Table of Contents

Advertisement

Quick Links

B A R K O

B A R K O

B A R K O

B A R K O

B A R K O

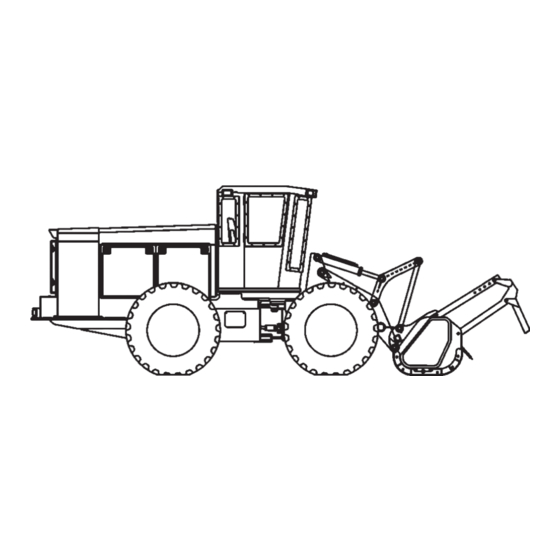

9 3 0 - 9 3 7

9 3 0 - 9 3 7

9 3 0 - 9 3 7

9 3 0 - 9 3 7

9 3 0 - 9 3 7

M U L C H E R

M U L C H E R

M U L C H E R

M U L C H E R

M U L C H E R

NOTE: The operating and safety instructions for a Attachment are not included in this manual.

See separate Attachment manual.

OPERATORS: 800-00256

OPERATORS: 800-00256

OPERATORS: 800-00256

OPERATORS: 800-00256

OPERATORS: 800-00256

060611

SERVICE MANUAL

SERVICE MANUAL

SERVICE MANUAL

SERVICE MANUAL

SERVICE MANUAL

930-937 Mulcher

930-937 Mulcher

930-937 Mulcher

930-937 Mulcher

930-937 Mulcher

Machine

Serial Number

The information and illustrations in this manual have

been approved as accurate at the time of printing.

However, the manual may contain information on

options not present on your loader. The right is reserved

by Barko Hydraulics,LLC to make changes and

improvements in its product at any time without notice

or obligation.

B A R K O

B A R K O

B A R K O

B A R K O

B A R K O

H Y D R A U L I C S ,

H Y D R A U L I C S ,

H Y D R A U L I C S ,

H Y D R A U L I C S ,

H Y D R A U L I C S ,

1 BANKS AVENUE, SUPERIOR, WI

1 BANKS AVENUE, SUPERIOR, WI

1 BANKS AVENUE, SUPERIOR, WI

1 BANKS AVENUE, SUPERIOR, WI

1 BANKS AVENUE, SUPERIOR, WI

phone: 715-392-5641 fax: 715-392-3931

website: www.barko.com email: barkohydraulics@barko.com

PARTS: 800-00257

PARTS: 800-00257

PARTS: 800-00257

PARTS: 800-00257

PARTS: 800-00257

L L C

L L C

L L C

L L C

L L C

54880

54880

54880

54880

54880

SERVICE: 800-00258

SERVICE: 800-00258

SERVICE: 800-00258

SERVICE: 800-00258

SERVICE: 800-00258

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Barko Hydraulics 930

- Page 1 However, the manual may contain information on options not present on your loader. The right is reserved by Barko Hydraulics,LLC to make changes and improvements in its product at any time without notice or obligation.

-

Page 2: Table Of Contents

..930 (NO FLOAT) 930 (NO FLOAT) ....................930 (NO FLOAT) 930 (NO FLOAT) 930 (NO FLOAT) ..............................31 Hydraulic Schematic .......... 31 Engine Maintenance ..........82 Hydraulic Assembly .......... 32 Pump Drive Maintenance ........83 Rear Frame ............ 32 A. - Page 3 3 page 3 page 3 page 3 page 3 930-937 Mulcher (S) 800-00258...

