Table of Contents

Advertisement

Installation and Operations Manual

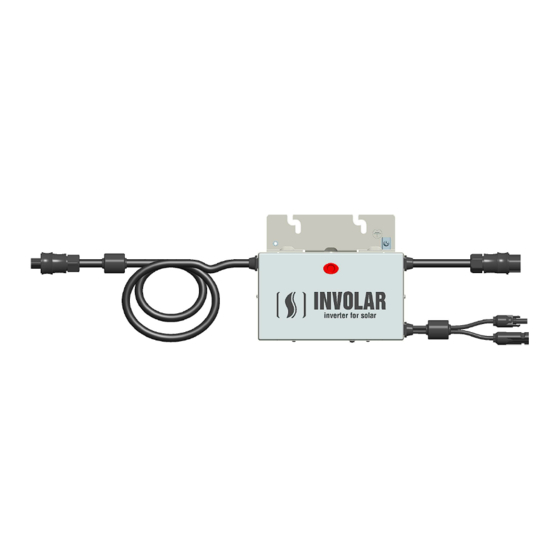

INVOLAR MAC250 Photovoltaic Micro-Inverter

Model number MAC250-230-EUR.

This manual is an integral part of the unit. Please read the instruction manual carefully

before installation, operation or maintenance. Keep this instruction manual for future

reference.

This document is not to be reproduced in any manner, nor are the contents to be disclosed

to anyone, without the express authorization of INVOLAR.

Version 4 Rev 1 Apr 2011

1

INVOLAR Corporation Ltd.

(EUR)

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Involar MAC250

- Page 1 Keep this instruction manual for future reference. This document is not to be reproduced in any manner, nor are the contents to be disclosed to anyone, without the express authorization of INVOLAR. Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd.

-

Page 2: Contact Information

Contact Information INVOLAR Corporation Ltd. Room 501, Building 84, No. 887, Zuchongzhi Road, Pudong District, 201203 Shanghai, PEOPLE’S REPUBLIC OF CHINA Tel: 86-21-50272208 Fax: 86-21-50277705 www.INVOLAR.com info@INVOLAR.com Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR) -

Page 3: Table Of Contents

LED I ......41 TATUS NDICATIONS AND RROR EPORTING INTERNET WEB ........................43 ......................43 EGISTRATION ........................43 OGIN INVOLAR MAC250 MICRO-INVERTER TECHNICAL DATA ............44 10.1 ..................... 44 ECHNICAL PECIFICATIONS APPENDIX ..........................46 11.1 ......................46 IMITED ARRANTY 11.2 INVOLAR MAC250 M ........ -

Page 4: Read This First

To reduce the risk of electrical shock, and to ensure the safe installation and operation of the INVOLAR MAC250 Micro-Inverter, please read this manual carefully and pay attention to the safety symbols appear throughout this document. This manual is for end users. -

Page 5: Safety Symbols

Please read following safety symbols to indicate dangerous conditions and important safety instruction. DANGER The DANGER symbols in this manual and on MAC250 Micro-inverter indicate a hazard with a high level of risk which, if not avoided, will result in death or serious injury. - Page 6 Please follow Local Ordinances or Regulations for disposal or contact an authorized representative of the manufacturer information concerning decommissioning of equipment. Direct current Alternating current Protective conductor Earth (ground) TERMINAL Protective Conductor Terminal Fuse Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR)

- Page 7 Vmax PV Maximum rated D.C. input voltage the PCE is designed to withstand from the PV array (i.e. maximum open circuit voltage) under worst case conditions of ambient temperature, irradiance, etc. Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR)

- Page 8 Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR)

-

Page 9: Safety Instructionsand Ec Directives

Involar require using only genuine replacement parts, manufactured or sold by Involar for all repair parts replacements. - Page 10 Be aware that only qualified personnel should maintain INVOLAR Micro-Inverter. Connect the INVOLAR Micro-Inverter to the electrical utility grid only after receiving prior approval from the utility company. In the day time, Use opaque covering on PV array to screen the sunshine before ...

- Page 11 45 minutes after disconnecting all sources of supply. WARNINGS The printed circuit boards contain components sensitive to electrostatic discharge. Wear a grounding wrist band when handling the boards. Do not touch the boards unnecessarily. Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR)

- Page 12 DVC-A are considered safe to touch, however, since the device is intended for outdoor use and Vmax PV is rated 50V D.C, which exceeds maximum 35V DC limit for DVC-A in WET LOCATION as below: Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR)

- Page 13 WARNING: Fire hazard. Suitable for mounting on concrete or other non-combustible surface only. Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR)

- Page 14 CAUTION: SAVE THESE INSTRUCTIONS– This manual contains important instructions for Model MAC250 that shall be followed during installation and maintenance of the photovoltaic micro-inverter. WARNING: To reduce the risk of fire, do not connect to an ac load...

