Summary of Contents for Engine distributors DSG-423

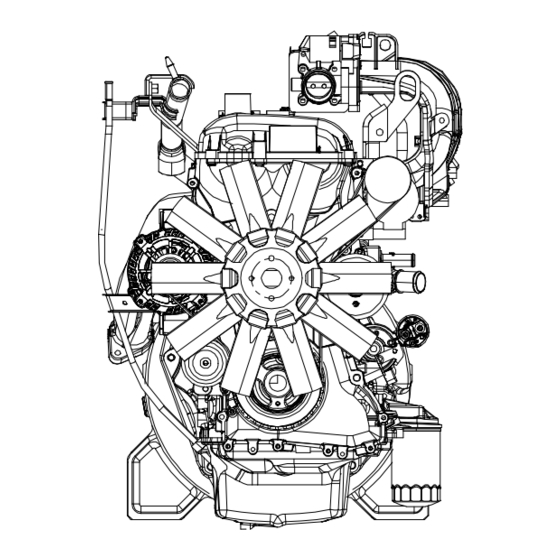

- Page 1 DSG-423 2.3 LITER INDUSTRIAL ENGINE SERVICE MANUAL Powertrain Assemblies & Components Provided By Ford Component Sales EDI 1060040 AUG, 2007...

- Page 2 Reproduction in any manner, in whole or in part, is Section 06 prohibited without the express permission in writing from: Engine Distributors Inc (EDI) STARTER Section 07 EDI policy is one of continuous improvement and while every effort is made to ensure that this publication is up...

- Page 3 HEALTH & SAFETY WARNING: THE FOLLOWING HEALTH AND SAFETY RECOMMENDATIONS SHOULD BE CAREFULLY OBSERVED WARNING: CARRYING OUT CERTAIN OPERATIONS AND HANDLING SOME SUBSTANCES CAN BE DANGEROUS OR HARMFUL TO THE OPERATOR IF THE CORRECT SAFETY PRECAUTIONS ARE NOT OBSERVED. SOME SUCH PRECAUTIONS ARE RECOMMENDED AT THE APPROPRIATE POINTS IN THIS BOOK.

-

Page 4: Table Of Contents

DSG-423 GENERAL INFORMATION INDEX Subject Page General Information Introduction ............................... 01 - 3 Safety Notice ............................. 01 - 3 Notes, Cautions, and Warnings......................... 01 - 3 Battery Handling and Charging ......................... 01 - 4 Forward ..............................01 - 5 Engine Identification ..........................01 - 5 Parts and Service ............................ - Page 5 DSG-423 GENERAL INFORMATION INDEX (CONT.) Subject Page General Service Procedures Connecting Rod Twist ..........................01 - 29 Connecting Rod Piston Pin Side Clearance.................... 01 - 30 Connecting Rod Journal Clearance ......................01 - 30 Bearing Inspection ..........................01 - 31 Roller Follower Inspection ........................

-

Page 6: General Information

• KEEP YOURSELF AND YOUR CLOTHING AWAY FROM MOVING PARTS WHEN THE ENGINE IS Engine Distributors Inc. (EDI) does not recommend RUNNING, ESPECIALLY THE FAN BELTS. using abrasive grinding discs to remove engine gasket • TO PREVENT SERIOUS BURNS, AVOID material. -

Page 7: Battery Handling And Charging

DSG-423 GENERAL INFORMATION Battery Handling and Charging It is important that all labelling on the battery is carefully read, understood and complied with. The format of the The handling and correct use of lead acid batteries is following symbols and labels is common to most brands not as hazardous provided that sensible precautions of lead acid battery. -

Page 8: Parts And Service

EDI distributor in your area. You can obtain a standard parts listing describing the parts. It remains The DSG-423 engine incorporates a closed positive a distributor function to identify the part number. crankcase ventilation system and an exhaust emission control system. -

Page 9: Special Tools

DSG-423 GENERAL INFORMATION DIAGNOSIS AND TESTING Special Tools Commercially Available Compression Tester Leakdown Tester 014-00707 or Equivalent Cup Shaped Adapter Dial Indicator with Bracketry TOOL-6565-AB or Equivalent TOOL-4201-C or Equivalent Engine Cylinder Leak Engine Oil Pressure Gauge Detection/Air Pressurization Kit... -

Page 10: Inspection And Verification

DSG-423 GENERAL INFORMATION Inspection and Verification • Loose mounting bolts, studs, and nuts. 1. Verify the customer concern by operating the engine to duplicate the condition. 3. If the inspection reveals obvious concerns that can 2. Visually inspect for obvious signs of mechanical and be readily identified, repair as required. - Page 11 DSG-423 GENERAL INFORMATION Condition Possible Source Action Excessive Oil Worn piston ring groove. Replace piston and pin. Consumption Sticking piston rings. Repair or replace piston rings. Worn piston or cylinders. Repair or replace piston or cylinder blocks. Worn valve stem seal.

- Page 12 DSG-423 GENERAL INFORMATION Condition Possible Source Action Engine Noise Excessive main bearing oil clearance. Adjust clearance or replace main bearing. Seized or heat damaged main bearing. Replace main bearing. Excessive crankshaft end play. Replace crankshaft thrust main bearing. Excessive connecting rod bearing oil clearance.

-

Page 13: Pcv System Malfunction

DSG-423 GENERAL INFORMATION PCV System Malfunction Pressure Method A malfunctioning Positive Crankcase Ventilation The crankcase can be pressurized to locate oil leaks. System (closed type) may be indicated by loping or The following materials are required to fabricate the tool rough engine idle. - Page 14 DSG-423 GENERAL INFORMATION • crankshaft front seal • crankshaft rear oil seal Leakage Points - with Flywheel Removed NOTE: Air leakage in the area around a crankshaft rear oil seal does not necessarily indicate a crankshaft rear oil seal leak. However, if no other cause can be found for oil leakage, assume that the crankshaft rear oil seal is the cause of the oil leak.

-

Page 15: Compression Tests

DSG-423 GENERAL INFORMATION Compression Tests Compression Pressure Limit Chart MAX-MIN MAX-MIN MAX-MIN MAX-MIN Compression Gauge Check kPa (psi) kPa (psi) kPa (psi) kPa (psi) 1. Make sure the oil in the crankcase is of the correct 924 - 696 1131 - 848... -

Page 16: Cylinder Leakage Detection

DSG-423 GENERAL INFORMATION Cylinder Leakage Detection Intake Manifold Vacuum Test When a cylinder produces a low reading, use of the Bring the engine to normal operating temperature. Engine Cylinder Leak Detection/Air Pressurization Kit, Connect a Vacuum/Pressure Tester, such as Rotunda... - Page 17 DSG-423 GENERAL INFORMATION Interpreting Vacuum Gauge Readings 4. WORN RINGS OR DILUTED OIL: When the engine is accelerated (dotted needle), the needle drops to 0 A careful study of the vacuum gauge reading while the kPa (0 in-Hg). Upon deceleration, the needle runs engine is idling will help pinpoint trouble areas.

-

Page 18: Excessive Engine Oil Consumption

DSG-423 GENERAL INFORMATION Excessive Engine Oil Consumption Oil Consumption Test The amount of oil an engine uses will vary with the way The following diagnostic procedure is used to determine the equipment is driven in addition to normal engine-to- the source of excessive internal oil consumption. -

Page 19: Oil Pressure Test

DSG-423 GENERAL INFORMATION Oil Pressure Test 11.Instruct the customer to run engine as usual and perform the following: 1. Disconnect and remove the oil pressure sensor from • Check the oil level regularly at intervals of the engine. 3 to 3-1/2 hours. -

Page 20: Valve Train Analysis – Static

DSG-423 GENERAL INFORMATION Valve Train Analysis – Static Valve Train Analysis – Dynamic With engine off and valve cover removed, check for Start the engine and, while idling, check for proper damaged or severely worn parts and correct assembly. operation of all parts. Check the following: Make sure correct parts are used with the static engine analysis as follows. - Page 21 DSG-423 GENERAL INFORMATION Camshaft Lobe Lift Check the lift of each lobe in consecutive order and make a note of the readings. 1. Remove the valve covers. 2. Remove the rocker arm seat bolts, rocker arm seat and rocker arms (if equipped).

- Page 22 DSG-423 GENERAL INFORMATION 8. Compare the total lift recorded on the dial indicator with specifications. 9. To check the accuracy of the original dial indicator reading, continue to rotate the crankshaft until the indicator reads zero. 10.Remove the dial indicator, adapter and auxiliary starter switch.

-

Page 23: Hydraulic Valve Lash Adjuster

DSG-423 GENERAL INFORMATION Hydraulic Valve Lash Adjuster 2. Place the lash adjuster in the tester with the plunger facing upward. Position the steel ball provided in the Hydraulic lash adjuster noise can be caused by any of plunger cap. Add testing fluid to cover the hydraulic... - Page 24 DSG-423 GENERAL INFORMATION GENERAL SERVICE PROCEDURES WARNING: TO AVOID THE POSSIBILITY OF PERSONAL INJURY OR DAMAGE TO THE EQUIPMENT, DO NOT OPERATE THE ENGINE UNTIL THE FAN BLADE HAS BEEN EXAMINED FOR POSSIBLE CRACKS AND SEPARATION. NOTE: Illustrations are typical and may not reflect your particular engine.

