Table of Contents

Advertisement

Newport Medical Instruments, Inc.

N

EWPORT

Service Manual

HT50 V

SERHT50NA Rev. A

September 2008

(P/N HT50-H, HT50-H1, HT50-H1-B)

ENTILATOR

Exclusively distributed by:

NEWPORT MEDICAL INSTRUMENTS, INC.

1620 Sunflower Avenue

Costa Mesa, CA 92626 USA

Tel: 1.714.427.5811 Ext. 500

Tel: 1.800.451.3111 (USA only)

Fax: 1.714.427.0572

Customer Service ext. 282

www.Ventilators.com

email: Info@Ventilators.com

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for Newport HT50

- Page 1 Newport Medical Instruments, Inc. HT50 V EWPORT ENTILATOR Service Manual SERHT50NA Rev. A September 2008 (P/N HT50-H, HT50-H1, HT50-H1-B) Exclusively distributed by: NEWPORT MEDICAL INSTRUMENTS, INC. 1620 Sunflower Avenue Costa Mesa, CA 92626 USA Tel: 1.714.427.5811 Ext. 500 Tel: 1.800.451.3111 (USA only) Fax: 1.714.427.0572...

- Page 2 MANUAL REVISION HISTORY HT50 Service Manual SERHT50NA DATE REVISION PAGES EFFECTED August 2008 New release for dual internal battery update SERHT50NA A0808...

-

Page 3: Table Of Contents

TABLE OF CONTENTS Section 1 ..OPERATOR’S RESPONSIBILITY • Operator’s Responsibility for Patient Safety • Limitation of Liability • Warranty • Definitions • Typing Conventions • Warnings and Cautions • Factory Maintenance or Repair •... - Page 4 • High Paw Alarm • Low Paw Alarm • Check Prox Line Alarm • Battery Test • Humidifier (for HT50-H) • OVP Test Record Section 6 ..MAINTENANCE PROCEDURES • Introduction •...

- Page 5 • RGA (Return Goods Authorization) • Packaging: Complete Unit • Packaging: Parts or Accessories Appendix A ..HT50 PARTS AND ACCESSORIES • HT50 Ventilator Parts and Accessories • Service Parts List SERHT50NA A0808...

- Page 6 1. OPERATOR’S RESPONSIBILITY Operator’s Responsibility for Patient Safety ..1-1 Limitation of Liability ......1-2 Warranty .

-

Page 7: Section 1

When the HT50 is used in home care and sub acute environments it is important that the primary caregiver has received training and has demonstrated competency in all equipment functions. -

Page 8: Limitation Of Liability

EWPORT due to such situations. WARRANTY The Newport HT50 Ventilator is guaranteed to be free of defects for a period of two (2) years from date of delivery. The following are exceptions to this warranty: 1. Defects caused by misuse, mishandling, tampering, or by modifications not authorized by Newport Medical Instruments, ) or its representatives. -

Page 9: Typing Conventions

To ensure complete protection under this warranty, the Warranty Registration Card must be returned to Newport within ten (10) days of equipment receipt. The above is the sole warranty provided by N . -

Page 10: Warnings And Cautions

OPERATOR’S RESPONSIBILITY WARNINGS AND CAUTIONS At all times, strictly follow this Manual. The safe use of the HT50 Ventilator requires a full understanding of its operation and adherence to the manual’s instructions. The equipment is only to be used for the purpose specified under “Intended Use” (see Section 2). - Page 11 Continuous oxygen monitoring is required for patient safety. The HT50 does not have a built-in alarm system to notify user of a failure or disconnection of the oxygen source. Ensure that the oxygen source is not empty before and during the use of the optional Air/Oxygen Entrainment Mixer or Oxygen Blending Bag Kit.

- Page 12 Always ensure that the green Ext. Power LED lights after connecting the HT50 to an external AC or DC power source (it can take up to two minutes to light). If the LED does not light, check all power connections and resolve any problems.

-

Page 13: Factory Maintenance Or Repair

Mixer or Oxygen Blending Bag Kit. Do not place liquid containers in the immediate vicinity or on top of the HT50. Liquids that get into the ventilator can cause equipment malfunction and damage. After servicing an HT50, it must completely pass an Operational Verification Procedure (see Service Manual) before being returned to patient use. -

Page 14: Contact Information

OPERATOR’S RESPONSIBILITY Current pricing for scheduled maintenance and labor rates can be found in Newport Medical Instruments Annual Price List. To obtain a copy, please contact your local Newport Sales Representative or contact our Customer Service Department using information below. -

Page 15: Specifications

2. SPECIFICATIONS Intended Use ......2-1 Symbols / Labeling Table ....2-1 Controls / Alarms / Monitors . -

Page 16: Intended Use

SIMV and SPONT modes of ventilation. The HT50 is suitable for use in hospital, sub-acute, emergency room, home care environments as well as for transport and emergency response applications. -