-

Page 4: Introduction

NOTE: NOTE: NOTE: NOTE: Information in this manual is current at the time of printing. Barko Hydraulics reserves the right to make changes and improvements to it's products and manuals at any time without notice or obligation. page 4 page 4... -

Page 5: Abbreviations And Symbols

Power Off Engine RPM Engine RPM Engine RPM Engine RPM Engine RPM Power On Power On Power On Power On Power On Faster Faster Faster Faster Faster page 5 page 5 page 5 930-937 Mulcher (S) page 5 page 5 800-00258... - Page 6 Barko warranties null and void and constitute an obvious misuse and abuse of our product. BARKO HYDRAULICS, LLC BARKO HYDRAULICS, LLC BARKO HYDRAULICS, LLC BARKO HYDRAULICS, LLC BARKO HYDRAULICS, LLC page 6 page 6 page 6 930-937 Mulcher (S) page 6 page 6 800-00258...

-

Page 7: Warranty

BARKO HYDRAULICS, L.L.C. ("Barko") warrants to the Distributor and/or original Buyer each new knuckle boom loader, feller buncher, Mulcher or other product in BARKO HYDRAULICS Equipment Group including attachments and accessories thereto, ("Product") sold by BARKO to be free from defects in material and workmanship under normal use, maintenance and service. -

Page 8: Know Your Machine

Don't stop here - read on. Don't stop here - read on. Don't stop here - read on. Don't stop here - read on. Don't stop here - read on. page 8 page 8 page 8 930-937 Mulcher (S) page 8 page 8 800-00258... -

Page 9: Safety Summary

9 page 9 page 9 930-937 Mulcher (S) page 9 page 9 800-00258... - Page 10 -Secure machine to trailer bed. -Secure machine to trailer bed. -Secure machine to trailer bed. -Secure machine to trailer bed. -Secure machine to trailer bed. page 10 page 10 page 10 930-937 Mulcher (S) page 10 page 10 800-00258...

- Page 11 Grease all pivot and cylinder points daily. Grease all pivot and cylinder points daily. Grease all pivot and cylinder points daily. Grease all pivot and cylinder points daily. page 11 page 11 page 11 930-937 Mulcher (S) page 11 page 11 800-00258...

- Page 12 Other fluids will cause machine damage. Other fluids will cause machine damage. Other fluids will cause machine damage. Other fluids will cause machine damage. Other fluids will cause machine damage. page 12 page 12 page 12 930-937 Mulcher (S) page 12 page 12 800-00258...

- Page 13 State of California to cause cancer, birth defects, and other reproductive harm. other reproductive harm. other reproductive harm. other reproductive harm. other reproductive harm. page 13 page 13 page 13 930-937 Mulcher (S) page 13 page 13 800-00258...

-

Page 14: Fire Prevention

Barko Hydraulics. authorized by Barko Hydraulics. authorized by Barko Hydraulics. authorized by Barko Hydraulics. authorized by Barko Hydraulics. Inspect cab, engine... -

Page 15: Model Description

Access Door to Transmission is under Transmission is under Transmission is under Transmission is under Transmission is under Axles Axles Axles Axles Axles machine. machine. machine. machine. machine. page 15 page 15 page 15 page 15 page 15 930-937 Mulcher (S) 800-00258... -

Page 16: Preventive Maintenance

A. PREVENTIVE MAINTENANCE A. PREVENTIVE MAINTENANCE A. PREVENTIVE MAINTENANCE A. PREVENTIVE MAINTENANCE A. PREVENTIVE MAINTENANCE page 16 page 16 page 16 page 16 page 16 930-937 Mulcher (S) 800-00258... -

Page 17: Safety While Servicing

Do not weld on any structural member unless CAUTION CAUTION CAUTION CAUTION CAUTION specifically authorized by Barko Hydraulics. specifically authorized by Barko Hydraulics. specifically authorized by Barko Hydraulics. specifically authorized by Barko Hydraulics. specifically authorized by Barko Hydraulics. Any unauthorized welding or welding procedures... -

Page 18: Preventive Maintenance

3. Change all filter elements. 4. Change hydraulic oil in hydraulic oil reservoir. Resume the normal maintenance intervals after this. See the Service Schedule for more information. page 18 page 18 page 18 930-937 Mulcher (S) page 18 page 18 800-00258... -

Page 19: Service Schedule

Hydraulic Oil Reservoir Hydraulic Oil Reservoir - On new machines the oil must be changed after the first 50 hours, and then every 1000 hours after that. page 19 page 19 page 19 930-937 Mulcher (S) page 19 page 19 800-00258... - Page 20 Barko also recommends that you consult your Operators manual provided by the engine manufacturer to ensure that filter elements other than the ones provided by the engine manufacturer have been tested and meet there qualifications. page 20 page 20 page 20 930-937 Mulcher (S) page 20 page 20 800-00258...