-

Page 25: Camshaft End Play

DSG-423 GENERAL INFORMATION Camshaft Lobe Lift Camshaft Runout Special Tool(s) Special Tool(s) Dial Indicator with Bracketry Dial Indicator with Bracketry TOOL-4201-C or Equivalent TOOL-4201-C or Equivalent Special Service Tools called for Special Service Tools called for by the procedures can be... -

Page 26: Crankshaft Main Bearing Journal Diameter

DSG-423 GENERAL INFORMATION Crankshaft Main Bearing Journal Diameter Crankshaft Main Bearing Journal Taper • Measure each of the crankshaft main bearing journal • Measure each of the crankshaft main bearing journal diameters in at least two directions. diameters in at least two directions at each end of the main bearing journal. -

Page 27: Crankshaft Main Bearing Journal Clearance

DSG-423 GENERAL INFORMATION Crankshaft Main Bearing Journal 4. Verify the crankshaft journal clearance. Clearance • If it is out of specification, replace as necessary Special Tool(s) Plastigage® D81L-6002-B or Equivalent Special Service Tools called for by the procedures can be... -

Page 28: Crankshaft End Play

DSG-423 GENERAL INFORMATION Crankshaft End Play Use the Dial Indicator with Bracketry to measure the crankshaft runout. Special Tool(s) • Rotate the crankshaft and subtract the lowest dial indicator reading from the highest dial indicator Dial Indicator with Bracketry reading to figure the crankshaft runout. If it is out of TOOL-4201-C or Equivalent specification, replace as necessary. -

Page 29: Piston Inspection

DSG-423 GENERAL INFORMATION Cylinder Bore Out-of-Round • Make sure the oil ring holes are clean. Measure the cylinder bore in two directions. The difference is the out-of-round. Verify the out-of-round is within the wear limit and bore the cylinder to the next oversize limit. -

Page 30: Piston Ring End Gap

DSG-423 GENERAL INFORMATION Piston Selection CAUTION: Use care when fitting piston rings to avoid possible damage to the piston ring or the cyl- NOTE: The cylinder bore must be within the inder bore. specifications for taper and out-of-round before fitting a piston. -

Page 31: Connecting Rod Cleaning

DSG-423 GENERAL INFORMATION Piston Ring-to-Groove Clearance Crankshaft Connecting Rod Journal Taper • Measure the crankshaft rod journal diameters in two Special Tool(s) directions perpendicular to one another at each end of the connecting rod journal. The difference in the Feeler Gauge... -

Page 32: Connecting Rod Larger End Bore

DSG-423 GENERAL INFORMATION Connecting Rod Larger End Bore Connecting Rod Bushing Diameter CAUTION: The connecting rod bolts are torque to • Measure the inner diameter of the connecting rod yield and must be discarded and replaced after this bushing. Verify the diameter is within specification. -

Page 33: Connecting Rod Piston Pin Side Clearance

DSG-423 GENERAL INFORMATION Connecting Rod Piston Pin Side Clearance 3. Install and torque to specifications, then remove the connecting rod bearing cap. • Measure the clearance between the connecting rod 4. Measure the Plastigage® to get the connecting rod and the piston. Verify the measurement is within bearing journal clearance. -

Page 34: Roller Follower Inspection

DSG-423 GENERAL INFORMATION Bearing Inspection Roller Follower Inspection Inspect bearings for the following defects. Possible • Inspect the roller for flat spots or scoring. If any causes are shown: damage is found, inspect the camshaft lobes and hydraulic lash adjusters for damage. -

Page 35: Valve Stem Diameter

DSG-423 GENERAL INFORMATION Valve Stem Diameter 2. Move the Valve Stem Clearance Tool toward the Dial Indicator and zero the Dial Indicator. Move the • Measure the diameter of each intake and exhaust Valve Stem Clearance Tool away from the Dial valve stem at the points shown. -

Page 36: Valve Guide Inner Diameter

DSG-423 GENERAL INFORMATION Valve Guide Inner Diameter Valve Spring Installed Length • Measure the installed length of each valve spring. 1. Measure the inner diameter of the valve guides in two directions where indicated. 2. If the valve guide is not within specifications, ream... -

Page 37: Valve Spring Compression Pressure

DSG-423 GENERAL INFORMATION Valve Spring Compression Pressure Valve Seat Width • Measure the valve seat width. If necessary, grind the Special Tool(s) valve seat to specification. Valve/Clutch Spring Tester TOOL-6513-DD or Equivalent Special Service Tools called for by the procedures can be... -

Page 38: Oil Pump Gear Radial Clearance

DSG-423 GENERAL INFORMATION Flywheel Inspection Oil Pump Rotor Inspection • Inspect the oil pump rotor tips for damage or wear. Special Tool(s) Dial Indicator with Bracketry TOOL-4201-C or Equivalent Special Service Tools called for by the procedures can be obtained by calling:... -

Page 39: Cylinder Bore Honing

DSG-423 GENERAL INFORMATION Cylinder Bore Honing Special Tool(s) Engine Cylinder Hone Set T73L-6011-A Special Service Tools called for by the procedures can be obtained by calling: 1-800-ROTUNDA (1-800-768-8632) NOTE: Before any cylinder bore is honed, all main bearing caps must be installed so the crankshaft bearing bores will not become distorted. -

Page 40: Cylinder Head - Distortion

DSG-423 GENERAL INFORMATION Cylinder Block Repair - Cast Iron Porosity Defects CAUTION: Do not attempt to repair cracks, areas where temperature will exceed 260°C (500°F) or ar- eas exposed to engine coolant or oil. These areas will not repair and could cause future failure. - Page 41 DSG-423 GENERAL INFORMATION Cylinder Block Core Plug – Cup-Type CAUTION: Do not contact the flange when installing a cup type cylinder block core plug as this could damage the sealing edge and result in leakage. NOTE: When installed, the flanged edge must be below the chamfered edge of the bore to effectively seal the bore.

-

Page 42: Spark Plug Thread Repair

DSG-423 GENERAL INFORMATION Spark Plug Thread Repair 2. Start the tap into the spark plug hole, being careful to keep it properly aligned. As the tap begins to cut new threads, apply aluminum cutting oil Special Tool(s) Tapersert Installation Kit... -

Page 43: Exhaust Manifold Straightness

DSG-423 GENERAL INFORMATION Exhaust Manifold Straightness 6. Tighten the tapersert into the spark plug hole. Special Tool(s) Straightedge 303-D039 (D83L-4201-A) or equivalent Special Service Tools called for by the procedures can be obtained by calling: 1-800-ROTUNDA (1-800-768-8632) • Place the Straightedge across the exhaust manifold flanges and check for warping with a feeler gauge. -

Page 44: Specifications

DSG-423 GENERAL INFORMATION SPECIFICATIONS GENERAL SPECIFICATIONS Epoxy Sealer M3D35-A (E) Threadlock WSK-M2G351-A6 E2FZ-19554-B Super Premium SAE5W20 WSS M2C930-A NOTE: Ford engines are designed to perform with engine oils that are licensed by the American Petroleum Institute (API), and oils carrying the most current API classification SJ or greater must be used. - Page 45 DSG-423 ENGINE NOTE: INDEX Subject Page General Information Engine ............................... 02 - 3 Positive Crankcase Ventilation System..................... 02 - 3 Engine Cooling System ..........................02 - 3 Lubrication System............................ 02 - 5 Drive Belt System............................02 - 5 Ignition System............................02 - 5 Fuel System ..............................

- Page 46 DSG-423 ENGINE INDEX Subject Page Removal And Installation Oil Pump - Removal ..........................02 - 26 Oil Pump - Installation ..........................02 - 26 Flywheel/Flexplate - Replacement ......................02 - 27 Crankshaft Rear Seal/Retainer - Removal ....................02 - 27 Crankshaft Rear Seal/Retainer - Installation ...................

-

Page 47: Engine Cooling System

DSG-423 ENGINE GENERAL INFORMATION All fuels are controlled in closed loop. Gasoline is delivered by sequential port fuel injection. The electronic engine management system has built in engine protection against: • detonation • high coolant temperature • low oil pressure •... - Page 48 DSG-423 ENGINE 02-4...

-

Page 49: Lubrication System

DSG-423 ENGINE Lubrication System Drive Belt System The engine lubrication system consists of: Engine accessories, such as the generator and water pump, are driven by a single serpentine belt. Tension is • Oil pan. automatically adjusted by a tensioner. •... -

Page 50: Intake Manifold - Installation

DSG-423 ENGINE REMOVAL & INSTALLATION Intake Manifold - Installation 1. Install new intake gaskets. Intake Manifold - Removal 2. Position intake manifold and install 5 bolts. 1. Drain the engine cooling system -- Refer to Section • Tighten to 18 Nm (13 lb-ft). -

Page 51: Camshaft Cover - Installation

DSG-423 ENGINE Camshaft Cover - Installation 9. Remove bolts and camshaft cover. Capacitor 1. Install new gaskets. Bolt 2. Position camshaft cover and install bolts in sequence shown. • Tighten to 10 Nm (89 lb-in). Cover Gaskets Tightening Sequence 3. Reconnect crankcase ventilation tube. -

Page 52: Crankshaft Pulley - Removal

DSG-423 ENGINE Crankshaft Pulley - Removal 6. Remove plug bolt. CAUTION: The crankshaft, the crankshaft sprocket and the pulley are fitted together by friction, with diamond washers between the flange faces on each part. For that reason, the crankshaft sprocket is also unfastened if you loosen the pulley. -

Page 53: Crankshaft Pulley - Installation

DSG-423 ENGINE 9. Remove bolt, washer and pulley. Discard crankshaft 3. Using special tools 205-126 and 205-072-02 to hold pulley bolt. the crankshaft pulley in place, tighten the crankshaft pulley bolt in 2 stages: Pulley • Stage 1: Tighten to 100 Nm (74 lb-ft). -

Page 54: Crankshaft Front Seal - Removal

DSG-423 ENGINE Crankshaft Front Seal - Removal 8. Using special tool 303-465, check the position of the camshaft. If it is not possible to install the special CAUTION: The crankshaft, the crankshaft sprocket tool, correct the engine timing. and the pulley are fitted together by friction, with diamond washers between the flange faces on each part. -

Page 55: Engine Front Cover - Removal

DSG-423 ENGINE Engine Front Cover - Removal Tensioner 1. Disconnect the negative battery cable -- refer to Section 6. CAUTION: The crankshaft, the crankshaft sprocket and the pulley are fitted together by friction, with diamond washers between the flange faces on each part. -

Page 56: Engine Front Cover - Installation

DSG-423 ENGINE Engine Front Cover - Installation 9. Using a 3 jaw puller, remove the fan drive pulley. NOTE: This step is needed only if a new front cover is being installed. 1. Install the fan drive pulley, using a nut and bolt with flat washers as shown below. - Page 57 DSG-423 ENGINE 3. Install the front cover and tighten the bolts in the 5. Position the coolant pump pulley and install the 3 sequence shown to the following specifications: bolts: • Tighten 8 mm bolts to 10 Nm (89 lb-in) •...

