Table of Contents

Advertisement

B A R K O

B A R K O

B A R K O

B A R K O

B A R K O

MULCHERS

MULCHERS

MULCHERS

MULCHERS

MULCHERS

Power View operating instructions attached

Power View operating instructions attached

Power View operating instructions attached

Power View operating instructions attached

Power View operating instructions attached

NOTE: The operating and safety instructions for a Mulching Attachment

are not included in this manual. See separate Mulching Attachment manual.

OPERATORS: 800-00256

OPERATORS: 800-00256

OPERATORS: 800-00256

OPERATORS: 800-00256

OPERATORS: 800-00256

111014

OPERATOR'S MANUAL

OPERATOR'S MANUAL

OPERATOR'S MANUAL

OPERATOR'S MANUAL

OPERATOR'S MANUAL

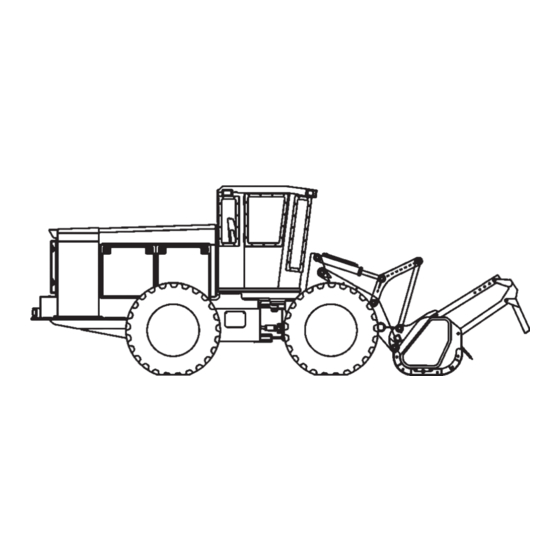

930/937 Mulcher

930/937 Mulcher

930/937 Mulcher

930/937 Mulcher

930/937 Mulcher

Machine

Serial Number

The information and illustrations in this manual have

been approved as accurate at the time of printing.

However, the manual may contain information on

options not present on your loader. The right is reserved

by Barko Hydraulics,LLC to make changes and

improvements in it's product at anytime without notice or

obligation.

B A R K O

B A R K O

B A R K O

B A R K O

B A R K O

H Y D R A U L I C S ,

H Y D R A U L I C S ,

H Y D R A U L I C S ,

H Y D R A U L I C S ,

H Y D R A U L I C S ,

1 Banks Avenue, Superior, WI 54880

phone: 715-395-6700 fax: 715-392-3931

website: www.barko.com email: barko@barko.com

PARTS: 800-00257

PARTS: 800-00257

PARTS: 800-00257

PARTS: 800-00257

PARTS: 800-00257

L L C

L L C

L L C

L L C

L L C

SERVICE: 800-00258

SERVICE: 800-00258

SERVICE: 800-00258

SERVICE: 800-00258

SERVICE: 800-00258

Advertisement

Table of Contents

Summary of Contents for Barko Hydraulics 930

- Page 1 However, the manual may contain information on options not present on your loader. The right is reserved by Barko Hydraulics,LLC to make changes and improvements in it's product at anytime without notice or obligation.

-

Page 2: Table Of Contents

TABLE OF CONTENTS TABLE OF CONTENTS TABLE OF CONTENTS TABLE OF CONTENTS TABLE OF CONTENTS Introduction Introduction .................................. 4 4 4 4 4 Introduction Introduction ............Introduction ............Introduction ................ 5 Abbreviations and Symbols ..........6 Hydraulic Pressure Warning Sheet ........7 Warranty ................ - Page 3 Special Torque Specifications ........69 General Torque Specifications ........70 Trouble Shooting ............71 Decals Decals Decals Decals Decals ..................................................7 5 ............. page 3 page 3 page 3 page 3 page 3 930/937 Mulcher (O) 800-00256...

- Page 4 4 page 4 page 4 page 4 page 4 930/937 Mulcher (O) 800-00256...

