Subscribe to Our Youtube Channel

Summary of Contents for kromo gr300

- Page 1 Istruzioni per l'installazione l'uso e la manutenzione Instructions for Installation, Use and Maintenance COD.: 4000 APPLICARE ETICHETTA Ed. 03 - 11/2010 MATRICOLA...

-

Page 2: Table Of Contents

TRANSLATION OF THE ORIGINAL INSTRUCTIONS CONTENTS Page WARNINGS INSTALLER SECTION 1. MACHINE INSTALLATION 1.1 Receiving product 1.2 Water connection 1.3 Electrical connection 1.4 Rinse aid dispenser operation 1.5 Detergent dispenser installation 1.6 Increase pressure/rinse pump 1.7 Emptying boiler and break tank 2. -

Page 3: Warnings

WARNINGS It is very important that this instruction manual is kept with the dishwasher for future consultation. If the dishwasher is sold or transferred to another user, make sure that the manual stays with it to allow to new owner to be informed on operations and warning. These warnings are supplied for safety reasons. -

Page 4: Installer Section

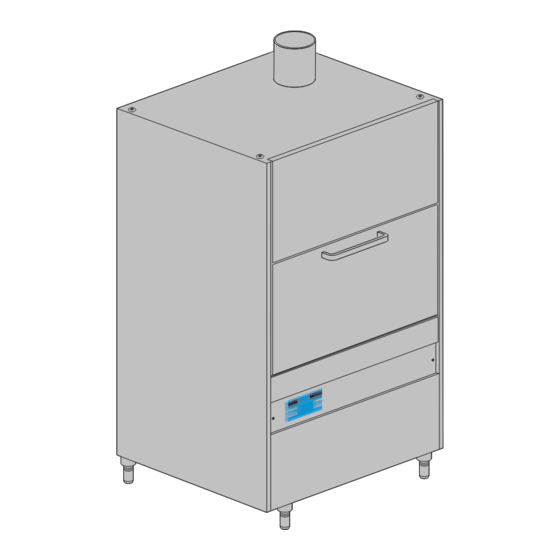

INSTALLER SECTION WARNINGS: Once installation is complete, it is recommended to detach the installer’s guide section of this manual for future reference. 1. MACHINE INSTALLATION 1.1 Receiving product After removing the packaging, make sure that the apparatus was not damaged during tran- sportation. -

Page 5: Rinse Aid Dispenser Operation

INSTALLER SECTION Attention: some of the machine versions can disperse more than 10mA to earth. Proceed to machine start-up and rinse aid dispenser calibration as follows: 1) Turn on the wall switch and the water tap. 2) Turn on the ware-washer by pressing key (B) (see par. 2). The relevant green led will come on. -

Page 6: Detergent Dispenser Installation

INSTALLER SECTION PROBLEM CAUSES AND REMEDY The suction valves 10705/D and flow do not seal due to foreign bodies is Water leaks from rins aid suction tube the clamping seats. Clean valves 10705/D, check if the rinse aid suction filter is present. Make sure there are no crystals or solid pieces inside the canister which could be due to old, dried-out product. -

Page 7: Increase Pressure/Rinse Pump

INSTALLER SECTION 1.6 Increase pressure/rinse pump After a period of inactivity of the ware-washer, check that the rinse pump rotates freely. If it is blocked, move the pump shaft, by inserting a screwdriver in the notch, rotating clockwise and counter-clockwise (see fig. 9). This operation may be necessary when the slow tank-loading alarm sounds (7) (chap. -

Page 8: Control Panel And Symbols

INSTALLER SECTION 2. CONTROL PANEL AND SYMBOLS The present specifications are not intended as a functional description of the display. To simplify function description, the control panel display with function control keys is reported below in accordance to operation modality. 2.1 Function keys during normal operation pict. -

Page 9: Machine Programming

INSTALLER SECTION 4. MACHINE PROGRAMMING The following is necessary to access programming: • simultaneously press keys “A” and “B”, making sure to press key “B” just a little before, for about 5 seconds after which the message “Key” shall be displayed; •... - Page 10 INSTALLER SECTION table 2 - push-button key code 50570/G Measure Parameter Min. MAX. Default Notes Unit 1 Rinse time cycle step 1" 2 Boiler temperature setting °C 85°C step 1/2°C 3 Tank temperature setting °C 55°C step 1/2°C 4 Energy-saving threshold cycle 1 °C 10°C step 1/2°C...

