Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Nanni T4.230

- Page 1 Nanni marine engine Operator’s manual Engines T4.230 T4.270...

- Page 2 You can download a copy of this manual in English on nannidiesel.com. Français Vous pouvez télécharger ce manuel en Français sur notre site Web à l’adresse www.nannidiesel.com. Italiano Scarica una copia del manuale in lingua Italiano sul nannidiesel.com. Deutsch Sie können eine Kopie dieses Handbuchs in Deutsch Sprache auf nanni- diesel.com.

-

Page 3: Table Of Contents

ONTENTS Introduction ......1 Maintenance ......32 About this manual ......2 Service schedule ......33 General inspection ......35 Safety ........3 Fuel system .........37 Emergency kit .......3 Lubrication system ......41 Safety alert symbols ......3 Cooling system ......43 Safety icons........4 Raw water system.......47 Safety precautions ......5 Electrical system ......51 Overview ........ -

Page 4: Introduction

NTRODUCTION Thank you for choosing a Nanni product! Contact a Nanni authorized dealer for the servicing of your product. A list of dealers can be found on our web site: www.nannidiesel.com Nanni engines are the product of many years of experience in the deve- lopment of marine engines and equipment designed for use in open seas. -

Page 5: About This Manual

We urge you time of its publication. Changes and to read it carefully and familiarize updates may be made by Nanni yourself with the engine before without notice. starting. Illustrations are intended as a... -

Page 6: Safety

I CAUTION Indicates a hazardous situation You can order an emergency kit which, if not avoided, could re- from any Nanni authorized dealer. sult in minor or moderate injury, or could cause property damage. The engine emergency kit contains several components to carry out simple repair in the event of a fault. -

Page 7: Safety Icons

Safety icons Indicates where to check the coolant level. Several stickers are fixed directly on the engine. They are intended Indicates where to check the to help you to quickly identify the engine oil level. location of certain components and avoid possible hazards when working on the engine. -

Page 8: Safety Precautions

Safety Burns precautions Never touch the hot parts of the engine! An operational engine gets very hot: the exhaust system, tur- Exhaust gas bocompressor (if equipped), starter, oil sump, oil, coolant in the hoses Exhaust gases contain carbon and pipes are hot and can burn. monoxide. - Page 9 Hazardous Voltage/ Immediately clean up any liquids Electrical Shock spilled and keep the engine com- partment clean and accessible so as to minimise the risk of fire. Be Electrocution is possible whenever careful as fuel can burn. Damaged electricity is present. Hazardous pipes can lead to fire.

- Page 10 Special attention must be brought Ventilate correctly storage batteries on boat with metallic hull, especially compartment. Avoid touching the concerning the protection of the battery terminals with metal tools persons against electrical shock so that no sparks are created which and the protection against galvanic could cause an explosion.

-

Page 11: Water Ingress

Chemical products do not start the engine, except in extreme emergencies, and contact The different fluids used to run the an authorized Nanni dealer. engine are a health hazard. Ca- refully read the instructions on the packaging of these products and always check that the ventilation in the hold space is adequate. -

Page 12: Overview

The engine identification plate is as follow: Engine installation The installation must be carried out by an authorized Nanni workshop in accordance with the installation instructions. Correct installation of the engine is of the greatest importance for safe navigation and protection of the environment. -

Page 13: Remote Control

The boat speed is Consult the boat builder or your reduced by 30% to 70%. Nanni dealer if you are not sure about the operation of the remote I CAUTION control. The Trolling valve system must never be used for manoeuvring. - Page 14 Operation in cold Oil viscosity weather conditions Use seasonal grade viscosity engine oil based on the expected Nanni engines are designed to ope- air temperature range between oil rate effectively in cold weather. changes. However, for effective starting Follow the diagram below to adapt...

- Page 15 Engine homologation Environmental responsibility The engine type can be exhaust emission certified. It means that Nanni designs its engines to have Nanni guarantees that all engines minimum environmental impact. of the same type that are manufac- This objective, however, can only...