Page 17: Symbols/Labeling Table

SPECIFICATIONS SPECIFICATIONS SYMBOLS/LABELING TABLE Controls/Alarms/Monitors Range/Selection MODE (Pressure or A/CMV Volume Control) SIMV SPONT Volume Control (Tidal Volume) 100 to 2,200 mL, ATPS, ± 10% Pressure Control PEEP + 5 to 60 cmH O / mbar (Target Pressure) • (Flow) 6 to 100 L/min (Inspiratory Time) 0.1 to 3.0 sec... - Page 18 19. On / Standby Button Press once to put in Setting condition. (On-Setting/LED off) Press again to begin ventilating (On-Ventilating/LED on). When the HT50 is ventilating, press two times to put ventilator into Standby/Off condition (LED off). 20. Push To Unlock Buttons &...

- Page 19 Yellow LED indicates that the audible alarm is silenced for 60 seconds. Auto Lock On Green LED indicates that the panel is currently locked. On / Standby Green LED indicates that the HT50 is ventilating. P trig Green LED blinks on to indicate patient breathing effort. • •...

- Page 20 30. Operating Humidity 15 to 95% non-condensing 31. Operating Altitude Sea level to 15,000 ft (0 to 4,572 m) There is no altitude limitation when HT50 is operated in a pressurized environment. SERHT50NA A0808...

- Page 21 600 to 1,100 mbar 33. Regulatory and Agency Complies with the following international standards & requirements: Standards/Requirements Testing and evaluation of the NEWPORT HT50 Ventilator has been conducted in compliance with the following voluntary standards: IEC 60601-1:1988 (+A1:1991 +A2:1995; EN 60601-1:1990...

- Page 22 Reusable 22 mm I.D. adult/pediatric circuit with 3/16 inch (4.8 mm) I.D. proximal pressure sensing line, 1/8 inch (3.2 mm) I.D. exhalation valve control drive line, and exhalation valve. 43. Exhalation Valve HT50 exhalation valve (P/N HT600039) is EWPORT manufactured and designed specifically for the N HT50 EWPORT Ventilator.

- Page 23 0.21 to 1.00 WARNING Continuous oxygen monitoring is required for patient safety. The HT50 does not have a built-in alarm system to notify user of a failure or disconnect of the oxygen source. (optional) Oxygen Blending Bag Kit Specifications...

- Page 24 3. DESCRIPTION OF CONTROLS, INDICATORS, ALARMS & CONNECTORS Front Panel Overview..... . . 3-1 Front Panel Controls and Indicators ... 3-5 Front Panel Alarms.

-

Page 25: Front Panel Overview

SECTION 3 FRONT PANEL OVERVIEW The following is an overview of the HT50 front panel button functions. For an indepth description, please review FRONT PANEL CONTROLS AND INDICATORS. Turning the HT50 On and Off The On/Standby button toggles between the following conditions:... - Page 26 DESCRIPTION OF CONTROLS, INDICATORS, ALARMS & CONNECTIONS On Condition: SPONT Setting Condition: A/CMV, SIMV, or SPONT Select—Adjust (LUp / MDown)—Accept Select the Pressure Control or Volume Control button. Both the LED indicator and target value will blink. Adjust the blinking target value for the selected control with the LUp / MDown buttons.

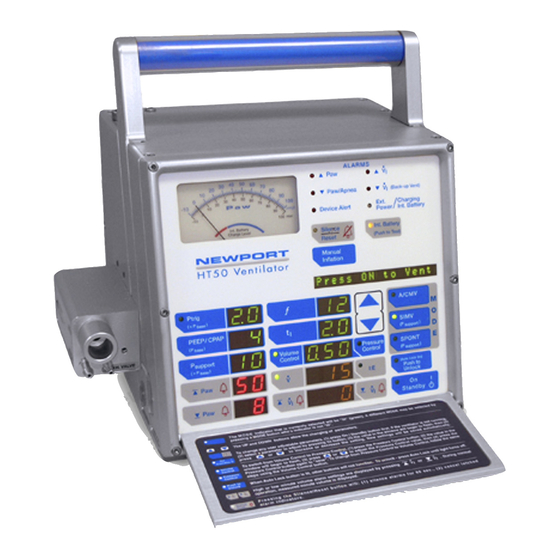

- Page 27 SECTION 3 Figure 3-1 HT50 Ventilator Front Panel (model HT50-H1, HT50-H1B) SERHT50NA A0808...

- Page 28 DESCRIPTION OF CONTROLS, INDICATORS, ALARMS & CONNECTIONS Figure 3-2 Newport HT50-H, HT50-HB (with built-in humidifier) SERHT50NA A0808...

