Table of Contents

Advertisement

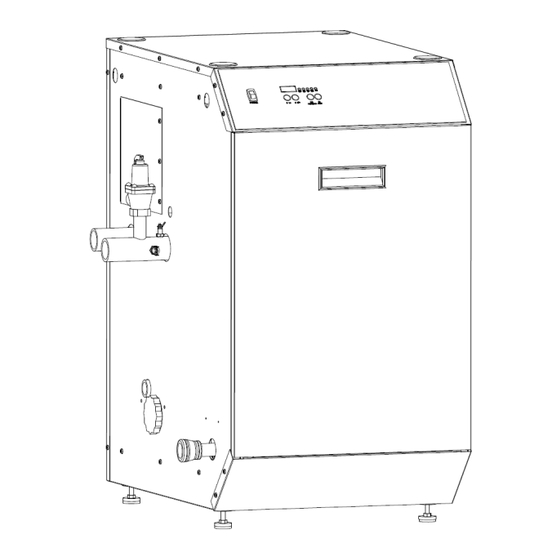

Mod Con

INSTALLATION

START-UP

MAINTENANCE

PARTS

Models

300 / 500 / 850

LP / HL / LPHL

Heat Exchanger Bears the ASME "H" Stamp

This manual must only be used by a qualified heating installer/service technician. Read all instructions in this manual before installing.

Perform steps in the order given. Failure to comply could result in substantial property damage, severe personal injury, or death.

NOTICE: HTP reserves the right to make product changes or updates without notice and will not be held liable for typographical errors

in literature.

NOTE TO CONSUMER: PLEASE KEEP ALL INSTRUCTIONS FOR FUTURE REFERENCE.

120 Braley Rd. P.O. Box 429

East Freetown, MA 02717-0429

www.htproducts.com

LP- 205 REV. 9.2.14

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for HTP Mod Con

- Page 1 Perform steps in the order given. Failure to comply could result in substantial property damage, severe personal injury, or death. NOTICE: HTP reserves the right to make product changes or updates without notice and will not be held liable for typographical errors in literature.

- Page 2 IF THE INFORMATION IN THIS MANUAL IS NOT FOLLOWED EXACTLY, A FIRE OR EXPLOSION MAY RESULT, CAUSING PROPERTY DAMAGE, PERSONAL INJURY, OR LOSS OF LIFE. DO NOT STORE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE. WHAT TO DO IF YOU SMELL GAS ...

- Page 3 In some circumstances, the property owner or his/her agent assumes the role, and at government installations, the commanding officer or departmental official may be the AHJ. NOTE: HTP, Inc. reserves the right to modify product technical specifications and components without prior notice. FOR THE INSTALLER This manual must only be used by a qualified heating installer/service technician.

-

Page 4: Table Of Contents

The latest version of the National Electrical Code, NFPA No. 70. NOTE: The gas manifold and controls met safe lighting and other performance criteria when the boiler underwent tests specified in ANSI Z21.13 – latest edition. The hydronic supply and return connections of these products are for installation in closed loop systems ONLY! Use of this product in any manner other than described in this manual may result in premature product failure, substantial property damage, severe personal injury, or death. - Page 5 PART 4 – BOILER PIPING ................................ 14 A. GENERAL PIPING INFORMATION ............................14 B. RELIEF VALVE ..................................15 C. BACKFLOW PREVENTER ............................... 15 D. SYSTEM WATER PIPING METHODS ............................. 15 E. CIRCULATORS ..................................16 F. HYDRONIC PIPING WITH CIRCULATORS, ZONE VALVES, AND MULTIPLE BOILERS ............16 G.

- Page 6 PART 12 – MAINTENANCE ..............................59 A. MAINTENANCE PROCEDURES .............................. 59 B. COMBUSTION CHAMBER COIL CLEANING INSTRUCTIONS FOR HEATER ..............60 BOILER START-UP REPORT ..............................67 MAINTENANCE REPORT ................................. 67 MAINTENANCE NOTES .................................. 71 HTP CUSTOMER INSTALLATION RECORD FORM........................72 LP- 205 REV. 9.2.14...