-

Page 58: Timing Drive Components - Removal

DSG-423 ENGINE 9. Adjust the CKP with the alignment tool supplied with 4. Remove the right timing chain guide. the new sensor. The tool must engage a tooth of the vibration damper. Tighten 2 bolts: • Tighten to 7 Nm (62 lb-in). -

Page 59: Timing Drive Components - Installation

DSG-423 ENGINE 7. If necessary, remove the bolts and the camshaft 3. Install the timing chain. sprockets. 4. Install the right timing chain guide. NOTE: Use the flats on the camshaft to prevent camshaft rotation. Timing Drive Components - Installation CAUTION: Do not rotate the camshafts. -

Page 60: Valve Spring - Installation

DSG-423 ENGINE CAUTION: Do not rely on the Camshaft Alignment Plate to prevent camshaft rotation. Damage to the tool or the camshaft can occur. 7. Using the flats on the camshaft to prevent camshaft rotation, tighten the sprocket bolts: •... -

Page 61: Valve Seal - Removal

DSG-423 ENGINE Valve Seal - Removal Valve Seal - Installation CAUTION: During engine repair procedures, 1. Install the valve stem seal installation sleeve. cleanliness is extremely important. Any foreign material, including any material created while cleaning gasket surfaces, that enters the oil... -

Page 62: Valve Tappet - Replacement

DSG-423 ENGINE Valve Tappet - Replacement NOTE: Note the position of the lobes on the No. 1 CAUTION: During engine repair procedures, cylinder before removing the camshafts for assembly cleanliness is extremely important. Any foreign reference. material, including any material created while cleaning gasket surfaces, that enters the oil 3. -

Page 63: Exhaust Manifold - Removal

DSG-423 ENGINE 2. Install timing chain and sprockets -- Refer to“Timing CAUTION: Do not use metal scrapers, wire brushes, power abrasive discs or other abrasive means to Drive Components - Installation” on page 15 of this clean the sealing surfaces. These tools cause section. -

Page 64: Cylinder Head - Removal

DSG-423 ENGINE 6. Install exhaust pipe to manifold. 7. Remove and discard cylinder head bolts. Bolt Head Coolant Pipes 7. Install accessory drive belt -- refer to Section 6. 8. Connect battery negative cable -- refer to Section 6. Gasket 9. - Page 65 DSG-423 ENGINE 2. Apply silicone gasket and sealant to the locations shown. NOTE: If not secured within 4 minutes, the sealant must be removed and the sealing area recleaned as before. Refer to previous CAUTION & WARNING. 3. Install a new cylinder head gasket.

- Page 66 DSG-423 ENGINE 6. Tighten bolts in sequence shown in 5 stages: • Stage 1: Tighten to 5 Nm (44 lb-in) • Stage 2: Tighten to 15 Nm (11 lb-ft) • Stage 3: Tighten to 45 Nm (33 lb-ft) • Stage 4: Tighten an additional 90 degrees •...

-

Page 67: Oil Filter Adapter - Removal

DSG-423 ENGINE Oil Filter Adapter - Removal 5. Tighten to 15 Nm (11 lb-ft). 6. Connect oil pressure sender connector. 1. Disconnect negative battery cable -- refer to Section 7. Fill the engine with clean engine oil. 2. Remove and/or disconnect components to allow 8. -

Page 68: Oil Level Indicator & Tube - Replacement

DSG-423 ENGINE Oil Level Indicator & Tube - Replacement 4. Remove oil pan and bolts. 1. Remove and/or disconnect components to allow access and removal of the oil level indicator & tube. Label if necessary to allow for correct reinstallation. -

Page 69: Oil Pan - Installation

DSG-423 ENGINE Oil Pan - Installation 3. Remove gasket and discard. 4. Clean the sealing surface with metal surface prep. NOTE: If not secured within 4 minutes, the sealant must be removed and the sealing area recleaned as before. Refer to previous CAUTION & WARNING. -

Page 70: Oil Pump - Removal

DSG-423 ENGINE Oil Pump - Removal 2. Install oil pump and 4 bolts in sequence shown in 2 stages: 1. Remove and/or disconnect components to allow • Stage 1: Tighten to 10 Nm (89 lb-in) access and removal of the oil pump. Label if •... -

Page 71: Flywheel/Flexplate - Replacement

DSG-423 ENGINE Flywheel/Flexplate - Replacement Crankshaft Rear Seal/Retainer - Removal 1. Remove any components necessary to gain access 1. Remove and/or disconnect components to allow to the flywheel/flexplate. access and removal of the rear seal. Label if necessary to allow for correct reinstallation. -

Page 72: Engine Disassembly

DSG-423 ENGINE 3. Install oil pan -- Refer to“Oil Pan - Installation” on 6. Remove generator and bracket assembly. page 25 of this section. 4. Install flywheel or flexplate -- Refer to“Flywheel/ Flexplate - Replacement” on page 27 of this section. - Page 73 DSG-423 ENGINE 11.Remove 4 bolts and power steering pump. Power Steering Knock Sensor Pump Bolt Bolt 12. Remove 5 bolts and intake manifold. 16.Remove engine vent cover. Engine Vent Cover Gasket Intake PCV Valve PCV Hose Manifold 17.Remove fuel rail and injectors. Discard o-rings.

- Page 74 DSG-423 ENGINE 19.Remove 3 bolts and coolant pump. Discard the o- CAUTION: Failure to position the No. 1 piston at top dead center (TDC) can result in damage to the ring. engine. Turn the engine in the normal direction of rotation only.

- Page 75 DSG-423 ENGINE 24.Install special tools 205-126 & 205-072-02. 28.Compress the timing chain tensioner and insert a paper clip into the hole. CAUTION: Failure to hold the crankshaft pulley in place during bolt loosening can cause damage to 29.Remove 2 bolts and tensioner.

- Page 76 DSG-423 ENGINE CAUTION: Do not rely on camshaft alignment plate CAUTION: Failure to follow the camshaft loosening to prevent camshaft rotation. Damage to the tool or procedure can result in damage to the camshafts. the camshaft can occur. NOTE: Note the position of the lobes on the number 33.Using a wrench on the camshaft flats, remove bolts,...

-

Page 77: Cylinder Head Disassembly

DSG-423 ENGINE 44.Remove the cylinder head alignment dowels. 47.Remove bolts, oil pump pickup tube and discard gasket. Gasket Pickup Tube Bolt Bolt 48.Remove 4 bolts and oil pump. 45.Remove bolts and oil pan. 49.Remove and discard oil pump gasket. 46.Remove bolts and rear seal retainer plate. -

Page 78: Engine Cleaning

DSG-423 ENGINE 2. Remove cylinder head temperature (CHT) sensor. extremely important. Any foreign material, including any material created while cleaning gasket surfaces can Tappet enter the oil passages, coolant passages or the oil pan, CHT Sensor and cause engine failure. -

Page 79: Cylinder Head Assembly

DSG-423 ENGINE Cylinder Head Assembly NOTE: Make sure keys are seated properly. CAUTION: Be sure to install tappets in the same CAUTION: If installing original valves, make sure location as removed. they are installed in the same position as removed. -

Page 80: Engine Assembly

DSG-423 ENGINE Engine Assembly 3. Install special tool 303-507. CAUTION: The crankshaft, the crankshaft sprocket and the pulley are fitted together by friction, with diamond washers between the flange faces on each part. For that reason, the crankshaft sprocket is also unfastened if you loosen the pulley. - Page 81 DSG-423 ENGINE 6. Using special tool 303-328, install a new crankshaft 9. Apply silicone gasket and sealant to the locations rear seal and retainer plate assembly. Tighten bolts shown. in the sequence shown: • Tighten to 10 Nm (89 lb-in).

- Page 82 DSG-423 ENGINE 12.Install the camshafts and bearing caps. Tighten bolts 14.Holding the oil pump chain sprocket in place, tighten in sequence shown in three stages: oil pump sprocket bolt: • Stage 1: Tighten finger tight • Tighten to 25 Nm (18 lb-ft).

- Page 83 DSG-423 ENGINE 19.Using a small pick, push back and hold the ratchet 23.Position timing chain guides and install guide bolts: mechanism. • Tighten to 10 Nm (89 lb-in). 20.While holding the ratchet mechanism, push the 24.Install timing chain tensioner and 2 bolts. Remove ratchet arm back into the tensioner housing.

- Page 84 DSG-423 ENGINE 28. Install the front cover and bolts. Tighten in the sequence shown in 3 stages: NOTE: Use a wrench on the flats between cylinders No.1 and No. 2 to hold the camshafts in place. • Stage 1: Tighten 8mm bolts to 10 nm (89 lb-in) •...

- Page 85 DSG-423 ENGINE 30.Install a standard 6 mm x 18 mm bolt through the 35.Install special tool 303-507. crankshaft pulley and thread it into the front cover. CAUTION: Only hand tighten the bolt in this next step or damage to the front cover can occur.