-

Page 29: Front Panel Controls & Indicators

FRONT PANEL CONTROLS & INDICATORS Front panel controls that have corresponding LED indicators are included with the description of the control. The HT50 front panel is shown in Figure 3-1 on pg 3-3. On / Standby This button toggles between the following conditions:... - Page 30 DESCRIPTION OF CONTROLS, INDICATORS, ALARMS & CONNECTIONS If the HT50 is in Setting condition, changes are made by pressing the requested MODE button once. If in ON condition, changes are made by pressing the requested MODE button twice. After the first press, the Message Display Window reads “PRESS AGAIN”...

- Page 31 See pg 3-23 for more information on the Message Display Window. When the HT50 is ventilating, and there are no alarm messages displayed on the Message Display Window, press the LUp control button to access the monitoring information. Pressing the LUp button again allows you to scroll through the messages.

- Page 32 DESCRIPTION OF CONTROLS, INDICATORS, ALARMS & CONNECTIONS ƒ (frequency) Range: 1 to 99 b/min ƒ (frequency) setting determines the minimum number of time triggered mandatory breaths in the A/CMV mode and the total number of mandatory breaths in the SIMV mode. The frequency or rate value is displayed in the window adjacent to the selector button.

- Page 33 Message Display Window. Adjust the tidal volume level by pressing the LUp/MDown controls while the LED and numerical display are blinking. If the HT50 is ventilating you will need to Press the Volume Control button again within 5 seconds following adjustment.

- Page 34 DESCRIPTION OF CONTROLS, INDICATORS, ALARMS & CONNECTIONS P trig (sensitivity) Range: 0.0 to –9.9 cmH O/mbar The P trig setting determines trigger sensitivity in terms of how far airway pressure must drop below the set baseline pressure for a patient’s spontaneous efforts to be detected. The P trig LED indicator illuminates each time the airway pressure reaches the set P trig level, and turns off once the airway pressure has returned to baseline pressure.

- Page 35 Pressure Control when the initial flow has not yet been optimized. Humidifier On Button (HT50-H, HT50-HB only) Range: 19ºC to 39ºC This touch button activates the built-in humidifier. Pressing this button displays the set target temperature in the adjacent window. While the display is blinking, use the LUp/MDown controls to adjust the target temperature.

-

Page 36: Mandatory Flow

I:E Ratio does not function during SPONT mode. Internal Battery Test Button and Indicator When the HT50 is powered by the dual internal battery, the LED on this button illuminates. A yellow LED indicates the internal battery system is in use. A blinking yellow LED indicates low power. - Page 37 Paw meter do not reflect the percent of charge. NOTE: The battery charge level is best maintained by keeping the HT50 continuously plugged into an external power source. Push to Unlock Button and Auto Lock Indicator Auto Panel Lock can be enabled or disabled via User Set Up (see pg 3-29).

-

Page 38: Front Panel Alarms

DESCRIPTION OF CONTROLS, INDICATORS, ALARMS & CONNECTIONS NOTE: The Battery Empty Alarm and the Device Alert Alarm can not be silenced permanantly. These alarms indicate that an alternate source of ventilation must be utilized. See pgs 3-20 and 3-21 for more details. - Page 39 SECTION 3 L Paw (High Pressure) Alarm (user adjustable) Audible Alarm: Intermittent beep Visual Alarm: LPaw indicator blinks red Message Window: HIGH PRESSURE The High LPaw Alarm is activated when airway pressure (Paw) reaches the LPaw alarm limit setting. Any breath in progress immediately cycles to exhalation.

- Page 40 DESCRIPTION OF CONTROLS, INDICATORS, ALARMS & CONNECTIONS • (High Insp. Minute Volume) Alarm (user adjustable) Audible Alarm: Intermittent beep • Visual Alarm: indicator blinks red • Message Window: HIGH V The High Insp. Minute Volume Alarm is activated when the •...

-

Page 41: High Baseline Pressure Alarm

When the Occlusion alarm is caused by a malfunction inside the ventilator, the HT50 will attempt to relieve circuit pressure through its redundant safety system. If successful, ventilation will continue, but in an alarmed state. - Page 42 DESCRIPTION OF CONTROLS, INDICATORS, ALARMS & CONNECTIONS WARNING Any time a Device Alert violation occurs along with the message “OCCLUSION,” an alternate method of ventilation should be provided for the patient as soon as possible so that the cause of the violation can be adequately and safely investigated.

- Page 43 Visual Alarm: Humidifier indicator blinks yellow The Humidifier Alarm is activated when any of the following conditions occur in the HT50 built-in humidifier. When an alarm condition is detected the humidifier heater shuts down. There are five humidifier alarms: Message Display Window...

