Table of Contents

Advertisement

Installation, Start-Up, and Operating Instructions

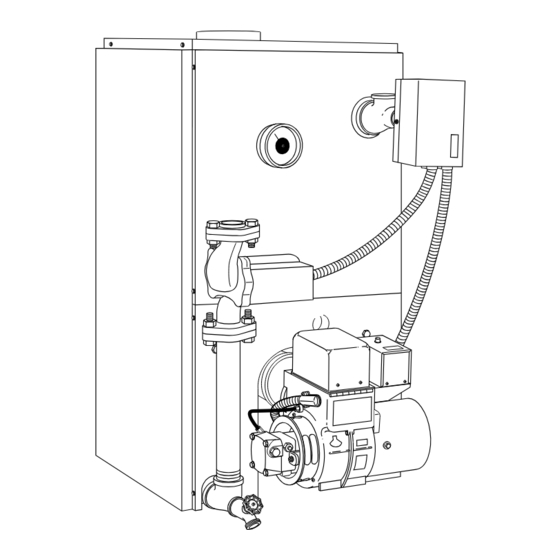

Oil-Fired

Cast Iron Hot Water Boilers

Sizes 74,000 through 239,000

Series A

NOTE: Read the entire instruction manual before starting the installation. These instructions must be affixed on or adjacent to the boiler.

This symbol → indicates a change since the last issue.

Form: IM-BW4A-03

ama

MODEL BW4/BW5

Cancels: IM-BW4A-02

ASME

Printed in U.S.A.

5-98

BW4

BW5

A88177

Catalog No. 63BW-4A0

®

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Carrier BW4

- Page 1 ® ASME NOTE: Read the entire instruction manual before starting the installation. These instructions must be affixed on or adjacent to the boiler. This symbol → indicates a change since the last issue. MODEL BW4/BW5 A88177 Form: IM-BW4A-03 Cancels: IM-BW4A-02 Printed in U.S.A.

- Page 2 INDEX Page SAFETY CONSIDERATIONS .....................................3 INTRODUCTION ..........................................3 BOILER RATINGS AND CAPACITIES..................................4 Explanation of Model Numbers and Rating Plate..............................4 General Information........................................4 LOCATING THE BOILER......................................5 INSTALLATION REQUIREMENTS...................................6 FRESH AIR FOR COMBUSTION ...................................6-7 Boiler Located in Unconfined Space ..................................6 Boiler Located in Confined Space..................................6-7 BOILERS WITH TANKLESS HEATER COIL ................................8 Mounting Aquastat Control ......................................8 Tankless Coil Piping.........................................8...

-

Page 3: Safety Considerations

SAFETY CONSIDERATIONS Installing and servicing heating equipment can be hazardous due to oil and electrical components. Only trained and qualified personnel should install, repair, or service heating equipment. Untrained personnel can perform basic maintenance functions such as maintaining water level. All other operations must be performed by trained service personnel. - Page 4 BOILER RATINGS AND CAPACITIES ⁄ IN. SUPPLY GAGE AQUASTAT CONTROL (WITHOUT COIL) AQUASTAT CONTROL 36″ (WITH COIL) ⁄ TANKLESS ⁄ HEATER ASME RETURN ⁄ IN. N.P.T. RELIEF VALVE ″ ⁄ 9″ FRONT SIDE REAR A96152 Oil-Fired Hot Water Boiler Ratings TYPICAL DIMENSIONS MAXIMUM...

-

Page 5: Locating The Boiler

LOCATING THE BOILER If boiler is part of a planned heating system, locate it as close as possible to where it is shown on plan. If boiler is to be part of an existing system, it is usually best to put it where the old one was. If location is to be changed, additional materials as well as an adequate base will be required. The following rules apply: 1. -

Page 6: Installation Requirements

INSTALLATION REQUIREMENTS Refer to Fig. 3 for the basic requirements of a typical installation. NOTE: Always keep manual fuel supply valve shut off if burner is shut down for an extended period of time. ELECTRIC LINE SERVICE LINE AUTOMATIC FILL VALVE ENTRANCE AND SHUTOFF SWITCH... - Page 7 Example: The boiler is rated at 100,000 Btuh. The water heater is rated at 30,000 Btuh. The total is 130,000 Btuh. Two grilles are needed, each with 130 sq in. of FREE opening. Metal grilles have about 60 percent FREE area. To find the louvered area needed, multiply the FREE area required by 1.7 (130 X 1.7 = 221.0 sq in.

