Table of Contents

Advertisement

OPERATOR MANUAL

IMPORTANT INFORMATION, KEEP FOR OPERATOR

This manual provides information for:

Steamer

MODEL:

ST-4G/6G

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE.

READ, UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND

WARNINGS CONTAINED IN THIS MANUAL.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

POST IN A PROMINENT LOCATION

Instructions to be followed in the event user smells gas.

This information shall be obtained by consulting your

local gas supplier. As a minimum, turn off the gas and

call your gas company and your authorized service agent.

Evacuate all personnel from the area.

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or

death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this

equipment.

NOTIFY CARRIER OF DAMAGE AT ONCE

It is the responsibility of the consignee to inspect the container upon receipt and

to determine the possibility of any damage, including concealed damage. LoLo

Commercial Foodservice Equipment suggests that if you are suspicious of dam-

age to make a notation on the delivery receipt. It will be the responsibility of the

consignee to file a claim with the carrier. We recommend that you do so at once.

Manufacturer's Service/Questions 877-246-5656

Information contained in this document is known to be current and accurate at the time of

printing/creation. LoLo Commercial Foodservice Equipment recommends referencing our product

line website, www.getLoLo.com, for current product information and specifications.

PART NUMBER 156071 Rev. C (08/13)

Advertisement

Table of Contents

Summary of Contents for LoLo ST-4G

- Page 1 NOTIFY CARRIER OF DAMAGE AT ONCE It is the responsibility of the consignee to inspect the container upon receipt and to determine the possibility of any damage, including concealed damage. LoLo Commercial Foodservice Equipment suggests that if you are suspicious of dam- age to make a notation on the delivery receipt.

- Page 2 IMPORTANT: DO NOT USE ANY DEGREASER THAT CONTAINS POTASSIUM HYDROXIDE OR SODIUM HYDROXIDE OR THAT IS ALKALINE. IMPORTANT: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY LOLO COMMERCIAL FOODSERVICE EQUIPMENT OR THEIR AUTHORIZED DISTRIBUTOR VOIDS ALL WARRANTIES AND CAN RESULT IN BODILY INJURY TO THE OPERATOR AND DAMAGE THE EQUIPMENT.

- Page 3 Therefore, installation should comply with all local codes. IMPORTANT FOR FUTURE REFERENCE Please record this information and retain this manual for the life of the equipment. For Warranty Service and/or parts, this information is required. Model Number Serial Number Date Purchased OM-ST-4G/6G 3...

-

Page 4: Table Of Contents

NATIONAL FIRE PROTECTION ASSOCIATION 60 Batterymarch Park Quincy, Massachusetts 02269 NFPA/70 The National Electrical Code NFPA/54 The National Fuel Gas Code NSF INTERNATIONAL 789 N. Dixboro Rd. Ann Arbor, Michigan 48113-0140 INTERTEK (ETL) 1950 Evergreen Blvd, Suite 100 Duluth, GA 30096 OM-ST-4G/6G... -

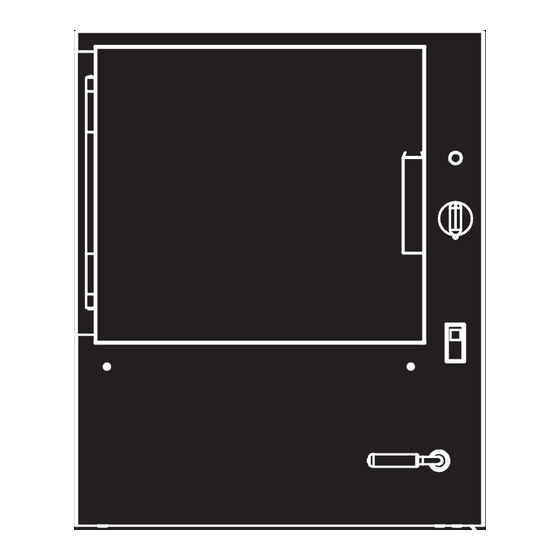

Page 5: Equipment Description

& pressure regulator ensure safe and trouble- free operation. The ST-4G model will hold up to four 2-1/2” deep steamer pans or two 4”deep pans. The ST-6G model will hold up to six 2-1/2” deep steamer pans or three 4” deep pans. -