- Page 11 INSTALLER SECTION NOTES page 34...

-

Page 12: User Section

USER SECTION 5. CONTROL PANEL AND SYMBOLS The present specifications are not intended as a functional description of the display. To simplify function description the control panel display with function control keys is reported below in accordance to operation modality. 5.1 Function keys during normal operation pict. -

Page 13: Operation

USER SECTION 7. OPERATION 7.1 General operation The machine needs 3 connections to run: • Electric; • Water supply; • Drain. The machine is designed with a wash chamber inside which there is: • A basket support, connected to a clutch equipped gear, where the rack is placed to rotate during the wash cycle. -

Page 14: Detergent Use

USER SECTION N.B.: The machine does not accept other cycles until the door is opened or the key (A) is pressed twice (see fig. 7). The cycles (1, 2, 3, 4, ∞) with granules and (1, 2, 3, 4) with only water are pre-set by the producer with times of 4-6-8-10-12 minutes for granule cycle, 4-6-8-10 minutes for only water cycle. - Page 15 USER SECTION The round basket can contain 2 GN 2/1 or 1 GN 2/1 and 3 GN 1/ 1. photo 4 photo 5 b) The pyramidal stand fixed to the centre of the basket supports the cutlery racks as well as pots without handles.

-

Page 16: Final Check

USER SECTION g) The four tray-stands allow the washing of bakery trays of various depths. photo 11/g It is also possible to prepare a basket mixing the above components. photo 12 photo 13 photo 14 Having a machine with lateral wash and rinse arms, an object must not be placed in front of another or else the one behind will not be washed. -

Page 17: Chamber Cleaning

USER SECTION • Replace with the strainer and two lateral compensation chutes. photo 18 photo 19 photo 20 Once this operation is complete, simply select cycle 1 granule mode and with the door shut press (START). One the cycle is finished, the granules shall be found in the collection strainer. - Page 18 USER SECTION 7.14 Conditions that inhibit the washing cycle start The cycle is inhibited under the following conditions: • if the door is open; in this situation the display shall read (Door) for 4 seconds; • if water is lacking; in this situation the display shall read (H O) for 4 seconds;...

-

Page 19: Maintenance

USER SECTION 8. MAINTENANCE WARNING: The machine is no protected against pressurized water jets. Avoid using pressure cleaning system against the machine's body. It is moreover recommended to contact the product seller for cleaning, in order to have detailed indications on methods and products for periodical machine sanitation. Do not clean with bleach or chlorine based detergents. -

Page 20: Ecological Aspects

USER SECTION If the user does not comply with the regulations he/she shall be subject to the penalties foreseen by each member state. Disconnect electricity and water before disposal. Cut the electrical cable to ensure that further use is impossible. All metal parts are recyclable as they are made of stainless steel. -

Page 21: Boiler Overheating Alarm

USER SECTION 11.2 50570/G dispaly signals Fault signals are displayed with the message (All) followed by the fault code. TYPE OF FAULT FAULT CODE SOLUTION Boiler probe fault Replace probe Tank probe fault Replace probe Boiler overheating Probe fault/control unit fault. Call Service Technician. -

Page 22: Troubleshooting

USER SECTION 12. TROUBLESHOOTING Trouble Possible causes Solution The machine does not turn on Main switch not ON Turn switch ON The machine does not load Water valve closed Open the water valve water Rinse area nozzles or electric valve Clean the rinse arm nozzles, conductors and electric filter blocked and/or encrusted with valve filter.

Need help?

Do you have a question about the gr300 and is the answer not in the manual?

Questions and answers