Table of Contents

Advertisement

Model(s):

NNXT4236I, NNXT4236IL

NNXT3933I, NNXT3933IL

• Important operating and

maintenance instructions

included.

WARNING

If the information in these instruc-

tions is not followed exactly, a

fi re may result causing property

damage, personal injury, or death.

• Do not store or use gasoline or other fl am-

mable vapors and liquids in the vicinity of

this or any other appliance.

• What to do if you smell gas:

- Do not try to light any appliance.

- Do not touch any electrical switch. Do not

use any phone in your building.

- Immediately call your gas supplier from

a neighbor's phone. Follow the gas

supplier's instructions.

- If you cannot reach your gas supplier, call

the fi re department.

• Installation and service must be performed

by a qualifi ed installer, service agency, or

the gas supplier.

This appliance may be installed as an OEM installation

in manufactured home (USA only) or mobile home and

must be installed in accordance with the manufacturer's

instructions and the manufactured home construction and

safety standard, Title 24 CFR, Part 3280 or Standard for

Installation in Mobile Homes, CAN/CSA Z240MH.

This appliance is only for use with the type(s) of gas

indicated on the rating plate.

CAUTION

DO NOT DISCARD THIS MANUAL

Read, understand and follow

•

these instructions for safe

installation and operation.

• CAREFULLY SUPERVISE children in same room as

appliance.

• A l e r t c h i l d r e n a n d a d u l t s t o h a z a r d s o f h i g h

temperatures.

High temperatures may ignite clothing or other

fl ammable materials.

• Keep clothing, furniture, draperies and other combustibles

away.

This appliance has been supplied with an integral

barrier to prevent direct contact with the fi xed glass

panel. Do NOT operate the appliance with the barrier

removed.

Contact your dealer or Hearth & Home Technologies if the

barrier is not present or help is needed to properly install one.

In the Commonwealth of Massachusetts installation must

be performed by a licensed plumber or gas fi tter;

See Table of Contents for location of additional

Commonwealth of Massachusetts requirements.

Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10

Owner's Manual

Installation and Operation

Leave this manual with

•

party responsible for

use and operation.

WARNING

HOT SURFACES!

Glass and other surfaces are hot during

operation and cool down.

Hot glass will cause burns.

• Do not touch glass until it is cooled

• NEVER allow children to touch glass

• Keep children away

Installation and service of this appliance should be performed

by qualified personnel. Hearth & Home Technologies

suggests NFI certifi ed or factory-trained professionals, or

technicians supervised by an NFI certifi ed professional.

1

Advertisement

Table of Contents

Summary of Contents for Heatilator NNXT4236I

- Page 1 NFI certifi ed or factory-trained professionals, or This appliance is only for use with the type(s) of gas technicians supervised by an NFI certifi ed professional. indicated on the rating plate. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

-

Page 2: Congratulations

As the owner of a new fi replace, you’ll want to read and Your new Heatilator gas fi replace will give you years of carefully follow all of the instructions contained in this durable use and trouble-free enjoyment. Welcome to the owner’s manual. -

Page 3: Table Of Contents

D. Mantel and Wall Projections Wall Switch Installation for Fan (Optional) 6 Termination Locations G. Control Module Operation A. Vent Termination Minimum Clearances H. Remote Control Installation & Operations Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... - Page 4 A. Intellifi re Plus™ Intermittent Ignition System 17 Reference Materials A. Appliance Dimension Diagram B. Vent Components Diagrams C. Service Parts D. Optional Components E. Contact Information = Contains updated information. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

-

Page 5: Limited Lifetime Warranty

3 years Firebox and heat exchanger Lifetime All replacement parts 90 Days beyond warranty period See conditions, exclusions, and limitations on next page. 4021-645B 04-02-09 Page 1 of 2 Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... - Page 6 THE EXTENT PROVIDED BY LAW, HHT MAKES NO EXPRESS WARRANTIES OTHER THAN THE WARRANTY SPECIFIED HEREIN. THE DURATION OF ANY IMPLIED WARRANTY IS LIMITED TO DURATION OF THE EXPRESSED WARRANTY SPECIFIED ABOVE. 4021-645B 04-02-09 Page 2 of 2 Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