-

Page 7: Part 1 - General Safety Information

Due to low water content of the boiler, improperly sizing the boiler in regard to heating system load will result in excessive boiler cycling and accelerated component failure. HTP DOES NOT warrant failures caused by improperly sized boiler applications. DO NOT oversize the boiler to the system. -

Page 8: Boiler Water

These chemicals can attack gaskets and seals in water boilers, are poisonous if consumed, and can cause injury or death. Consider piping and installation when determining boiler location. NOTE: Damages resulting from incorrect installation or from use of products not approved by HTP, Inc. ARE NOT covered by warranty. PART 2 – BEFORE YOU START A. -

Page 9: Optional Equipment

Indirect Tank Sensor (optional) – Monitors storage tank temperature. C. OPTIONAL EQUIPMENT Below is a list of optional equipment available from HTP. These additional options may be purchased through your HTP distributor. System Sensor (Part # 7250P-324) ... -

Page 10: Leveling And Dimensions

Failure of boiler or components due to incorrect operating conditions IS NOT covered by product warranty. 1. Installation Area (Mechanical Room) Operating Conditions Ensure ambient temperatures are higher than 32 C and lower than 104 F/40 Prevent the air from becoming contaminated by the products, places, and conditions listed in this manual, Part 3, Section F. ... - Page 11 Figure 2 – Specifications and Dimensions LP- 205 REV. 9.2.14...

-

Page 12: Clearances For Service Access

C. CLEARANCES FOR SERVICE ACCESS See Figure 3 for recommended service clearances. If you do not provide the minimum clearances shown, it might not be possible to service the boiler without removing it from the space. Space must be provided with combustion / ventilation air openings correctly sized for all appliances located in the same space as the boiler. -

Page 13: Removing A Boiler From A Common Vent System

PRODUCTS TO AVOID AREAS LIKELY TO HAVE CONTAMINANTS Spray cans containing fluorocarbons Dry cleaning/laundry areas and establishments Permanent wave solutions Swimming pools Chlorinated waxes/cleaners Metal fabrication plants Chlorine-based swimming pool chemicals Beauty shops Calcium chloride used for thawing Refrigeration repair shops Sodium chloride used for water softening Photo processing plants Refrigerant leaks... -

Page 14: Uncrating And Moving Boiler

Plumbing of this product should only be done by a qualified, licensed plumber in accordance with all local plumbing codes. The boiler may be connected to a storage tank to supply domestic hot water. HTP offers 60/80/119/175 gallon size storage tanks in either stainless steel or glass-lined construction. -

Page 15: Relief Valve

All piping methods shown in this manual use primary/secondary connection to the boiler loop. This is to avoid the possibility of inadequate flow through the boiler. For other piping methods, consult your local HTP representative, or refer to Boiler Piping Details in this manual, Part 4, Section G. -

Page 16: Circulators

On a boiler installed above radiation level, some states and local codes require a low water cut off device. This is provided standard on the Mod Con boiler. Check with local codes for additional requirements. If the boiler supplies hot water to heating coils in air handler units, flow control valves or other devices must be installed to prevent gravity circulation of boiler water in the coils during the cooling cycle. -

Page 17: Circulator Sizing

4. Install a back flow preventer on the cold feed make-up water line. 5. Install a pressure reducing valve on the cold feed make-up water line (15 PSI nominal on the system return). Check temperature and pressure gauge when operating. It should read a minimum pressure of 12 PSI. 6. -

Page 18: Fill And Purge Heating System

To size, simply add up the number of boilers and the required flow rates for the system design temperature. Example: (5) Mod Con 300 boilers with a design of 30 F temperature rise with each boiler having an individual flow rate of 20 GPM. To correctly size the manifold feeding these boilers, you would need a pipe size of 3”. -

