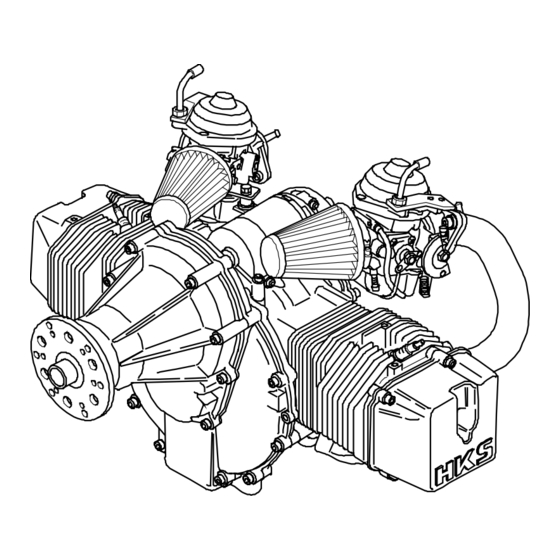

HKS 700E Service Manual

Non-certified aircraft engine

Hide thumbs

Also See for 700E:

- Operation manual (36 pages) ,

- Installation instructions manual (25 pages)

Summary of Contents for HKS 700E

- Page 1 HKS 700E Service Manual 2006 June Ver. 2.02 HKS CO.,LTD 7181 KITAYAMA FUJINOMIYA SHIZUOKA JAPAN 418-0192 TEL +81(0)544-54-1781 FAX +81(0)544-54-1410 hks_aviation@hks-power.co.jp http://www.hks-power.co.jp/hks_aviation/...

-

Page 2: Table Of Contents

Service Manual CONTENTS PG1-3 Introduction General information 2.1 Special tools Disassembly 3.1 Carburetor disassembly 3.1.1 Upper type 3.1.2 Horizon type 3.2 Intake manifolds removal 3.3 Electric starter removal 3.4 Spark plug removal 3.5 Gearbox removal and disassembly 3.5.1 A type (ratio 2.58) 3.5.2 B type (ratio 3.47) 3.6 Front cover removal 3.6.1 Drive gear removal... - Page 3 Service Manual Assembly 4.1 Connecting rod reassembly 4.2 Crankcase reassembly 4.2.1 Crankshaft Bearing and Thrust bearing 4.2.2 Crankshaft 4.2.3 Camshaft 4.2.4 Oil strainer 4.2.5 LH crankcase 4.3 Piston reassembly 4.3.1 Piston ring 4.4 Cylinder reassembly 4.4.1 Hydraulic lifter 4.5 Cylinder heads reassembly 4.5.1 Push rod 4.5.2 Rocker arm compartment 4.6 Cylinder head cover reassembly...

- Page 4 Service Manual 4.12 Electric starter reassembly 4.13 Spark plug reassembly 4.14 Intake manifolds reassembly 4.15 Carburetors reassembly 4.15.1 Upper type 4.15.2 Horizon type Table for torque values Selection of metal bearing 6.1 Connecting rod bearing 6.2 Crankshaft bearing Grading of cylinder and piston Wear limits Effectivity: HKS700E after S/N 100600 - 3 -...

- Page 5 Service Manual WARNING! This is a non-certified aircraft engine; the possibility of engine failure exists at all times. Do not operate this engine over densely populated areas. Do not operate this engine over terrain where a safe, power off landing cannot be performed. The operating and maintenance instructions supplied with this engine must be followed at all times.

-

Page 6: Introduction

Service Manual Introduction Effectivity: HKS700E after S/N 100600 - 5 -... -

Page 7: General Information

ST-01 ST-02 ST-07 ST-08 ST-09 In addition to this service manual, please refer to the following. (1) HKS 700E Installation instruction Manual (2) HKS 700E Operations Manual (3) HKS 700E Parts List Effectivity: HKS700E after S/N 100600 - 6 -... -

Page 8: Disassembly

Service Manual Disassembly 3.1 Carburetors removal NOTE: Identify both carburetors to RH/LH cylinders. 3.1.1 Upper type • Remove 2 nuts 3.1.2 Horizon type • Remove tension spring. • Loosen clamp screw and remove carburetor by turning action. 3.2 Intake manifolds removal •... -

Page 9: Electric Starter Removal

Service Manual 3.3 Electric starter removal • Remove 2 bolts • Shift remove electric starter. 3.4 Spark plug removal • Remove 4 spark plugs. Effectivity: HKS700E after S/N 100600 - 8 -... -