Page 6: Inspect For Shipping Damage

Obtain help as needed, or use materials handling equipment, to lift the steamer off and clear of wood pallet. ThE lOlO STEAmERS ARE hEAvY, wEIghINg Remove any banding or tape used to secure the compartment door. 220 OR 275 POUNdS (100-125 Kg), dEPENdINg ON mOdEl. -

Page 7: Installation Instructions

ElECTRICITY ANd PlUmbINg. ImPROPER INSTAllATION CAN CAUSE INjURY TO mINImUm ClEARANCES PERSONNEl ANd/OR dAmAgE TO ThE LoLo steamer requires the following minimum clearances to any surface, combustible EQUIPmENT. ThE UNIT mUST bE INSTAllEd IN or non-combustible: ACCORdANCE wITh APPlICAblE COdES. - Page 8 Pressure Ratings for gas (measured on top of gas valve) model bTU/hr. Operating minimum maximum Pressure Incoming gas Incoming gas Feed Rate Feed Rate ST-4G NG 42,000 3.5” WC 5” WC 14” WC ST-4G LP 42,000 10” WC 12” WC 14” WC ST-6G NG 52,000 3.5”...

- Page 9 1/4” per foot. Observe local code regarding air gap spacing and drain connec- tions. STANd-STACKEd UNITS This section is applicable only if you are installing two steamers on the optional LoLo Diagram 9-1 support stand. Installation of stand-stacked steamers is similar to installing a single Improper Drain unit.

- Page 10 TO SUPPORT ThE wEIghT OR INSUlATEd AgAINST ThE hEAT PROdUCEd bY ThE The LoLo Stacked Flue Kit (P/N 156599) is designed to shield and divert flue STEAmER. FAIlURE TO USE A PURPOSE- gases and heat from the bottom steamer past the top steamer toward the bUIlT REFRIgERATEd EQUIPmENT STANd ventilation hood.

-

Page 11: Initial Start-Up

Initial Start-Up After the LoLo steamer has been installed, test it to ensure that the unit is operating correctly. whEN YOU OPEN ThE dOOR, STAY AwAY FROm STEAm COmINg OUT OF ThE UNIT. Remove all literature and packing materials from the interior of the unit. -

Page 12: Operation - General Steamer Use

Slide steamer pans on to pan using hot pads or oven mitts, to protect your hands from the hot pans. supports (Model ST-4G shown) NOTE: You can open the door at any time to check progress, season or stir food. When the compartment door is opened, a switch will cut power to the steam generator, but steam will still roll out of the compartment. -

Page 13: Cleaning

If scale is excessive, then refer to deliming instructions that follow. Clean right front drain opening thoroughly to remove any build-up of debris. Replace pan supports and water grate, if used. Steamer is now cleaned and ready to use. OM-ST-4G/6G 13... - Page 14 Cleaning Cooking Compartment deliming When using a Water Treatment System use vinegar as a deliming agent. LoLo AllOw ThE STEAmER TO COOl Commercial Foodservice Equipment approved delimer may be used to remove COmPlETElY bEFORE ClEANINg. hOT excessive scale build-up. SURFACES CAN CAUSE SEvERE bURNS.

-

Page 15: Maintenance

The LoLo steamer is designed for minimum maintenance and no user adjustments should be necessary. Certain parts may need replacement after prolonged use. If USE OF ANY REPlACEmENT PARTS OThER there is a need for service, only LoLo Authorized Service Agents should perform the ThAN ThOSE SUPPlIEd bY lOlO COmmERCIAl work. -

Page 16: User Troubleshooting Guide

Wiring diagrams are furnished inside the right side service access panel. If an item on the check list is marked with and (X), it means that the work should be done by an a LoLo Authorized Service Agent. CAUTION: USE... - Page 17 WELDMENT, FLUE STACK, 4 156426 COVER, FLUE 4-PAN ITEM NO. PART NUMBER DESCRIPTION QTY. 156340 RACK, LID SUPPORT LEFT PAN, 4-PAN 156503 PANEL, LEFT SIDE 4-PAN WELDMENT PANEL, RIGHT SIDE 4-PAN 156502 WELDMENT 156396 WELDMENT, TOP COVER, 4-PAN OM-ST-4G/6G 17 094151 TRAY DRIP...