-

Page 16: Warranty

Warranty. The validity of the Warranty is also dependent on proper installation and maintenance operation being carried out by an authorized Nanni representative. NOTICE: Late or improper mainte- nance or use of spare parts other than Nanni original spare parts will invalidate Nanni’s responsibility for... -

Page 17: Behaviour Of The Boat

Behaviour of the boat If this is your first boat or if you are not familiar with the boat, we urge you to practice controlling the boat at slow speed as a first step. Avoid violent manoeuvres or unexpected speed changes while sailing. -

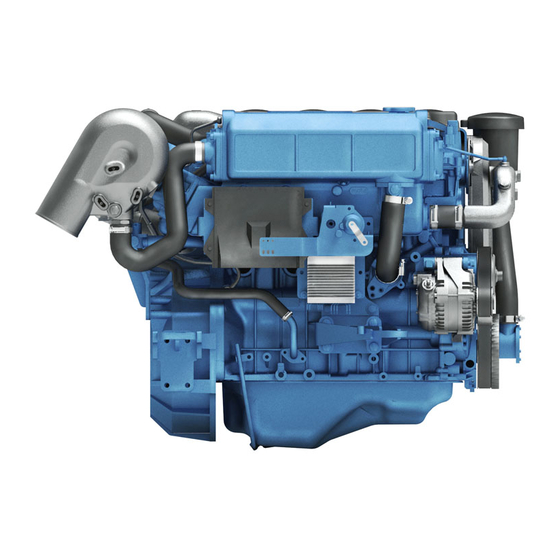

Page 18: Engine Main Components

Engine main components NOTICE: The engine may not be exactly as represented here. Some com- ponents may not be part of the engine ordered. COMPONENTS 1 Alternator 2 Alternator belt 3 Starter 4 Fuses box 5 Air filter 6 Fuel filter 7 Fuel cooler 8 High pressure Injection pump 9 Heat exchanger... - Page 19 T4.230 - T4.270...

-

Page 20: Instruments Panel

NSTRUMENTATION This chapter describes all available instruments for your engine. Contact your dealer if the boat is fitted with instruments not described in this chapter or if you are not sure about their function. Depending the boat, the instruments can be installed on panel or separate- ly on the dashboard. - Page 21 Operate the engine when the to IGNITION position. oil pressure is too low can lead to severe engine damage. Do not operate the engine if the problem persist and contact a Nanni workshop as soon as pos- sible.

- Page 22 Operating the engine while the coolant temperature is too high can lead to severe engine damage. Do not operate the engine if the problem persists and contact a Nanni workshop as soon as possible.

- Page 23 Trim indicator Three operating ranges are avail- able: ONLY IN STERN DRIVE VERSION 1. TRIM RANGE The trim indicator displays the level The trim range is used to adjust the of tilt of the Stern drive. boat trim at all engine rpm speed, from idle to max rpm at wide open throttle.

-

Page 24: Lcd Display

LCD Display The LCD display integrated to the hourmeter allows you to view several information. The structure of the menus is describe hereafter. Navigate through menus using NOTE: The LCD display has been set up during the installation of the en- gine. - Page 25 Note...

-

Page 26: Operation

PERATION Before starting 3. Check that there is sufficient fuel. 4. Move the control lever to the WARNING neutral position. Put all the protective covers back 5. Open fuel cock, prime the sys- before starting the engine. tem if necessary. 6. -

Page 27: Starting The Engine

Starting the Starting using booster batteries engine CAUTION DANGER Make sure to use batteries with The propeller can cause se- the same rated voltage as the rious injury when rotating. Check engine’s system voltage. that nobody is in the water near the propeller before starting. - Page 28 Panel with key Panel without key 1. Move the control lever to the 1. Switch the key of the main neutral position. panel to ignition (if equipped). 2. Insert the key in the ON/STOP 2. Move the control lever to the starter switch.

-

Page 29: During Operation

Do not operate the engine if the could lead among other things to problem persists and contact a increased oil consumption. Nanni workshop as soon as pos- sible. Deposits may also form in the injec- tion system if the engine do not reach its nominal operating tem- perature regularly. - Page 30 Manoeuvring Cruising in shallow water WARNING Use extreme caution when cruising in shallow water or in areas likely Shifting between ahead and to contain submerged objects that astern should be done at idling can hit the propeller, the drive, the speed.

- Page 31 Operating the trim NOTICE: The model of control system station and trim control can vary according the boat. Informations are given as an example. Control ONLY IN STERN DRIVE VERSION station and trim control can be diffe- The trim system allows to adapt the rent.

-

Page 32: Stopping The Engine

Stopping the After the engine has stopped: engine 1. Switch off the main switch. 2. Close the sea cock and the fuel cock. CAUTION 3. Inspect the engine compart- Never stop the engine by using ment and check for any leaks. the main switch. - Page 33 LONG-TERM STORAGE. the hull and spray a coat of anti- All these operations should be fouling. Never paint the anodes. carried out by a Nanni authorized Furthermore, when the boat is workshop. at anchor or in port for extended...