-

Page 44: Battery Low Alarm

If the battery is completely depleted, it takes approximately 7 to 8 hours to fully recharge. NOTE: If the HT50 is to be powered from the dual internal battery for an extended period, ensure that the dual internal battery is fully charged prior to use. -

Page 45: Power Switchover Alarm

If internal battery operation has lasted longer than 60 seconds, there will be a delay of up to an additional 60 seconds before the HT50 will switch back to external power. If “No ext power” message is still displayed following the re-connection to external power, press Silence/Reset button to cancel the message. - Page 46 NOTE: If the cause of the SYSTEM ERROR does not allow the HT50 to display the alarm message and the Device Alert indicator to light, the ventilator will shut down and the Shut Down Alert Alarm will activate.

-

Page 47: Front Panel Message Display Window

SECTION 3 FRONT PANEL MESSAGE DISPLAY WINDOW All messages and alarms are displayed in a 16 character, alpha numeric window located above the MODE controls. Message Display Window Monitoring Messages: When the Message Display Window is blank (no message displayed) press the LUp control button to scroll through the monitoring messages available. -

Page 48: Left Side Connectors

DESCRIPTION OF CONTROLS, INDICATORS, ALARMS & CONNECTIONS Alarm and Caution Messages: All alarms have corresponding messages in the Message Display Window. See pg 2-3 for list of alarms. If more than one alarm is violated, they are displayed in order of medical priority. Alarm messages override the display of monitored parameters. -

Page 49: Emergency Air Intake

The Fresh Gas Intake is the attachment socket for the optional HT50 Air/Oxygen Entrainment Mixer or an Oxygen Blending Bag. WARNING Do not block the Fresh Gas Intake. -

Page 50: Optional Accessories

12-30 VDC, max. 12A 50/60/400 Hz The HT50 uses a single inlet for both A.C. and D.C. power sources. The inlet power connector automatically recognizes A.C. voltage ranges from 100 to 240 and D.C. ranges from 12 to 30. A Newport approved external battery can be attached to this connector. -

Page 51: Auto Lighter Cable

User Set Up and makes changes. NOTE: To enter User Set Up the HT50 must be in the Standby condition. To access User Set Up, when connected to A.C. power, press and hold the Silence/Reset button down. - Page 52 Off. To conserve battery power consumption during internal battery operation, the Power Save function automatically blanks the HT50’s numeric displays if the ventilator has operated for 2 minutes with no buttons pressed or alarms violated. MODE, On/Standby, Int. Battery indicators and message display window remain active at all times.

- Page 53 2-7. NOTE: HOME CAREGIVERS: This parameter should always be set to USER for home use to ensure that when the HT50 is powered off and on the physician directed ventilation settings remain in place. Auto Panel Lock This setting allows the user to enable (turn on) or disable (turn off) the Auto Panel Lock feature.

- Page 54 4. THEORY OF OPERATION General System Overview ....4-1 A/CMV Mode (Assist/Control Mandatory Ventilation)....4-2 SIMV Mode (Synchronized Intermittent Mandatory Ventilation).

-

Page 55: General System Overview

There is an Auto-Lock feature that may be enabled or disabled. The alarm loudness may be set to two different levels. The HT50 may be operated from a variety of AC (100-240 VAC @ 50 / 60 / 400 Hz) or DC (12-30 VDC) external power sources or from the Dual Pac Internal Battery System. -

Page 56: A/Cmv Mode (Assist/Control Mandatory Ventilation)

30 minutes operating time remains. The HT50 is available with a built-in humidifier or without. The HT50 is very easy to set up and use with clear indications of all ventilation and alarm settings and alarm violations. -

Page 57: Simv Mode

This limits the number of mandatory breaths (time triggered or patient triggered) the patient ƒ receives in 60 seconds to the (b/min) setting. As with all HT50 operating modes, Back-up Ventilation is activated • if the Low MV alarm limit is violated. SPONT MODE... -

Page 58: Psupport (Pressure Support)

THEORY OF OPERATION When PEEP/CPAP is set above 0, the ventilator mode is CPAP (without P support) or Bi-level Positive Airway Pressure (with Psupport). Ensure that P trig is set so the HT50 detects all spontaneous patient efforts. ƒ Entries for tidal volume, pressure control, , t I and Low Paw alarm limit are all inactive in SPONT mode. -

Page 59: Volume Control Ventilation

This will not cancel Back- up Ventilation. NOTE: Back-up Ventilation in the HT50 is based on the delivered inspiratory minute volume. The inspiratory minute volume may be different from the expiratory minute volume in some conditions, such as in the case of a patient breathing circuit or patient airway leak. - Page 60 10%, Back-up Ventilation is cancelled, the audible • alarm stops, the Low MV (Back-up Vent) alarm indicator latches and the HT50 resumes ventilation at the user-selected parameters. Press the Silence/Reset button to cancel the latched alarm indicator and alarm message in the Message Display Window.

- Page 61 Battery Test......5-10 Humidifier (for HT50-H) ....5-11 OVP Test Record .

