Table of Contents

Advertisement

Quick Links

25589, Highway 1

McBee, SC 29101

WARNING: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

•

Do not try to light any appliance.

•

Do not touch any electrical switch; do

not use any phone in your building.

•

Immediately call your gas supplier

from a neighbor's phone. Follow the

gas supplier's instructions.

•

If you cannot reach your gas supplier,

call the fire department.

Installation

performed by a

service agency or the gas supplier.

Thank you for buying this energy efficient boiler.

We appreciate your confidence in our products.

PRINTED IN THE U.S.A. 0811

and

service

must

qualified

installer,

be

User's Manual

xp boiler

MoDelS: xb/ xW

1000, 1300, 1700

2000, 2600, 3400

SerieS 100/101

operATioN - MAiNTeNANCe -

liMiTeD WArrANTY

320820-001

Advertisement

Table of Contents

Summary of Contents for A.O. Smith XB1000

-

Page 1: Limited Warranty

User’s Manual xp boiler MoDelS: xb/ xW 1000, 1300, 1700 2000, 2600, 3400 SerieS 100/101 operATioN - MAiNTeNANCe - 25589, Highway 1 liMiTeD WArrANTY McBee, SC 29101 WARNING: If the information in these instructions is not followed exactly, a fire or explosion may result causing property damage, personal injury or death. -

Page 2: Table Of Contents

TAble oF CoNTeNTS TABLE OF CONTENTS ................2 Installation Instructions (S7999B OI Display) ........18 SAFE INSTALLATION, USE AND SERVICE.......... 3 Quick Setup (S799 9B OI Display) ..........18 APPROVALS ..................3 Starting up the S7999B OI Display ..........19 GENERAL SAFETY................ -

Page 3: Safe Installation, Use And Service

SAFe iNSTAllATioN, USe AND SerViCe The proper installation, use and servicing of this boiler is extremely important to your safety and the safety of others. Many safety-related messages and instructions have been provided in this manual and on your boiler to warn you and others of a potential injury hazard. -

Page 4: General Safety

GeNerAl SAFeTY Breathing Hazard - Carbon Monoxide Gas Special consideration must be taken with installation above 4500 feet. Please contact an A. O. Smith qualified service agent to obtain the proper setup and instructions before lighting. Failure to implement the proper setup will result in improper and inefficient operation of the appliance resulting in production of increased levels of carbon monoxide gas... -

Page 5: Introduction

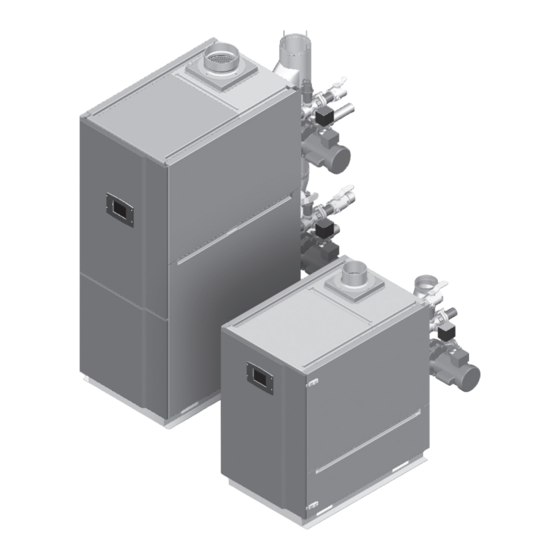

iNTroDUCTioN QUAliFiCATioNS This Instruction Manual covers XP Boiler models XB/XW 1000, 1300, 1700, 2000, 2600, 3400 - Series 100/101. The instructions QUAliFieD iNSTAller or SerViCe AGeNCY and illustrations contained in this Instruction manual will provide Installation and service of this boiler requires ability equivalent you with troubleshooting procedures to diagnose and repair common problems and verify proper operation. -

Page 6: Control Components

CoNTrol CoMpoNeNTS The CoNTrol SYSTeM The R7910A1138 is a burner control system that provides heat control, flame supervision, circulation pump control, fan control, boiler control sequencing, and electric ignition function. It will also provide status and error reporting. FiGUre 3. loW / hiGh GAS preSSUre SWiTCh GAS VAlVe The gas valve is a normally closed, servo regulated gas valve. -

Page 7: Flame Sensor

FlAMe SeNSor WATer TeMperATUre SeNSorS Each burner is equipped with a flame sensor to detect the presence of the burner flames at high and low fire conditions. If no flame is sensed, the gas valve will close automatically. The voltage sensed by the flame sensor will also be displayed on the Burner Screen. -

Page 8: Boiler Start Up And Operations

boiler STArT Up AND operATioNS iMporTANT Only an A. O. Smith Certified Start-up Agent must perform the initial firing of the boiler. At this time the user should not hesitate to ask the start-up agent any questions regarding the operation and maintenance of the unit. - Page 9 TAble 2. children, the infirm or physically/mentally disabled. If anyone WATer hArDNeSS MeDiUM (0-12 GrAiNS per GAlloN) using hot water in your home fits into one of theses groups or if there is a local code or state law requiring a specific xW MoDel ∆T ºF ∆P FeeT...