- Page 34 Note...

-

Page 35: Maintenance

AINTENANCE We recommend to have all your I WARNING works checked by a Nanni author- ized workshop. As far as possible, perform maintenance operations with the Independent repair and adjust- engine stopped, remove the key ment work on the engine beyond a... -

Page 36: Service Schedule

100 hours or every year, and so on. Some components may not be part of the engine ordered. Operations marked with should be done in a Nanni workshop. * Operations to perform after 20 operating hours or 45 days after commis- sioning. - Page 37 EVERY 200 OPERATING HOURS / AT LEAST EVERY YEAR. Change the engine and transmission oil *. Change the oil filters *. Change the fuel filters *. Check the raw water pump impeller. Change if needed. Check the engine flexible mountings. Adjust as necessary *. ...

-

Page 38: General Inspection

Adjust the tension of the cable if If too much water comes in, stop necessary. If any defect appears the engine and contact your Nanni (rust, crack, etc), the control cable dealer as soon as possible. must be changed. -

Page 39: Exhaust System

Exhaust system The reliability and the perform- ances of the engine depend among Inspect all exhaust system com- other things on the quantity and the ponents (hoses, clamps, mixing temperature of the intake air. elbow, manifold, etc.) Check for To check the air filter: cracks, leaks and corrosion. -

Page 40: Fuel System

NOTICE: All work on the fuel injec- engine fuel filter. It must never be tion system must be carried out by a installed on the engine as vibra- authorized Nanni technician. tions affect the water/fuel separa- tion process. Check regularly the condition of... - Page 41 Fuel requirements Fuel prefilter Only use grade of fuels indicated The fuel prefilter is an optional ex- in the chapter TECHNICAL DATA. tra not in the scope of supply of the Other grades of fuel can increase engine. The model of prefilter can fuel consumption and cause vary according the boat.

- Page 42 Replacing the fuel filter Air bleeding NOTICE: Do not fill the new filter Bleeding the air in the fuel system with fuel before assembly. is necessary : • After a maintenance operation on the fuel system. • If the fuel tank has been emp- tied.

-

Page 43: Lubrication System

Lubrication To bleed the fuel system IF IT IS FITTED WITH AN ADDITIONAL system ELECTRIC FUEL FEED PUMP : 1. Fill totally the fuel tank. Open I CAUTION the fuel cock. Never over-fill the engine oil 2. Loose the venting screw crankcase. -

Page 44: Changing The Oil Filter

Changing the oil filter If the level is too low, remove the oil filler plug and add oil slowly. Wait Change the oil filter each time the few minutes before checking the oil engine oil is drained. level to let the oil drain down to the oil pan. - Page 45 Nanni workshop. It may indi- cate a water leak in the Stern drive unit. Check the gear lube with the en- gine cold, before starting.

-

Page 46: Cooling System

Recovery tank (if fi tted) • The RAW WATER CIRCUIT which cools the coolant via heat Coolant pump exchange with raw water. Nanni engines comes as standard with an heat exchanger, in which the coolant is cooled by heat exchange with raw water taken from a sea cock. - Page 47 Coolant Choose additive that will not have any adverse effects on the materi- als of the cooling system. Never I CAUTION mix different additive as it may Always use coolant made of cause chemical reactions and therefore malfunctions. 50% antifreeze with anticorro- sion additive and 50% of clean WATER BOILER water.

- Page 48 Coolant level NOTICE: The Min and Max level indicated on the recovery tank (if fitted) does not indicate the correct I DANGER level of coolant. Never open the coolant filler cap Draining the coolant or any plug of the cooling system when the engine is operating circuit or warm.

- Page 49 Coolant - Filling I CAUTION Mix the anti-freeze with water in a If a boiler is connected to the clean container before filling the engine, follow the filling proce- heat exchanger. The coolant must dure given by the manufacturer be totally free from dust.

-

Page 50: Raw Water System

Raw water system Siphon breaker I DANGER I DANGER Close the sea cock before any When the boat is in the water, operation on the siphon breaker. water can flow into the boat via components located below the waterline. Close the raw water NOTICE: The use of a siphon cock (if fitted) or prevent water breaker is mandatory if the exhaust... - Page 51 Raw water pump 4. Mark the position of the neo- impeller prene impeller inside the pump in order to install it in the correct position in case of rein- I CAUTION stallation. If the engine has been run wi- 5. Carefully remove the impeller thout supply of raw water, check using an extractor.

