Table of Contents

Advertisement

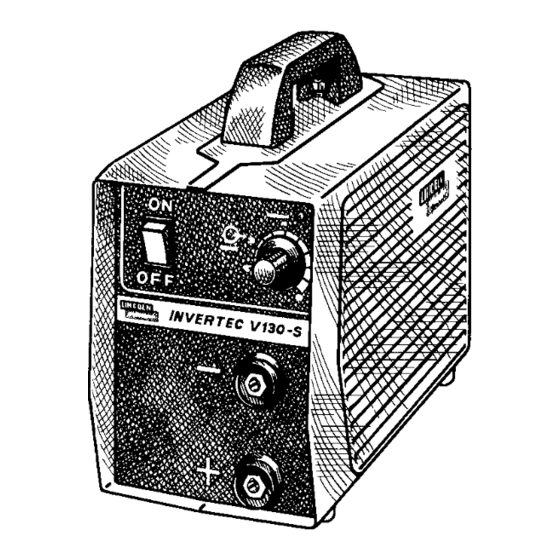

INVERTEC V100-S & V130-S

For use with machines having Code Numbers:

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thought-

ful operation on your part. DO

NOT INSTALL, OPERATE OR

REPAIR THIS EQUIPMENT

WITHOUT

READING

MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED

THROUGHOUT. And, most

importantly, think before you act

and be careful.

Date of Purchase:

Serial Number:

Code Number:

Model:

Where Purchased:

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

®

V100-S 10461

V130-S 10462

THIS

OPERATOR'S MANUAL

• World's Leader in Welding and Cutting Products •

Copyright © 2002 Lincoln Global Inc.

IM585

January, 2002

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Lincoln Global INVERTEC V100-S

- Page 1 Model: Where Purchased: OPERATOR’S MANUAL Copyright © 2002 Lincoln Global Inc. • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com...

-

Page 2: California Proposition 65 Warnings

SAFETY WARNING CALIFORNIA PROPOSITION 65 WARNINGS Diesel engine exhaust and some of its constituents The engine exhaust from this product contains are known to the State of California to cause can- chemicals known to the State of California to cause cer, birth defects, and other reproductive harm. -

Page 3: Electric Shock Can Kill

SAFETY ARC RAYS can burn. ELECTRIC SHOCK can 4.a. Use a shield with the proper filter and cover kill. plates to protect your eyes from sparks and 3.a. The electrode and work (or ground) circuits the rays of the arc when welding or observing are electrically “hot”... - Page 4 SAFETY WELDING SPARKS can CYLINDER may explode cause fire or explosion. if damaged. 6.a. Remove fire hazards from the welding area. 7.a. Use only compressed gas cylinders If this is not possible, cover them to prevent containing the correct shielding gas for the the welding sparks from starting a fire.

- Page 5 SAFETY zones où l’on pique le laitier. PRÉCAUTIONS DE SÛRETÉ 6. Eloigner les matériaux inflammables ou les recouvrir afin de Pour votre propre protection lire et observer toutes les instructions prévenir tout risque d’incendie dû aux étincelles. et les précautions de sûreté specifiques qui parraissent dans ce manuel aussi bien que les précautions de sûreté...

- Page 6 for selecting a QUALITY product by Lincoln Electric. We want you Thank You to take pride in operating this Lincoln Electric Company product ••• as much pride as we have in bringing this product to you! Please Examine Carton and Equipment For Damage Immediately When this equipment is shipped, title passes to the purchaser upon receipt by the carrier.

-

Page 7: Table Of Contents

TABLE OF CONTENTS Page Installation........................Section A Technical Specifications V100-S ..................A-1 Technical Specifications V130-S ..................A-2 Safety Precautions.......................A-3 Select Suitable Location .......................A-3 Stacking..........................A-3 Tilting ............................A-3 High Frequency Precautions ....................A-3 Input Supply Connections ....................A-3 Input Fuse and Supply Wire ....................A-3 Output Connections......................A-3 Output Connections ......................A-4 Output Connection for Stick Welding ................A-4 Output and Gas Connection for TIG Welding ...............A-4... -

Page 8: Installation

INSTALLATION Technical Specifications - Invertec V100-S INPUT SINGLE PHASE INPUT Input Current Voltage at Rated Output Hertz 32A @ 100A OUTPUT 115V 25A @ 85A OUTPUT 50/60 Hz 20A @ 70A OUTPUT RATED OUTPUT Volts at Duty Cycle Amps Rated Amps... -