- Page 86 DSG-423 ENGINE 39.Install the plug bolt: 42.Apply silicone gasket and sealant to the locations shown. • Tighten to 20 Nm (15 lb-ft). 40.Position a new crankshaft position (CKP) sensor and 43.Install camshaft cover and tighten bolts in sequence loosely install 2 bolts.

- Page 87 DSG-423 ENGINE 47.Lubricate a new coolant pump o-ring seal with clean engine coolant and install coolant pump and 3 bolts: • Tighten to 10 Nm (89 lb-in). Knock Coolant Pump Sensor Bolts Bolt O-ring 51.Install engine vent cover and bolts: 48.Install coolant pump pulley and 3 bolts:...

- Page 88 DSG-423 ENGINE 56.Install intake manifold and bolts: 59.Install 7 new exhaust manifold studs: • Tighten to 18 Nm (13 lb-ft). • Tighten to 17 Nm (13 lb-ft). Gasket Gasket Exhaust Stud Manifold Intake Manifold Bolt 60.Position a new gasket and install exhaust manifold and 7 new nuts: 57.Install power steering pump and bolts:...

-

Page 89: Valve Clearance Check

DSG-423 ENGINE ADJUSTMENTS 64.Install oil level indicator tube: • Tighten to 10 Nm (89 lb-in). Valve Clearance Check 1. Remove camshaft cover -- Refer to“Camshaft Cover Oil Level - Removal” on page 6 of this section. Indicator CAUTION: Turn the engine clockwise only, and use the crankshaft bolt only. - Page 90 DSG-423 ENGINE SPECIFICATIONS 02-46...

- Page 91 DSG-423 ENGINE 02-47...

- Page 92 DSG-423 ENGINE 02-48...

- Page 93 DSG-423 ENGINE 02-49...

- Page 94 DSG-423 IGNITION SYSTEM INDEX Subject Page General Information ............................03 - 2 Description ..............................03 - 2 Operation ..............................03 - 3 Wiring Diagram............................03 - 4 Diagnosis and Testing............................ 03 - 5 Spark Plug Inspection ..........................03 - 5 Removal and Installation..........................

- Page 95 • Ignition Coils • Spark Plugs. The DSG-423 engine is equipped with an individual coil on plug electronic ignition system. The brain of this system is the Electronic Engine Control (GCP) Module WARNING: HIGH TENSION VOLTAGE PRODUCED which receives inputs from the following: BY A DISTRIBUTORLESS IGNITION SYSTEM IS •...

- Page 96 DSG-423 IGNITION SYSTEM Compression Stroke Exhaust Stroke Operation Engine Temperature With this system, the GCP monitors the engine speed The Engine Coolant Temperature (ECT) Sensor sends and operating temperature and decides what degree of engine temperature information to the GCP. It is located spark advance is correct for all of the operating in the rear coolant outlet pipe.

- Page 97 DSG-423 IGNITION SYSTEM Wiring Diagram 03-4...

- Page 98 DSG-423 IGNITION SYSTEM DIAGNOSIS AND TESTING Spark Plug Inspection Inspect the spark plug tip as in the chart below: 03-5...

-

Page 99: Removal And Installation

DSG-423 IGNITION SYSTEM REMOVAL AND INSTALLATION Spark Plug - Removal Ignition Coil - Replacement Spark Plug Bolt Ignition Coil 1. Remove ignition coil -- Refer to“Ignition Coil - Replacement” on page 6 of this section. 2. Loosen spark plugs and remove any dirt or foreign material from spark plug areas of cylinder head with compressed air. - Page 100 DSG-423 IGNITION SYSTEM SPECIFICATIONS GENERAL SPECIFICATIONS Firing Order 1-3-4-2 Spark Plug Type: AGSF32YPC Gap: 1.25 - 1.35 mm (0.049 - 0.053 in.) Silicone Brake Caliper Grease ESE-M1C171-A and Dielectric Compound XG- TORQUE SPECIFICATIONS Description lb.ft. lb.in. Spark plugs Coil bolts...

- Page 101 DSG-423 FUEL SYSTEM INDEX Subject Page Cautions & Warnings............................04- 2 General Information - Gasoline ........................04- 3 Description ..............................04- 3 Operation ..............................04- 4 Fuel System Requirements ........................04- 4 Wiring Diagrams............................04- 5 General Information - Dry Fuel ........................04- 7 Description ..............................

- Page 102 DSG-423 FUEL SYSTEM CAUTIONS & WARNINGS WARNING: DO NOT SMOKE OR CARRY LIGHTED TOBACCO OR OPEN FLAME OF ANY TYPE WHEN WORKING ON OR NEAR ANY FUEL-RELATED COMPONENT. HIGHLY FLAMMABLE MIXTURES ARE ALWAYS PRESENT AND MAY BE IGNITED. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

-

Page 103: General Information - Gasoline

DSG-423 FUEL SYSTEM GENERAL INFORMATION - GASOLINE Engine Coolant Temperature (ECT) Sensor Camshaft Position (CMP) Sensor Fuel Rail Actuator Injectors Description Camshaft Position (CMP) Sensor The fuel system delivers fuel by an electronic fuel pump. The Camshaft Position (CMP) Sensor is mounted in the camshaft cover. -

Page 104: Fuel System Requirements

DSG-423 FUEL SYSTEM Fuel Pressure Sensor Fuel Injectors Fuel Pump Fuel Filter Return to Tank From Tank Operation Fuel System Requirements The fuel delivery system starts with the fuel in the tank. Fuel Tanks Fuel is drawn up to the fuel pump through a pre-filter. -

Page 105: Wiring Diagrams

DSG-423 FUEL SYSTEM Wiring Diagrams Revision Level The following wiring schematics are taken from the wiring diagram labeled below: Fuel Injectors 04-5... - Page 106 DSG-423 FUEL SYSTEM Actuator / Data Link Connector (DLC) 04-6...

-

Page 107: General Information - Dry Fuel

DSG-423 FUEL SYSTEM GENERAL INFORMATION - DRY FUEL Liquid Propane Vapor Line Carburetor Vapor Propane Line Engine Description the throat and hence on the top of the diaphragm. When the pressure on the top of the diaphragm is low enough,... - Page 108 DSG-423 FUEL SYSTEM drawn into the engine. carburetor so that the actual “Delta P” matches the Delta P command from the GCP. This provides an extremely accurate open loop type of fuel control. There is also a dry fuel temperature sensor for increased pressure command accuracy.

- Page 109 DSG-423 FUEL SYSTEM Wiring Diagrams Revision Level The following wiring schematics are taken from the wiring diagram labeled below: Engine Controls - Dry Fuel EPR 04-9...

-

Page 110: Diagnosis And Testing - Lpg

DSG-423 FUEL SYSTEM DIAGNOSIS AND TESTING - LPG Symptom Chart Symptom Go to Engine Cranking But Will Not Start Page Engine Starts But Has Rough Idle Page Engine Idles with Rough Acceleration at Load Page Engine Is Unable To Reach Full Power... -

Page 111: Preliminary Test

DSG-423 FUEL SYSTEM Preliminary Test This Pinpoint Test checklist is your guide to the most probable causes of an engine performance complaint when the malfunction is due to the fuel system. Test Step Result Action to Take Inspect installation. Go to Step 2.. -

Page 112: Diagnostic Charts

DSG-423 FUEL SYSTEM Diagnostic Charts Perform the preliminary test before proceeding. Engine Cranking But Will Not Start Test Step Result Action to Take Check fuel tank. Fill or replace the fuel tank. (Do not exceed 80% of liquid capacity) Is fuel tank empty? Go to Step 2. - Page 113 DSG-423 FUEL SYSTEM Engine Cranking But Will Not Start (Continued) Test Step Result Action to Take Check FCV vacuum fitting bypass port. Clean out bypass with a .050 size pin or drill bit and retest. • CAUTION: Do not enlarge the by-...

- Page 114 DSG-423 FUEL SYSTEM The pinpoint tests below should be performed after the preliminary tests and “Engine Cranks but Will Not Start” chart Steps 1-3. Any electrical diagnostics should have been performed to eliminate any sensor, GCP or solenoid valve problems before proceeding.

- Page 115 DSG-423 FUEL SYSTEM Engine Starts But Has Rough Idle (Continued) Test Step Result Action to Take Check regulator operation. The Regulator is malfunctioning. See section 475R-1 for service of the • Using Woodward WTK-1 test kit, install the primary and converter.

- Page 116 DSG-423 FUEL SYSTEM The pinpoint tests below should be performed after the preliminary tests and “Engine Cranks but Will Not Start” chart Steps 1-3. Any electrical diagnostics should have been performed to eliminate any sensor, GCP or solenoid valve problems before proceeding...

- Page 117 DSG-423 FUEL SYSTEM Engine Idles With Rough Acceleration At Load (Continued) Test Step Result Action to Take Check FCV operation. This would indicate the engine is too lean. Possible causes: • Accelerate engine to induce symptom. • Plugged bypass port, go to Step 7.

- Page 118 DSG-423 FUEL SYSTEM The pinpoint tests below should be performed after the preliminary tests and “Engine Cranks but Will Not Start” chart Steps 1-3. Any electrical diagnostics should have been performed to eliminate any sensor, GCP or solenoid valve problems before proceeding...

- Page 119 DSG-423 FUEL SYSTEM Engine Is Unable To Reach Full Power (Continued) Test Step Result Action to Take Check FCV operation. This would indicate the engine is too lean. Possible causes: • Accelerate engine to induce symptom. • Plugged bypass port, go to Step 7.

- Page 120 DSG-423 FUEL SYSTEM The pinpoint tests below should be performed after the preliminary tests and “Engine Cranks but Will Not Start” chart Steps 1-3. Any electrical diagnostics should have been performed to eliminate any sensor, GCP or solenoid valve problems before proceeding.