-

Page 10: Lighting And Operating Instructions

liGhTiNG AND operATiNG iNSTrUCTioNS... - Page 11 ADJUSTMeNT There must be sufficient load to operate the boiler at high fire to perform the following adjustments. Start the boiler and observe FiGUre 12. bUrNer iNForMATioN SCreeN proper operating parameters for the system. required Tools: Click on Operation button, and under the Modulation Menu, set the required Firing rate (High/Low) by setting the RPM.

- Page 12 hiGh FiriNG rATe SeTTiNG Set the boiler to the high firing rate by setting the High Firing Rate RPM as described below. Check combustion readings using a combustion analyzer. If combustion readings are not in accordance with the chart below adjust the gas valve as follows: remove the flat, round, blue plastic cap from the cover.

-

Page 13: Control System

CoNTrol SYSTeM bUrNer CoNTrol SYSTeM The R7910 maximum version of the controller offers: 1. NTC-temperature sensor for: • Outlet Limit And Temperature • DHW (Domestic Hot Water) Limit and Temperature • Stack Temperature Limit and Temperature • Inlet Temperature • Outdoor Temperature (R7910 only) 2. -

Page 14: Communications And Displays

CoMMUNiCATioNS AND DiSplAYS Meets CSD-1 section CW-400 requirements as a Temperature Operation control. Two modes of communications are available to the R7910. Meets CSD-1 section CW-400 requirements as a Temperature High Limit Control when configured for use with 10 kohm NTC The R7910 has two RS485 communication ports for sensors. -

Page 15: General Operational Sequence

6. MAiN FlAMe eSTAbliShiNG perioD (MFep): • Frequency fluctuations vary +/-5% (57 to 63 Hz). • If Demand, LCI, or Stat interrupt (open) during the Prepurge a. Lockout Interlock opens (if enabled). Period. b. Pilot valve terminal is not energized. c. -

Page 16: Lead Lag

DoMeSTiC hoT WATer leAD lAG (ll) MASTer GeNerAl operATioN Start-up sequence DHW-request (system in standby): The XP Boiler is a multiple burner application and it works on the basis of the Lead Lag Operation. The XB Boiler is factory Heat request detected (either DHW Sensor Only, DHW configured for Hydronic/Central Heating application, whereas the Sensor and Remote Command or DHW Switch and Inlet XW Boiler is factory configured for Domestic Hot Water application. -

Page 17: Local Operator Interface: Display System

loCAl operATor iNTerFACe: DiSplAY SYSTeM For example: — If its add-stage action has been triggered, it will remain in this condition until either a stage has been added, — The criteria for its being in an add-stage condition is no longer met;... -

Page 18: Specifications

• Allows for lead/lag commissioning. 10. Drill 1/4 in. holes through the panel at the marked locations and secure the power supply with the two #6-32 screws • Locates attached boiler(s). and nuts provided. • Allows boiler naming. 11. Remove the 9-pin connector plug from the back of the OI •... -

Page 19: Starting Up The S7999B Oi Display

STArTiNG Up The S7999b oi DiSplAY On System applications, each Burner Control System is represented on the Home page by an icon and name. Pressing poWer-Up VAliDATioN the icon allows the user to zoom in on that boiler and see its specific details. - Page 20 FiGUre 21. S7999b DiSplAY pAGe FloW...

- Page 21 STATUS or hoMe pAGe CoNFiGUre bUTToN A status (summary) page (Figure 22) is displayed when the Pressing the Configure button (bottom left) on the Status page S7999B display is connected. This status page appears on the opens the Configuration page. S7999B when the Burner control icon is pressed on the “Home”...

- Page 22 CoNFiGUrATioN pASSWorD KeYboArD Some parameters require a valid configuration password be Some pages request user entry of characters. When this type of entered by the user before the parameter can be changed. The input is required, a keyboard page appears, as shown in Figure password need only be entered once while the user remains on 26.

- Page 23 NOTE: When the installer proceeds with the safety parameter configuration, the control unlocks the safety parameters in this group and marks them unusable. Failure to complete the entire safety configuration procedure leaves the control in an un- runnable state (lockout 2). All safety configuration parameters in the group should have the same access level.

- Page 24 Safety lockouts are indicated on each configuration page as an alarm bell symbol. At the status page (for S7999B), the History button turns red. If the S7999B is displaying the system status icons, the control in alarm will turn red. The lockout history can be displayed by pressing on the History button.