-

Page 5: Introduction

NOTE: NOTE: NOTE: NOTE: Information in this manual is current at the time of printing. Barko Hydraulics reserves the right to make changes and improvements to it's products and manuals at any time without notice or obligation. page 5 page 5... -

Page 6: Abbreviations And Symbols

R P M R P M R P M R P M Power On Power On Power On Power On Power On Faster Faster Faster Faster Faster page 6 page 6 page 6 page 6 page 6 930/937 Mulcher (O) 800-00256... -

Page 7: Hydraulic Pressure Warning Sheet

BARKO HYDRAULICS, LLC BARKO HYDRAULICS, LLC BARKO HYDRAULICS, LLC BARKO HYDRAULICS, LLC BARKO HYDRAULICS, LLC page 7 page 7 page 7 page 7 page 7 930/937 Mulcher (O) 800-00256... -

Page 8: Warranty

L L C L L C BARKO HYDRAULICS, L.L.C. ("Barko") warrants to the Distributor and/or original Buyer each new hydraulic knuckle boom loader, mulcher tractor or other product in BARKO's Equipment Group including attachments and accessories thereto, ("Product") sold by BARKO to be free from defects in material and workmanship under normal use, maintenance and service, as follows:... -

Page 9: Know Your Machine

Don't assume that because you know the control functions of other similar machinery, that you Don't assume that because you know the control functions of other similar machinery, that you can run the Barko 930/937 Mulcher. can run the Barko 930/937 Mulcher. -

Page 10: Safety Summary

10 page 10 page 10 page 10 page 10 930/937 Mulcher (O) 800-00256... - Page 11 -Secure machine to trailer bed. -Secure machine to trailer bed. repair. repair. repair. repair. repair. -Cover exhaust pipe. -Cover exhaust pipe. -Cover exhaust pipe. -Cover exhaust pipe. -Cover exhaust pipe. page 11 page 11 page 11 page 11 page 11 930/937 Mulcher (O) 800-00256...

- Page 12 Grease all pivot and cylinder points daily. Grease all pivot and cylinder points daily. Grease all pivot and cylinder points daily. Grease all pivot and cylinder points daily. page 12 page 12 page 12 page 12 page 12 930/937 Mulcher (O) 800-00256...

- Page 13 Other fluids will cause machine damage. Other fluids will cause machine damage. Other fluids will cause machine damage. Other fluids will cause machine damage. Other fluids will cause machine damage. page 13 page 13 page 13 page 13 page 13 930/937 Mulcher (O) 800-00256...

- Page 14 Gain experience and improve skills over time by gradually increasing the angle of slopes on which you are working. As operating conditions change make the appropriate decisions and adjustments to maintain safe machine operation. page 14 page 14 page 14 page 14 page 14 930/937 Mulcher (O) 800-00256...

-

Page 15: Fire Prevention

Any portable extinguisher or authorized by Barko Hydraulics. authorized by Barko Hydraulics. authorized by Barko Hydraulics. authorized by Barko Hydraulics. authorized by Barko Hydraulics. sparks, hot components or fumes. -

Page 16: Model Description

Access Door to Axles Axles Axles Axles Axles Transmission is Transmission is Transmission is Transmission is Transmission is under machine. under machine. under machine. under machine. under machine. page 16 page 16 page 16 page 16 page 16 930/937 Mulcher (O) 800-00256... - Page 17 17 page 17 page 17 page 17 page 17 930/937 Mulcher (O) 800-00256...