- Page 121 DSG-423 FUEL SYSTEM Engine Misses (Continued) Test Step Result Action to Take Check carburetor air valve for binding. Refer to section 475-1 for servicing the carburetor. • With the air cleaner removed, pull the air valve piston upwards to ensure free movement of the carburetor air valve.

-

Page 122: Engine Backfires

DSG-423 FUEL SYSTEM The pinpoint tests below should be performed after the preliminary tests and “Engine Cranks but Will Not Start” chart Steps 1-3. Any electrical diagnostics should have been performed to eliminate any sensor, GCP or solenoid valve problems before proceeding. - Page 123 DSG-423 FUEL SYSTEM Engine Backfires (Continued) Test Step Result Action to Take Check carburetor air valve for binding. Refer to section 475-1 for servicing the carburetor. • Key ON, Engine Running. • With the air cleaner removed, pull the air valve piston upwards to ensure free movement of the carburetor air Go to ?????????.

- Page 124 DSG-423 FUEL SYSTEM The pinpoint tests below should be performed after the preliminary tests and “Engine Cranks but Will Not Start” chart Steps 1-3. Any electrical diagnostics should have been performed to eliminate any sensor, GCP or solenoid valve problems before proceeding.

- Page 125 DSG-423 FUEL SYSTEM The pinpoint tests below should be performed after the preliminary tests and “Engine Cranks but Will Not Start” chart Steps 1-3. Any electrical diagnostics should have been performed to eliminate any sensor, GCP or solenoid valve problems before proceeding.

- Page 126 DSG-423 FUEL SYSTEM Emission Failure - Lean Mixture (Continued) Test Step Result Action to Take Check air valve operation. Refer to section 475-1 for servicing the carburetor. • Using the WTK-1 test kit, connect the vacuum gauge between the carburetor and the FCV valve to measure the carburetor air valve vacuum (AVV).

-

Page 127: Engine Overheats

DSG-423 FUEL SYSTEM The pinpoint tests below should be performed after the preliminary tests and “Engine Cranks but Will Not Start” chart Steps 1-3. Any electrical diagnostics should have been performed to eliminate any sensor, GCP or solenoid valve problems before proceeding. - Page 128 DSG-423 FUEL SYSTEM The pinpoint tests below should be performed after the have been performed to eliminate any sensor, GCP or preliminary tests and “Engine Cranks but Will Not solenoid valve problems before proceeding. Start” chart Steps 1-3. Any electrical diagnostics should...

- Page 129 DSG-423 FUEL SYSTEM Engine Stops Running - Dies (Continued) Test Step Result Action to Take Check air valve operation. Refer to section 475-1 for servicing the carburetor. • Using the WTK-1 test kit, connect the vacuum gauge between the carburetor and the FCV valve to measure the carburetor air valve vacuum (AVV).

-

Page 130: Visual Inspection

DSG-423 FUEL SYSTEM DIAGNOSIS AND TESTING - GASOLINE NOTE: For diagnosis of Electronic Engine Control - WARNING: REFER TO WARNINGS AT THE refer to Section 08. BEGINNING OF THIS SECTION. Visual Inspection 1. Remove the Schrader valve cap and attach a fuel pressure gauge. -

Page 131: Fuel Pressure Relief

DSG-423 FUEL SYSTEM GENERAL SERVICE PROCEDURES 3. Install special tool 310-D005 as shown. Fuel Pressure Relief WARNING: REFER TO WARNINGS AT THE BEGINNING OF THIS SECTION. 1. Disconnect the negative battery cable -- refer to Section 6. 2. Remove the Schrader valve cap and attach a fuel pressure gauge. -

Page 132: Spring Lock Coupling - Type Ii - Connect

DSG-423 FUEL SYSTEM 2. Lubricate o-ring seals with clean engine oil. push into fitting. CAUTION: Make sure the fuel tube clicks into place 4. Separate the fitting. when installing the tube. To make sure that the fuel tube is fully seated, pull on the tube. -

Page 133: Quick Connect Coupling - Type I - Connect

DSG-423 FUEL SYSTEM then install safety clip. it is fully seated. 4. Pull on the fitting to make sure it is fully engaged. Quick Connect Coupling - Type I - Disconnect Quick Connect Coupling - Type II - Disconnect WARNING: REFER TO WARNINGS AT THE BEGINNING OF THIS SECTION. -

Page 134: Quick Connect Coupling - Type Ii - Connect

DSG-423 FUEL SYSTEM Quick Connect Coupling - Type II - Connect 1. Inspect for damage and clean fittings. CAUTION: Make sure the fuel tube clicks into place when installing the tube. To make sure that the fuel tube is fully seated, pull on the tube. -

Page 135: Fuel Rail & Injectors - Replacement

DSG-423 FUEL SYSTEM REMOVAL AND INSTALLATION RESULTING IN POSSIBLE PERSONAL INJURY. Fuel Rail & Injectors - Replacement WARNING: FUEL IN THE FUEL SYSTEM REMAINS UNDER HIGH PRESSURE EVEN WHEN THE ENGINE IS NOT RUNNING. BEFORE WORKING ON OR DISCONNECTING ANY OF THE FUEL LINES OR... -

Page 136: Actuator - Removal

DSG-423 FUEL SYSTEM Actuator - Removal Actuator - Installation 1. Remove and/or disconnect components to allow 1. Inspect gasket and install a new one if necessary. access and removal of the actuator. Label if 2. Position actuator onto studs. necessary to allow for correct reinstallation. - Page 137 DSG-423 FUEL SYSTEM SPECIFICATIONS GENERAL SPECIFICATIONS Fuel pressure 414-448 kPa (60-65 psi) Motorcraft SAE 5W20 Super WSS-M2C930-A Premium TORQUE SPECIFICATIONS Description lb.ft. lb.in. Fuel rail bolts 04-37...

- Page 138 DSG-423 COOLING SYSTEM INDEX Subject Page General Information ............................05 - 3 Description ..............................05 - 3 Diagnosis and Testing............................ 05 - 5 Visual Inspection ............................05 - 5 Coolant Inspection ............................ 05 - 5 Coolant Range Check ..........................05 - 5 Drive Belt Inspection ..........................

- Page 139 DSG-423 COOLING SYSTEM CAUTIONS & WARNINGS This may cause permanent damage to the engine. CAUTION: The use of straight water as a coolant will cause permanent damage to the engine. CAUTION: Never use a cold coolant mixture to top- WARNING: THE RADIATOR OR DEGAS TANK IS up the radiator or degas tank of a hot engine if the EQUIPPED WITH A PRESSURE CAP.

- Page 140 DSG-423 COOLING SYSTEM GENERAL INFORMATION system as it cools. The degas bottle allows air separation during operation which reduces engine hot spots. Upper Hose Radiator Fan Assembly Degas Bottle Belt Tensioner Coolant Lower Hose Pump Description The cooling system consists of the following: •...

- Page 141 DSG-423 COOLING SYSTEM CAUTION: Not all coolant recycling processes pro- duce coolant which meets Ford specification ESE- M97B44-A or WSS-M97B44-D. Use of coolant that does not meet specifications may harm engine and cooling system components. CAUTION: Do not use alcohol type antifreeze, alka- line brine solutions, or 100,000 mile, red in color an- tifreeze.

-

Page 142: Coolant Inspection

DSG-423 COOLING SYSTEM DIAGNOSIS AND TESTING Coolant Inspection WARNING: REFER TO CAUTIONS AND WARNINGS WARNING: REFER TO CAUTIONS AND WARNINGS AT THE BEGINNING OF THIS SECTION. AT THE BEGINNING OF THIS SECTION. Check level and condition of coolant: Begin diagnosis by verifying the customer’s concern by •... -

Page 143: Drive Belt Inspection

DSG-423 COOLING SYSTEM Drive Belt Inspection • Longer deposits building up to 50% of the rib height is also not a concern, except it can result in excessive noise. WARNING: REFER TO CAUTIONS AND WARNINGS AT THE BEGINNING OF THIS SECTION. - Page 144 DSG-423 COOLING SYSTEM Symptom Chart Refer to the following Diagnosis Chart for cooling system problems, their possible cause and recommended correction. CONDITION POSSIBLE SOURCE ACTION • • Loss of coolant Pressure cap and gasket Inspect, wash gasket and test. Replace only if cap will not hold pressure to specification.

-

Page 145: Cooling System Pressure Test

DSG-423 COOLING SYSTEM Cooling System Pressure Test 2. Fit the radiator cap to the pressure tester using an adapter. Pressure Tester Pressure Adapter Tester NOTE: If the plunger of the pressure tester is depressed too fast, an incorrect pressure reading will result. -

Page 146: Draining The Cooling System

DSG-423 COOLING SYSTEM GENERAL SERVICE PROCEDURES Flushing the Cooling System To remove rust, sludge and other foreign material from Draining the Cooling System the cooling system, use Rotunda Cooling System Cleanser. Removal of such material restores cooling efficiency and avoids overheating. -

Page 147: Drive Belt - Removal

DSG-423 COOLING SYSTEM REMOVAL AND INSTALLATION Idler Pulley Tensioner Belt NOTE: If a major component of the cooling system is on page 10 of this section. renewed such as the radiator, water pump etc., the 2. Remove bolt. system should be flushed and re-filled with a 50% solution of Motorcraft Premium Gold engine coolant, or 3. -

Page 148: Radiator Hose - Removal

DSG-423 COOLING SYSTEM Radiator Hose - Removal Radiator Hose - Installation 1. Position the clamps at least 1/8 inch from each end of the hose. WARNING: REFER TO CAUTIONS AND WARNINGS AT THE BEGINNING OF THIS SECTION. 2. Coat the connection areas with an approved water- resistant sealer and slide the hose on the connection. -