Page 19: Freeze Protection Fluids

I. FREEZE PROTECTION FLUIDS Use only inhibited glycol solutions which are specially formulated for hydronic systems. Ethylene glycol is toxic and can attack gaskets and seals used in hydronic systems. Glycol mixtures should not exceed 50%. 1. Glycol in hydronic applications is specially formulated for this purpose, and includes inhibitors that prevent the glycol from attacking metallic system components. -

Page 20: Boiler Piping Details

6. The minimum pipe size for connecting an HTP indirect fired water heater is 1”. 7. The minimum pipe size for connecting a Mod Con boiler is 1 ½” for the 300 and 2” for the 500 and 850. 8. System flow (Secondary Loop) must be greater than the boiler’s Primary Loop flow. - Page 21 Figure 9 – Cascade Multiple Boilers – Indirect Priority on One FIGURE NOTES: 1. This drawing is meant to demonstrate system piping concept only. 2. A mixing valve is recommended if the DHW temperature is set above the factory setting of 119 3.

- Page 22 4. Install a minimum of 6 diameters of straight pipe up and downstream of all closely spaced tees. 5. The minimum pipe size for connecting a Mod Con boiler is 1 ½” for the 300 and 2” for the 500 and 850.

-

Page 23: Part 5 - Venting, Combustion Air And Condensate Removal

Figure 11 – Cascaded Boilers – Space Heating FIGURE NOTES: 1. This drawing is meant to demonstrate system piping concept only. 2. Installations must comply with all local codes. 3. Install a minimum of 12 diameters of straight pipe upstream of all circulators. 4. -

Page 24: General

A. GENERAL This boiler is certified as a “Category IV” appliance, and requires a special venting system. The vent system will operate with a positive pressure in the pipe. Exhaust gases must be piped directly outdoors using the vent materials and rules outlined in these instructions. Do not connect vent connectors serving appliances vented by natural draft into any portion of mechanical draft systems operating under positive pressure. -

Page 25: Requirements For Installation In Canada

When installing AL29-4C vent piping, install a PVC-to-stainless adapter at the boiler vent connection, and at the termination when using an HTP PVC termination kit. DO NOT mix AL-29-4C piping from different manufacturers unless using adapters specifically designed for the purpose by the manufacturer. -

Page 26: Exhaust Vent And Intake Air Vent Pipe Location

Figure 12 D. EXHAUST VENT AND INTAKE AIR VENT PIPE LOCATION You must insert the provided intake and exhaust screen at your vent termination to prevent blockage caused by debris or birds. NOTE: SEE ADDITIONAL REQUIREMENTS FOR MASSACHUSETTS IN THE BACK OF THIS MANUAL. 1. - Page 27 Condensate from the boiler is slightly acidic with a pH of 3.2 - 4.5. To avoid long term damage to the drainage system and to meet local code requirements, HTP recommends neutralizing the condensate with a Condensate Neutralizer Kit (Part # 7350P-611). The neutralizer kit connects to the drain system and contains marble chips that neutralize the pH level of the water vapor.

- Page 28 Figure 13 – Condensate Piping NOTE: Blow water into the condensate collector to remove any foreign matter that may block the line. NOTES: 1. Condensate line must be pitched at least 1/4" per foot to properly drain. If this cannot be done, or a very long length of condensate hose is used, you must increase the condensate line to a minimum of 1”...

-

Page 29: Exhaust Vent And Intake Air Vent Sizing

E. EXHAUST VENT AND INTAKE AIR VENT SIZING 1. The exhaust vent and intake air vent pipes are 4” for the Mod Con 300 and 500 and 6” for the Mod Con 850. 2. The total combined equivalent length of exhaust vent and intake air pipe should not exceed 200 feet. -

Page 30: Boiler Removal From A Common Vent System

NOTE: For Canadian Installations, it is required that Non Metallic Vent Installations conform to ULC S636. Where plastic venting is not allowed, HTP recommends AL294C Stainless Steel Venting be used for Exhaust venting installations and “B” vent for intake air. -