Page 10: Gearbox Removal And Disassembly

Service Manual 3.5 Gearbox removal and disassembly 3.5.1 A type (ratio2.58) • Remove 8 bolts 3.5.2 B type (ratio3.47) • Remove 10 bolts • Shift to remove gearbox. • Remove circlip ST-07 • Set ST-07 as shown. • Compress gear and remove half rings Effectivity: HKS700E after S/N 100600 - 9 -... - Page 11 Service Manual • Remove Inner race following below instruction.. STEP 1: Compress ST-07 to make clearance between Inner race and Retainer. STEP 2: Insert one ST-08. STEP 3: Decompress ST-07. Inner race will move to upward by spring washers. If three ST-08s are inserted, go to STEP 4 else go to STEP 1. STEP 4: Remove ST-08s and ST-07.

-

Page 12: Front Cover Removal

Service Manual 3.6 Front cover removal ST-02 3.6.1 Drive gear removal • Block crankshaft with ST-02. • Remove nut M25 and washer • Shift to remove drive gear • Remove 12 bolts • Shift to remove front cover. Effectivity: HKS700E after S/N 100600 - 11 -... -

Page 13: Rear Cover Removal And Disassembly

Service Manual 3.7 Rear cover removal and disassembly • Remove oil filter with oil filter wrench. • Remove 10 bolts • Shift to remove rear cover. NOTE: Do not lose the thrust washer 3.7.1 Oil pump disassembly • Remove bolt •... - Page 14 Service Manual • Remove inner rotor (15mm). • Remove woodruff key • Shift to remove pump body (15mm). • Shift to remove inner feed rotor Assy Effectivity: HKS700E after S/N 100600 - 13 -...

-

Page 15: Stator Removal

Service Manual 3.8 Stator removal • Block crankshaft with ST-02. ST-02 • Remove bolts M10. • Remove stator with tightening ST-03 (M16 x P1.5). ST-03 • Remove woodruff key Effectivity: HKS700E after S/N 100600 - 14 -... -

Page 16: Starter Idler Gear And Driven Gear Removal

Service Manual 3.9 Starter idler gear and Driven gear removal • Remove idler gear , idler shaft and 2 thrust washers • Remove driven gear by turning clockwise (left). 3.10 Flywheel removal • Block crankshaft same as 1.8 • Remove 6 bolts •... -

Page 17: Cylinder Head Removal

Service Manual 3.11 Cylinder head removal • Remove 5 bolts M5 and cylinder head cover. • Remove head cover gasket. CAUTION: Do not damage contact surface! • Rotate crankshaft to set piston to bottom dead center position. • Remove bolt •... -

Page 18: Cylinder Head Disassembly

Service Manual 3.11.1 Cylinder head disassembly • Remove bolt M5 and banjo bolt M10. • Remove oil jet pipe • Compress valve spring with valve spring mounting device and clamp or similar tool. • Remove valve cotters and release valve spring. •... -

Page 19: Cylinder And Piston Disassembly

Service Manual 3.12 Cylinder and Piston disassembly NOTE: Identify both cylinders and pistons to RH/LH. • Rotate crankshaft to set piston to top dead center position. • Shift to remove cylinder. Support piston by hand to avoid damaging piston and piston rings. •... -

Page 20: Crankcase Disassembly

Service Manual 3.13 Crankcase disassembly • Remove 2 bolt • Remove 8 bolts • Remove 2 bolts • Remove 4 bolts M10. • Set crankcase on ST-01. • Attach ST-04 at mounting boss. ST-01 ST-04 • Split crankcase with tightening bolt. - Page 21 Service Manual • Remove oil strainer. • Remove camshaft. • Remove crankshaft. • Remove 4 thrust bearing • Remove 4 main bearing Effectivity: HKS700E after S/N 100600 - 20 -...