- Page 52 Cleaning the raw water R aw water system - filter Draining A raw water filter must be fitted be- I WARNING tween the raw water intake and the raw water pump of the engine. It is highly recommended to carry out these operations when The model of prefilter can vary ac- the boat is laid up on land.

- Page 53 Raw water system - 5. Let the engine run few minutes Cleaning and inhibiting at idle. Add fresh water in the container if necessary. The raw water system must be 6. Stop the engine. flushed with fresh water to prevent the buildup of deposits and salt 7.

-

Page 54: Electrical System

Change it if any defect ap- pears. Contact your Nanni dealer for more informations. Tighten the cable terminals and lubricate them with appropriate grease. -

Page 55: Battery

Contact discharging, notably in wet weather. an authorized Nanni dealer. Use a brass brush to clean battery terminals. When storing the engine, adjust the... - Page 56 Alternator belt To change the belt: I DANGER Stop the engine and remove the key before servicing the alterna- tor belt. NOTICE: Always keep a replace- ment belt on-board. The alternator belt drives both the coolant pump and the alternator. 1.

-

Page 57: Corrosion Protection

Corrosion Anodes in magnesium or zinc are generally used to protect the boat protection against galvanic corrosion. Due to their intrinsic nature, these anodes The engine and all metal item in the will wear down in place of other boat that are exposed to water or metallic components. - Page 58 Electrolytic corrosion I DANGER Electrolytic corrosion is caused by For engine with a two-pole externally generated DC electrical electrical system, the negative currents that pass through a metal pole of the battery must never item to another in an electrolyte be connected to the common such as raw water.

- Page 59 necessary to check and/or change I CAUTION the anode more frequently. Screw the anode cap back on To remove the anode: tightly and do not forget to re- open the sea cock. I WARNING Carry out these operations when Mercathode system the engine is stopped and cold.

-

Page 60: Long Term Storage

NOTICE: It might be necessary to 4. Run the engine to normal oper- adapt these operations depending ating temperature. the climatic conditions. Contact a Nanni authorized workshop for 5. Stop the engine and take the further informations. boat out of water. For prolonged storage (>12 6. - Page 61 12. Clean the engine. Repair any 5. Check the condition of the raw damaged areas of paintwork with water pump impeller. Change it if Nanni original paint. needed. Install the impeller. 6. Remove cloth and tape from I CAUTION openings. Install the air filter.

-

Page 62: Troubleshooting

ROUBLESHOOTING If the engine does not function properly, use the following chart to identify the cause. If the cause of trouble can not be found, contact a Nanni autho- rized workshop. NOTICE: Some components may not be part of the engine ordered. This list is not exhaustive and is only an assistance in case of emergencies. - Page 63 1. Lack of fuel 2. Air in fuel system 3. Fuel filter fouled or clogged 4. Fuel do not meet specified standard 5. Water/contaminants in fuel 6. Valve clearance is wrong * 7. Low compression * 8. Insufficient battery charge / Defective battery 9.

-

Page 64: Technical Data

ECHNICAL DATA MODEL T4.230 T4.270 ENGINE CHARACTERISTICS Type 4 stroke, Diesel Max. power - kW (hp)* 169.1 - 230 194.9 - 265 Number of cylinders / Arrangement 4 in line Displacement (cm 2982 Bore and stroke (mm) 96 - 103 Air intake Turbo &... - Page 65 MODEL T4.230 T4.270 ELECTRICAL SYSTEM Recommended starter battery capa- 100 ~ 140 city (Ah) Starter (kW) Standard Alternator (V-A) FUEL SYSTEM Injection system Direct Common Rail Injection timing before TDC (°) ECU controlled Fuel injection pressure (bar) 1800 maxi Specific fuel consumption (g/kWh) at wide open throttle EN 590 / ASTM D975 No.2-D...

- Page 66 Note...

- Page 67 Note...

- Page 68 NANNI INDUSTRIES SAS 11,Avenue Mariotte-Zone Industrielle 33260 La Teste France Tel: + 33 (0)5 56 22 30 60 Fax: +33 (0)5 56 22 30 79 032014.IndB Email: contact@nannidiesel.com www.nannidiesel.com...

Need help?

Do you have a question about the T4.230 and is the answer not in the manual?

Questions and answers