-

Page 7: Listing And Code Approvals

Orifi ce Size (LP) #52/.0635/1.62 mm .061/155 mm with the applicable electrical codes, when it is installed in locations such as in bathrooms or near sinks. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 8: Requirements For The Commonwealth Of Massachusetts

See Gas Connection section for additional Common- read, in print size no less than one-half (1/2) in. in size, wealth of Massachusetts requirements. “GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

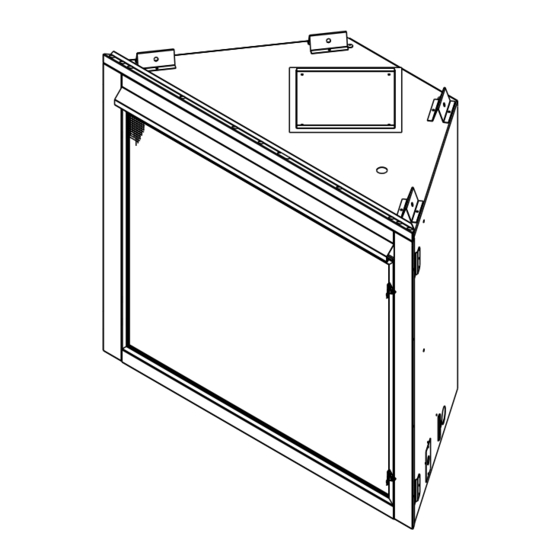

Page 9: User Guide

Decorative Doors (not shown) Section 2 Fixed Glass Assembly Section 15 Mantel Fan Kits Section 2 Clear Space Section 2 Hearth (not required) Figure 2.1 General Operating Parts Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 10: Fan Kit (Optional)

Contact your dealer or Hearth & Home Technologies if the barrier is not present or help is needed to properly install one. For more information refer to the instructions supplied with your decorative door or front. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 11: Lighting Instructions (Ipi)

* For U.S. only! NATURAL GAS Due to high surface temperatures, keep children, clothing and furniture away. Keep burner and control compartment clean. See installation and operating instructions accompanying the appliance. 33631D Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 12: After Fireplace Is Lit

Some optional control systems available with IPI models may allow pilot fl ame to remain lit. In a standing pilot system the pilot will always stay on. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 13: Maintenance And Service

Carefully set fi xed glass assembly in place on fi replace. Hold glass in place with one hand and secure glass latches with the other hand. • Reinstall door or decorative front. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 14: Maintenance Tasks-Qualifi Ed Service Technician

Use caution when cleaning these areas. Screw tips that have penetrated the sheet metal are sharp and should be avoided. • Remove all foreign objects. • Verify unobstructed air circulation. Figure 3.1 IPI Pilot Flame Patterns Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 15: Installer Guide

(Section 5) Optional Wall Switch (Section 12) Mantel & Mantel Leg (Section 5 & 14) Surround (Section 14) Hearth Extension (Not required) Gas Line (Section 12) Figure 4.1 Typical System Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 16: Design And Installation Considerations

Level Reciprocating saw Manometer Flat blade screwdriver Non-corrosive leak check solution 1/2 - 3/4 in. length, #6 or #8 Self-drilling screws One 1/4 in. female connection (for optional fan). Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 17: Framing And Clearances

1 in. (25 mm) min. pipe to combustibles Model 35-1/2 19-5/8 43-3/8 53-1/4 NNXT3933 1102 1194 1353 1016 37-5/8 19-5/8 43-3/8 53-1/4 NNXT4236 1067 1102 1194 1353 1092 Figure 5.1 Appliance Locations Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 18: Construct The Appliance Chase

The chase should not break the outside building envelope in any manner. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 19: Clearances