Page 149: Thermostat & Housing - Replacement

DSG-423 COOLING SYSTEM Thermostat & Housing - Replacement 1. Allow the engine to cool down until the coolant has lowered in temperature to below 110°F. 2. Drain the radiator so coolant level is below the thermostat -- Refer to“Draining the Cooling System”... -

Page 150: Coolant Pump - Replacement

DSG-423 COOLING SYSTEM Coolant Pump - Replacement Cooling System” on page 9 of this section. 2. Remove or disconnect components as necessary to gain access to the coolant pump. WARNING: REFER TO CAUTIONS AND WARNINGS 3. Remove the drive belt -- Refer to“Drive Belt - AT THE BEGINNING OF THIS SECTION. -

Page 151: Block Heater - Replacement

DSG-423 COOLING SYSTEM Block Heater - Replacement 1. Drain the cooling system -- Refer to“Draining the Cooling System” on page 9 of this section. 2. Disconnect the block heater electrical connector. Block Heater Electrical Connector Screw Outlet Pipe - Replacement NOTE: Do not loosen the screw more than necessary for removal. -

Page 152: Coolant Bypass - Replacement

DSG-423 COOLING SYSTEM Coolant Bypass - Replacement 2. Remove or disconnect components as necessary to gain access to the bypass hose. 1. Drain the cooling system -- Refer to“Draining the 3. Detach coolant bypass hose from the routing clip. Cooling System” on page 9 in this section. - Page 153 DSG-423 COOLING SYSTEM SPECIFICATIONS GENERAL SPECIFICATIONS Coolant/Water Mixture 50/50 Pressure Relief Cap Opening 89 - 124 kPa (13 - 18 psi) Pressure kPa (psi) Radiator Pressure Test 138 kPa (20 psi) Thermostat start to open 90°C (194° F) temperature Thermostat full open 97 - 106°C (206 - 222°...

- Page 154 DSG-423 CHARGING SYSTEM INDEX Subject Page General Information ............................06- 3 Description ..............................06- 3 Operation ..............................06- 3 Wiring Diagram............................06- 4 Diagnosis and Testing............................. 06- 5 Preliminary Checks ............................ 06- 5 Warning Indicator Check ..........................06- 5 Symptom Chart ............................06- 6 Battery Drain Test ............................

- Page 155 DSG-423 CHARGING SYSTEM CAUTIONS & WARNINGS Typical Battery Labeling The handling and correct use of lead acid batteries is not as hazardous provided that sensible precautions are observed and that operatives have been trained in their use and are adequately supervised. It is important that all labeling on the battery is carefully read, understood and complied with.

- Page 156 DSG-423 CHARGING SYSTEM GENERAL INFORMATION Battery power The battery is a 12 volt DC source connected in a Bracket negative ground system. There are three main functions of the battery: Generator Drive Belt • To supply power to the starter and ignition system so the engine can be cranked and started.

-

Page 157: Wiring Diagram

DSG-423 CHARGING SYSTEM Wiring Diagram Revision Level The following wiring schematics are taken from the wiring diagram labeled below: Charging System 06-4... -

Page 158: Preliminary Checks

DSG-423 CHARGING SYSTEM DIAGNOSIS AND TESTING Warning Indicator Check Check the operation of the charging system warning indicator as follows: WARNING: REFER TO CAUTIONS & WARNINGS AT • Ignition OFF = Indicator should be OFF. THE BEGINNING OF THIS SECTION. - Page 159 DSG-423 CHARGING SYSTEM Symptom Chart CONDITION POSSIBLE SOURCE ACTION • Dead battery. Key-off battery drain. Repair as necessary • Battery will not stay charged. Open/voltage drop in B+ circuit. Slow crank. • Open voltage drop in A circuit. Low battery voltage.

-

Page 160: Battery Drain Test

DSG-423 CHARGING SYSTEM Battery Drain Test Battery Load Test WARNING: REFER TO CAUTIONS & WARNINGS AT WARNING: REFER TO CAUTIONS & WARNINGS AT THE BEGINNING OF THIS SECTION. THE BEGINNING OF THIS SECTION. A defective component or wiring defect may be causing 1. -

Page 161: Generator Output Test

DSG-423 CHARGING SYSTEM Generator Output Test Generator Voltage Test WARNING: REFER TO CAUTIONS & WARNINGS AT THE BEGINNING OF THIS SECTION. WARNING: REFER TO CAUTIONS & WARNINGS AT CAUTION: To prevent damage to the generator, do THE BEGINNING OF THIS SECTION. -

Page 162: Battery Cleaning And Inspection

DSG-423 CHARGING SYSTEM GENERAL SERVICE PROCEDURES Use a suitable battery carrier for lifting and transporting the battery. The illustration shows a clamp-type carrier used to grip the sidewalls of the container just below the lip of the cover. The carrier is used on the sidewalls, WARNING: REFER TO CAUTIONS &... - Page 163 DSG-423 CHARGING SYSTEM Battery Charging • Perform a two-hour charge using 20A constant current (manual setting on charger). • Perform a two-hour charge using a constant potential (automatic setting on charger). WARNING: REFER TO CAUTIONS & WARNINGS AT THE BEGINNING OF THIS SECTION.

-

Page 164: Voltage Regulator - Replacement

DSG-423 CHARGING SYSTEM REMOVAL AND INSTALLATION Voltage Regulator - Replacement 1. Remove the generator -- Refer to“Generator - Replacement” on page 11 of this section. 2. Remove 4 screws and voltage regulator (includes brush and holder). Generator Bolts Voltage Regulator... -

Page 165: Generator Pulley - Replacement

DSG-423 CHARGING SYSTEM Generator Pulley - Replacement 1. Remove generator assembly -- Refer to“Generator - Replacement” on page 11 of this section. 2. Remove nut. Pulley 3. Remove pulley. 4. Reverse procedure to install: • Tighten nut to 109 Nm (80 lb-ft). -

Page 166: Battery - Removal

DSG-423 CHARGING SYSTEM Battery - Removal Battery - Installation 1. Clean cable terminals and battery hold down clamp with a wire brush. Replace all cables or parts that are worn or frayed. 2. Clean battery tray with a wire brush and scraper. - Page 167 DSG-423 CHARGING SYSTEM SPECIFICATIONS GENERAL SPECIFICATIONS Generator output 65/110 max. amps @ 1800 - 6000 generator rpm (approx. 500 - 2000 engine rpm). Battery Motorcraft 12 Volt 540 CCA (at -18°C (0°F) 58 amp/hr. Battery Charging Voltage 13 - 15.5 volts...

- Page 168 DSG-423 STARTER INDEX Subject Page Cautions & Warnings............................07 - 2 General Information ............................07 - 3 Description ..............................07 - 3 Operation ..............................07 - 3 Wiring Diagram............................07 - 4 Diagnosis and Testing............................ 07 - 5 Visual Inspection ............................07 - 5 Symptom Chart ............................

- Page 169 DSG-423 STARTER CAUTIONS & WARNINGS CAUTION: Be sure to disconnect the battery ground cable before repairing the starter motor. WARNING: WHEN SERVICING STARTER OR PERFORMING OTHER WORK IN THE VICINITY OF THE STARTER, BE AWARE THAT THE HEAVY GAUGE BATTERY INPUT LEAD AT THE STARTER WARNING: HYDROGEN AND OXYGEN GASES ARE SOLENOID IS “ELECTRICALLY HOT”...

- Page 170 DSG-423 STARTER GENERAL INFORMATION • starter solenoid • starter relay Description • battery. The starter motor provides the rotation of the engine The starter motor is a permanent magnet, gear crankshaft, through the flywheel, that is needed to start reduction type. It runs on 12 volts DC current. The the engine.

- Page 171 DSG-423 STARTER Wiring Diagram Revision Level The following wiring schematics are taken from the wiring diagram labeled below: Starting System 07-4...

- Page 172 DSG-423 STARTER DIAGNOSIS AND TESTING WARNING: REFER TO CAUTIONS & WARNINGS AT THE BEGINNING OF THIS SECTION. NOTE: When testing with a meter, always make connections with the component terminal rather than at the wiring end connector. Making connection with the...

- Page 173 DSG-423 STARTER Symptom Chart CONDITION POSSIBLE SOURCE ACTION Starter does not crank (audible click may or Open fuse Check fuse continuity may not be heard) Low battery Refer to battery diagnosis in section 6 Defective remote relay Check relay Open circuit or high resistance in external...

-

Page 174: Motor Feed Circuit - Voltage Drop Test

DSG-423 STARTER Motor Feed Circuit - Voltage Drop Test Starter Motor - Ground Circuit Check Slow cranking is often caused by high resistance in the A slow cranking condition can be caused by resistance battery cables or connections, especially in cold in the ground or return portion of the cranking circuit. -

Page 175: Jump Starting

DSG-423 STARTER GENERAL SERVICE PROCEDURES WARNING: REFER TO CAUTIONS & WARNINGS AT THE BEGINNING OF THIS SECTION. Jump Starting For cases of a starter that cranks the engine very WARNING: TO AVOID INJURY, USE PARTICULAR slowly, connect a 12 volt booster battery to the system. -

Page 176: Starter Motor - Replacement

DSG-423 STARTER REMOVAL AND INSTALLATION WARNING: REFER TO CAUTIONS & WARNINGS AT WARNING: WHEN SERVICING STARTER OR THE BEGINNING OF THIS SECTION. PERFORMING OTHER WORK IN THE VICINITY OF THE STARTER, BE AWARE THAT THE HEAVY Starter Motor - Replacement GAUGE BATTERY INPUT LEAD AT THE STARTER SOLENOID IS “ELECTRICALLY HOT”... - Page 177 DSG-423 STARTER SPECIFICATIONS GENERAL SPECIFICATIONS Current draw NO load 60 - 80 AMPS Current draw NORMAL load Current draw MAX. load 800 AMPS Minumum stall torque 14.7 Nm (16 lb-ft) (@5 volts) Cranking speed 140 - 220 RPM Max. voltage drop (normal operating temp.)