-

Page 18: Operator's Station

J o y s t i c k s J o y s t i c k s J o y s t i c k s page 18 page 18 page 18 page 18 page 18 930/937 Mulcher (O) 800-00256... -

Page 19: Joystick Control Functions - Mulcher

Damage to axles can Damage to axles can Damage to axles can Damage to axles can Damage to axles can result. result. result. result. result. page 19 page 19 page 19 page 19 page 19 930/937 Mulcher (O) 800-00256... -

Page 20: Throttle Knob

Low gear is used for mulching. High gear is used for moving machine when attachment is empty. Figure 3 Figure 3 Figure 3 Figure 3 Figure 3 page 20 page 20 page 20 page 20 page 20 930/937 Mulcher (O) 800-00256... -

Page 21: Travel Foot Pedals

Adjustment and Backward and Backward and Backward and Backward and Backward Weight Adjustment Weight Adjustment Weight Adjustment Weight Adjustment Weight Adjustment Adjustment Adjustment Adjustment Adjustment Adjustment page 21 page 21 page 21 page 21 page 21 930/937 Mulcher (O) 800-00256... -

Page 22: Emergency Door Lock

Control/Servo power is activated when pin is located in right hole. When pin is located in left hole, door is locked and control/servo power is deactivated Unlocked Locked Trun Style Door Lock Unlock emergency door to activate control/servo power. Rotate clockwise to unlock. Emergency Door Lock page 22 page 22 page 22 page 22 page 22 930/937 Mulcher (O) 800-00256... -

Page 23: Gauges, Switches And Accessories

CD / Radio 11-4 Attachment Pump 17 CD / Radio CD / Radio CD / Radio Used to connect diagnostic device Accessory see separate illustration to machine. page 23 page 23 page 23 page 23 page 23 930/937 Mulcher (O) 800-00256... - Page 24 FOR FIXED VS. VARIABLE FLOAT FUNCTION FOR FIXED VS. VARIABLE FLOAT FUNCTION FOR FIXED VS. VARIABLE FLOAT FUNCTION INSTRUMENT PANEL RIGHT SIDE OF CAB CONTINUED - NEXT 2 PAGES page 24 page 24 page 24 page 24 page 24 930/937 Mulcher (O) 800-00256...

- Page 25 Both locking switches for the attachment and float must be in the "off" position in order to start the engine. INSTRUMENT PANEL RIGHT SIDE OF CAB CONTINUED - NEXT PAGE page 25 page 25 page 25 page 25 page 25 930/937 Mulcher (O) 800-00256...

- Page 26 Tempature Up Tempature Up Tempature Up Tempature Up Tempature Up Increases the tempature Tempature Down Tempature Down Tempature Down Tempature Down Tempature Down Decreases the tempature page 26 page 26 page 26 page 26 page 26 930/937 Mulcher (O) 800-00256...

-

Page 27: Am/Fm Stereo Cd Player

MENU / SCAN Button MENU / SCAN Button sources. Short press: MENU button, to open the basic settings menu. Long press: SCAN, to start scan function page 27 page 27 page 27 page 27 page 27 930/937 Mulcher (O) 800-00256... -

Page 28: Engine Protection System

0 PSI 0 PSI 0 PSI 0 PSI 8 PSI 6 PSI 1200 25 PSI 17 PSI 1600 32 PSI 30 PSI 2500 42 PSI 30 PSI page 28 page 28 page 28 page 28 page 28 930/937 Mulcher (O) 800-00256... -

Page 29: Murphy Power View Operation

• Engine oil pressure • Intake temperature • Electrical potential • Wheel based vehicle speed • Fuel rate • Instantaneous fuel economy • Average fuel economy page 29 page 29 page 29 page 29 page 29 930/937 Mulcher (O) 800-00256... - Page 30 Right Arrow – Scroll the screen and move the parameter selection to the right or downward. Enter Key – Select a menu or parameter or hide/view an active fault code. page 30 page 30 page 30 page 30 page 30 930/937 Mulcher (O) 800-00256...

- Page 31 Menu is pressed, the main menu items are displayed. Menu 2. Touching the Arrow Keys Arrow Keys Arrow Keys Arrow Keys will move the selection bar to other menu items. Arrow Keys page 31 page 31 page 31 page 31 page 31 930/937 Mulcher (O) 800-00256...

- Page 32 Arrow Keys there are more screens that may be viewed. Use Arrow Keys the Arrow Keys Arrow Keys Arrow Keys Arrow Keys Arrow Keys to scroll to the next screen of information. page 32 page 32 page 32 page 32 page 32 930/937 Mulcher (O) 800-00256...