-

Page 62: Introduction

SECTION 5 INTRODUCTION This procedure is intended to assist a Newport authorized service technician to establish a routine verification program to verify proper operation of the HT50 Ventilator (p/n HT50-H1, HT50-H1-B, HT50-H). An OVP must be performed each time the ventilator is serviced or a minimum of once a year. -

Page 63: Pre-Test Inspection

CALIBRATION / OPERATIONAL VERIFICATION PROEDURE PRE-TEST INSPECTION Refer to Figure 9-1. 1. General Inspection • Inspect the patient breathing circuit, exhalation valve, and 500 cc test lung for any deterioration which may cause leaks in the system. Replace any defective parts prior to performing the OVP. -

Page 64: Front Panel Test/Alarm Check

Newport technical support. 8. Connect the ventilator to A.C. power. SYSTEM LEAK TEST 1. Set the HT50 to Standard Test Settings. 2. Check the 3 thumbscrews of the inlet filter cover in order to ensure no leakage around the cover. -

Page 65: Pressure Transducers Calibration

CALIBRATION / OPERATIONAL VERIFICATION PROEDURE NOTE: If system leak test fails and the leak exists in the pneumatic system between the manifold and patient circuit, calibration shall be performed again after the leak is fixed. PRESSURE TRANSDUCERS CALIBRATION 1. Connect the T-connector between the patient fitting on the exhalation valve and a test lung. -

Page 66: Pressure Meter Calibration

SECTION 5 PRESSURE METER CALIBRATION 1. Use the Int. Battery button to scroll to “Meter Cal.” 2. Press the LUp control button to select “Meter Cal.” The Message Display Window will display “Adjust to 0.” 3. Use the LUp/MDown control buttons to adjust the Paw needle to 0. -

Page 67: Pressure Relief Valve Calibration

CALIBRATION / OPERATIONAL VERIFICATION PROEDURE PRESSURE RELIEF VALVE CALIBRATION 1. Use the Int. Battery button to scroll to “Adjust Rel Valve.” 2. Block the Mainflow outlet using CAP100P, and press the LUp control button. This will start the motor and pressure in the system will begin to rise. -

Page 68: Operational Set-Up (Standard Test Settings)

3. Press the Manual Inflation button once, then again within three seconds. 4. The HT50 will start the exhalation valve calibration and the ventilator will automatically test the exhalation valve. If it passes the test, the messages "Cal Completed", then "Press ON to Vent"... -

Page 69: Pressure Verification

CALIBRATION / OPERATIONAL VERIFICATION PROEDURE PRESSURE VERIFICATION 1. Connect the T-connector between the test lung and the exhalation valve. Connect the tubing from the T-connector to a calibrated pressure gauge. 2. Press the LUp control button to select “Paw P M B” in the Message Display Window. -

Page 70: Pressure Control

O/mbar. 5. Remove T-connector, leaving the Rp50 inline. EXHALATION VALVE SEALING 1. Set the HT50 to Standard Test Settings. Set the ƒ to 5. 2. Change the Volume Control setting so that the Paw meter reaches 70 ±5 cmH O/mbar during inspiration. -

Page 71: Check Prox Line Alarm

Verify that the audible alarm ceases. Press the Silence/Reset to clear the visual alarm. BATTERY TEST NOTE: Before proceeding with this test, ensure that the HT50 has been connected to an external power source for the purpose of charging the Int. Battery. -

Page 72: Humidifier (For Ht50-H)

3. Verify the continuously displayed temperature is stable and is approximately room temperature for at least 5 seconds. 4. Use the HT50 On/Standby button to enter the ON condition. Verify the continuously displayed temperature is stable and is approximately room temperature for at least 5 seconds. - Page 73 ID NO. Calibration Analyzer Oxygen Analyzer Electrical Safety Analyzer Digital Multimeter ELECTRICAL SAFETY TEST COMMENTS TEST TOLERANCE ACTUAL Ground Resistance < 0.1Ω Maximum Leakage < 500 µA The HT50 is operational when all tests have been performed successfully. 5-12 SERHT50NA A0808...

- Page 74 6. MAINTENANCE PROCEDURES Introduction....... 6-1 Tools Required ......6-1 Parts Required .

-

Page 75: Introduction

24 months. If the dual internal battery no longer meets the time requirements of the user, it should be replaced. NOTE: When 10,000 hours has elapsed, the HT50’s Message Display Window will indicate “Service Needed” after the next power... -

Page 76: Parts Required

Inspect the heater plate for corrosion and clean as necessary. WARNING Before disassembly of parts on the inside of the HT50 takes place, the HT50 power supply needs to be discharged. Cleaning the HT50 Ventilator Wipe the surfaces of the ventilator with a damp cloth containing a mild medical detergent. -

Page 77: Annual Maintenance Procedure

NOTE: Perform all Routine Maintenance procedures with the addtion of the following to replace the internal battery. Discharge the HT50 Power Supply Discharge the HT50 power supply per Discharge the HT50 Power Supply in Section 8. Removal of Lower Case Assembly Remove the lower case assembly per Disassembly (lower case) in Section 8. -

