HKS 700E Operation Manual

Hide thumbs

Also See for 700E:

- Service manual (49 pages) ,

- Installation instructions manual (25 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for HKS 700E

- Page 1 Operations Manual HKS700E Operations Manual Please read this manual before using. Engine S/N: 2014 February Ver.7.00 ASTM F2339 HKS CO.,LTD 7181 KITAYAMA FUJINOMIYA SHIZUOKA JAPAN 418-0192 FAX: +81-(0)544-54-1410 E-MAIL: aircraft-engine@hks-power.co.jp http://www.hks-power.co.jp/hks_aviation/...

-

Page 2: Table Of Contents

3.9 Propeller reduction unit. 3.9.1 Propeller mass moment of inertia. 3.10 Exhaust gas temperature. 4 PERFORMANCE CURVE 5 MANUAL OF INSTRUCTION HKS-700E 5.1 Before starting the engine. 5.2 Starting the engine. 5.3 Warm up and run up. 5.4 Take-off and climbing flight. - Page 3 Operations Manual HKS 700E 6 MAINTENANCE INSTRUCTIONS 6.1 Daily inspection. 6.2 Periodic checks. 6.2.1 First 25-hour-check, 50-hour-check. 6.2.2 100-hour-check. 6.2.3 200-hour-check. 6.3 Preservation of the engine during storage. 6.4 Winter operation. 6.4.1 Care of the electrical system. 6.4.2 Cold starting.

- Page 4 Operations Manual HKS 700E Do not operate this engine over densely populated areas. Do not operate this engine over terrain where a safe, power off landing cannot be performed. The operating and maintenance instructions supplied with this engine must be followed at all times. Flying any aircraft involves the risk of injury or death,...

-

Page 5: General

Operations Manual HKS 700E 1. GENERAL 1.1. Log of revisions. Revision No. Date Pages affected Description 3.00 2003/09 Change the oil temperature. 4.00 2004/12/01 TBO extended. 5.00 2006/07/01 5.10 2008/01/14 P9,P21,P31 * Max. percentage of alcohol in fuel. * Oil viscosity. -

Page 6: Hks700E Engine

2. HKS700E ENGINE 2.1. Type designation. HKS-700E 1. Manufacturer: HKS. 2. Piston displacement in c.c. 2.2. Description of the HKS-700E. Air-cooled, four-stroke. Cylinder arrangement: 2 cylinders, horizontally opposed. One central camshaft-pushrods-OHV, hydraulic lifters. Oil cooled cylinder head. Dual CDI (capacitive discharge ignition). -

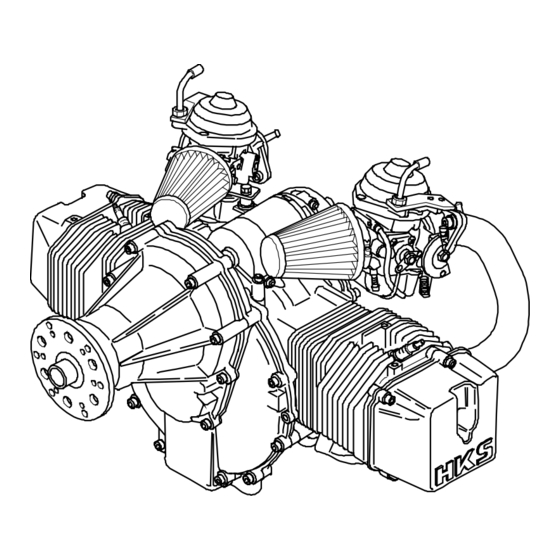

Page 7: Views Of The Engine

Operations Manual HKS 700E 2.3. Views of the engine. -

Page 8: Technical Data Hks700E

9 volts. Ignition timing: 10 DEG. B.T.D.C (below 2000r/min) 23 DEG. B.T.D.C (over 4000r/min) Spark plugs: HKS SUPER FIRE RACING Electrode spacing: 0.7 mm (.028") Alternator performance: 210W DC at 4000 to 6200 r/min 120W at 1750 r/min and up... -