Page 31: Sidewall Venting Diagrams

I. SIDEWALL VENTING DIAGRAMS Figure 15 – Sidewall Venting Diagrams All vent pipes must be glued, properly supported, and the exhaust must be pitched a minimum of ¼” per foot back to the boiler to allow drainage of condensate. Exhaust connection insertion depth should be a minimum of 2 ½” for models 300/500 and 3” for 850. When placing support brackets on vent piping, the first bracket must be within 1’... - Page 32 Figure 16 – Sidewall Venting with Tee and Coupling All vent pipes must be glued, properly supported, and the exhaust must be pitched a minimum of ¼” per foot back to the boiler to allow drainage of condensate. Exhaust connection insertion depth should be a minimum of 2 ½” for models 300/500 and 3” for 850. When placing support brackets on vent piping, the first bracket must be within 1’...

-

Page 33: Vertical Venting Diagrams

J. VERTICAL VENTING DIAGRAMS Figure 17 – Two Pipe Roof Venting with Tee and Coupling All vent pipes must be glued, properly supported, and the exhaust must be pitched a minimum of ¼” per foot back to the boiler to allow drainage of condensate. - Page 34 Figure 18 – Roof and Sidewall Venting with Stainless Steel Take extra precaution to adequately support the weight of vent pipes terminating through the roof. Failure to properly support roof terminated vent piping could result in property damage, serious personal injury, or death due to flue gas leakage. All vent pipes must be glued, properly supported, and the exhaust must be pitched a minimum of ¼”...

-

Page 35: Part 6 - Gas Piping

Failure to follow this warning could result in substantial property damage, severe personal injury, or death. The gas connection on the boiler is 1-1/4” for the Mod Con 300, 1-1/2” for the Mod Con 500, and 2” for the Mod Con 850. It is mandatory that this fitting is used for connection to a field fabricated drip leg as shown in the illustration above per the National Fuel Gas Code. -

Page 36: Gas Table

Maximum capacity of pipe in cubic feet of gas per hour for gas pressures of .5 w.c. or less and a pressure drop of .3 inch w.c. Table 8 – Gas Supply Piping Size Chart for Mod Con Boilers D. CHECK INLET GAS PRESSURE The gas valve is equipped with an inlet gas pressure tap that can be used to measure the gas pressure to the unit. -

Page 37: Gas Valve

Attempts by the installer to adjust or measure the gas valve outlet pressure could result in damage to the valve and cause substantial property damage, severe personal injury, or death. E. GAS VALVE Figure 20 – Mod Con 300/500 Gas Valve LP- 205 REV. 9.2.14... - Page 38 Figure 21 – Mod Con 850 Gas Valve Do not do a gas conversion on this boiler without an officially approved conversion kit and instructions supplied by HTP. Failure to use a conversion kit when converting the boiler to fire on Natural or LP gas will result in extremely dangerous burner operation, leading to fire, explosion, severe injury or death.

-

Page 39: Part 7 - Field Wiring

All connections made to the boiler in the field are done inside the electrical junction box located on the side of the unit. The electrical junction box is located on the right side of the Mod Con 300, and the left side of both the Mod Con 500 and 850. Multiple knockout loca- tions are available to route field wires into and out of the electrical junction box. -

Page 40: Alarm Connections

3. If the thermostat is equipped with an anticipator and it is connected directly to the Mod Con boiler, the anticipator should be set at .1 amps. If the thermostat is connected to other devices, the anticipator should be set to match the power requirements of the device it is connected to. -

Page 41: Optional 0-10 Volt Building Control Signal

1. The boiler will operate an indirect fired water heater with either a thermostat type aquastat installed in the indirect tank, or an HTP 7250P-325 tank sensor. When a tank sensor is used, the control will automatically detect its presence and a demand for heat from the indirect water heater will be generated when the tank temperature falls below the user selected set point by more than the user selected offset. -

Page 42: Optional Ul353 Low Water Cut-Off Interface Kit

NOTE: Installing the optional flow switch will disable the built-in low water cutoff. If a flow switch and a low water cutoff are necessary for the installation, purchase and install the optional UL353 LWCO (available from HTP, Part # 7350P-601). In this installation, it is recommended to install the flow switch kit first. -