Page 78: 10,000 Hour Maintenance Procedure

Replacement of the Internal Secondary Battery NOTE: To ensure the NiMH battery can supply adequate power to the HT50 after the LOW BATTERY alarm Newport recommends the NiMH battery to be replaced every 2 years or if the NiMH battery no longer meets the time requirements of the user, it should be replaced. - Page 79 SECTION 6 Burn-in Test WARNING The ventilator is a critical life support device. Upon replacement of any critical assembly, it is important to complete a 24 hour burn-in to assure proper operation. 1. To complete the burn-in test, set the ventilator to the Standard Test Settings detailed in Section 5.

-

Page 81: Troubleshooting Guide

7. TROUBLESHOOTING GUIDE Introduction....... 7-1 Mechanical and Pneumatic Troubleshooting ..7-2 Electronic Troubleshooting . - Page 82 SECTION 7 INTRODUCTION This troubleshooting guide is intended to assist a NEWPORT authorized service technician to troubleshoot and repair the HT50 ventilator. The troubleshooting instructions are separated into two sections: • Mechanical and Pneumatic • Electronic. NOTE: Refer to the Troubleshooting section of the Operating manual for more clinically oriented ventilator problems.

-

Page 83: Troubleshooting

Newport approved exhalation valve is used it may begin to leak at lower maximal pressures than the permanent blue exhalation valve. This is a limitation of the exhalation valve and the HT50 driving pressure. The ventilator is performing appropriately. Torn or improperly sealed manifold Remove manifold pump and inspect diaphragm. - Page 84 Calibrate the exhalation valve. Retest for baseline stability. If the problem persists, replace the Pump Assembly (Note: Solenoid is part of the pump.) Main board not calibrated correctly. Calibrate entire HT50 (see Section 5) SERHT50NA A0808...

- Page 85 TROUBLESHOOTING PROBLEM POTENTIAL CAUSE SUGGESTED CORRECTIVE ACTION Baseline shows PEEP Water inside exhalation valve Disconnect the exhalation drive line tubing, w/ PEEP set to zero. diaphragm. then turn exhalation valve upside down to allow any water that is trapped to exit. If problem still persists, replace exhalation valve.

- Page 86 POTENTIAL CAUSE SUGGESTED CORRECTIVE ACTION Ventilator does not Battery fully discharged. Connect HT50 to A.C. power, allowing operate on internal battery. battery to charge for several hours, then check charge level. If the battery does not seem to be charging, disconnect the battery wiring harness from the charger.

- Page 87 Verify that both ends of the ribbon cable are control panel button(s) securely fastened. do not function. Defective Panel PCB. Replace Panel PCB. Unit auto triggers Relief vavle set too high or Perform a complete HT50 calibration (see pressure transducers out of calibration. Section 5) SERHT50NA A0808...

- Page 88 Tools Required ......8-1 Discharge the HT50 Power Supply ... . 8-2 Disassembly (Lower Case) .

-

Page 89: Introduction

Follow the shipping instructions detailed in Section 10. Replacement parts and assemblies which are returned to the manufacturer in the proper manner will be credited according to the warranty core charge list. Contact Newport Service Department for more information. 1.714.427.5811, ext. 500 Fax: 714.427.0572 Warning Hazardous voltages are present inside the ventilator. -

Page 90: Discharge The Ht50 Power Supply

ELECTRONIC & PNEUMATIC COMPONENT REMOVAL & REPLACEMENT WARNING Before disassembly of parts on the inside of the HT50 takes place, the HT50 power supply needs to be discharged. DISCHARGE THE HT50 POWER SUPPLY NOTE: Refer to pg. 3-26, External Power Connector, for proper connection of an external DC power source. -

Page 91: Internal Battery Assembly Replacement

(+) terminal and the black wire terminal connector is attached to the negative (-) terminal on the battery. Write the installation date and hours of the HT50 on the side of the new battery. Lay the battery on the side with the negative terminal closest... - Page 92 ELECTRONIC & PNEUMATIC COMPONENT REMOVAL & REPLACEMENT Caution The HT50 ventilator contains an internal sealed lead acid battery. After replacing the battery, be certain to recycle or dispose of it properly. Removal of the Secondary Internal Battery Remove lower case assembly. See above steps Disconnect the 2 cables on the dual pack battery circuit board connecting the NiMH battery to the circuit board.

-

Page 93: Pump Assembly Replacement

SECTION 8 Figure 8-4 PUMP ASSEMBLY REPLACEMENT Refer to Figure 9-1 (Internal View). 1. Follow steps 1- 3 in the DISASSEMBLY (Lower Case) section. Disconnect the solenoid two-pin wiring harnesses from the Main harness by pressing the release tab on each connector. Slide the Muffler Assembly (#13) from the pump inlet by pushing and twisting it back and forth until it disengages from the silicone cuff on the pump. - Page 94 Follow these steps: 1. Record the current hours meter reading. 2. Connect the HT50 to the computer with the PCS download program via the communication cable P/N V23-00001-29. 3. Connect the HT50 to an AC power source.