- Page 178 DSG-423 ENGINE CONTROLS Subject Page General Information ............................08 - 2 GCP and Sensors ............................. 08 - 2 Fuel System Components - Gasoline......................08 - 8 Coil-on-plug Ignition ..........................08 - 9 Open Loop and Closed Loop Operation....................08 - 10 Adaptive Learn ............................

-

Page 179: General Information

DSG-423 ENGINE CONTROLS GENERAL INFORMATION GCP and Sensors CMP Sensor CKP Sensor TMAP Sensor HO2S Sensor KS Sensor ECT Sensor Actuator Fuel Injector Ignition Coil • Engine Control Module (GCP) Configurable inputs available based on customer requirements. The Engine Control Module (GCP) has the following •... - Page 180 DSG-423 ENGINE CONTROLS speeds (with customer-specified minimum and operational problems, alert the operator through the maximum) based on a variable signal input. Malfunction Indicator Lamp (MIL), and store diagnostic trouble codes (DTC’s). DTC’s identify the problem • It can be an electronic replacement for a throttle areas to aid the technician in making repairs.

- Page 181 DSG-423 ENGINE CONTROLS Crankshaft Position (CKP) Sensor The Crankshaft Position (CKP) Sensor provides a signal used by the Engine Control Module (GCP) to calculate the ignition sequence. The sensor initiates the reference pulses which the GCP uses to calculate RPM and crankshaft position.

- Page 182 DSG-423 ENGINE CONTROLS Engine Coolant Temperature (ECT) Sensor NOM Rt, NOM E TEMP. C° TEMP. F° (OHMS) (VOLTS) The Engine Coolant Temperature (ECT) Sensor is a 925,021 4.54 thermistor (a resistor which changes value based on temperature) mounted in the engine coolant stream.

- Page 183 DSG-423 ENGINE CONTROLS Cylinder Head Temperature (CHT) Sensor result in a lean command to compensate. The Cylinder Head Temperature (CHT) Sensor is a thermistor which changes its resistance based on the temperature of cylinder head. Low temperature produces a high resistance of 100,000 ohms at -40°C (- 40°F).

- Page 184 DSG-423 ENGINE CONTROLS Temperature Manifold Absolute Pressure (TMAP) electronically-actuated throttle plate, and a built-in throttle position (TP) Sensor. Sensor The Temperature Manifold Absolute Pressure (TMAP) Sensor responds to changes in intake manifold pressure (vacuum). The TMAP sensor signal voltage to...

-

Page 185: Fuel System Components - Gasoline

DSG-423 ENGINE CONTROLS Fuel System Components - Gasoline Fuel Injector The fuel metering system is made up of the following The Electronic Fuel Injection (EFI) fuel injector is a parts: solenoid operated device controlled by the GCP. The GCP energizes the solenoid, which opens a valve to •... -

Page 186: Coil-On-Plug Ignition

DSG-423 ENGINE CONTROLS Fuel Filter The fuel filter is an inline filter assembly. Refer to Ignition Coil Section 4 for information on relieving fuel pressure, (coil-on-plug) disconnecting fuel lines and fuel filter replacement. Fuel Filter The coil-on-plug design has individual coils mounted directly over each spark plug. -

Page 187: Open Loop And Closed Loop Operation

DSG-423 ENGINE CONTROLS Open Loop and Closed Loop Operation megohms. • NOTE: No DTC will be set unless engine has operated Do not employ any non-standard practices such as charging the battery with an arc welder. in closed loop status for more than 6 seconds. -

Page 188: Diagrams And Schematics

DSG-423 ENGINE CONTROLS Diagrams and Schematics Symbols 08-11... - Page 189 DSG-423 ENGINE CONTROLS GCP - Power Distribution Box Part of -5250010- Wiring Harness Starter Empty Relay Fuse Amps Circuits protected Battery Voltage to EPR Ignition Voltage to GCP and Relays Battery Voltage to GCP Fuel pump Battery Voltage out of Power Relay...

- Page 190 DSG-423 ENGINE CONTROLS Wire Colors Symbol Color BLACK BROWN BLUE DARK BLUE DARK GREEN GREEN GRAY LIGHT BLUE LIGHT GREEN NATURAL ORANGE PINK SILVER VIOLET WHITE YELLOW Revision Level The following wiring schematics are taken from the wiring diagram labeled below:...

- Page 191 DSG-423 ENGINE CONTROLS Power Distribution 08-14...

- Page 192 DSG-423 ENGINE CONTROLS Ignition System 08-15...

- Page 193 DSG-423 ENGINE CONTROLS Starting System 08-16...

- Page 194 DSG-423 ENGINE CONTROLS Charging System 08-17...

- Page 195 DSG-423 ENGINE CONTROLS Engine Controls - Sensors (1 of 2) 08-18...

- Page 196 DSG-423 ENGINE CONTROLS Engine Controls - Sensors (2 of 2) 08-19...

- Page 197 DSG-423 ENGINE CONTROLS Fuel Injectors 08-20...

- Page 198 DSG-423 ENGINE CONTROLS Engine Controls - Actuator / Data Link Connector (DLC) 08-21...

- Page 199 DSG-423 ENGINE CONTROLS Engine Controls - Dry Fuel EPR 08-22...

-

Page 200: Engine Component Locator View

DSG-423 ENGINE CONTROLS Engine Component Locator View CMP Sensor TMAP Sensor CHT Sensor Actuator with Throttle ECT Sensor Position (TP) Sensor HO2S Sensor Sensor 08-23... -

Page 201: Diagnosis And Testing

DSG-423 ENGINE CONTROLS DIAGNOSIS AND TESTING unless directed to do otherwise by the fault tree. The DTC’s are numbered in order of importance. Having Diagnostic Approach DTC 112 and DTC 122, both concerning the oxygen sensor, is possible. By repairing DTC 112 first, the Use the following step by step approach when problem causing the DTC 122 may also be corrected. -

Page 202: Intermittent Mil

DSG-423 ENGINE CONTROLS The actuator is limited to a maximum opening of 20%. If RPM. If the “Force to Idle” is active, it will remain active “Power Derate 2” is active, it will remain active until the until the active DTC goes away. -

Page 203: Diagnosis Using A Personal Computer

DSG-423 ENGINE CONTROLS • KOER operation a DTC is stored, the MIL will illuminate Windows 95 or newer operating system and remain on steady if the code is active. • No speed minimum • 32 MB of RAM MIL Bulb Test... - Page 204 DSG-423 ENGINE CONTROLS Interface Hook-up laptop computer. Connect interface cable to serial cable. Connect interface cable to the 4 pin diagnostic For connection to a laptop, use kit PN 2U1L 6K947-AA. connector on the engine harness. Connect serial cable to RS232 port on the back of the...

- Page 205 DSG-423 ENGINE CONTROLS GCP Software Installation A screen will pop up telling you the name of the destination folder. Insert CD into CD-ROM drive. Double click “My Computer” Icon. Double Click CD-ROM drive letter This will display the contents of the CD as shown.

- Page 206 DSG-423 ENGINE CONTROLS You will see an Installation Success” screen when the Using GCP Software - Menu Functions software is finished installing. You can begin using the technicians GCP software after installation, by clicking Start - Programs - FPP Display - FPP Display as shown.

- Page 207 DSG-423 ENGINE CONTROLS Diagnostic Trouble Codes Hear is an example of a DTC Dialogue Box. The System Fault screen is used to view and clear DTC’s, which have been set. Checking Diagnostic Trouble Codes Snap Shot Data The System Fault screen contains a listing of all of the The Snap Shot Data is a listing of specific engine Historic and Active DTC’s set within the FORD system.

- Page 208 DSG-423 ENGINE CONTROLS Flight Data Recorder Data Stream - Reading Sensor & Actuator Values The Flight Data Recorder is also a listing of specific engine system variables. These variables are recorded by the GCP for an interval of 10 seconds. The 10 second interval includes 8 seconds before the DTC sets and 2 seconds after the DTC sets.

- Page 209 DSG-423 ENGINE CONTROLS Plotting and Data Logging Here is a sample of a plot. Logging Recording the values and voltages can be a very useful Logging variables means the variables are stored to the tool while diagnosing engine problems. The FORD PC.

- Page 210 DSG-423 ENGINE CONTROLS Ignition System Test The Spark Kill diagnostic mode allows the technician to disable the ignition on individual cylinders. If the Spark Kill diagnostic mode is selected with the engine running below 1000 RPM, the minimum throttle command will lock into the position it was in when the test mode was entered.

- Page 211 DSG-423 ENGINE CONTROLS Injector Test Throttle Test To select this test mode the engine must be off, but the key must be in the ON position. The Injector Kill mode is used to disable individual fuel injectors. If the Injector Kill mode is selected with the...

- Page 212 DSG-423 ENGINE CONTROLS RAW VOLTS Screen The RAW VOLTS screen shows actual voltage readings from various circuits. Use the keys at the upper left corner or the “page” command to toggle the three main screens (GAUGES, FAULTS AND RAW VOLTS).

-

Page 213: Visual Inspection

DSG-423 ENGINE CONTROLS Visual Inspection Intermittent Problems NOTE: An intermittent problem may or may not turn on Perform a careful visual and physical engine inspection before performing any diagnostic procedure. Perform the MIL or store a DTC. Do not use the DTC charts for intermittent problems. -

Page 214: Symptom Charts

DSG-423 ENGINE CONTROLS Symptom Charts illuminate the MIL light. NOTE: EDI engines are used in many different NOTE: If you have a symptom of the pedal not working, applications and equipment. When performing any and no DTC is set, go to the voltage screen and check system diagnosis be aware of any OEM inputs or pedal voltage. - Page 215 DSG-423 ENGINE CONTROLS Engine Performance - While Under Load SYMPTOM POSSIBLE CAUSE Engine Stalls/Quits • Faulty OEM Drivers Safety Shut-off Seat Switch • Low Battery Voltage • Low Fuel Pressure • OEM Safety Shutdowns • Bad MAP Sensor • Air Restriction •...