- Page 21 NOTE : Use the intervals on Service Schedule when operating in normal conditions. Service the machine at shorter NOTE : NOTE : intervals when operating in very hot, cold, dusty, or humid conditions. page 21 page 21 page 21 930-937 Mulcher (S) page 21 page 21 800-00258...

-

Page 22: Tires

TIRE INFLATION PRESSURE TIRE INFLATION PRESSURE TIRE INFLATION PRESSURE TIRE INFLATION PRESSURE TIRE INFLATION PRESSURE Tire pressure may vary slightly depending upon the tires: 28L-26 Tires 30 PSI page 22 page 22 page 22 930-937 Mulcher (S) page 22 page 22 800-00258... -

Page 23: Lubrication Points

23 page 23 page 23 930-937 Mulcher (S) page 23 page 23 800-00258... - Page 24 See detail at right. Detail of Centralized Lube System Detail of Centralized Lube System Detail of Centralized Lube System Detail of Centralized Lube System Detail of Centralized Lube System page 24 page 24 page 24 930-937 Mulcher (S) page 24 page 24 800-00258...

-

Page 25: Fluid Specifications

In cold weather operation, the cloud point should be 10 degrees F. below lowest normal air temperatures. page 25 page 25 page 25 930-937 Mulcher (S) page 25 page 25 800-00258... - Page 26 26 page 26 page 26 930-937 Mulcher (S) page 26 page 26 800-00258...

-

Page 27: Special Torque Specifications

K170 valves ....... 43 Ft. Lbs. (60 Nm) K220 valves ....... 59 Ft. Lbs. (80 Nm) L90 valves ......... 33 Ft. Lbs. (45 Nm) page 27 page 27 page 27 930-937 Mulcher (S) page 27 page 27 800-00258... -

Page 28: General Torque Specifications

P O U N D S P O U N D S P O U N D S P O U N D S P O U N D S page 28 page 28 page 28 930-937 Mulcher (S) page 28 page 28 800-00258... -

Page 29: Hydraulic System

B. HYDRAULIC SYSTEM B. HYDRAULIC SYSTEM B. HYDRAULIC SYSTEM B. HYDRAULIC SYSTEM B. HYDRAULIC SYSTEM page 29 page 29 page 29 page 29 page 29 930-937 Mulcher (S) 800-00258... -

Page 30: Hydraulic Hose Hookup

Lift arms, lift cylinders and lift hoses are not shown. Lift hoses run from end of lift cylinders through cutouts in each side of front frame plate to valve bank. page 30 page 30 page 30 930-937 Mulcher (S) page 30 page 30 800-00258... -

Page 31: No Float) 930 (No Float)

930 (NO FLOAT) 930 (NO FLOAT) 930 (NO FLOAT) 930 (NO FLOAT) 930 (NO FLOAT) HYDRAULIC SCHEMATIC HYDRAULIC SCHEMATIC HYDRAULIC SCHEMATIC HYDRAULIC SCHEMATIC HYDRAULIC SCHEMATIC 607-00145 607-00145 607-00145 607-00145 607-00145 page 31 page 31 page 31 930-937 Mulcher (S) page 31... -

Page 32: Hydraulic Assembly

HYDRAULIC ASSEMBLY HYDRAULIC ASSEMBLY HYDRAULIC ASSEMBLY 765-40035 765-40035 765-40035 HYDRAULIC ASSEMBLY HYDRAULIC ASSEMBLY 765-40035 765-40035 REAR FRAME REAR FRAME REAR FRAME REAR FRAME REAR FRAME page 32 page 32 page 32 930-937 Mulcher (S) page 32 page 32 800-00258... -