-

Page 8: Boilers With Tankless Heater Coil

BOILERS WITH TANKLESS HEATER COIL Boilers may be factory packaged with a tankless heater coil. The use of this coil eliminates the need for a hot water storage tank. Instantaneous heating of water in coil provides a flow of hot water for domestic use if proper burner and water supply line controls are used. - Page 9 TO ZONE 2 SUPPLY MAIN TO ZONE 1 MAIN AIR VENT TO RADIATION SUPPLY MAIN AIR PURGER COLD WATER INLET AND SUPPLY MAIN AUTOMATIC FILL VALVE DIAPHRAGM-TYPE FRONT EXPANSION TANK FRONT A95598 A95599 Fig. 8—Forced Hot Water Typical Piping Fig. 9—Forced Hot Water Typical Piping with Zone Control Valves TO SYSTEM WATER...

-

Page 10: Chimney And Chimney Connection

CHIMNEY AND CHIMNEY CONNECTION Follow local codes. In the absence of local codes, follow ANSI/NFPA 31 Installation of Oil Burning Equipment, latest revision. PROCEDURE 1—CHECKING CHIMNEY The chimney is a very important part of the heating system. No boiler, however efficient its design, can perform satisfactorily if the chimney serving it is inadequate. - Page 11 MUST BE REQUIRED MINIMUM HEIGHT. MUST BE AT LEAST 3 FT HIGHER THAN HIGHEST PART OF PASSAGE THROUGH ROOF. MUST BE AT LEAST 2 FT HIGHER THAN ANY NEIGHBORING OBJECT. MUST HAVE AN UNOBSTRUCTED TOP OPENING. MUST BE AT LEAST 4 IN.

-

Page 12: Electrical Wiring

ELECTRICAL WIRING See Fig. 13-15 for wiring diagrams for the various models. PROCEDURE 1—INSTALLING THERMOSTAT (NOT PROVIDED) The 24-v thermostat location has an important effect on operation of boiler system. BE SURE TO FOLLOW INSTRUCTIONS INCLUDED WITH THERMOSTAT. PROCEDURE 2—GROUNDING Permanently ground boiler according to local codes and the National Electrical Code. - Page 13 BOILER WITH TANKLESS HEATER COIL BOILER WITHOUT TANKLESS HEATER COIL COLOR CODE 24 VOLT THERMOSTAT 120/60/1 OVERCURRENT PROTECTED DISCONNECT FIELD WIRING B=BLACK W=WHITE LINE O=ORANGE NEUT Y=YELLOW 120V NEUTRAL LINE POWER L8124C VOLTAGE SUPPLY AQUASTAT CLASS II OVERCURRENT 24 V THERMOSTAT 24 VOLTS PROTECTED FIELD WIRING...

- Page 14 120/60/1 OVERCURRENT PROTECTED DISCONNECT THERMOSTAT NEUT LINE RELAY L8124C AQUASTAT CK-KIT JUNCTION WMO-1 SECONDARY SAFETY SWITCH (SPILL SWITCH) 120 VAC SWG POWER VENTER MOTOR CIRCULATOR PUMP PPC-4 R4184 RELAY CAD CELL IGNITION OIL BURNER TRANSFORMER MOTOR A96154 Fig. 14—Boiler With Tankless Heater Coil (With Optional Field SWG Power Venter and CK-62 Control Kit) 120/60/1 OVERCURRENT PROTECTED DISCONNECT THERMOSTAT...

