Summary of Contents for Econoburn EBW-100

- Page 1 G A S I F I C A T I O N B O I L E R S E B W A N D E B W C S E R I E S H I G H E F F I C I E N C Y W O O D F I R E D B O I L E R S INSTAL L AT I ON A N D OPER AT I NG M A NUAL...

- Page 2 G A S I F I C A T I O N B O I L E R S Manufactured by: Alternative Fuel Boilers 795 Deer Street PO Box 281 Dunkirk, New York 14048 United States of America Website: www.alternativefuelboilers.com Email: sales@alternativefuelboilers.com ©...

-

Page 3: Table Of Contents

DRAFT FAN CONTROL UNIT ELECTRICAL POWER FAILURE BOILER OPERATING CHECKLIST SECTION 3 - MAINTENANCE AND CLEANING BOILER MAINTENANCE TURBULATOR CLEANING ASH DISPOSAL HEAT EXCHANGER MAINTENANCE CHIMNEY MAINTENANCE TROUBESHOOTING GUIDE SECTION 4 - ECONOBURN™ BOILER WARRANTY WARRANTY PERIOD CONDITIONS OF WARRANTY WARRANTY... -

Page 4: Introduction

To ensure you have a clear understanding of the operating procedures of this boiler, please take the time to read this manual thoroughly. If you have any questions, you may contact us by email, through the ECONOBURN™ website at www.alternativefuelboilers.com, or call toll free at 1-866-940-BURN (2876) and we will be happy to answer them for you. -

Page 5: Specifications

SPECIFICATIONS ECONOBURN™ Specifications (subject to change without notice) Boiler Model EBW-100 EBW-150 EBW-200 EBW-300 EBWC-500 EBWC-1000 Depth 42” 42” 42” 45” 50” 80” Width 25” 25” 30’ 36” 40” 42” Height 60” 64” 64” 70” 78“ 82“ Firebox Length 23”... -

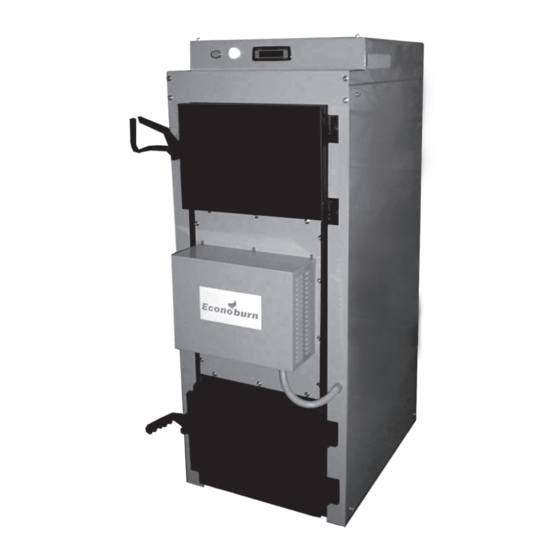

Page 6: Boiler Diagram

BOILER DIAGRAM Rigging Hook Access Supply Control Panel Pressure Emergency Cooling Relief Valve Connection Turbulator Agitation Lever Firebox Door Flue Draft Handle Draft Fan Cover Return (Lower back panel) Gasification Chamber and Ash Pit Door... -

Page 7: Section 1 - Installation Instructions

UNCRATING When you receive your ECONOBURN™ Wood-Fired Boiler, check it carefully to ensure that all components are present and in good condition. If there has been any damage or loss in trans- portation, please notify the carrier at once. Remove the following from the boiler chambers: (2) handles, aquastat, silicone, manual, boiler seal, (conditioning agent), pressure relief valve, and circulator. -

Page 8: Combustion Air Supply

Note: If the ECONOBURN™ boiler is installed above the radiation level, a low water cut off is re- quired. It should be installed on pipe tees positioned at the supply and return points of the boiler. - Page 9 OUTSIDE COMBUSTION AIR MAY BE NECESSARY IF: 1. Fans that are installed in the fuel storage area create negative pressures in the room where the solid fuel-burning appliance is located. 2. The solid-fuel-fired appliance does not draw steadily, smell, experiences smoke roll-out, burns poorly, or back-drafts whether or not there is combustion present.

-

Page 10: Connecting Boiler To An Existing System

BOILERS CONNECTED TO AN EXISTING SYSTEM Shall be installed without interfering with the normal delivery of heated water from the original boiler. ii. Shall be installed without affecting the operation of the electrical and mechanical safety controls of the original boiler. iii. - Page 11 OPERATE THE (GAS, OIL, ELECTRIC) BOILER PERIODICALLY TO EN- SURE THAT IT WILL OPERATE SATISFACTORILY WHEN NEEDED. DO NOT RELOCATE OR BYPASS ANY OF THE SAFETY CONTROLS IN THE ORIGINAL (GAS, OIL, ELECTRIC) BOILER INSTALLATION. THE OPERATION OF THE GAS BOILER MUST BE VERIFIED FOR AC- CEPTABLE OPERATION BEFORE AND AFTER INSTALLATION OF THE ADD-ON APPLIANCE BY A GAS FITTER WHO IS RECOGNIZED BY THE REGULATORY AUTHORITY.