Page 33: Front Frame

HYDRAULIC ASSEMBLY HYDRAULIC ASSEMBLY HYDRAULIC ASSEMBLY 765-40035 765-40035 765-40035 HYDRAULIC ASSEMBLY HYDRAULIC ASSEMBLY 765-40035 765-40035 FRONT FRAME FRONT FRAME FRONT FRAME FRONT FRAME FRONT FRAME page 33 page 33 page 33 930-937 Mulcher (S) page 33 page 33 800-00258... -

Page 34: No Float) 937 (No Float)

937 (NO FLOAT) 937 (NO FLOAT) 937 (NO FLOAT) 937 (NO FLOAT) HYDRAULIC SCHEMATIC HYDRAULIC SCHEMATIC HYDRAULIC SCHEMATIC 607-00149 607-00149 607-00149 HYDRAULIC SCHEMATIC HYDRAULIC SCHEMATIC 607-00149 607-00149 page 34 page 34 page 34 930-937 Mulcher (S) page 34 page 34 800-00258... -

Page 35: Hydraulic Assembly

HYDRAULIC ASSEMBLY HYDRAULIC ASSEMBLY HYDRAULIC ASSEMBLY 765-40040 765-40040 765-40040 HYDRAULIC ASSEMBLY HYDRAULIC ASSEMBLY 765-40040 765-40040 REAR FRAME REAR FRAME REAR FRAME REAR FRAME REAR FRAME page 35 page 35 page 35 930-937 Mulcher (S) page 35 page 35 800-00258... -

Page 36: Front Frame

HYDRAULIC ASSEMBLY HYDRAULIC ASSEMBLY HYDRAULIC ASSEMBLY 765-40040 765-40040 765-40040 HYDRAULIC ASSEMBLY HYDRAULIC ASSEMBLY 765-40040 765-40040 FRONT FRAME FRONT FRAME FRONT FRAME FRONT FRAME FRONT FRAME page 36 page 36 page 36 930-937 Mulcher (S) page 36 page 36 800-00258... -

Page 37: Pressure Settings (Mulcher Machines)

Figure 1 - Top View of Mulcher Valve Bank Figure 1 - Top View of Mulcher Valve Bank Figure 1 - Top View of Mulcher Valve Bank page 37 page 37 page 37 930-937 Mulcher (S) page 37 page 37 800-00258... -

Page 38: Pump Layout

Pressure P u m p P u m p P u m p P u m p P u m p Pressure Pressure Pressure Pressure Pressure page 38 page 38 page 38 930-937 Mulcher (S) page 38 page 38 800-00258... -

Page 39: Rexroth Accessory Pump

S e a l S e a l Jamb Nut Jamb Nut Jamb Nut Jamb Nut Jamb Nut Set Screw Set Screw Set Screw Set Screw Set Screw page 39 page 39 page 39 page 39 page 39 930-937 Mulcher (S) 800-00258... -

Page 40: Differential Lock/Servo Valve

NOTE: With the differential lock switch in the cab disengaged, NOTE: NOTE: pressure will read 450 - 500 PSI (this is standby pressure for the Accessory Pump). page 40 page 40 page 40 930-937 Mulcher (S) page 40 page 40 800-00258... -

Page 41: Mulcher Pump

Single Pressure Transducer Assembly Single Pressure Transducer Assembly Single Pressure Transducer Assembly Charge Pressure Adjustments Charge Pressure Adjustments Charge Pressure Adjustments Charge Pressure Adjustments Charge Pressure Adjustments page 41 page 41 page 41 930-937 Mulcher (S) page 41 page 41 800-00258... - Page 42 17. Turn mulcher switch to off position. 18. Shut down engine. 19. Return electric wire back to original position. 20. Reconnect mulcher hoses or free mulcher drum. 21. Remove pressure gauge. page 42 page 42 page 42 930-937 Mulcher (S) page 42 page 42 800-00258...

