Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Belle Group BHB Breakers

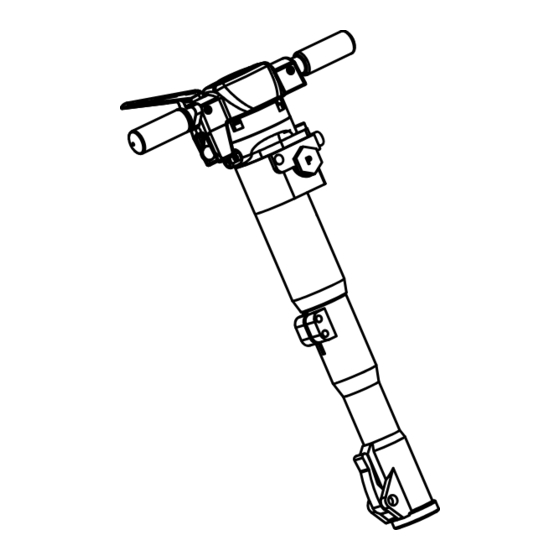

- Page 1 Operators Manual - Spare Parts Book 870/90000/2...

-

Page 2: Declaration Of Conformity

Nous soussignons, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK17 0EU, GB, certifions que si le produit décrit dans ce certificat est acheté chez un distributeur autorisé Belle Group au sein de la CEE, il est conforme aux normes CEE ci-après: 98/37/CE (Cette norme est une codification des normes de la machine d'origine 89/392/CEE), Norme compatible pour l'électromagnisme 89/336/CEE (modifié... - Page 3 Teknisk dokumentation vad gäller test av maskiners ljud/bullernivå finns dokumenterad hos Belle-Groups huvudkontor i Sheen, England. Vi, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK17 0EU, GB, bekrefter med dette at det produktet som står beskrevet i denne erklæringen er kjøpt fra en autorisert Belle Group forhandler innen EØF, og at det oppfyller følgende direktiver: 98/37/CE dette direktivet er et sammendrag av det opprinnelige maskindirektivet...

-

Page 4: Table Of Contents

How To Use This Manual This manual has been written to help you operate and service the Belle Group BHB Hydraulic Breaker safely. This manual is intended for dealers and operators of the Belle Group BHB Hydraulic Breaker. Foreword The ‘Machine Description’ section helps you to familiarise yourself with the machine’s layout, controls and Decals. -

Page 5: Machine Description

Machine Description Serial Plate Belle Group +44 (0)1298 84606 Sheen, Nr. Buxton, +44 (0)1298 84722 Derbyshire, A. Maximum permitted Hydraulic Oil Flow. sales@belle-group.co.uk SK17 0EU, www.BelleGroup.com B. Breaker Model. C. Maximum permitted Hydraulic Pressure. MODEL YEAR D. Serial Number. FLOW MAX. -

Page 6: Technical Data

Technical Data Model BHB12 BHB19 BHB23 BHB19 USA BHB25X Restrictor Open Open Open Open Open Weight (Kg) 23.5 27.5 Hydraulic Flowrate (Ltrs/Min) Working Pressure (Bar) 70 - 90 90 - 110 90 - 110 90 - 110 90 - 110 Max Pressure (Bar) Max. -

Page 7: Matching The Breaker To The Power Source

Matching The Breaker To The Power Pack Restrictor / Fitting Identifi cation The tank Restrictors / Fittings can be identifi ed by using this simple procedure. Check your Breaker and identify the P and T side of the body by looking for a letter stamp on the large bung. -

Page 8: Safety Instructions

Safety Instructions To reduce risk of serious injury or death to yourself or others, read these safety instructions before operating the machine. Post these safety instructions at work locations, provide copies to employees, and make sure that everyone reads the safety instructions before operating or servicing the machine. WARNING Follow all safety instructions given in this manual. - Page 9 Safety Instructions Hydraulic Oil and Lubrication Hazards Thin jets of hydraulic oil under high pressure can penetrate the skin and cause permanent damage. • Never use your hands when searching for oil leaks. • Keep your face away from any possible leaks. •...

-

Page 10: Safety Instructions

fi lter out microscopic particles. Machine Modifi cation Hazard Any machine modifi cation not approved by Belle Group may result in serious injuries to yourself or others. • The machine must not be modifi ed without Belle Groups permission. -

Page 11: General Safety

Wear clothing suitable for the work you are doing. Tie back long hair and remove any jewellery which may catch in the equipment’s moving parts. Recommended Hydraulic Oil In order to protect the environment, Belle Group recommends the use of biologically degradable hydraulic oil. • Viscosity (preferred) 20-40 cSt. -

Page 12: Environment

Environment A used machine must be treated and disposed of in such a way that the greatest possible portion of the material can be recycled and any negative infl uence on the environment is kept as low as possible. NOTE:- Before a used machine is scrapped, it must be emptied and cleaned from all hydraulic oil. -

Page 13: Operating Instructions

Quick-release couplings The original Belle Group hydraulic hoses are fi tted with Flat-Face quick-release couplings that are strong and easy to clean. The quick- release couplings are fi tted so that the male connection supplies oil and the female connection receives oil. - Page 14 Operating Instructions Choosing working tool A correct working tool is a prerequisite for good operation. To avoid unnecessary machine damage, it is important to choose working tools of a high quality. The narrow chisel should be used for demolition and cutting work in concrete and other types of hard material. The moil point should only be used for creating holes in concrete and other types of hard material.