Page 9: Technical Specifications V130-S

INSTALLATION Technical Specifications - Invertec V130-S INPUT SINGLE PHASE INPUT Input Current Voltage at Rated Output Hertz 25A @ 130A OUTPUT 230V 19A @ 105A OUTPUT 50/60 Hz 16A @ 90A OUTPUT RATED OUTPUT Volts at Duty Cycle Amps Rated Amps 20% Duty Cycle 25.5 60% Duty Cycle... -

Page 10: Safety Precautions

INSTALLATION Read this entire installation section before you INPUT SUPPLY CONNECTIONS start installation. Be sure the voltage, phase and frequency of the input SAFETY PRECAUTIONS power is as specified on the rating plate, located on WARNING the rear of the machine. ELECTRIC SHOCK can kill. -

Page 11: Output Connection For Stick Welding

INSTALLATION OUTPUT CONNECTIONS QUICK DISCONNECT PLUG A quick disconnect system is used for the welding cable connections. The electrode and work cables Refer to Figure A.1 for the location of the output terminals. A quick-disconnect system using Twist-Mate cable plugs is have the plug attached, on both machines an addition- used for the welding cable connections. -

Page 12: Operation

Read and understand this entire section before GENERAL DESCRIPTION operating your machine. The Invertec V100-S is a light industrial 100 amp arc SAFETY INSTRUCTIONS welding power source and the V130-S is a light indus- trial 130 amp arc welding power source both of which... -

Page 13: Controls And Settings

OPERATION CONTROLS AND SETTINGS All operator controls and adjustments are located on the case front of the V100-S and V130-S machines. Refer to Figure B.1 and the corresponding explanations. FIGURE B.1 — CASE FRONT CONTROLS. LED 1 Power Switch Output Terminals Power Switch - Controls the power input to the Output Terminals - These quick disconnect terminals... -

Page 14: Constant Current Processes

OPERATION CONSTANT CURRENT PROCESSES OVERLOAD PROTECTION MANUAL ARC WELDING (STICK) The machine is electrically protected from producing excessive currents. The maximum current obtainable with the V100-S is approximately 120 amps, and that The Invertec may be utilized as a manual DC arc of the V130-S is approximately 150 amps. -

Page 15: Accessories

ACCESSORIES OPTIONS / ACCESSORIES K909-1 - EH-200 Insulated electrode holder designed for maximum operator comfort and convience. K859-”L” - LA-9 125 amp air-cooled, lightweight, and versatile TIG torch for thin gauge materials. Includes two piece cable. Available in 12.5 ft. and 25 ft. lengths. -

Page 16: Maintenance

MAINTENANCE SAFETY PRECAUTIONS • Printed circuit boards WARNING • Power switch ELECTRIC SHOCK can kill. • Fan blades • Have an electrician install and ser- vice this equipment. • Louvers • Turn the input power off at the fuse box, disconnect supply lines and •... -

Page 17: How To Use Troubleshooting Guide

TROUBLESHOOTING HOW TO USE TROUBLESHOOTING GUIDE WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. -

Page 18: Troubleshooting

TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE AREAS OF RECOMMENDED (SYMPTOMS) MISADJUSTMENTS(S) COURSE OF ACTION The machine is dead - no output - 1. The input power switch must be no fan. in the ON position. 2. - Page 19 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE AREAS OF RECOMMENDED (SYMPTOMS) MISADJUSTMENTS(S) COURSE OF ACTION Poor welding, weld settings drift, or 1. Make sure the machine settings output power is low. are correct for the weld process being used.

-

Page 20: Diagrams

DIAGRAMS INVERTEC® V100-S & V130-S... - Page 21 DIAGRAMS INVERTEC® V100-S & V130-S...

- Page 22 Now Available...12th Edition New Lessons in Arc Welding The Procedure Handbook of Arc Welding Lessons, simply written, cover manipulatory techniques; With over 500,000 copies of previous editions published machine and electrode characteristics; related subjects, since 1933, the Procedure Handbook is considered by many to such as distortion;...

- Page 23 Do not touch electrically live parts or Keep flammable materials away. Wear eye, ear and body protection. WARNING electrode with skin or wet clothing. Insulate yourself from work and ground. Spanish No toque las partes o los electrodos Mantenga el material combustible Protéjase los ojos, los oídos y el AVISO DE bajo carga con la piel o ropa moja-...

- Page 24 Keep your head out of fumes. Turn power off before servicing. Do not operate with panel open or WARNING Use ventilation or exhaust to guards off. remove fumes from breathing zone. Spanish Los humos fuera de la zona de res- Desconectar el cable de ali- No operar con panel abierto o AVISO DE...

- Page 25 • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com...

Need help?

Do you have a question about the INVERTEC V100-S and is the answer not in the manual?

Questions and answers