Rough Opening Rough Opening Rough Opening Model (Width) (Height) (Depth) (DVP Pipe) (SLP Pipe) NNXT3933 34 7/8 19 5/8 NNXT4236 1067 34 7/8 19 5/8 Figure 5.2 Clearances to Combustibles Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 20: Mantel And Wall Projections

1 in. (25 mm) min. to perpendicular wall 3-1/2 in. (89 mm) min. from fireplace opening to perpendicular wall Figure 5.4 Mantel Leg or Wall Projections (Acceptable on both sides of opening) Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 21: Termination Locations

Over 18/12 to 20/12 Over 10/12 to 11/12 3.25 Over 20/12 to 21/12 * 3 ft. minimum in snow regions Figure 6.1 Minimum Height From Roof To Lowest Discharge Opening Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... - Page 22 (30 cm) minimum. these requirements. Figure 6.3 Minimum Clearances for Termination CAUTION: IF EXTERIOR WALLS ARE FINISHED WITH VINYL SIDING, IT IS SUGGESTED THAT A VINYL PROTECTOR KIT BE INSTALLED. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

-

Page 23: Vent Information And Diagrams

Horizontal terminations are measured to the outside mounting surface (fl ange of termination cap) (see Figure 6.4.). • Vertical terminations are measured to bottom of termination cap. • Horizontal pipe installed level with no rise. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 24: Vent Diagrams

60 ft (18.29 m) max. 60 ft (18.29 m) max. 0.46 5.49 0.61 7.62 7.62 5.18 7.01 5.18 You may install the elbow directly on top of the appliance (DVP only). Figure 7.3 Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... - Page 25 H max. Two Elbows 0.15 1.83 0.30 3.35 3.35 0.46 5.18 5.18 0.61 5.18 5.18 7.62 5.18 5.18 7.01 5.18 5.18 Installed Vertically Installed Horizontally Figure 7.5 Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

- Page 26 Remove the refractory retainer from one side refractory. Remove lower refractory retainer 12 ft (3.66 m) min. 60 ft (18.29 m) max. Figure 7.7a Remove Refractory Retainer from one Side Figure 7.7 Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

- Page 27 Figure 7.7c Remove Top Refractory Figure 7.7e 31-60 ft Vertical Run • Reinstall Refractory: Replace top refractory. Lift top refractory and slide side refractory back into position. Replace bottom retainer. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

- Page 28 2. Top Vent - Vertical Termination - (continued) Three Elbows Maximum horizontal run is 100% of vertical, but cannot exceed 17 ft (5.18 m) 12 ft (3.66 m) min. 60 ft (18.29 m) max. Figure 7.8 Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

- Page 29 2. Top Vent - Vertical Termination - (continued) Two Elbows 12 ft (3.66 m) min. 60 ft (18.29 m) max. Maximum horizontal run is 100% of vertical, but cannot exceed 17 ft (5.18 m) Figure 7.9 Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

- Page 30 3. Rear Vent - Horizontal Termination No Elbow 18 in. (457 mm) max. Figure 7.10 One 45° Elbow 18 in. (457 mm) max. Figure 7.11 Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

- Page 31 Three Elbows 0.30 0.91 0.61 0.30 0.91 1.22 0.61 1.83 1.83 0.91 2.74 2.44 1.22 3.66 2.44 1.52 4.57 2.44 1.83 5.49 Installed Horizontally Figure 7.13 Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

- Page 32 12 ft (3.66 m) min. 6 ft (1.83 m) max. 60 ft (18.29 m) max. Maximum horizontal run is 100% of vertical, but cannot exceed 18 ft (5.49 m) Figure 7.15 Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

- Page 33 6 ft (1.83 m) max. 12 ft (3.66 m) min. 60 ft (18.29 m) max. Maximum horizontal run is 100% of vertical, but can- not exceed 18 ft (5.49 m) Figure 7.16 Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