- Page 18 070467 SHOULDER SCREW - RACK, LID SUPPORT RI 156358 WELDMENT, CAVITY 145297 VACUUM 073242 LOCTITE 142810 BRACKET, FLUE, 156473 COVER, FLUE 6-PA 156472 WELDMENT, FLUE STAC ITEM NO. PART NUMBER DESCRIPTION QTY. OM-ST-4G/6G 156357 RACK, LID SUPPORT LEFT PAN, 6-PAN...

- Page 19 ITEM NO. PART NUMBER DESCRIPTION SECTION A-A QTY. SCALE 1 : 2 156392 PANEL FRONT DOOR ASSY, 4-PAN 156390 LATCH, ASM 4-PAN ITEM NO. 156388 GASKET, DOOR 4-PAN SILICONE 156387 PANEL, DOOR INSIDE 4-PAN OM-ST-4G/6G 19 005764 SCREW TRUSS HEAD MACHINE...

- Page 20 SCREW, HEX HEAD CAP, 1/4"-20 127179 SCREW, 8-32 X 3/8" PHIL HEAD ITEM NO. QTY. PART NO. DESCRIPTION 140751 PANEL, DOOR INSIDE 124793 SILICONE, ALUMINUM 140748 GASKET .01OZ 073282 LOCTITE 242 OM-ST-4G/6G 140750 PANEL, FRONT DOOR ASSEMBLY 001711 RTV 732 SEALANT...

- Page 21 Diagram Water & Drain Systems RIGHT SIDE VIEW OM-ST-4G/6G 21...

- Page 22 141668 SHAFT, DRAIN ACTUATOR 156479 BRACKET, DRAIN VALVE CONNECTION GVR-0002 HOSE, STEAM UNIT 18” LONG 125954 CLEAR 3/8 HOSE 092124 REDUCER, WATER FLOW, .110 ID 144481 REDUCER, FLOW 147371 DRAIN THERMOSTAT 156487 NUT HEXAGON KEPS 4-40 (QTY 2) 071297 OM-ST-4G/6G...

- Page 23 SCREW, #8 X 1/2 HEX HD SLOT MACHINE SELF ZINC TIMER STEAMER (ATMOSPHERIC) 096857 SWITCH, DOOR 155548 POWER SWITCH, WITH GREEN INDICATOR LIGHT 096841 SCREW #4-40 X 1/4" HEX MS OM-ST-4G/6G 23 123100 KNOB, TIMER 156501 FLAME SENSOR 116384 LIGHT, INDICATOR AMBER 143559...

- Page 24 12 156486 BEEPER 13 071485 SCREW HEX SLOTTED 14 145660 RECTIFIER 208/240V POWER TILT 15 155506 ST-4G & ST-6G W/ FLOAT 120 VAC HARNESS(NOT SHOWN) OM-ST-4G/6G ITEM PART 16 155507 ST-4G & ST-6G W/ FLOAT 24VAC HARNESS(NOT SHOWN) DESCRIPTION QTY.

- Page 25 NUT, HEX KEPS 1/4” - 012940 20 (QTY 2) U BOLT, 3/4” PIPE N87786 Default/ ITEM NO. PART NUMBER DESCRIPTION QTY. 098458 VALVE, GAS. 1/2" VALVE GAS JOHNSON CONTROLS 098443 OM-ST-4G/6G 25 004185 ELBOW 90 DEG STREET 008747 ELBOW 90 DEG 1/2" NPT...

- Page 26 1. 4-PAN GAS ORIFICE IS 156508 NAT. 0'-2000', SIZE 0.092 BOM Table ITEM NO. PART NUMBER DESCRIPTION QTY. 005680 ELBOW 90 DEG REDUCING 042364 ELBOW 90 DEG STREET 050879 CONNECTOR MALE 3/8" 143976 INFRARED BURNER 156506 ORIFICE IGNITER , 0.104 OM-ST-4G/6G...

-

Page 27: Wiring Diagram

Wiring Diagram PDF created with pdfFactory Pro trial version www.pdffactory.com OM-ST-4G/6G 27... - Page 28 5925 I-55 South • Byram MS 39272 877-2GO-LOLO (877-246-5656) • Fax 877-504-4073 www.getLoLo.com © 2013 LoLo Commercial Foodservice Equipment. All Rights Reserved. PART NUMBER 156071 Rev. C (08/13)

Need help?

Do you have a question about the ST-4G and is the answer not in the manual?

Questions and answers