9 Turning the knob clockwise increases the amount of tilt.

-

Page 7: Draining Tanks

OPERATION 3. Rinse tank with clean water and empty at the end CLEANING WITH ACCESSORY TOOLS of the day. 1. Attach solution and vacuum hose as described in FOR SAFETY: Remove all water from machine the “Machine Operation – Wand” section of this before trying to lift it. -

Page 8: Machine Maintenance

OPERATION gearbox shaft, if not removed, may damage the MACHINE MAINTENANCE gearbox oil seal resulting in loss of oil in the gearbox. If the gearbox is operated without oil, severe damage may occur. (This requires To keep machine in good working condition, simply removing the cleaning head. - Page 9 OPERATION step by step instructions on removing the WEEKLY MAINTENANCE cleaning head and seal, refer to the “Repair (Every 20 Hours of Operation) Guide” section of this manual.) Always keep a 1. Inspect vacuum hoses for holes and loose cuffs. spare felt seal soaking in 30 weight oil.

-

Page 10: Storing Machine

OPERATION QUARTERLY MAINTENANCE STORING MACHINE (Every 250 hours of Operation) Check vacuum motor for carbon brush wear. Replace 1. Before storing machine, be certain to drain and motor if worn to a length of 10mm (0.38”) or less. rinse tanks of all water. 2. -

Page 11: Trouble Shooting

OPERATION TROUBLE SHOOTING PROBLEM CAUSE SOLUTION Machine does not operate. Faulty switches or wiring. Contact Service Center. Faulty power cord. Contact Service Center. Building circuit breaker tripped. Reset Breaker. Solution pump does not operate. Faulty switch or wiring. Contact Service Center. Vacuum switch not turned on. -

Page 12: Specifications

OPERATION SPECIFICATIONS Model EXPRESS MULTI SURFACE CLEANER LENGTH 1308 mm (51.5 in) WIDTH 406 mm (16 in) HEIGHT 1047.7 mm (41.25 in) WEIGHT 71.6 Kg (158lbs) SOLUTION TANK CAPACITY 45 L (12 gal) RECOVERY TANK CAPACITY 45L (12 gal) SOLUTION PUMP 120 V, 4.13 bar (60psi), .7 A VACUUM MOTOR –... -

Page 13: Electrical Diagram

ELECTRICAL DIAGRAM EXPRESS MULTI SURFACE CLEANER 120 V WIRING DIAGRAM Mnl50005 (02-03) -

Page 14: Parts List

PARTS LIST EXPRESS MULTI SURFACE CLEANER TANK GROUP Mnl50005 (02-03) -

Page 15: Parts List

PARTS LIST EXPRESS MULTI SURFACE CLEANER TANK GROUP PART # DESCRIPTION QTY. PART # DESCRIPTION QTY. B-09.07 6-32 X 3/8 PHXZINC J-803 LID, VAC EXPRESS B-12.6 6-32 X 1 1/4 PHXZINC K-09.6 CORD 50' 12/3 SJT YELLOW W/LOCK B-14.6 NUT, 6 -32 HEX ZINC NYLOK K-16.96 BUSHING,RELIEF 1/2 NPT B-14.9... - Page 16 PARTS LIST EXPRESS MULTI SURFACE CLEANER BASE GROUP Mnl50005 (02-03)

-

Page 17: Base Group

PARTS LIST EXPRESS MULTI SURFACE CLEANER BASE GROUP PART # DESCRIPTION QTY. PART # DESCRIPTION QTY. B-11.2 6-32 X 3/4 FHXSS 100 DEG C-59 PUSHNUT FASTNER, 1/2 CAP B-14.6 NUT, 6 -32 HEX ZINC NYLOK C-97 YOKE END LINKAGE,1/4-28 STEEL B-21 10-32 X 5/16 PHXSS D-04... - Page 18 PARTS LIST EXPRESS MULTI SURFACE CLEANER ROTARY HEAD ASSMEBLY PART NO DESCRIPTION QTY. 000-006-009 BASE, HIGH SPEED 000-052-080 NIPPLE, 1/8" X 4" BRASS 000-052-089 ELBOW, 1/8"BRASS FEMALE 000-052-276 ROTARY UNION, 1/8" NPT 000-052-427 BUSHING, 1/8” MPT X 1/8” FPT 000-057-047 GASKET, FELT HUB 000-059-001 GEARBOX, COMPLEATE - SPUR...

- Page 19 PARTS LIST PUMP 60 PSI BREAKDOWN SL-24 SL-24.136 L-24.13 PART # DESCRIPTION QTY. • SL-24 PUMP,DIA 60 PSI 120V W/WIR & SW • L-24.13 PUMP,DIA HEAD ASM W/SWT 60PSI • SL- MOTOR, 60PSI 120V W/PLUGS 24.136 • RECOMMENDED STOCK ITEMS Mnl50005 (02-03)

-

Page 20: Options

OPTIONS 20258 ECONO FLOOR TOOL PART # DESCRIPTION QTY. PART # DESCRIPTION QTY. • F-09 B-24.1 10-32 X 3/4 PHXZINC Q/C 1/4" PLUG BR SHUT OFF B-26.57 10-32 X 1 3/8 PHX ZINC G-23 VALVE, KNGSTN STD S BND • H-37 B-28.03 NUT, 10-32 NYLOK ZINK... -

Page 21: Hand Tool

OPTIONS 20078A HAND TOOL PART # Description QTY. PART # Description QTY. B-05.5 4-40 X 7/8 PHXZINC GR-2-006N70 O-RING,2 -006 BUNA 70DR B-07.5 NUT, 4 -40 HEX ZINC NYLOK GR-2-011N70 O-RING,2 -011 BUNA 70DR B-11.5 6-32 X 1 PHXZINC GR-2-013N70 O-RING,2 -013 BUNA 70DR B-14.6 NUT, 6 -32 HEX ZINC NYLOK... -

Page 22: Warranty Policy

The failed part will be returned to you at your request. CleanMaster will pay labor for warranty repairs on new machines for 90 days from the date of purchase and must be pre-approved. CleanMaster will pay Authorized Distributors at the current warranty labor rate. - Page 23 CleanMaster’s control. In no event shall CleanMaster be liable for loss of use, incidental or consequential damages or any damages to persons or property.

- Page 24 Mnl50005 (02-03)

- Page 25 CleanMaster’s control. In no event shall Cleanmaster be liable for loss of use, incidental or consequential damages or any damages to persons or property.

- Page 26 Mnl50005 (02-03)

Need help?

Do you have a question about the 100-041-017 and is the answer not in the manual?

Questions and answers