Page 9: Performance

Operations Manual HKS 700E 3.3. Performance Take-off power (3 min.). Approx. 44.7kW (60HP) at 6200 r/min Max continuous power. Approx. 41.7kW (56HP) at 5800 r/min 3.4. RPM limitations Max. permissible r/min 6200 r/min Max. continuous r/min 5800 r/min Idle r/min 1400 to 1750 r/min (Within 1900 r/min if necessary for low vibration.) -

Page 10: Information About Fuels And Lubricants

Operations Manual HKS 700E 3.6. Information about fuels and lubricants Fuel: Automobile fuel, unleaded premium 95 Octane (RON) minimums or aviation gasoline 100LL. Fuel pressure: 15 - 40 kPa kgf/cm (0.15 - 0.4 , 2.2 - 5.8 psi) Oil type: No aircraft engine oils. -

Page 11: Cylinder Head Temperatures

Operations Manual HKS 700E 3.7. Cooling system Free air-cooling. For the engines with full-cowled engine installation, ducting is required to properly channel cooling air to the cylinders. 3.8. Cylinder head temperature Max. permissible cylinder head temperature (Measured on the hottest cylinder): 170 Deg. -

Page 12: Performance Curve

Operations Manual HKS 700E 4. PERFORMANCE CURVE... -

Page 13: Manual Of Instruction Hks-700E

Operations Manual HKS 700E 5. OPERATING INSTRUCTIONS FOR THE HKS-700E These instructions and procedures must be followed in detail for the proper operation of the engine and systems. To deviate from these instructions may lead to increased engine wear and a loss of reliability. -

Page 14: Warm Up And Run Up

Operations Manual HKS 700E 5.3. Warm up and run up • Let the engine run at 2000-3000 r/min for about 5 minutes so that the oil pressure will not exceed the 390kPa (57psi, 4bar) maximum during run up. • Choke off (if used). - Page 15 Operations Manual HKS 700E 5.6. Engine shutdown and restarting in flight • Let the engine cool sufficiently. Wait for the cylinder head temperature to reach less than 120Deg.C (248 Deg.F). • Throttle: IDLE • Ignitions: The in-flight re-start procedure is the same as on the ground. Use choke if...

- Page 16 Operations Manual HKS 700E 6. MAINTENANCE INSTRUCTIONS 6.1. Daily check • Take off the engine cowling (if so equipped). • Check the engine for missing or loose parts as well as for any wear. • Check the condition of the ignition harness.

- Page 17 Operations Manual HKS 700E 6.2. Periodic inspections After the first 25 hours of operation the inspections listed in 6.2.1 are to be performed. The next inspection is due to at 50 hours and thereafter every 50 hours. The 100-hour inspection mentioned under 6.2.2 is to be performed every 100 hours but at least annually.

- Page 18 Operations Manual HKS 700E 6.2.2. 100-hour-inspection • Carry out the 50-hour-check. • Perform a compression check. (See Sec 7.3) 6.2.3. 200-hour-inspection • Carry out the 100-hour inspection. • Check the spark plug caps. Change if necessary. • Change the spark plugs.

-

Page 19: Winter Operation

Operations Manual HKS 700E 6.3. Preservation of the engine for long term storage For long out of operation periods and at extreme climatic conditions, we recommend the following instructions to protect against corrosion. Extra protection against corrosion beyond these recommendations is not necessary. -

Page 20: Cold Starting

Operations Manual HKS 700E 6.4.2. Cold starting procedures Preheating the engine using hot air is recommended. • Throttle • Choke Limit cranking the engine to periods not much longer than 10 sec. After the engine starts, operate the choke as required to keep the engine running but avoid allowing the engine to exceed 2500 R/MIN. -

Page 21: Maintenance

Operations Manual HKS 700E 7. MAINTENANCE 7.1. Changing the engine oil • Warm the engine up to normal operational temperatures. • Remove the oil drain screws from the engine and oil tank, drain oil, and replace the oil filter. • Drain the oil from the oil cooler and oil lines. -

Page 22: Carburetor Adjustment

Operations Manual HKS 700E 7.4. Carburetor adjustments. NOTE! The combustion condition of both cylinders is very important to achieve a smooth running engine. Carburetor adjustments are a flight critical operation; if you do not have experience in this operation, please get qualified assistance. -