-

Page 43: Rexroth Drive Pump

12. Tighten jamb nut. 13. Shut down engine. 14. Replace travel pump centering hose. NOTE: NOTE: NOTE: NOTE: NOTE: P.O.R. controls maximum system pressure in both directions. page 43 page 43 page 43 930-937 Mulcher (S) page 43 page 43 800-00258... -

Page 44: Sauer Drive Pump

12. Repeat steps for Reverse Pressure Adjustment. 13. Remove pressure gauge. Reverse Pressure Adjustment Reverse Pressure Adjustment Reverse Pressure Adjustment Reverse Pressure Adjustment Reverse Pressure Adjustment 14. Connect spool centering hose. page 44 page 44 page 44 930-937 Mulcher (S) page 44 page 44 800-00258... -

Page 45: Rexroth Drive Motor

Ports may contain trapped pressure. Use care when removing gauges and installing plugs. Use care when removing gauges and installing plugs. Use care when removing gauges and installing plugs. page 45 page 45 page 45 930-937 Mulcher (S) page 45 page 45 800-00258... -

Page 46: Sauer Drive Motor

Ports may contain trapped pressure. Ports may contain trapped pressure. Use care when removing gauges and installing plugs. Use care when removing gauges and installing plugs. page 46 page 46 page 46 930-937 Mulcher (S) page 46 page 46 800-00258... -

Page 47: Hydraulic Hose Hookup (Mulcher)

Lift arms, lift cylinders and lift hoses are not shown. Lift hoses run from end of lift cylinders through cutouts in each side of front frame plate to valve bank. page 47 page 47 page 47 930-937 Mulcher (S) page 47 page 47 800-00258... -

Page 48: Hydraulic Reservoir Maintenance

Check oil level in reservoir before each period of operation, or daily. If, at any time, you find the level is low, check the machine for leaks around tubes, hoses, fittings, and couplings. page 48 page 48 page 48 930-937 Mulcher (S) page 48 page 48 800-00258... - Page 49 5. Check hydraulic oil level again after machine has been operating for an hour or two. page 49 page 49 page 49 930-937 Mulcher (S) page 49 page 49 800-00258...

-

Page 50: Hydraulic Oil Filter Maintenance

Remove diverter/bypass valve assembly. Remove element from diverter/bypass valve assembly. A. Disposable Type: Replace element if a disposable paper or synthetic media is used. See next page. page 50 page 50 page 50 930-937 Mulcher (S) page 50 page 50 800-00258... - Page 51 FILTER ELEMENT REPLACEMENT INTERVALS On new machine filter elements should be replaced after 50 hours of operation and then every 400 hours of operation after that. page 51 page 51 page 51 930-937 Mulcher (S) page 51 page 51 800-00258...

-

Page 52: Eliminating Air From The Sytem

The pump intake line should always be below the fluid surface for the same reason. Improved service life depends on maintaining proper conditions within the system. page 52 page 52 page 52 930-937 Mulcher (S) page 52 page 52 800-00258... -

Page 53: Hydraulic Fittings, Hoses And Tubing

Barko recommends the use of pipe thread sealer on all exterior pipe plug threads and pipe fittings. page 53 page 53 page 53 930-937 Mulcher (S) page 53 page 53 800-00258... -

Page 54: Hydraulic Cylinder Maintenance

14. Reinstall on machine and reattach hydraulics lines. NOTE: The more common cylinders use the following tool sizes: Hex head cap screws require 15/16" wrench. Nut requires 3-1/8" wrench. page 54 page 54 page 54 930-937 Mulcher (S) page 54 page 54 800-00258... - Page 55 MODULAR BACKUP RING MODULAR BACKUP RING MODULAR BACKUP RING MODULAR BACKUP RING 1 1 1 1 1 O-RING O-RING 1 1 1 1 1 O-RING O-RING O-RING page 55 page 55 page 55 930-937 Mulcher (S) page 55 page 55 800-00258...

-

Page 56: Axle Maintenance (John Deere)

Confirm the oil level after allowing time for oil to flow into all compartments. 3. Check differential oil level: Remove the differential oil check plugs. The oil level should be slightly above the check hole. page 56 page 56 page 56 930-937 Mulcher (S) page 56 page 56 800-00258... - Page 57 Seals used at each brake piston use rubber compounds which are incompatible with this fluid and rapid deterioration of these packings is very likely to occur if such fluid is used. page 57 page 57 page 57 930-937 Mulcher (S) page 57 page 57 800-00258...