-

Page 95: Outlet Assembly Replacement

NOTE: The “NextService” number comes from the factory set to 10. This indicates the “Service Needed” message will appear when the HT50 hour meter reading equals 10,000 hours. If the motor pump was replaced at 10,000 hours, the “NextService” number should be changed to 20. -

Page 96: Humidifier Heater Assembly Replacement

ELECTRONIC & PNEUMATIC COMPONENT REMOVAL & REPLACEMENT 4. Install the new Outlet Assembly, making certain the o-ring seal and the humidifier’s heater wires (HT50-H only) are within the counterbore of the Outlet Assembly so that neither are pinched by the Outlet Assembly when securing it to the ventilator housing. -

Page 97: Front Panel Board Replacement

Remove the ten (10) Philips head screws securing the Front Panel PCB to the front panel plate. NOTE: Some older HT50 units have nine (9) Phillips screws securing the Front Panel PCB to the front panel plate. 4. Remove Front Panel PCB and place it inside an anti-static bag. -

Page 98: Main Board Assembly Replacement

ELECTRONIC & PNEUMATIC COMPONENT REMOVAL & REPLACEMENT MAIN BOARD ASSEMBLY REPLACEMENT Refer to drawing Figure 9-1, Internal View, Figure 9-3, Final Assembly Front View, Figure 9-4, Main Board with Mounting Hardware and Figure 9-5 Main Board Tubing Connection. NOTE: Any electronic malfunction that is not resolved with the replacement of the Front Panel PCB is usually resolved by replacing the Main PCB Assembly 1. -

Page 99: Power Supply Board Replacement

POWER SUPPLY BOARD REPLACEMENT WARNING Before disassembly of parts on the inside of the HT50 takes place, the HT50 power supply needs to be discharged. See instructions on pg. 8-2. WARNING Ensure that the HT50 is unplugged from the AC power source. - Page 101 9. DIAGRAMS AND PARTS LIST Figure 9-1, Internal View Figure 9-2, Final Assembly, Front View HT50-H Figure 9-3, Final Assembly, Front View HT50-T, HT50-H1 Figure 9-4, Main Board with Mounting Hardware Figure 9-5, Main Board Tubing Connection, Left Side Figure 9-6, Right Side Case...

- Page 103 SECTION 9 V09-13134-03 Battery Spring V09-13130-60 NIMH Battery Pack Assy. V09-13120-60 Battery Board Assy. V11-26700-06 SILICONE TUBE 3x7 (OF PART 3) G29-00012-29 CONNECTOR 2 PINS 6471 CIDEV (OF ALARM ASSY.) V11-31001-65 POWER SUPPLY ASSY. G23-00001-23 TORX SCREW HD, 6-32 UNC x 1/4” LG. V12-12110-03 HEAT ELEMENT HOUSING G29-00013-29...

-

Page 105: Final Assembly

UPPER CASE COVER V11-35100-03 FILTER THUMB SCREW V11-36000-26 O-RING 50 DUROMETER SILICONE V11-35201-07 FILTER COVER V11-38100-03 CASE SIDE PLATE RIGHT V11-12100-03 LOWER CASE COVER PART NUMBER QTY. DESCRIPTION AND REFERENCE DESIGNATION Figure 9-2 Final Assembly Front View HT50-H SERHT50NA A0808... - Page 106 V11-41000-03 UPPER CASE V11-36100-03 FILTER THUMB SCREW V11-36301-20 FILTER GS-100 DIAMETER 80 mm V11-36201-07 FILTER COVER V11-30000-60 RIGHT SIDE ASSY. V09-13000-60 LOWER CASE ASSY. PART NUMBER QTY. DESCRIPTION AND REFERENCE DESIGNATION Figure 9-3 Final Assembly Front View HT50-H1 SERHT50NA A0808...

- Page 107 SECTION 9 V11-61400-03 BRACKET ELECTRONIC COMPONENT V11-63000-03 CIRCUIT BOARD RETAINER CONNECTOR G27-00007-27 TRANSISTOR WASHER TW-6 CONNECTOR V11-65000-06 SEAL PAD TO-220A TRANSISTOR V11-62000-03 MAIN BOARD MOUNTING BRACKET 53, 61, 63 G23-00001-23 TORX HEAD SCREW T10 6-32 UNC-2Ax1/4” SS 52, 58 G23-00014-23 PHIL.

- Page 108 SECTION 9 Figure 9-5 Main Board Tubing Connection, Left Side SERHT50NA A0808...