-

Page 34: Vent Clearances And Framing

Figure 8.1 Horizontal Venting Clearances To Combustible Materi- * To center of pipe. Top Vent Rear Vent Model 39-1/2 23-1/2 NNXT4236 NNXT3933 1003 Figure 8.2 Wall Penetration Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 35: Install The Ceiling Firestop

3 fasteners per side Ceiling firestop Ceiling firestop installed below ceiling. installed above ceiling. Figure 8.4 Installing the Attic Shield Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 36: Install Attic Insulation Shield

Bend all tabs inward 90° around the top of the shield. These tabs must be used to prevent blown insulation from getting between the shield and vent pipe, and to maintain air space clearance. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 37: Appliance Preparation

Remove the center insulation plug. Figure 9.5 • Snap the fi rst vent section into place. Figure 9.2 • Cut the metal retaining band and fold the sides out. Figure 9.3 Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 38: Rear Vent

Figure 9.7 Figure 9.10 • Fold the center parts of the retaining band out and use to remove the vent cap. Figure 9.8 Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 39: Secure And Level The Appliance

Secure the appliance to the framing by using nails or screws through the nailing tabs. • Secure the appliance to the fl oor by inserting two screws through the pilot holes at the bottom of the appliance. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 40: Install Vent Pipe

fl ue at the horizontal elbow joint to prevent the elbow from rotating. Use screws no longer than 1/2 in. (13 mm). If predrilling screw holes, DO NOT penetrate inner pipe. INCORRECT Figure 10.4 Seams Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 41: Assemble Vent Sections (Slp Only)

• Only outer pipes are sealed, sealing the inner fl ue is not required. • All unit collar, pipe, slip section, elbow and cap outer fl ues shall be sealed. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 42: Secure The Vent Sections

Figure 10.10 Rotate Seams for Disassembly Figure 10.8 Securing Vertical Pipe Sections Figure 10.11 Align and Disassemble Vent Sections Figure 10.9 Securing Horizontal Pipe Sections Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 43: Install Decorative Ceiling Components (Slp Only)

fl aps and the roof. WARNING! Risk of Fire! Clean out ALL materials from inside the support box and complete the vertical vent run and termination. Figure 10.13 Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 44: Install Metal Roof Flashing

Caulk the perimeter of the fl ashing where it contacts the roof surface. See Figure 10.15. Pipe Caulk Figure 10.17 Assembling the Storm Collar Around the Pipe Flashing Figure 10.15 Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 45: Install Vertical Termination Cap

Once the pipe section and the termination cap have been connected, slide the wall thimble up to the interior wall surface and attach with screws provided. See Figure 10.19. Figure 10.19 Wall Thimble Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 46: Install Horizontal Termination Cap

SLP-TRAP2 can adjust 4 in. (5 1/4 to 9 1/4)) DVP-HPC1 can adjust 2 1/8 in. (4 1/4 to 6 3/8) DVP-HPC2 can adjust 4 1/8 in. (6 3/8 to 10 1/2) Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 47: Shrouds

Top Dim. 483 x 483 Min. Top Dim. Min. Top Dims. 16 x 16 406 x 406 Min. Base Dim. Min. Base Dim. Figure 11.1 Open Top Shroud Dimensions Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... - Page 48 20 x 20 508 x 508 Min. Height Minimum Height Minimum Opening Min. Opening Width Height Min. Opening Width Minimum Base Dimension Min. Opening Height Figure 11.2 Roofed Style Shroud Dimensions Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

-

Page 49: Gas Information

fl exible gas connector are connected to the 1/2 in. (13 consult local gas utility. mm) control valve inlet. • If substituting for these components, please consult local codes for compliance. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 50: Electrical Information

(not included) into the battery pack before use. Remove batteries if the fi replace will not be used for an extended period of time. NOTICE: Battery polarity must be correct or module damage will occur. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 51: Electrical Service And Repair

6V DC BOX (120V) SUPPLY 3 PRONG 120VAC CONTROL MODULE AUX200 MODULE FLAME TO JUNCTION MODULATION BOX 120VAC BATTERY PACK 6V DC (AA X 4) Figure 13.1 RC200 Wiring Diagram Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 52: Junction Box Installation