-

Page 15: Ec Directives

The device is not provided with automatic disconnecting means – this device shall be provided with external relaying protection in accordance with local codes and local utility requirements. [Use Condition] Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR) - Page 16 Over-voltage protection with surge arresters should be provided when the PV power system is installed. The grid connected inverter is not fitted with SPDs in both PV input side and MAINS side. Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR)

- Page 17 Spark gap devices are not suitable for use in D.C. circuits as once conducting, they won’t stop conducting until the voltage across their terminals is typically less than 30 volts. Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR)

- Page 18 Select DC cables based on the above inverter back feed current and Isc PV rating and Vmax ratings. Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR)

- Page 19 Dual supply labeling should be provided at the service termination, meter position and all points of isolation to indicate the presence of onsite generation and indicating the position of the main A.C. switch disconnector. Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR)

- Page 20 The data should be recorded in an equipment log. If the device is not functioning properly or fails any of tests, the device has to be repaired. Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR)

- Page 21 Exceeding this limit will trigger de-energized-to-trip system and alarm within time as specified in the following tables. WARNING! The device is not provided with ground-fault detector/interrupter unit. Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR)

- Page 22 Disconnection is provided in case of any hardware malfunctioning. The solar inverter will cease to energize the network in response to an interface protection; however, this is not achieved by disconnecting means between inverter and grid. Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR)

- Page 23 Unauthorized access to factory safety parameters setting and software should be prohibited. A reset to the factory safety parameters requires retesting and verification in conjunction with the end-use system. Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR)

-

Page 24: The Involar Micro-Inverter System Instruction

PV module The INVOLAR Micro-Inverter maximizes energy production from the PV array. Each INVOLAR Micro-Inverter is individually connected to one PV module in the array. (See Figure 4-1). This unique configuration means that a Maximum Peak Power Point Tracker (MPPT) controls each PV module. -

Page 25: The Involar Mac250 Micro-Inverter

4.2 The INVOLAR MAC250 Micro-Inverter By adopting high frequency DC link topology (Figure 4-2) and dual –DSP controller, the Involar MAC250 achieves precise variable frequency control for soft-switching during full load range. So that the MAC250 exhibit slow profile and high efficiency. -

Page 26: Involar Micro-Inverter Installation

Anti-abnormal discharge protection Recovery of grid-connected protection 5 INVOLAR Micro-Inverter Installation WARNINGS: In case of installation in PV system, startup of the unit (i.e. start of designated operation) is prohibited until it is determined that the full system meets the requirements stipulated in the EC Directive (2006/95/EC, 2004/108/EC etc.). - Page 27 62109-1, and supporting characteristics will be impaired by wear, corrosion, material fatigue or ageing. This shall be calculated by inspection of the design data of supporting material and consulting construction engineer. Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR)

-

Page 28: Involar Mac250Micro-Inverter Operational Environment

Humidity Air humidity≤90%。 Storage If the INVOLAR MAC250 Micro-Inverter had been stored for 2 years, the inverter need pretreatment. The way of pretreatment is input 85% rated voltage under the condition of no output power for 30 minutes. 5.2 INVOLAR MAC250 Micro-Inverter operational condition in PV System PV Module The max PV Module open circuit voltage is no more than 50V. - Page 29 Calculate the max. input current and max. output current of the inverter according to the actually TECHNICAL PARAMETER system , inverter rating label and . For details, refer to this manual, Section 3 Safety instruction and EC Directives, [Selection of fuse and cables]. Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR)

- Page 30 INVOLAR MAC250 Micro-Inverter outside Dimension Dimension as following Figure 5-1 shows: Figure 5-1 INVOLAR MAC250 Micro-Inverter outside dimension NOTE Allow enough space around the Micro-Inverter. Allow 350mm between two Micro-Inverters. The cables we recommend are as follow. AC cable Model...

- Page 31 Be aware that only qualified personnel could connect INVOLAR Micro-Inverter to the electrical utility grid. DANGER DO NOT connect INVOLAR Micro-Inverter to the utility grid or energize the AC circuit(s) until the all installation procedures have been completed.