- Page 216 DSG-423 ENGINE CONTROLS Engine Concerns SYMPTOM POSSIBLE CAUSE Oil System Concerns • Positive Crankcase Ventilation (PCV) System - High Oil Consumption • Oil Viscosity • External Leaks • Improper Oil Dipstick • Valve Seals • Cylinder Wall Taper Excessive •...

-

Page 217: Engine Control Module (Gcp) - Diagnostic Trouble Codes

DSG-423 ENGINE CONTROLS Engine Control Module (GCP) - Diagnostic Trouble Codes CAUTION: When checking codes with the diagnos- tic software, the DTC terminal can NOT be ground- CAUTION: Removing battery power before access- ing diagnostic program will erase all codes record- This section contains circuit description information and troubleshooting charts on all the DTC’s obtained by... - Page 218 DSG-423 ENGINE CONTROLS Diagnostic Trouble Code (DTC) Diagnostic Trouble Code (DTC) DTC 111 Closed Loop Multiplier High (LPG) DTC 353 MegaJector Delivery Pressure Higher than Expected DTC 112 HO2S Open/Inactive (Bank 1) DTC 354 MegaJector Delivery Pressure Lower than Expected...

- Page 219 DSG-423 ENGINE CONTROLS DTC Charts ??need DTC charts?? 08-42...

-

Page 220: Removal And Installation

DSG-423 ENGINE CONTROLS REMOVAL AND INSTALLATION 5. Install special tool 303-507 and turn the crankshaft pulley bolt to position the No. 1 cylinder at top dead center (TDC). Camshaft Position (CMP) Sensor - Replacement CMP Sensor 6. Remove 2 bolts and CKP sensor. -

Page 221: Crankshaft Position (Ckp) Sensor - Installation

DSG-423 ENGINE CONTROLS Crankshaft Position (CKP) Sensor - 6. Install the plug: Installation • Tighten to 10 Nm (89 lb-in) 1. Position CKP sensor and loosely install the 2 bolts. NOTE: The CKP sensor alignment tool is supplied with the new sensor and is not available separately. -

Page 222: Cylinder Head Temperature (Cht) Sensor - Replacement

DSG-423 ENGINE CONTROLS Cylinder Head Temperature (CHT) Sensor - Heated Oxygen Sensor (HO2S) - Replacement Replacement Boot CHT Sensor HO2S Sensor 1. Disconnect battery ground cable -- refer to section 6. 2. Remove or disconnect any component to allow 1. Disconnect battery ground cable -- refer to section 6. -

Page 223: Knock Sensor (Ks) - Replacement

DSG-423 ENGINE CONTROLS Knock Sensor (KS) - Replacement Temperature Manifold Absolute Pressure (TMAP) Sensor - Replacement Knock Sensor TMAP Sensor 1. Disconnect battery ground cable -- refer to section 6. 2. Remove or disconnect any component to allow access and removal of the knock sensor. - Page 224 DSG-423 ENGINE CONTROLS SPECIFICATIONS GENERAL SPECIFICATIONS TORQUE SPECIFICATIONS Description lb.ft. lb.in. CHT Sensor CMP Sensor CKP Sensor ECT Sensor HO2S Sensor Knock Sensor TMAP Sensor SPECIAL TOOLS HO2S Removal Tool 303-476 08-47...

- Page 225 DSG-423 METRICS INDEX Subject Page Introduction ..............................09 - 2 Nomenclature for Bolts ..........................09 - 2 Bolt Strength Identification ..........................09 - 3 Hex Nut Strength Identification ........................09 - 3 Other Types of Parts............................09 - 4 English/Metric conversion ..........................09 - 5 Decimal and Metric Equivalents ........................

-

Page 226: Nomenclature For Bolts

DSG-423 METRICS INTRODUCTION Most threaded fasteners are covered by specifications that define required mechanical properties, such as tensile strength, yield strength, proof load and hardness. These specifications are carefully considered in initial selection of fasteners for a given application. To ensure continued satisfactory vehicle performance, replacement fasteners used should be of the correct strength, as well as the correct nominal diameter, thread pitch, length, and finish. -

Page 227: Bolt Strength Identification

DSG-423 METRICS BOLT STRENGTH IDENTIFICATION English System English (inch) bolts: Identification marks correspond to bolt strength, increasing number of slashes represent increasing strength. Metric System Metric (mm) bolts: Identification class numbers correspond to bolt strength, increasing numbers represent increasing strength. Common metric fastener bolt strength property are 9.8 and 10.9 with the class identification embossed on the bolt head. -

Page 228: Dsg-423 Metrics

DSG-423 METRICS OTHER TYPES OF PARTS Metric identification schemes vary by type of part, most often a variation of that used of bolts and nuts. Note that many types of English and Metric fasteners carry no special identification if they are otherwise unique. -

Page 229: English/Metric Conversion

DSG-423 METRICS ENGLISH/METRIC CONVERSION TO CONVERT FROM MULTIPLY BY FROM DIVIDE BY TO CONVERT Energy FROM MULTIPLY BY FROM DIVIDE BY kW.h Joules (J) 3,600,000 Distance lb/ft Joules (J) 1.3558 inches 25.4 Joules (J) 1055.06 inches 0.0254 Kcal Joules (J) 4186.8... - Page 230 DSG-423 METRICS DECIMAL AND METRIC EQUIVALENTS TORQUE CONVERSION FRACTIONS DECIMAL INCH METRIC MM Newton Pound Newton Pound 1/64 .015625 .397 Meters Feet Meters Feet 1/32 .03125 .794 (Nm) (lb-ft) (Nm) (lb-ft) 3/64 .046875 1.191 0.7376 1.356 1/16 .0625 1.588 5/64 .078125...

-

Page 231: J1930 Terminology List

DSG-423 METRICS J1930 TERMINOLOGY LIST Certain Ford Component names have been changed in this Service Manual to conform to Society of Automotive Engineers (SAE) directive J1930. SAE J1930 standardizes automotive component names for all vehicle manufacturers. New Term New Acronym... - Page 232 DSG-423 METRICS New Term New Acronym Old Terms (Acronyms) Continuous Fuel Injection - Continuous Injection System (CIS) - Continuous Injection System - Electronic (continuous Injection System-E) (CIS-E) - Fuel Injection (FI) - K-Jetronic - KE-Jetronic - KE-Motronic Continuous Fuel Injection system...

- Page 233 DSG-423 METRICS New Term New Acronym Old Terms (Acronyms) Engine Coolant Level Engine Coolant Level (ECL) Engine Coolant Level Indicator ECL Indicator Engine Coolant Level Indicator Engine Coolant Temperature Engine Coolant Temperature (ECT) Engine Coolant Temperature Sensor ECT Sensor - Coolant Temperature Sensor (CTS)

- Page 234 DSG-423 METRICS New Term New Acronym Old Terms (Acronyms) Fan Control Relay FC Relay - Fan Motor Control Relay - Radiator Fan Relay Feedback Pressure Exhaust Gas Recirculation Feedback Pressure Pressure Feedback Exhaust Gas Recirculation Feedback Pressure Exhaust Gas Recirculation...

- Page 235 DSG-423 METRICS New Term New Acronym Old Terms (Acronyms) Ignition Control - Electronic Spark Advance (ESA) - Electronic spark Timing (EST) Ignition Control Module - Distributorless Ignition System Module (DIS Module) - Thick Film Ignition Module (TFI Module) Indirect Fuel Injection...

- Page 236 DSG-423 METRICS New Term New Acronym Old Terms (Acronyms) Multiport Fuel Injection - D-Jetronic - Digital Fuel Injection (EFI) - Electronic Fuel Injection (EFI) - Fuel Injection (FI) - L-Jetronic - LH-Jetronic - Motronic - Multipoint Injection (MPI) - Multiport Injection (MPI)

- Page 237 DSG-423 METRICS New Term New Acronym Old Terms (Acronyms) Relay Module Integrated Relay Module Scan Tool Scan Tool Secondary Air Injection - Air Injection (AI) - Air Injection Reactor (AIR) - Thermac - Thermactor Secondary Air Injection Bypass AIR Bypass...

- Page 238 DSG-423 METRICS New Term New Acronym Old Terms (Acronyms) Torque Converter Clutch Relay TCC Relay Lock Up Relay Torque Converter Clutch Solenoid Valve TCC Solenoid Valve Lock Up Solenoid Valve (LUS) Transmission Control Module Transmission Control Module Transmission Range - Park, Reverse, Neutral, Drive, Low (PRNDL)

- Page 239 EDI DISTRIBUTORS North America - Canada ONTARIO, M-K Power 5641 McAdam Road 905-890-5323 QUEBEC, Products Corp. Mississauga, Ontario, MONITOBA Canada, L4Z-1N9 ALBERTA, Industrial Engines, 14355 120th Avenue 780-484-6213 SASKATCHEWAN Ltd. Edmonton, Alberta Canada, T5L 2R8 North America - United States ALABAMA M&I Ford 30762 State Highway 181...

- Page 240 EDI Worldwide Service Engine Distributors Inc 400 University Court Blackwood NJ 08012 Service/Warranty 1-800-220-2700 1-856-228-7298 1-856-228-5657(fax parts & service) 1-856-228-5531(fax sales)

Need help?

Do you have a question about the DSG-423 and is the answer not in the manual?

Questions and answers

where is the engine fuel filter located on a genie boom lift ford DSG-423?

The fuel filter is located between the fuel supply and the electronic actuator mounted on the intake manifold.

This answer is automatically generated