Minimum 14-3 AWG with Ground Black Black White White Green Green Junction Box Power Switch Box Supply Wires Knockout Figure 13.3 Junction Box Wired to Wall Switch or BC10 Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 53: Control Module Operation

If the ignition command again fails, the module will emit an LED error code prior to going back into LOCK-OUT mode. Contact your dealer for service if this occurs. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 54: Remote Control Installation & Operations

• Connect the equipment into an outlet on a circuit dif- ferent from that to which the receiver is connected. • Contact the dealer or an experienced radio TV techni- cian for help. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... - Page 55 • Insert the 3 prong plug from the fan into the receptacle Figure 1. Mounting Remote Control Housing located in the AUX200 module. See Figure 5. 4. Place remote control inside housing. See Figure 2. Figure 2. Remote in Housing Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

- Page 56 10 seconds DO NOT press any buttons on the remote during the ten seconds that the green LED blinks. The memory will be cleared. REMOTE POSITION REMOTE POSITION Figure 6. Programming RC200 Figure 7. Child Lock Switch Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

-

Page 57: Power Outage

Use caution when accessing module. Please contact your Hearth & Home Technologies dealer with any questions or concerns. For the location of your nearest Hearth & Home Technologies dealer, please visit www.fi reside.com. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 58: Finishing

1 in. (25 mm) min. to perpendicular wall 3-1/2 in. (89 mm) min. from fireplace opening to perpendicular wall Figure 14.2 Mantel Leg or Wall Projections (Acceptable on both sides of opening) Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 59: Facing Material

Finish wall material may be combustible - Top and Sides 0 in. 0 in. 0 in. High Temperature Sealant (300° F/149° C min.) Top and Side Seal Joint Figure 14.3 Non-combustible Facing Diagram Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 60: Appliance Setup

Figure 15.2 Lift up on Screen Package F. Remove Packing Material • Remove packing material (Figure 15.5). Figure 15.3 Remove Screen Package Figure 15.5 Remove Lytherm Pieces Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 61: Clean The Appliance

Lava Rock & Vermiculite Figure 15.6 Placement of Rockwool, Lava Rock and Vermiculite K. Place the Vermiculite Sprinkle on top of lava rock. Figure 15.9 Install Left Top Log Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 62: Replacing Fixed Glass Assembly

The Y end of the log should rest on the top indent in the right middle log and the top of the right bottom log. Close Open Figure 15.12 Adjusting Air Shutter Figure 15.11 Install Top Right Y Log Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 63: Remove Screen Protector

P. Unpackage the Hood & Floor Cover Remove parts package from appliance as shown in Fig- Control Heat Shield ure 5.15. Figure 15.17 Locate Control Heat Shield Figure 15.5 Removing Parts Package Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 64: Install Floor Cover

Figure 15.19 Control Heat Shield - Installed • Make sure all wires are under the top of the control heat shield and that there are no wires pinched between legs and the bottom pan. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 65: Close The Screen Assembly

Open Figure 15.23 Rotate the Screen Down Figure 15.21 Magnetic Touch Latch Open Hang Screen on Shoulder Screws Figure 15.24 Press on Bottom of Screen Figure 15.22 Hang Screen Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 66: Troubleshooting

D. Pilot valve solenoid Verify that 1.5 to 1.8 VDC is supplied to pilot solenoid from module. If below 1.5 volts, replace module. If 1.5 volts or greater, replace valve. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... - Page 67 fl ame sensing rod. Verify continuity with a multi-meter with ohms set at lowest range. Replace pilot if any damage is detected. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

-

Page 68: Reference Materials

3 in. (165 mm) 1-1/2 in. 1-3/4 in. 8 in. (76 mm) (38 mm) (203 mm) (44 mm) 15-3/4 in. (400 mm) 23-1/2 in. (597 mm) Figure 17.1 Appliance Dimensions Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... -