-

Page 15: Ehtma - Code Of Practice

Operating Instructions STARTING A CUT 1) Stand steady and make sure that your feet and hands are at a safe distance from the working Breaker. 2) Press the machine against the surface of the workpiece before starting. 3) Adjust the breaking distance (A) so that the working Breaker does not get stuck. 4) Do not try to cut too big a bite. -

Page 16: Service & Maintenance

Inspection and service on the accumulator must only be done by a certifi ed person. • For major service to the machine, contact the Belle Group or your nearest authorised dealer. NOTE!:- Maintenance must only be done by suitably qualifi ed and competent persons. Before doing any maintenance, make sure that the machine is safe and correctly sited on the ground. -

Page 17: Troubleshooting Guide

Replace bushing or ‘Steel’. Warranty Your new Belle Group BHB Hydraulic Breaker is warranted to the original purchaser for a period of one-year (12 months) from the original date of purchase. The Belle Group warranty is against defects in design, materials and workmanship. - Page 18 BHB 19, BHB 19 USA, BHB 23, BHB 25, BHB 27 & BHB 30 USA 1-01 1-01 Top Cover Assembly, Boitier de commande complet , Montaje Tapa Superior, Montagem da Cobertura Superior 971/00101 ... Head ............................................1 01997 ....Handle ....... Guidon .......Manillar ......Pega ..................1 01998 ....

- Page 19 BHB 25X 1-02 1-02 Top Cover Assembly, Boitier de commande complet , Montaje Tapa Superior, Montagem da Cobertura Superior 01949-00 ..... UD Head Machined ........................................1 01997 ....Handle ....... Guidon .......Manillar ......Pega ..................1 01998 ....Handle ....... Guidon .......Manillar ......Pega ..................1 02203-00 .....

- Page 20 BHB 12 2-01...

-

Page 21: Main Assembly

2-01 Main Assembly, 971/00801 ... Spring ........ Ressort ........Resorte ........Mola .................1 971/00802 ... Washer ......Rondelle .........Arandela ........Anilha ................1 971/00803 ... Seal ........Joint d’étanchéité ....Obturador .........Vedante ........ø8/14 x 3.5/5 ....1 971/00804 ... Gland ......... Presse-étoupe ......Prensaestopas ......Bucha ................1 971/00805 ... - Page 22 BHB 19, BHB 19 USA, BHB 23, BHB 25X 2-02...

- Page 23 2-02 Main Assembly, 971/00806 ... O-Ring ....... Joint torique ......Junta tórica .......Anel Vedante ......ø16.3x2.4 ......1 971/00803 ... Seal ........Joint d’étanchéité ....Obturador .........Vedante ........ø8/14x3.5/5 ....1 971/99028 ... Gland ......... Presse-étoupe ......Prensaestopas ......Bucha ................1 971/00805 ... O-Ring ....... Joint torique ......Junta tórica .......Anel Vedante ......ø8.3x2.4 ......1 971/00807 ...

- Page 24 BHB 25, BHB 27 2-03...

- Page 25 2-03 Main Assembly, 971/99046 ... Body ........Carène ........Cuerpo........Corpo ................1 971/01100 ... Body ........Carène ........Cuerpo........Corpo ................1 971/01200 ... Cylinder ......Vérin ........Cilindro ........Cilindro ................1 971/99047 ... Piston ......... Piston ........Pistón ........Pistão ................1 971/99049 ... Cover ......... Capot ........Cubierta ........Tampa ................1 971/00205 ...

- Page 26 BHB 30 USA 2-04...

- Page 27 2-04 Main Assembly, 971/99046 ... Body ........Carène ........Cuerpo........Corpo ................1 971/01100 ... Body ........Carène ........Cuerpo........Corpo ................1 971/01300 ... Cylinder ......Vérin ........Cilindro ........Cilindro ................1 971/99048 ... Piston ......... Piston ........Pistón ........Pistão ................1 971/99049 ... Cover ......... Capot ........Cubierta ........Tampa ................1 971/00205 ...

- Page 28 BHB 19, BHB 19 USA, BHB 23, BHB 25X, BHB 25, BHB 27 & BHB 30 USA 3-01 3-01 Nose Assembly, Corps de marteau complet, Montaje Cuerpo Intermedio, Conjunto do Encabadouro BHB 19, BHB 23 971/01502 ... Nose Piece ..... Extrémité ......Ojiva ........Encabadouro ........Hex 25 ......1 971/01503 ...

- Page 29 BHB 12, BHB 19, BHB 19 USA, BHB 23, BHB 25X, BHB 25, BHB 27 & BHB 30 USA 4-01 4-01 Hose Assembly, Assemblage de la Durite, Con. de Manguera, Montagem de Mangueira 0.4m 7.0m 971/01801 ... Hose ........Durit ........Flexible ......Mangueira ........1/2” BSP ....2 ..- 971/01901 ...

- Page 30 No.1 for Light Construction Equipment www.BelleGroup.com Belle Group Head Office Belle Poland sp. z.o.o. Belle Group (GB), Shanghai Office Sheen, nr. Buxton 96-200 Rawa Mazowiecka Room 213, Zhonghuang Building, Derbyshire. SK17 OEU GB. Ul. Mszczonowska 36, 1007 Zhongshan Nan Er Road,...

Need help?

Do you have a question about the BHB Breakers and is the answer not in the manual?

Questions and answers