- Page 25 This History dialog box provides an exploded view of the status NOTE: The system time can be set in the OI display to ensure information displayed in the History button (the font is larger). that correct timestamps are given to the controls’ lockouts and One of the four buttons (OK, Lockouts, Alerts, or Silence) can alerts.

- Page 26 FiGUre 36. CoNTrol expANDeD AlerT DeTAil FiGUre 38. proGrAMMAble ANNUNCiATioN operATioN bUTToN The operation button displays the Burner Control running operation, including setpoint and firing rate values. From this page the user can change setpoints, manually control the boiler’s firing rate, manually turn pumps on, view annunciation information, and switch between hydronic heating loops (Central Heat and Domestic Hot Water), as shown in Figure 37.

- Page 27 DiAGNoSTiCS bUTToN SYSTeM CoNFiGUrATioN (S7999b oi DiSplAY oNlY) The Diagnostics button displays analog and digital I/O status The OI Display has some functions related to general of the Burner Control. A snapshot of the diagnostic status is configuration for the control in the end user installation. Pressing displayed and updated once per second as it changes in the the Display Refresh button invokes a search procedure (see control.

- Page 28 Lead Lag Slave Configuration Lead Lag Master Configuration Most of this configuration is performed by the Service Agent or at A.O. Smith. Each functional group is displayed on the Configuration menu page. Parameters in functional groups that are not applicable for the installation can be ignored.

-

Page 29: Troubleshooting

TroUbleShooTiNG To support the recommended Troubleshooting, the R7910 has an Alert File. Review the Alert history for possible trends that may have been occurring prior to the actual Lockout. Note Column: H= Hold message; L=Lockout message; H or L= either Hold or Lockout depending on Parameter Configuration. TAble 9. - Page 30 CoDe DeSCripTioN reCoMMeNDeD TroUbleShooTiNG oF NoTe loCKoUT CoDeS Internal fault: Flame bias shorted to adjacent pin Internal Fault. Reset Module. Internal fault: SLO electronics unknown error If fault repeats, replace module. 32 - 46 Internal fault: Safety Key 0 through 14 System Errors Flame Rod to ground leakage Static flame (not flickering)

- Page 31 CoDe DeSCripTioN reCoMMeNDeD TroUbleShooTiNG oF NoTe loCKoUT CoDeS ILK OFF Check wiring and correct any possible shorts. H or L Check Interlock (ILK) switches to assure proper ILK ON H or L function. Verify voltage through the interlock string to the interlock input with a voltmeter.

- Page 32 CoDe DeSCripTioN reCoMMeNDeD TroUbleShooTiNG oF NoTe loCKoUT CoDeS Header sensor fault Check wiring and correct any possible errors. Replace the header sensor. If previous steps are correct and fault persists, replace the module. Stack sensor fault Check wiring and correct any possible errors. Replace the stack sensor.

- Page 33 CoDe DeSCripTioN reCoMMeNDeD TroUbleShooTiNG oF NoTe loCKoUT CoDeS High fire switch OFF Check wiring and correct any potential wiring errors. High fire switch stuck ON Check High Fire Switch to assure proper function (not welded or jumpered). Manually drive the motor to the High Fire position and adjust the HF switch while in this position and verify voltage through the switch to the HFS input with a voltmeter.

- Page 34 CoDe DeSCripTioN reCoMMeNDeD TroUbleShooTiNG oF NoTe loCKoUT CoDeS Flame not detected OEM Specific Sequence returns to standby and restarts sequence at the beginning of Purge after the HF switch opens. If flame detected during Safe Start check up to Flame Establishing period. High fire switch ON OEM Specific H or L...

- Page 35 CoDe DeSCripTioN reCoMMeNDeD TroUbleShooTiNG oF NoTe loCKoUT CoDeS Block intake ON OEM Specific Check wiring and correct any errors. Block intake OFF Inspect the Block Intake Switch to make sure it is working correctly. Reset and sequence the module. During Standby and Purge, measure the voltage across the switch.

- Page 36 CoDe DeSCripTioN reCoMMeNDeD TroUbleShooTiNG oF NoTe loCKoUT CoDeS Invalid Preignition time setting Return to Configuration mode and recheck selected parameters, reverify and reset module. Invalid Prepurge rate setting If fault repeats, verify electrical grounding. Invalid Prepurge time setting If fault repeats, replace module. Invalid Purge rate proving setting Invalid Run flame failure response setting Invalid Run stabilization time setting...

- Page 37 TAble 10. AlerTS CoDe DeSCripTioN CoDe DeSCripTioN EE Management Faults Program Module application parameter revision differs from application processor None (No alert) Program Module safety parameter revision differs Alert PCB was restored from factory defaults from safety processor Safety configuration parameters were restored PCB incompatible with product contained in from factory defaults Program Module...