-

Page 15: Equipment And Optional Accessories

EQUIPMENT AND OPTIONAL ACCESSORIES PROCEDURE 1—RELIEF VALVE (PROVIDED) Each low-pressure hot water heating boiler is provided with a relief valve for over-pressure protection of boiler and heating system. The relief valve opens when pressure in boiler rises to 30 psig. Each relief valve is provided with a lifting device for testing and should be tested monthly during heating season. -

Page 16: Operating Boiler

3. Open valve in line from boiler to expansion tank. 4. Open water inlet to boiler and leave it open. 5. Start with the LOWEST radiation unit. Open the air vent on this radiation unit. When all air has escaped and water starts to flow from vent, close air vent. - Page 17 DIMENSION "H" SEE BELOW DIMENSION "Z" ″ ELECTRODE ⁄ ″ ± ″ ⁄ ⁄ WITNESS MARK LOCATION OF HEAD AT "0" POSITION ON ADJUSTING PLATE ″ ABOVE PRIMARY ⁄ ADJUSTING NOZZLE PLATE L1 OR V1 SECONDARY HEAD ADJUSTING PLATE DIMENSION "N" SEE BELOW KNURLED A95603...

-

Page 18: Checking And Adjusting Controls

Table 3—Oil Burner Nozzles DELAVAN NOZZLE TYPE FOR DELAVAN NOZZLE TYPE FOR UNIT SIZE UNIT CAPACITY BECKETT AFG OIL BURNER BECKETT AFII OIL BURNER OIL PUMP 100 PSI OIL PUMP 140 PSI 74,000 0.65-70°-B — 92,000 0.75-70°-A 0.65-70°-B 120,000 1.00-70°-A 0.85-60°-B 111,000 0.90-60°-W... -

Page 19: Oil Boiler/Burner Cleaning Instructions

PROCEDURE 2—EXPANSION TANK As previously noted, this tank may become waterlogged or may receive an excess of air. Frequent automatic opening of relief valve indicates waterlogging. A high boiler temperature accompanied by unusually low radiation unit temperature (and "knocking") indicates excess air in tank. To correct either condition, close valve between boiler and tank. - Page 20 14. Carefully vacuum soot accumulations from combustion chamber area being particularly careful not to damage target wall with vacuum. 15. Reinstall burner/fire door assembly. 16. Reinstall flue collector top, "Z" bars, and top jacket support bracket and secure with 2 brass wing nuts. 17.

-

Page 21: Service Hints

240 F (116 C) SWITCH BREAKS ON RISE, TURNS BURNER HI LIMIT OFF. CIRCULATOR SETTING OPERATES ON CALL 10 F (5.6 C) FOR HEAT. DIFF SWITCH MAKES ON FALL. BURNER OPERATES ON CALL FOR HEAT. SWITCH MAKES R-W, BREAKS R-B ON RISE (25 F [13.9 C] 25 F (13.9 C) DIFFERENTIAL). -

Page 22: Repair Parts

REPAIR PARTS → OIL-FIRED HOT WATER BOILERS 18 BLOCK ASSEMBLY A96157 Boiler Parts This is a Repair Parts List—Not a Packing List PART NO. DESCRIPTION 3 Section 4 Section 5 Section 403-00-004 403-00-004 403-00-004 Fire Door 403-00-005 403-00-005 403-00-005 Observation Door 146-95-006 146-95-006 146-95-006... - Page 23 REPAIR PARTS OIL-FIRED HOT WATER BOILERS A95613 Flush Jacket Parts This is a Repair Parts List—Not a Packing List PART NO. DESCRIPTION 3 Section 4 Section 5 Section 425-00-271 425-00-271 425-00-271 Back Panel 425-00-251 425-00-252 425-00-253 Top Panel 425-00-241 425-00-242 425-00-243 Right Side Panel 425-00-270...

- Page 24 REPAIR PARTS OIL-FIRED HOT WATER BOILERS A96156 Controls PART NO. DESCRIPTION 3 Section 4 Section 5 Section 146-19-012 146-19-013 146-19-013 Beckett AFG Oil Burner, Primary Control and Cad Cell 146-19-026 146-19-026 — Beckett AF-II Oil Burner, Primary Control and Cad Cell 146-95-101 146-95-101 146-95-101...

Need help?

Do you have a question about the BW4 and is the answer not in the manual?

Questions and answers