- Page 33 Right Arrow Key will display the coolant temperature. The screen can be changed to other parameters Right Arrow Key by pressing Menu Menu Menu Menu Menu. page 33 page 33 page 33 page 33 page 33 930/937 Mulcher (O) 800-00256...

- Page 34 8. Once the USE DEFAULTS, CUSTOM SETUP and AUTOMATIC SCAN functions have been set, touch Menu Menu Menu Menu Menu once to return to the main menu, or twice to display the 1-up display screen. page 34 page 34 page 34 page 34 page 34 930/937 Mulcher (O) 800-00256...

- Page 35 8. The parameter in the selected quadrant has changed to the parameter selected in the previous screen. 9. Repeat the parameter selection process until all spaces are filled. page 35 page 35 page 35 page 35 page 35 930/937 Mulcher (O) 800-00256...

- Page 36 VISUAL INDICATION VISUAL INDICATION VISUAL INDICATION · Amber LED (Warning) · Red LED (Derate / Shutdown) FAULT INDICATORS FAULT INDICATORS FAULT INDICATORS FAULT INDICATORS FAULT INDICATORS page 36 page 36 page 36 page 36 page 36 930/937 Mulcher (O) 800-00256...

- Page 37 · BACKLIGHT DIMMER, the default setting, will accept an optional backlighting dimmer. · FUEL LEVEL accepts an optional Murphy fuel sender (model ES2F recommended) for fuel level information. page 37 page 37 page 37 page 37 page 37 930/937 Mulcher (O) 800-00256...

- Page 38 Enter Enter. 4. Continue to scroll each selection (BAUD RATE, PARITY, DATA BITS, STOP BITS) to configure the serial port parameters for your Modbus slave application. page 38 page 38 page 38 page 38 page 38 930/937 Mulcher (O) 800-00256...

-

Page 39: Md3 - Quick Attach Control

USB Port USB Port USB Port USB Port USB Port The USB Port is used to plug a computer into the MD3 Control Panel. (not shown) page 39 page 39 page 39 page 39 page 39 930/937 Mulcher (O) 800-00256... -

Page 40: Md3 Display - Button Locations & Button Labels

UP arrow activates. When there is no label here the arrow is used to scroll up when the option is available. page 40 page 40 page 40 page 40 page 40 930/937 Mulcher (O) 800-00256... -

Page 41: Md3 Display - Icon Locations

(CCW). MAIN SCREEN ICONS MAIN SCREEN ICONS MAIN SCREEN ICONS MAIN SCREEN ICONS MAIN SCREEN ICONS DETAIL 1 DETAIL 1 DETAIL 1 DETAIL 1 DETAIL 1 page 41 page 41 page 41 page 41 page 41 930/937 Mulcher (O) 800-00256... -

Page 42: Setting Attachment Pump Flow

Once OK has been pushed, this warning message is displayed. You must either press F4 to accept the changes made or F2 to cancel your changes. page 42 page 42 page 42 page 42 page 42 930/937 Mulcher (O) 800-00256... -

Page 43: Setting Attachment Pump Pressure

Once OK has been pushed, this warning message is displayed. You must either press F4 to accept the changes made or F2 to cancel your changes. page 43 page 43 page 43 page 43 page 43 930/937 Mulcher (O) 800-00256... -

Page 44: Adjust Control Sensitivity

OK button to accept the change. To return to the Main menu, press F1. Once in the Adjust screen, highlight Control Sensitivity . With the Controls Group highlighted, press the OK button. page 44 page 44 page 44 page 44 page 44 930/937 Mulcher (O) 800-00256... -

Page 45: Engine Fault Codes

Engine power derate. Yellow 32 of the engine harness. P108 Low voltage detected at ambient air pressure signal Engine power derate. Yellow 32 of the engine harness. page 45 page 45 page 45 page 45 page 45 930/937 Mulcher (O) 800-00256... - Page 46 Power to the real time clock has been interrupted and its Time stamp in ECM powerdown data will be incorrect. Maintenance setting is no longer valid. page 46 page 46 page 46 page 46 page 46 930/937 Mulcher (O) 800-00256...