Page 23: Carburetor Setting Table

Operations Manual HKS 700E 7.4.3. Carburetor setting table TABLE 1. Upper manifold Horizontal manifold MAIN JET (MJ) 125 (130* 135(140* NEEDLE JET (NJ) DIFFUSER (CK) IDLE JET (PK) IDLE MIXTURE SCREW 1-1/2 turn JET NEEDLE (JN) 251/ 4th groove from top. -

Page 24: Spark Plugs

• Do not use a brass brush or a steel wire brush for cleaning. • After 200 hours, replacement of the spark plugs is required. • Spark plug to use: HKS SUPER FIRE RACING • Torque the spark plugs with a cold engine only. (See Chapter 9.) The shade of the spark plugs can give you the following information: •... -

Page 25: Resistance Of The Electrical Equipment

Operations Manual HKS 700E 7.8. Resistance of electrical equipment Check the resistance of the electrical equipment according to TABLE 2. TABLE 2. EQUIPMENT LOCATION OF MEASUREMENT RESISTANCE VARIATION AC Magnetic White - White of 3 phase 0.4ohms + - 20%... -

Page 26: Overhauls

Operations Manual HKS 700E 8. OVERHAULS 8.1. A major inspection at TBO is to be performed by the manufacturer or approved service centers only. For this purpose the engine is to be sent with its logbook to the manufacturer or the nearest approved service center. - Page 27 Operations Manual HKS 700E 10. TROUBLE SHOOTING 10.1. Engine does not fire Cause Action Ignitions OFF Spark plug gap too big Change plugs. Fuel shutoff valve OFF or fuel filter Fuel shutoff valve ON, clean or blocked replace fuel filter.

- Page 28 Operations Manual HKS 700E 10.2. Warm engine shows irregular idling Cause Action Choke ON Choke OFF. Idle mixture incorrectly adjusted Adjust carburetors according 7.4.1. Float needle valve dirty, jammed Clean float needle valve or replace it or worn out. Intake manifold leaky Tighten all connections of the intake.

- Page 29 Operations Manual HKS 700E 10.4. Engine overheats, Oil temperature over 120 Deg.C (248 Deg.F) Cause Action Fuel-air mixture too lean Check adjustment and operation of carburetor and correct if necessary. Too much oil remaining in the Check the oil return line.

- Page 30 Operations Manual HKS 700E 10.6. Low oil pressure Cause Action Insufficient oil in oil tank Check oil level and fill if necessary. Oil remains in engine and doesn't Check oil return line to tank. circulate High oil temperature See 10.4.

- Page 31 Operations Manual HKS 700E 10.9. Engine "knocks" Cause Action Using fuel with a low octane rating Use fuel with a higher octane rating. Spark plug fitted without sealing Use one sealing washer on each washer plug. Residue in combustion chamber Inspect and remove residue.

- Page 32 Operations Manual HKS 700E 11. INSPECTION AND MAINTENANCE ITEMS HKS-700E Inspection and maintenance program Inspection-maintenance item. Hourly inspection routine First Every Every Every 25hr. 50hr. 100hr. 200hr. 1. Check condition of throttle cable, starting carb. 2. Engine mounts-check for cracks, looseness of mounts, and looseness of engine to mount.

- Page 33 1) Period HKS as manufacturer, warrants through their authorized HKS distributors from the date of sale to the first consumer, every HKS non-certified engines, sold as NEW and UNUSED, and delivered by an authorized HKS distributor for a period of the earliest of:...

- Page 34 HKS or any other person. HKS reserves the right to modify its warrantee policy at any time, being understood that such modification will not alter the warrantee conditions...

- Page 35 7) Warrantee will only be valid if the end user completes this registration card as soon as the aircraft engine goes into service, and returns it to the national authorized HKS distributor of the area in which the aircraft engine is firstly operated.

- Page 36 WARRANTEE / OWNER'S REGISTRATION CARD 1. To be eligible for warrantee, this registration card must be returned completed and signed by the end user to the authorized HKS distribution partner of the area of the permanent residence of the end user and/or in which this non-certified aircraft engine is firstly operated, within 30 days as of date of purchase.

Need help?

Do you have a question about the 700E and is the answer not in the manual?

Questions and answers