-

Page 22: Crankshaft Disassembly

Service Manual 3.14 Crankshaft disassembly • Remove 4 connecting rod bolts • Remove connecting rod cap end • Remove connecting rod bearing Effectivity: HKS700E after S/N 100600 - 21 -... -

Page 23: Assembly

Service Manual Assembly 4.1 Connecting rod reassembly • Clean all parts. • Fit connecting rod bearings . Apply motor oil to metal surface. NOTE: Confirm the turn stop of bearing entered the ditch. • Assemble connecting rod. Apply motor oil to bolt and thread. -

Page 24: Crankcase Reassembly

Service Manual 4.2 Crankcase reassembly 4.2.1 Crankshaft bearing and Thrust bearing • Clean bearing seat and remove oil. • Visually check the metal bearing surface. Remove oil from back of metal bearing. • Place metal bearing into both crankcases. • Place thrust bearing to crankcase with applying grease to back side of thrust bearing. NOTE: There are two kinds of bearings. -

Page 25: Camshaft

Service Manual 4.2.3 Camshaft • Apply motor oil to camshaft journal and all teeth of drive and driven gear. • Place camshaft to RH crankcase while uniting punch marks. 4.2.4 Oil strainer • Fit new O-ring to oil strainer with applying motor oil. •... -

Page 26: Lh Crankcase

Service Manual 4.2.5 LH crankcase • Clean and remove oil from both contact surface of crankcase. • Apply LOCTITE 5699 on contact surface of RH crankcase. • Place 2 pipe knock-pins 8 and 2 pipe knock-pins • Place LH crankcase on RH crankcase. •... - Page 27 Service Manual • Wipe off the protruding LOCTITE. • Fix oil strainer with 2 bolts M6-20 with applying LOCTITE 243. Tighten to 1.2 [kgfm]. Effectivity: HKS700E after S/N 100600 - 26 -...

-

Page 28: Piston Reassembly

Service Manual 4.3 Piston reassembly 4.3.1 Piston ring • Fit Top and Second rings using piston ring pliers, with the dot mark towards piston crown. • Insert new piston pin circlip in groove of FRONT MARK front marked (triangular sign) side. •... -

Page 29: Cylinder Reassembly

Service Manual 4.4 Cylinder reassembly 4.4.1 Hydraulic lifter • Fill hydraulic lifter with motor oil. • Insert hydraulic lifter into crankcase with applying motor oil • Clean and remove oil from contact surface of crankcase and cylinder. • Place new gasket to crankcase. -

Page 30: Cylinder Heads Reassembly

Service Manual Apply MOLYPASTE 4.5 Cylinder heads reassembly • Place valve spring seat on valve guide. Insert valve with MOLYPASTE, place valve spring Color mark and spring retainer in position. NOTE: Place valve spring with the color mark towards upper side. CHANGE PARTS AT OVERHAUL: IN and EX valve •... -

Page 31: Push Rod

Service Manual • Clean and remove oil from contact surface of cylinder and cylinder head. • Place new gasket to cylinder. • Place 2 pipe knock-pins • Place cylinder head. 4.5.1 Push rod • Place push rod on hydraulic lifter. NOTE: Coloring side is turned to cylinder head side. -

Page 32: Rocker Arm Compartment

Service Manual 4.5.2 Rocker arm compartment • Rotate crankshaft to set both lifters to bottom position. • Place 2 pipe knock-pins • Attach rocker arm component to cylinder head with 4 nuts M8 and 4 washers applying motor oil to thread. Tighten evenly to 2.0 [kgfm]. •... -

Page 33: Cylinder Head Cover Reassembly

Service Manual 4.6 Cylinder head cover reassembly • Clean and remove oil from contact surface of cylinder head and cylinder head cover. • Place new gasket to cylinder head. • Attach cylinder head cover to cylinder head with 5 bolts M5-25 with LOCTITE 243 and washers. -

Page 34: Driven Gear And Starter Idler Gear Reassembly

Service Manual 4.8 Driven gear and Starter idler gear reassembly • Attach driven gear to crankshaft by turning to left. Apply motor oil over the whole of one-way clutch, bush bearing and gear tooth. NOTE: The driven gear must engaged on crankshaft when turning clockwise (right) looking from rear side, and turn freely when turning counter-clockwise (left). -

Page 35: Oil Pump

Service Manual 4.9.2 Oil pump • Attach inner feed rotor Assy outer rotor in rear cover. • Fit 4 new O-rings • Attach 2 knock-pins • Attach pump body (15mm). • Attach woodruff key • Attach inner rotor (15mm). • Attach outer rotor (15mm). -

Page 36: Pressure Regulator

Service Manual • Attach inner rotor (25mm). • Attach outer rotor (25mm). • Fit 2 new O-rings • Attach oil pump cover. • Tighten oil pump with bolt M6-60, 4 bolts M6-110 and washers evenly to 1.2 [kgfm] applying LOCTITE243. NOTE: The oil pump must rotate freely when turning by hand. -