- Page 38 CoDe DeSCripTioN CoDe DeSCripTioN Fan Parameter Errors MIX modulation range (max minus min) was too small (< 4% or 40 RPM) Periodic Forced Recycle Modulation Operation Faults Absolute max fan speed was out of range Fan was limited to its minimum duty cycle Absolute min fan speed was out of range Manual rate was >...

- Page 39 CoDe DeSCripTioN CoDe DeSCripTioN Minimum water temperature parameter was Lead Lag base load common setting was invalid greater than time of day setpoint Lead Lag DHW demand switch setting was Minimum pressure parameter was greater than Lead Lag Mix demand switch setting was invalid setpoint Lead Lag modulation sensor setting was invalid Minimum pressure parameter was greater than...

- Page 40 CoDe DeSCripTioN CoDe DeSCripTioN Lead Lag CH setpoint was invalid Abnormal Recycle: Demand off during Pilot Flame Establishing Period Lead Lag CH time of day setpoint was invalid Abnormal Recycle: LCI off during Drive to Purge LL outdoor temperature was invalid Rate Lead Lag ODR time of day setpoint was invalid Abnormal Recycle: LCI off during Measured Purge...

- Page 41 CoDe DeSCripTioN CoDe DeSCripTioN Abnormal Recycle: ILK off during Measured Purge Abnormal Recycle: Hardware SLO electronics Time Abnormal Recycle: Hardware processor clock Abnormal Recycle: ILK off during Drive to Lightoff Abnormal Recycle: Hardware AC phase Rate Abnormal Recycle: Hardware A2D mismatch Abnormal Recycle: ILK off during Pre-Ignition test Abnormal Recycle: Hardware VSNSR A2D Abnormal Recycle: ILK off during Pre-Ignition time...

- Page 42 CoDe DeSCripTioN CoDe DeSCripTioN Abnormal Recycle: Fan Speed Range High Internal error: Safety key bit 4 was incorrect 383-450 RESERVED Internal error: Safety key bit 5 was incorrect Circulator Errors Internal error: Safety key bit 6 was incorrect Circulator control was invalid Internal error: Safety key bit 7 was incorrect Circulator P-gain was invalid Internal error: Safety key bit 8 was incorrect...

- Page 43 CoDe DeSCripTioN CoDe DeSCripTioN Mix circulator sensor was invalid Heat exchanger high limit response was invalid Mix flow control was invalid Heat exchanger high limit was exceeded Mix temperature was invalid Heat exchanger high limit wasn't allowed due to stack limit setting Mix sensor was invalid Heat exchanger high limit wasn't allowed due to Mix PID setpoint was invalid...

-

Page 44: Maintenance Procedures

MAiNTeNANCe proCeDUreS MAiNTeNANCe SCheDUleS iNSpeCT boiler AreA Yearly procedures for Qualified Service Agent: Verify that boiler area is free of any combustible materials, gasoline and other flammable vapors and liquids. • Check for reported problems. Verify that air intake area is free of any of the contaminants. •... -

Page 45: Burner Maintenance

If the preceding burner characteristics are not evident, check for Loosen the seven bolts on the blower adapter at the base accumulation of lint or other foreign material that restricts or blocks and move the burner ground wire (Green) aside. the air openings to the burner or boiler. -

Page 46: Condensate Removal System

CoNDeNSATe reMoVAl SYSTeM 1. Turn off the electrical power, and manual gas shut-off. • Allow boiler parts to cool before disassembly. Due to the highly efficient operation of this boiler, condensate 2. Remove the vent pipe. is formed during operation and must be removed by the •... -

Page 47: Handling Ceramic Fiber Materials

hANDliNG CerAMiC Fiber MATeriAlS Apply enough water to the combustion chamber lining to prevent airborne dust. removal of combustion chamber lining: Remove the combustion chamber lining from the boiler and The combustion chamber insulation in this appliance contains place it in a plastic bag for disposal. ceramic fiber material. -

Page 48: Notes

NoTeS... -

Page 49: Limited Warranty

liMiTeD WArrANTY liMiTeD WArrANTY A. O. Smith Corporation, the warrantor, extends the following LIMITED WARRANTY to the owner of this boiler: 1. If within TEN years after initial installation of the boiler, a heat exchanger or gas burner should prove upon examination by the warrantor to be defective in material or workmanship, the warrantor, at his option will exchange or repair such part or portion. - Page 50 25589 Highway 1, McBee, SC 29101 Technical Support: 800-527-1953 • Parts: 800-433-2545 • Fax: 800-644-9306 www.hotwater.com...

Need help?

Do you have a question about the XB1000 and is the answer not in the manual?

Questions and answers