- Page 47 Engine idles when validation switch indicates idle and ramps up to Yellow supply pin 29 of the OEM harness. a default set speed when idle validation switch indicates off-idle. page 47 page 47 page 47 page 47 page 47 930/937 Mulcher (O) 800-00256...

- Page 48 Error detected in the Output device Driver (VGT of Can not control the VGT or Transmission, depending on application. Yellow Transmission Shift Modulation signal) signal pin 21 of the OEM harness. page 48 page 48 page 48 page 48 page 48 930/937 Mulcher (O) 800-00256...

-

Page 49: Start-Up Procedure

10. Never operate machine within 300 feet of personnel or other operating equipment. Clear all personnel from area. 11. Familiarize yourself with work site: note any hazards, obstructions or power lines, note ground conditions, terrain, and timber distribution. page 49 page 49 page 49 page 49 page 49 930/937 Mulcher (O) 800-00256... -

Page 50: Operating Instructions And Precautions

Keep all personnel back 300 feet. - Always remain in operator's seat with seat belt and harness on, while operating. page 50 page 50 page 50 page 50 page 50 930/937 Mulcher (O) Mulcher Attachment: Mulcher Attachment: Mulcher Attachment: Mulcher Attachment: Mulcher Attachment: 800-00256... - Page 51 51 page 51 page 51 page 51 page 51 930/937 Mulcher (O) 800-00256...

-

Page 52: Starting The Engine

52 page 52 page 52 page 52 page 52 930/937 Mulcher (O) 800-00256... -

Page 53: Shut-Down Procedure

53 page 53 page 53 page 53 page 53 930/937 Mulcher (O) 800-00256... -

Page 54: Mulching Attachment Safety

Read and understand those instructions before Read and understand those instructions before Read and understand those instructions before operating machine. operating machine. operating machine. operating machine. operating machine. page 54 page 54 page 54 page 54 page 54 930/937 Mulcher (O) 800-00256... -

Page 55: Transporting

When driving machine on highway, know what Shut off machine engine and set parking warnings must be placed on machine and whether an brake. escort is needed. page 55 page 55 page 55 page 55 page 55 930/937 Mulcher (O) 800-00256... -

Page 56: Towing

With brake disconnect, machine is allowed to roll With brake disconnect, machine is allowed to roll The Barko 930/937 Mulcher tractors can be towed when freely and can cause severe injury or death. freely and can cause severe injury or death. - Page 57 57 page 57 page 57 page 57 page 57 930/937 Mulcher (O) 800-00256...

-

Page 58: Safety While Servicing

Do not weld on any structural member unless Do not weld on any structural member unless Do not weld on any structural member unless specifically authorized by Barko Hydraulics. specifically authorized by Barko Hydraulics. specifically authorized by Barko Hydraulics. specifically authorized by Barko Hydraulics. -

Page 59: Welding

Ground as close as possible to the welding location. Do NOT ground through a bearing or bushing when welding. Procedure for Welding on 930 / 937 with John Deere engine Procedure for Welding on 930 / 937 with John Deere engine... -

Page 60: Preventive Maintenance

Check torque of bolts and nuts (retorque if necessary): Change all filter elements. Resume the normal maintenance intervals after this. See the Service Schedule for more information. page 60 page 60 page 60 page 60 page 60 930/937 Mulcher (O) 800-00256... -

Page 61: Service Schedule

Barko also recommends that you consult your Operators manual provided by the engine manufacturer to ensure that filter elements other than the ones provided by the engine manufacturer have been tested and meet there qualifications. page 61 page 61 page 61 page 61 page 61 930/937 Mulcher (O) 800-00256... - Page 62 Pump Drive Pump Drive Pump Drive - Replace. See Lubrication Points page oil specification. Engine Coolant Engine Coolant Engine Coolant - Replace coolant. Engine Coolant Engine Coolant page 62 page 62 page 62 page 62 page 62 930/937 Mulcher (O) 800-00256...