-

Page 12: Flue Pipe Installation

FLUE PIPE AND CHIMNEY The Boiler must be located as close as possible to the chimney. It should be ducted so that there is a minimum number of elbows used. The flue pipe must be installed with a gradual rise of 1/2” or more per foot from the Boiler to the flue. -

Page 13: Clearances

CLEARANCES The ECONOBURN™ Wood-Fired Boiler is to be installed in accordance with the National Building Code or local regulations. Allowances front and rear must be made for cleaning and servicing. Minimum safety clearances to combustibles are: Front: 48” Right Side: 18”... -

Page 14: Plumbing Connections Diagram

DURING A POWER FAILURE NEVER REFUEL THE BOILER. GRAVITY LOOP (NO POWER) A normally open powered zone valve must be installed to allow a free flow of water in a power off situation. The override loop for the safety shall have at least 30 ft. of radiation above the wood boiler for a gravity flow. -

Page 15: Freestanding Installation

FREE STANDING INSTALLATION In the freestanding, or stand-alone system, the ECONOBURN™ boiler is the sole source of cen- tral heating. In this system connect the piping as you would for any conventional hydronic heating system (using zone valves, circulator zoning, or single zone flow check system). -

Page 16: Wiring Diagrams

BOILER WIRING DIAGRAM FOR EWB-100 EWB-500 EWB-1000 Figure 3... - Page 17 BOILER WIRING DIAGRAM FOR EWB-150 EWB-200 EWB-300 Figure 4...

- Page 18 Figure 5...

- Page 19 Figure 6...

-

Page 20: Installers Final Checklist

INSTALLERS FINAL CHECKLIST PIPING INSPECTION 1. Boiler plumbed properly? 2. Is a new expansion tank or equivalent installed? 3. Normally closed by-pass zone valve installed? 4. Does the normally open zone valve by-pass to the main living area loop? 5. Is the normally open zone valve on the most direct piping loop (fewest elbows)? BOILER INSPECTION 1. -

Page 21: Section 2 - Operating Instructions

10 to 12 hours. WOOD-BURNING The ECONOBURN™ Wood-Fired Boiler will burn most solid wood fuels, however it is recom- mended that hardwoods be used for their superior energy content. Burning dry seasoned wood is alright, although unnecessary, as a residual moisture content of 20% is required for optimal gasifi- cation combustion. -

Page 22: Creosote And Cleaning

CREOSOTE AND CLEANING 1. Establish a routine for the storage of fuel, care of the appliance, and firing techniques. 2. Check daily for creosote build up until experience shows how often cleaning is necessary. 3. Be aware that the hotter the fire, the less creosote is deposited, and that weekly cleaning may be necessary in mild weather, even though monthly cleaning may be enough in the coldest months. -

Page 23: Flue Draft Control Operation

FLUE DRAFT CONTROL OPERATION The purpose of the Flue Draft Control (Fig. 6) is to prevent flames from coming out of the fire door to- ward the operator. The draft control lever is designed in such a way so that the upper door may not be opened without opening the rear damper and allowing the draft to go up the chimney. -

Page 24: Draft Fan Control Unit

DRAFT FAN CONTROL UNIT The Draft Fan Controller (Fig.10) is an Aquastat which is set at the temperature desired for the temperature of the water jacket of the boiler. A probe is clamped to the top of the boiler to monitor this temperature. -

Page 25: Electrical Power Failure

The Thermo Overload switch protects the Control Panel from any electrical shorts or power surges in excess of 5 amps with any external electrical devices wired through the rear of the boiler. This could include the main or circulating pump, or an overheat valve if installed, and connected to the electrical box at the rear of the boiler. -

Page 26: Boiler Operating Checklist

BOILER OPERATING CHECKLIST a. Keep area around ECONOBURN™ boiler clean and clear of combustibles. b. Use only wood. DO NOT burn any other combustible material, or liquid. c. Remove ashes as directed. d. Watch for soot in flue pipe - clean regularly. -

Page 27: Section 3 - Maintenance And Cleaning

SECTION 3 - MAINTENANCE AND CLEANING The ECONOBURN™ Wood-Fired Boiler must be cleaned regularly to maintain top efficiency. A good practice is to establish a routine for the storage of fuel, care of the appliance, and firing tech- niques. BOILER MAINTENANCE TURBULATOR ARMS AND SHAFT SHOULD BE CLEANED EVERY 3 DAYS OF BOILER USAGE WHEN THE UNIT IS HOT. -

Page 28: Ash Disposal

ASH DISPOSAL Before removing ashes, cease refueling and allow the fire to die down. Before opening the Ash Pit door, ensure the fire in the boiler is completely extinguished. Ashes should be placed in a metal container with a tight fitting lid. The closed container of ashes should be placed on a non-combustible floor or on the ground, well away from all combustible materials, pending final disposal. -

Page 29: Chimney Maintenance

CHIMNEY MAINTENANCE Inspect monthly during heating season. For extra safety, have your chimney inspected by an ac- credited professional yearly, prior to the heating season. TROUBLESHOOTING GUIDE PROBLEM CAUSE SUGGESTED REMEDY Wood too moist. Use properly seasoned wood. Nozzle plugged. Clean firebox. -

Page 30: Section 4 - Econoburn™ Boiler Warranty

3. This warranty shall not apply to any ECONOBURN™ boilers, or any parts of them, which have been repaired or altered, without company’s written consent, outside company’s factory or altered...

Need help?

Do you have a question about the EBW-100 and is the answer not in the manual?

Questions and answers

Can am ebw-100 also burn coal.

No, the Econoburn EBW-100 is designed for wood-fired operation only. It is not intended to burn coal.

This answer is automatically generated