Page 37: Oil Filter

Service Manual • Place new gasket to crankcase. • Place 2 pipe knock-pins • Turn oil pump shaft into a position to align with groove of camshaft. • Place rear cover on crankcase. • Tighten rear cover with 10 bolts M6-20 and washers evenly to 1.2 [kgfm] applying LOCTITE 243. -

Page 38: Front Cover Reassembly

Service Manual 4.10 Front cover reassembly • Clean and remove oil from contact surface of crankcase and front cover. • Place new gasket to crankcase. • Place 2 pipe knock-pins • Apply motor oil to bearing bush of front cover and crankshaft. •... -

Page 39: Gearbox Reassembly

Service Manual 4.11 Gearbox reassembly • Insert new oil seal from the inside, using insertion jig. • Add seat PTO shaft with rounded side towards oil seal. • Heat up gearbox in oven to approx. 120 . • Press in ball bearing and fit circlip in the groove. - Page 40 Service Manual • Attach retainer • Compress gear using ST-07 and attach half rings with the flat side out. ST-07 Press • Set inner race with ST-09. Press ST-07 to insert inner race. ST-09 • Fit circlip in the groove. Effectivity: HKS700E after S/N 100600 - 39 -...

-

Page 41: A Type (Ratio2.58)

Service Manual • Clean and remove oil from contact surface of front cover and gearbox. • Place new gasket to front cover. • Place 2 pipe knock-pins • Apply motor oil to roller bearing and gear tooth. • Place gearbox on front cover. 4.11.1 A type (ratio2.58) •... -

Page 42: Electric Starter Reassembly

Service Manual 4.12 Electric starter reassembly • Apply motor oil to gear tooth and installation bore. Fit electric starter into crankcase. • Tighten electric starter with 2 bolts M6-35 and washers to 1.2 [kgfm] applying LOCTITE 243. 4.13 Spark plug reassembly •... -

Page 43: Carburetors Reassembly

Service Manual 4.15 Carburetors reassembly • Attach carburetor by turning action and tighten clamp screw CHANGE PARTS AT OVERHAUL: Insulator rubber 4.15.1 Upper type • Tighten 2 nuts 4.15.2 Horizon type • Hook tension spring. Effectivity: HKS700E after S/N 100600 - 42 -... - Page 44 Service Manual Table for torque values Designation Size Torque [kgfm] Remark Connecting rod Engine oil Flywheel LOCTITE 243 Drive gear (nut) 10.0 Crankcase Engine oil LOCTITE 243 Cylinder - Crankcase Oil jet pipe - Cylinder head M10 (Banjo) Stud bolt - Crankcase Engine oil Rocker arm component (nut) 2.0 + 90 [deg]...

-

Page 45: Selection Of Metal Bearing

Service Manual Selection of metal bearing 6.1 Connecting rod bearing Rear PIN Front PIN No. on P1/P2 O.D of pin [mm] Wear limit No. on con-rod I.D of journal [mm] [mm] 40.994 41.000 44.000 44.008 40.960 40.988 40.993 44.009 44.016 Color of bearing BROWN BLACK... -

Page 46: Crankshaft Bearing

Service Manual 6.2 Crankshaft bearing Rear Journal Front Journal No. on D1/D2 I.D of journal [mm] No. on J1/J2 O.D of journal [mm] Wear limit [mm] 49.000 49.006 44.994 45.000 44.960 49.007 49.012 44.988 44.993 Color of bearing BROWN BLACK Color mark BLUE New [mm]... -

Page 47: Wear Limits

Service Manual Wear limits Designation New [mm] Wear limit [mm] Remark Cylinder/Piston Piston O.D & Cylinder bore See Para 7 Clearance 0.005-0.025 0.050 Piston pin Piston pin 19.996 - 20.000 19.990 Piston pin bore 20.002 - 20.008 20.012 Clearance, pin in piston 0.002 - 0.012 0.015 Con-rod bore, small end... - Page 48 Service Manual Designation New [mm] Wear limit [mm] Remark Crankcase Crankshaft bearing See Para 6.2 - S/N100895 21.440 - 21.460 21.490 Lifter hole bore S/N100896 - 21.414 - 21.434 21.475 Camshaft bore 26.000-26.012 26.035 Hydraulic lifter Lifter O.D. 21.387-21.404 21.350 Radial - S/N100895 0.036-0.073...

- Page 49 Service Manual Effectivity: HKS700E after S/N 100600 - 48 -...

Need help?

Do you have a question about the 700E and is the answer not in the manual?

Questions and answers