- Page 63 NOTE : Use the intervals on Service Schedule when operating in normal conditions. Service the machine at shorter NOTE : NOTE : intervals when operating in very hot, cold, dusty, or humid conditions. page 63 page 63 page 63 page 63 page 63 930/937 Mulcher (O) 800-00256...

-

Page 64: Tires

Tire pressure may vary slightly depending upon the application of the machine (saw head, mulcher head...). As a general guide the following is suggested: Front Tires (saw machines) 28L Tires 30 PSI 67x34 Tires 50 PSI page 64 page 64 page 64 page 64 page 64 930/937 Mulcher (O) 800-00256... -

Page 65: Lubrication Points

65 page 65 page 65 page 65 page 65 930/937 Mulcher (O) 800-00256... - Page 66 See detail at right. Detail of Centralized Lube Detail of Centralized Lube Detail of Centralized Lube Detail of Centralized Lube Detail of Centralized Lube System System System System System page 66 page 66 page 66 page 66 page 66 930/937 Mulcher (O) 800-00256...

-

Page 67: Fluid Specifications

In cold weather operation, the cloud point should be 10 degrees F. below lowest normal air temperatures. page 67 page 67 page 67 page 67 page 67 930/937 Mulcher (O) 800-00256... - Page 68 Engine coolant supplied from the factory meets or exceeds engine manufacturer specifications. Please see the engine manufacturer's manual to determine correct coolant and mixture, (ambient temperature dependent), when servicing the radiator. Current cooling system capacities are: 930 Cummins 305HP approx. 7 gallons 937 Cummins 365HP approx. 8 gallons...

-

Page 69: Special Torque Specifications

K170 valves ....... 43 Ft. Lbs. (60 Nm) K220 valves ....... 59 Ft. Lbs. (80 Nm) L90 valves ......... 33 Ft. Lbs. (45 Nm) page 69 page 69 page 69 page 69 page 69 930/937 Mulcher (O) 800-00256... -

Page 70: General Torque Specifications

P O U N D S P O U N D S P O U N D S 1-3/8 3250 3700 1950 2220 1-1/2 4350 4850 2600 2900 page 70 page 70 page 70 page 70 page 70 930/937 Mulcher (O) 800-00256... -

Page 71: Trouble Shooting

Tighten or replace belt. Radiator plugged. Clean and inspect radiator. Air filter elements plugged. Clean or replace elements. Recharge battery. Engine will not start. Low or discharged battery. page 71 page 71 page 71 page 71 page 71 930/937 Mulcher (O) 800-00256... - Page 72 Low hydraulic oil supply. Fill hydraulic reservoir with proper hydraulic oil. Inspect lines. Replace parts if Obstruction in line or line damaged. necessary. page 72 page 72 page 72 page 72 page 72 930/937 Mulcher (O) 800-00256...

- Page 73 Defroster switch needs service. Replace switch. Defroster fan motor needs Repair or replace motor. service. Disconnected or damaged wiring. Inspect wiring. Connect or replace wiring as necessary. page 73 page 73 page 73 page 73 page 73 930/937 Mulcher (O) 800-00256...

- Page 74 Add oil. Low oil level in reservoir. Repair or replace steering valve Sticky steering valve spool. spool. Repair or replace steering Loose cylinder piston. cylinder. page 74 page 74 page 74 page 74 page 74 930/937 Mulcher (O) 800-00256...

- Page 75 N O T E N O T E N O T E N O T E This section of the manual is used for the decal kits appropriate for the 930/937 Mulcher. Those kits are: 930 Base Kit (539-01064) 930 Cab Kit (539-01051)

- Page 76 MANUAL ORDERING FORM You may order one free Parts Manual and one free Service Manual (if available) for your machine by sending this completed form to Barko Hydraulics,LLC. NOTE: No manuals can be shipped out without the serial number of the machine written in below, since all manuals are made per machine serial number.

Need help?

Do you have a question about the 930 and is the answer not in the manual?

Questions and answers