- Page 32 Yellow/Green - PE L -Brown Brown N -Light Blue Light Blue PE - Yellow/Green Note MAC250 Micro-Inverter DC connectors are standard, and they should match to the connectors on PV Modules. Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR)

-

Page 33: Grid Connection

Grid connection 1. Wire fastening and split Screw connection: Tightening torque typically 0.8Nm-1.0Nm Click! Click! 2. Connector fastening and split Tightening torque: Click! 4+1 Nm Click! Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR) - Page 34 3. Connector Locking and split Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR)

-

Page 35: Function Instructions

Standby The detailed working mode descriptions are as below: Startup Startup mode is for a newly installed INVOLAR Micro-Inverter. This startup mode must base on the proper AC and DC cables connecting and whole PV system grounding. Active When the Micro-Inverter is in normal operation process, this insures that the power available from each PV module is exported to the utility grid. -

Page 36: Grid-Connection

INVOLAR MAC250 Micro-Inverter system begin connect grid and generate electricity. In the process of connecting grid and generating electricity, a Maximum Peak Power Point Tracker (MPPT) controls each PV module by INVOLAR Micro-Inverter system. 6.3 Grid Disconnect If the state grid cannot match the following situations (diagram 6-1), it bring the INVOLAR Micro-Inter to a rest. -

Page 37: Start-Up- Checks

4. Measurement of insulation resistance 5. Measurement of earth resistance 6. Mounting structures: Verify tightness and integrity of bolts and other fastening devices; Verify if there is significant corrosion. Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR) -

Page 38: Disconnecting A Microinverter From The Pv Module

6. Disconnect the PV module DC wire connectors from the microinverter. 7. Remove the microinverter from the PV array racking. Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR) -

Page 39: Monitoring And Troubleshooting And Maintenance

1. Check that if the inlet and outlet of the inverter are blocked, if the fans work normally, the machine can be cleaned and absorbed dust when necessary. This work Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR) -

Page 40: Overview

PV system through internet, that is use The SEDAS (Solar Energy Data Acquisition System) developed by INVOLAR to real time track the statistics information of the energy harvest for all INVOLAR Micro-Inverter system and monitor per-module’s performance which is integrated into the INVOLAR Micro-Inverter system. -

Page 41: Mac250 Micro-Inverter Status Led Indications And Error Reporting

Figure 7-1 MAC250 Micro-Inverter Communication System 8.2 MAC250 MICRO-INVERTER Status LED Indications and Error Reporting You can access the INVOLAR MAC250 Micro-Inverter system LED menu to detect the operation conditions. MAC250 MICRO-INVERTER Status LED indications and error report shows as below diagram (7-1) - Page 42 Island effect Anti-island protection Diagram 7-2-2Information of Disable Mode NOTE Disable Micro-Inverter does not affect the operation of all INVOLAR Micro-Inverter system. System will bypass the disable Micro-Inverter. WARNING Be aware that only qualified personnel should troubleshoot the PV array or the INVOLAR Micro-Inverter.

-

Page 43: Internet Web

9 Internet WEB Introduction Use The SEDAS (Solar Energy Data Acquisition System) developed by Involar to real time track the statistics information of the energy harvest for all Involar Microinverter system and monitor per-module’s performance which is integrated into the Involar Microinverter system. -

Page 44: Involar Mac250 Micro-Inverter Technical Data

10 INVOLAR MAC250 Micro-Inverter Technical Data 10.1 Technical Specifications Model MAC250 PV Input Quantities Rated DC Power 250W Rated D.C. Voltage (VMAX PV) 50V D.C. PV input Operating Voltage Range 24-40V Maximum Operating PV Input Current Absolute Maximum Total PV Array Short Circuit Current (ISC PV) Max. - Page 45 During transportation: Temperature : –25 °C to +70 °C; Relative or absolute humidity: 5 % to 95 % Air pressure: 70 kPa to 106 kPa Dimensions (WxHxD) 235mmx144mmx53mm Weight 2.9kg Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR)

-

Page 46: Appendix

INVOLAR provides the 15-year warranty (The exact time depends on the contract) due to our responsible attitudes toward customers and partners and our confidence in INVOLAR products. During the warranty period, if any defect in workmanship and materials of the INVOLAR micro-inverters is detected, customers is entitled by the warranty to ask for replacement or repairing from INVOLAR with no extra cost. -

Page 47: Involar Mac250 Micro-Inverter System Sample Wiring Diagram

11.2 INVOLAR MAC250 Micro-Inverter System Sample Wiring Diagram Version 4 Rev 1 Apr 2011 INVOLAR Corporation Ltd. (EUR) -

Page 48: Ec Declaration Of Conformity

Single-phase, with MAC250 Microinverter Transformers, Grid-tied INVOLAR Corporation hereby certifies the following in reference to the above product: 1) It fulfills all the safety requirements according to IEC62109 -1 “Safety of power converters for use in photovoltaic power systems”; 2) In case of power failure on the part of the power grid, it shall shut down and stop outputting voltage and current;...

Need help?

Do you have a question about the MAC250 and is the answer not in the manual?

Questions and answers