-

Page 58: Electrical System

C. ELECTRICAL SYSTEM C. ELECTRICAL SYSTEM C. ELECTRICAL SYSTEM C. ELECTRICAL SYSTEM C. ELECTRICAL SYSTEM page 58 page 58 page 58 page 58 page 58 930-937 Mulcher (S) 800-00258... -

Page 59: Electrical Schematic (Cummins)

ELECTRICAL SCHEMATIC ELECTRICAL SCHEMATIC ELECTRICAL SCHEMATIC 903-00122 903-00122 903-00122 903-00122 903-00122 (CUMMINS ENGINE) (CUMMINS ENGINE) (CUMMINS ENGINE) (CUMMINS ENGINE) (CUMMINS ENGINE) 903-00122 Replaced by 903-00140 Starting 8/20/07 page 59 page 59 page 59 930-937 Mulcher (S) page 59 page 59 800-00258... - Page 60 ELECTRICAL SCHEMATIC ELECTRICAL SCHEMATIC ELECTRICAL SCHEMATIC 903-00140 903-00140 903-00140 903-00140 903-00140 (CUMMINS ENGINE) (CUMMINS ENGINE) (CUMMINS ENGINE) (CUMMINS ENGINE) (CUMMINS ENGINE) 903-00122 Replaced by 903-00140 Starting 8/20/07 page 60 page 60 page 60 930-937 Mulcher (S) page 60 page 60 800-00258...

-

Page 61: Electrical Schematic (Johndeere)

903-00120 903-00120 903-00120 903-00120 903-00120 (JOHN DEERE ENGINE) (JOHN DEERE ENGINE) (JOHN DEERE ENGINE) (JOHN DEERE ENGINE) (JOHN DEERE ENGINE) 903-00120 Replaced by 903-00141 Starting 8/20/07 page 61 page 61 page 61 930-937 Mulcher (S) page 61 page 61 800-00258... - Page 62 903-00141 903-00141 903-00141 903-00141 903-00141 (JOHN DEERE ENGINE) (JOHN DEERE ENGINE) (JOHN DEERE ENGINE) (JOHN DEERE ENGINE) (JOHN DEERE ENGINE) 903-00120 Replaced by 903-00141 Starting 8/20/07 page 62 page 62 page 62 930-937 Mulcher (S) page 62 page 62 800-00258...

-

Page 63: Heater-Air Conditioner Electrical Schematic

HEATER-AIR CONDITIONER ELECTRICAL SCHEMATIC HEATER-AIR CONDITIONER ELECTRICAL SCHEMATIC HEATER-AIR CONDITIONER ELECTRICAL SCHEMATIC HEATER-AIR CONDITIONER ELECTRICAL SCHEMATIC HEATER-AIR CONDITIONER ELECTRICAL SCHEMATIC page 63 page 63 page 63 930-937 Mulcher (S) page 63 page 63 800-00258... - Page 64 HEATER-AIR CONDITIONER ELECTRICAL SCHEMATIC HEATER-AIR CONDITIONER ELECTRICAL SCHEMATIC HEATER-AIR CONDITIONER ELECTRICAL SCHEMATIC HEATER-AIR CONDITIONER ELECTRICAL SCHEMATIC HEATER-AIR CONDITIONER ELECTRICAL SCHEMATIC page 64 page 64 page 64 930-937 Mulcher (S) page 64 page 64 800-00258...

-

Page 65: Electrical System Maintenance

"jump" start an engine, make connections in order given in this manual. order given in this manual. order given in this manual. order given in this manual. order given in this manual. page 65 page 65 page 65 930-937 Mulcher (S) page 65 page 65 800-00258... -

Page 66: Installing A New Battery

3. Clean terminal posts of new battery and cable connections with wire brush. 4. Install new battery in compartment. Install hold-down bar. 5. Install and tighten battery cables. Connect negative cable last to prevent sparks. page 66 page 66 page 66 930-937 Mulcher (S) page 66 page 66 800-00258... -

Page 67: Alternator Drive Belt Adjustment

No. 2 terminal No. 2 terminal "BAT" terminal "BAT" terminal "BAT" terminal "BAT" terminal "BAT" terminal Figure 2 Figure 2 Figure 2 Figure 2 Figure 2 page 67 page 67 page 67 930-937 Mulcher (S) page 67 page 67 800-00258... - Page 68 (Remove both cables from the battery.) extra battery cables (booster cables) are connected wrong. page 68 page 68 page 68 930-937 Mulcher (S) page 68 page 68 800-00258...