- Page 109 FI L TER COVER LOOSEN SCREW S TO REM OVE COVER. FI L TER I S TO BE CHECKED W EEKL Y AND REPLACED W HEN DI RTY. DO NOT REVERSE FI L TER W HEN DI RTY. ATTACHM ENT SOCKET FOR OXYGEN BLENDER FRESH GAS I NTAKE DO NOT BL O CK! 100- 240V~m ax.

- Page 110 SECTION 9 5 19 Figure 9-6 Right Side Case SERHT50NA A0808...

- Page 111 SECTION 9 9-10 SERHT50NA A0808...

- Page 112 SECTION 9 9-11 SERHT50NA A0808...

- Page 113 Humid. Bottle, Lower HT460920 Humid. Heat Sink HT460930 Humid. Heater Assembly V12-10000-60 Torx Screw, K35 x 10 G23-00006-23 Pump Diaphragm V11-21700-06 Outlet Assembly., HT50-H V10-24000-63 Outlet Assembly, HT50-H1 V11-24000-63 Pump (manifold) Assembly V11-21000-60 Rubber Foot G01-00001-67 Silicone Tubing Kit, Solenoid V11-26000-60...

- Page 114 10. REPACKAGING AND SHIPPING INSTRUCTIONS Introduction......10-1 RGA (Return Goods Authorization) ... 10-1 Packaging: Complete Unit .

-

Page 115: Rga (Return Goods Authorization)

Instruments. Please follow the instructions below. This will help you avoid any inconveniences or delays when returning merchandise. RGA (RETURN GOODS AUTHORIZATION) 1. All returns to Newport Medical Instruments must have an RGA number assigned. Returning goods without an RGA number could delay service, replacement or credit issues. -

Page 116: Packaging: Parts Or Accessories

3. When addressing the shipping label, use use the following address: Newport Medical Instruments, 1620 Sunflower Avenue, Costa Mesa, California, USA 92626. NOTE: When calling Newport Medical Instruments regarding a return, please have your assigned RGA number available to avoid any delays in answering your inquiry. - Page 117 HT50 PARTS AND ACCESSORIES HT50 Ventilator Parts and Accessories..A-1 Service Parts List......A-3...

- Page 118 APPENDIX A HT50 Ventilator Parts and Accessories For more details contact your N representative or N Customer Service. EWPORT EDICAL EWPORT EDICAL Part number Description Quantity HUMIDIFIER ACCESSORIES HT460910 Humidifier Bottle – upper HT460920 Humidifier Bottle – lower HT460930 Humidifier – heat sink HT460940 Humidifier –...

- Page 119 HT50 PARTS AND ACCESSORIES Part number Description Quantity MOUNTING ACCESSORIES HTBKT01 Bracket, humidifier pole mount (for stand) HTECH01 Bracket, e-cylinder holder (for stand) HTECH02 Bracket, dual e-cylinder holder (for stand) MISCELLANEOUS ACCESSORIES HT460300 Air inlet particle filter (disposable) 5/ea LNG500A...

- Page 120 Silicone Tubing Kit, Solenoid V11-28000-06 Silicone Tubes, Transducer V11-29000-06 Plug, Alarm Comm. Port V11-25000-60 Temp. Probe Conn. Kit V11-27100-06 Plug, Temp. Probe (HT50-T, -H1) V11-31001-65 Power Supply Assembly. G23-00031-23 Cap Screw, 6/32" x 1/4" V09-60000-65 Main PCB Assembly. G23-00014-23 Pan Head Screw, 4-40 x 1/4"...

- Page 121 INDEX – PEEP Too Low 3-23 10,000 Hour Maintenance Procedure 6-4 Changing a Parameter 3-2 10V Shutdown 3-21 Charge Fault Alarm 3-12 Check Humidifier Alarm 3-19 Check Prox Line Alarm 3-18,5-9 Check Temp Probe Alarm 3-19 A/CMV (Assist/Control Mandatory Ventilation) 3- Checking the battery.

- Page 122 Operational Set-Up Test 5-7 Alarms 3-20 Operator’s Responsibility 1-1 Charge Level Meter 3-13 Outlet Assembly Replacement 8-7 General Warnings 1-5 OVP Test Record for HT50 5-12 Recharge Time 3-20 Oxygen Accessories. See Air/Oxygen Specifications 2-4 Entrainment Mixer, Oxygen Blending Bag Test Button 3-12...

- Page 123 Pressure Units 3-28 Transport Use 4-1 Pressure Verification Test 5-8 Troubleshooting Guide 7-1 Psupport (Pressure Support) 3-10,4-3 Turning On/Off the HT50 3-1 Ptrig (Sensitivity) 3-10 Ptrig Test 5-8 Pump Assembly Replacement 8-5 Push to Unlock Button 3-13 Unlock Panel. See Auto Panel Lock...

Need help?

Do you have a question about the HT50 and is the answer not in the manual?

Questions and answers