Page 43: Cascade Master Pump And Sensor Wiring

Figure 24 Figure 25 – Cascade Resistor Plug Installation Detail O. CASCADE MASTER PUMP AND SENSOR WIRING 1. Place the cascade master overlay sticker onto the field connection board on the boiler designated as the cascade master. 2. Connect the system pump hot wire to the terminal marked SYS PUMP. 3. -

Page 44: Cascade Follower Pump And Sensor Wiring

7. Connect the outdoor sensor (if used) to the terminals marked OUTDOOR SEN. 8. Connect the signal to start the system to the terminals marked THERMOSTAT. NOTE: This signal can come from a room thermostat or a dry contact closure. No power of any voltage should be fed into either of these terminals. - Page 45 Figure 26 – Mod Con Cascade Master and Follower Wiring LP- 205 REV. 9.2.14...

- Page 46 Figure 27 – Mod Con Internal Connection Diagram LP- 205 REV. 9.2.14...

-

Page 47: Part 8 - Start-Up Preparation

PART 8 – START-UP PREPARATION Thoroughly clean and flush any system that has used glycol before installing the boiler. Provide the customer with a material safety data sheet (MSDS) on the fluid used. A. CHECK / CONTROL WATER CHEMISTRY Chemical imbalance of your water can cause severe damage to your boiler and associated equipment, and may also affect efficiency. You may have to have your water quality professionally analyzed to determine whether you need to install a water softener. -

Page 48: Freeze Protection (When Used)

B. FREEZE PROTECTION (WHEN USED) NEVER use automotive or standard glycol antifreeze, or ethylene glycol made for hydronic systems. Use only freeze-protection fluids certified by fluid manufacturer as suitable for use with stainless steel boilers, verified in fluid manufacturer’s literature. Thoroughly clean and flush any system that has used glycol before installing the new boiler. -

Page 49: Check For Gas Leaks

If the condensate outlet on the boiler is lower than the drain, you must use a condensate removal pump, available from HTP (554200). This pump is equipped with two leads that can be connected to an alarm or another type of warning device to alert the user of a condensate overflow, which, if not corrected, could cause property damage. -

Page 50: Cascade System

4. Verify electrical connections are correct and securely attached. 5. Inspect intake piping and exhaust piping for signs of deterioration from corrosion, physical damage or sagging. Verify intake piping and exhaust piping are intact and correctly installed per Venting Section and local code. I. -

Page 51: Part 9 - Start-Up Procedure

PART 9 – START-UP PROCEDURE FOR YOUR OWN SAFETY READ BEFORE OPERATING 1. This boiler does not have pilot. It is equipped with an ignition device which automatically lights the burner. Do not try to light the burner by hand. 2. -

Page 52: Status Menu

Function Display Press {S3} once Boiler Temperature Set Point Press {S3} twice Boiler Differential Set Point Press {S3} three times Indirect Temperature Set Point Press {S3} four times Indirect Differential Set Point Press {S3} five times Temperature Measurement Units Table 9 – Additional Setting Options To decrease or increase values, press {S1} to decrease and... -

Page 53: Test Mode

Carbon Dioxide (CO 8 ½ - 9 ½% 8 ½ - 9 ½% 9 ½ - 10 ½% 9 ½ - 10 ½% Table 11 – Combustion Settings on All Models MOD CON FAN SPEEDS MODEL IGNITION 3000 1250 5500... - Page 54 Changes the indirect circulator post purge time once the sensor is satisfied. 0 min. (NOTE: Post purge time should be set no greater than 5 minutes.) Range: 0 to 10 minutes Outdoor temperature that will disable central heating (warm weather shutdown) Range: 41 F to 122 DEFAULT...

- Page 55 Parameter set on 0 = There will be no extra boiler on the Cascade Master. Parameter greater than 0 = Percentage of the cascade output that will turn on the auxiliary boiler. N/A (do not change) Table 13 *Central Heating Curve Function The central heating demand is detected when the room thermostat closes.