-

Page 69: Electrical System Trouble Shooting

4. The ground connection is not making a good contact. 5. The alternator is damaged. 6. The engine is locked. 7. The starter has damage. 8. The wiring or the solenoid is damaged. page 69 page 69 page 69 930-937 Mulcher (S) page 69 page 69 800-00258... -

Page 70: Air Conditioner Maintenance

CAUTION CAUTION CAUTION CAUTION Charge the 930-937 Mulcher Air Conditioner system with Charge the 930-937 Mulcher Air Conditioner system with Charge the 930-937 Mulcher Air Conditioner system with Charge the 930-937 Mulcher Air Conditioner system with Charge the 930-937 Mulcher Air Conditioner system with R134a refrigerant. -

Page 71: Refrigerant

AIR CONDITIONER MAINTENANCE (930-937 MULCHER) CONTINUED... Hot High Pressure Gas Hot High Pressure Gas Hot High Pressure Gas Hot High Pressure Gas Hot High Pressure Gas Low Pressure Gas Low Pressure Gas Low Pressure Gas Low Pressure Gas Low Pressure Gas... -

Page 72: Checking/Adding Refrigerant

CHECKING/ADDING REFRIGERANT CHECKING/ADDING REFRIGERANT CHECKING/ADDING REFRIGERANT CHECKING/ADDING REFRIGERANT Allow only certified personnel to service the heater/air conditioner system. For Barko 930-937 Mulcher, 1 lb.-14 oz. of refrigerant is required for the system to operate properly. CAUTION CAUTION CAUTION CAUTION CAUTION Charge the 930 Mulcher Air Conditioner system with 1 lb - 14 oz. -

Page 73: Air Conditioner Trouble Shooting

AIR CONDITIONER MAINTENANCE (930-937 MULCHER) CONTINUED... AIR CONDITIONER TROUBLE SHOOTING AIR CONDITIONER TROUBLE SHOOTING AIR CONDITIONER TROUBLE SHOOTING AIR CONDITIONER TROUBLE SHOOTING AIR CONDITIONER TROUBLE SHOOTING To display diagnostics depress the ON key three times. The digital display will then display any active fault codes. - Page 74 AIR CONDITIONER TROUBLE SHOOTING (930-937 MULCHER) CONTINUED... Problem: Evaporator Core Icing Up (Freezing Up) Evaporator Probe (2-pin black connector) 1. Set the control temperature to a low value. Verify that the compressor is on. Pull the probe and place is in a bath of ice water.

- Page 75 AIR CONDITIONER TROUBLE SHOOTING (930-937 MULCHER) CONTINUED... ATC CONTROLLER ATC CONTROLLER ATC CONTROLLER ATC CONTROLLER ATC CONTROLLER RFI INTERFERENCE RFI INTERFERENCE RFI INTERFERENCE RFI INTERFERENCE RFI INTERFERENCE It has been discovered that the Programmable Control Panel may have some RFI interference that causes the panel to change programs.

- Page 76 AIR CONDITIONER TROUBLE SHOOTING (930-937 MULCHER) CONTINUED... INSTRUCTIONS FOR ADVANCED DIAGNOSTICS ATC SYSTEM AND PROGRAMMING INSTRUCTIONS FOR ADVANCED DIAGNOSTICS ATC SYSTEM AND PROGRAMMING INSTRUCTIONS FOR ADVANCED DIAGNOSTICS ATC SYSTEM AND PROGRAMMING INSTRUCTIONS FOR ADVANCED DIAGNOSTICS ATC SYSTEM AND PROGRAMMING INSTRUCTIONS FOR ADVANCED DIAGNOSTICS ATC SYSTEM AND PROGRAMMING (Programming and Advanced Diagnostics Only on New StyleDiagnostics Only on Old Style) Error code display is accessed by pressing the “ON”...

- Page 77 AIR CONDITIONER TROUBLE SHOOTING (930-937 MULCHER) CONTINUED... A9: No Connection A10: No Connection A11: No Connection A12: No Connection B1: Cab Temperature Signal for 30K Thermistor B2: Cab Temperature Ground B3: Ambient Temperature Signal B4: Water Valve Feedback Signal B5: No Connection...

- Page 78 AIR CONDITIONER TROUBLE SHOOTING (930-937 MULCHER) CONTINUED... Programming 1) Turn on. 2) Error code display mode is accessed by pressing the “ON” key three times quickly. 3) The advanced diagnostics display mode is activated by pressing and holding the “ON”...

- Page 79 AIR CONDITIONER TROUBLE SHOOTING (930-937 MULCHER) CONTINUED... Press the “FAN UP”/”FAN DOWN” keys to select a config setting. Press the “TEMP UP”/”TEMP DOWN” keys to change the selected setting. Barko Programming Barko Programming Barko Programming Barko Programming Barko Programming P0 – 1 P1 –...

- Page 80 AIR CONDITIONER TROUBLE SHOOTING (930-937 MULCHER) CONTINUED... 5) Turn off when done programming. 6) Check error code display by pressing the "on" key three times quickly Should read "EQ" page 80 page 80 page 80 930-937 Mulcher (S) page 80...

-

Page 81: Power Unit Maintenance

D. POWER UNIT MAINTENANCE D. POWER UNIT MAINTENANCE D. POWER UNIT MAINTENANCE D. POWER UNIT MAINTENANCE D. POWER UNIT MAINTENANCE page 81 page 81 page 81 page 81 page 81 930-937 Mulcher (S) 800-00258... -

Page 82: Engine Maintenance

Either of these manuals may also include information on other, similar, engines. Be sure to use only the information which applies to the engine used on your machine. page 82 page 82 page 82 930-937 Mulcher (S) page 82 page 82 800-00258... -

Page 83: Pump Drive Maintenance

4. Change the fluid after every 400 hours of operation. Also, the fluid in the unit should be changed whenever the fluid level shows traces of dirt or effects of high temperature, evidenced by discoloration or strong odor. page 83 page 83 page 83 930-937 Mulcher (S) page 83 page 83 800-00258... - Page 84 Bearings are press fitted to gear hubs. It may be necessary to tip gear slightly to clear pinion gear bearing pocket. page 84 page 84 page 84 930-937 Mulcher (S) page 84 page 84 800-00258...

- Page 85 The hub should slide into the pilot bearing bore of the flywheel to ensure proper alignment of the drive hub and drive shaft. page 85 page 85 page 85 930-937 Mulcher (S) page 85 page 85 NOTE: NOTE: NOTE: NOTE: NOTE: Arrow indicates engine side.

-

Page 86: Single Pad Pump Drives

Figure 5 Figure 5 Figure 5 Figure 5 Figure 5 For cold weather start-up using Disconnect Clutch, see Start-up instructions in Operator's Manual. page 86 page 86 page 86 930-937 Mulcher (S) page 86 page 86 800-00258... -

Page 87: Air Cleaner Maintenance

WING NUT WING NUT WING NUT CUMMINS ONLY CUMMINS ONLY CUMMINS ONLY CUMMINS ONLY CUMMINS ONLY Figure 2 Figure 2 Figure 2 Figure 2 Figure 2 page 87 page 87 page 87 930-937 Mulcher (S) page 87 page 87 800-00258... - Page 88 The safety element is not intended to be cleaned. For maximum engine protection and air cleaner service life, replace the safety element with a new safety element every third primary element change. page 88 page 88 page 88 930-937 Mulcher (S) page 88 page 88 800-00258...

- Page 89 Make certain the cause of that leak is identified and rectified before replacing the element. page 89 page 89 page 89 930-937 Mulcher (S) page 89 page 89 800-00258...

- Page 90 The only dirty element until you can get the correct model. way to be sure nothing got in is to be sure nothing gets in. page 90 page 90 page 90 930-937 Mulcher (S) page 90 page 90 800-00258...

-

Page 91: Machine Photos

91 page 91 page 91 page 91 page 91 930-937 Mulcher (S) 800-00258... -

Page 92: Decals Decals

N O T E N O T E N O T E N O T E This section of the manual is used for the decal kits appropriate for the 930/937 Mulcher. Those kits are: 930 Base Kit (539-01064) 930 Cab Kit (539-01051)

Need help?

Do you have a question about the 930 and is the answer not in the manual?

Questions and answers