-

Page 56: Part 11 - Troubleshooting

Table 14 PART 11 – TROUBLESHOOTING A. ERROR CODE If any of the sensors detect an abnormal condition or an internal component fails during the operation of the boiler, the display may show an error code. This code may be the result of a temporary condition, in which case the display will revert to its normal readout when the condition is corrected, or it may be the result of a condition that the controller has evaluated as not safe to restart the boiler. - Page 57 1. Check line voltage. Must be between 100 – 128 volts. 2. If available, connect a PC and, using HTP service software, check the 24v supply display in the lower left corner of the screen. The number displayed here must be greater than 128 and should be greater than 250. Use this as a troubleshooting guide as you follow the steps below.

- Page 58 1. If the boiler is equipped with High and/or Low gas pressure switches, examine the yellow LED lights on each switch. If lit, correct the gas supply problem associated with the switch. Then, reset the switch by pressing on the cover of the switch over the red button. Pressing the button requires a firm push. Finally, press the RESET button on the front panel of the boiler to reset the boiler control.

-

Page 59: Part 12 - Maintenance

Figure 29 PART 12 – MAINTENANCE In unusually dirty or dusty conditions, care must be taken to keep appliance cabinet door in place at all times. Failure to do so VOIDS WARRANTY! Allowing the appliance to operate with a dirty combustion chamber will hurt operation. Failure to clean the heat exchanger as needed by the installation location could result in appliance failure, property damage, personal injury, or death. -

Page 60: Combustion Chamber Coil Cleaning Instructions For Heater

The combustion chamber insulation in this product contains ceramic fiber material. Ceramic fibers can be converted to cristobalite in very high temperature applications. The International Agency for Research on Cancer (IARC) has concluded, “Crystalline silica inhaled in the form of quartz or cristobalite from occupational sources is carcinogenic to humans (Group 1).”... - Page 61 c. Replace and tighten the (6) 10 mm nuts to the burner plate using staggered tightening sequence (see detail). d. Re-connect all wiring connections. e. Inspect the gas valve to assure the O-ring is in place. f. Replace the (4) screws on the aluminum connector on the gas valve. Turn the gas back on. (IMPORTANT: CHECK FOR GAS LEAKS BEFORE TURNING THE APPLIANCE ON!) g.

- Page 62 Figure 31 LP- 205 REV. 9.2.14...

- Page 63 Figure 32 LP- 205 REV. 9.2.14...

- Page 64 Figure 33 – NOTE: Ceramic Refractory Part # 7250P-162 LP- 205 REV. 9.2.14...

- Page 65 Figure 34 – LP-205-H LP- 205 REV. 9.2.14...

- Page 66 Figure 35 LP- 205 REV. 9.2.14...

-

Page 67: Boiler Start-Up Report

BOILER START-UP REPORT LIGHT OFF ACTIVITIES DATE COMPLETED ________________ 1) Fill the Check all piping and gas connections, verify all are heating system tight Pressurize system (12 – 15 PSI) ____ PSI Add water to prime condensate cup Percentage of glycol in system (0-50%) ____% Verify near heater piping is properly supported 2) Check gas... - Page 68 INSPECTION ACTIVITIES DATE LAST COMPLETED PIPING YEAR YEAR YEAR YEAR* Near heater piping Check heater and system piping for any sign of leakage; make sure they are properly supported. Vent Check condition of all vent pipes and joints. Check for any obstructions at intake and exhaust termination points.

- Page 69 LP- 205 REV. 9.2.14...

- Page 70 LP- 205 REV. 9.2.14...

-

Page 71: Maintenance Notes

MAINTENANCE NOTES LP- 205 REV. 9.2.14... -

Page 72: Htp Customer Installation Record Form

HTP CUSTOMER INSTALLATION RECORD FORM The following form should be completed by the installer for you to keep as a record of the installation in case of a warranty claim. After reading the important notes at the bottom of the page, please also sign this document.

Need help?

Do you have a question about the Mod Con and is the answer not in the manual?

Questions and answers