Page 69: Vent Components Diagrams

(254 mm) 8 in. (203 mm) 14 in. (356 mm) 12 in. (305 mm) 5 in. (127 mm) DVP-WS DVP-HVS Wall Shield Firestop Vent Support Figure 17.2 DVP Vent Components Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... - Page 70 Flashing 13-7/8 in. 9-1/2 in. (352 mm) (241 mm) 26 in. (660 mm) 14 in. (356 mm) DVP-HSM-B DRC-RADIUS Extended Heat Shield Cap Shield Figure 17.3 DVP Vent Components Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

- Page 71 7-1/8 in. 12-1/8 in. Fire Brick Termination Cap (181 mm) (314 mm) 8-3/4 in. (222 mm) 1-5/8 in. (41 mm) DVP-HPC High Performance Cap Figure 17.4 DVP Vent Components Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

- Page 72 5-3/8 in. 9-3/8 in. 12 in. Trap2 Effective (305 mm) 137 mm 238 mm Length DVP-TRAP Horizontal Termination Cap DVP-TRAPK1 DVP-TRAP1 DVP-TRAP2 DVP-TRAPK2 DVP-HPC1 DVP-HPC2 Figure 17.5 DVP Vent Components Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

- Page 73 8-3/8 in. 5-3/4 to 8-3/8 in. 140 mm 213 mm 146 to 213 mm 3° 87° 10-1/2 in. 267 mm 10-7/8 in. 276 mm DVP-HRC-ZC-SS Figure 17.6 DVP Vent Components Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

- Page 74 (660 mm) SLP-HVS DVP-HSM-B Horizontal Pipe Extended Heat Shield Support SLP-FS SLP-WS SLP-DCF-BK SLP-WT-BK Ceiling Firestop Wall Shield Firestop Decorative Ceiling Wall Thimble-Black Firestop-Black Figure 17.7 SLP Series Vent Components Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

- Page 75 140 mm 213 mm 146 to 213 mm 3° 87° 10-1/2 in. 267 mm 10-7/8 in. 276 mm SLP-TRAP2 Horizontal SLP-HRC-ZC-SS Termination Cap Figure 17.8 SLP Series Vent Components Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

- Page 76 121 mm 5 1/4 in. 9 1/4 in. 12 in. Trap2 Effective (305 mm) 133 mm 235 mm Length SLP-TRAP Horizontal Termination Cap Figure 17.9 SLP Series Vent Components Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

-

Page 77: Service Parts

C. Service Parts Service Parts Diagram Beginning Manufacturing Date: Aug 2009 Novus DV Heater IPI Appliance Ending Manufacturing Date: Active Log Set Assembly Part number list on following page. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... - Page 78 Back Gasket 4000-225 Cord Clip 14218 Refractory, Back 4055-855 Refractory, Right Side 4055-859 Refractory, Left Side 4055-860 Refractory, top 4055-865 Installation manual 4055-979 Additional service parts on following page. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

- Page 79 Orifi ce LP (.052C) 582-852 Conversion Kit NG DCKVN-NNXT Conversion Kit LP DCKVP-NNXT Pilot Orifi ce NG 593-528 Pilot Orifi ce LP 593-527 Regulator NG NGK-DXV-50 Regulator LP LGK-DXV-50 Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

-

Page 80: Log Set Assembly

NNXT4236I, NNXT4236IL Beginning Manufacturing Date: Aug 2009 Service Parts Diagram Ending Manufacturing Date: Active Novus DV Heater IPI Appliance Log Set Assembly Part number list on following page. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... - Page 81 Back Gasket 4000-225 Cord Clip 14218 Refractory, Back 4055-856 Refractory, Right Side 4055-859 Refractory, Left Side 4055-860 Refracotry. Top 4055-866 Installation Manual 4055-879 Additional service parts on following page. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

- Page 82 Orifi ce LP (.052C) 582-852 Conversion Kit NG DCKVN-NNXT Conversion Kit LP DCKVP-NNXT Pilot Orifi ce NG 593-528 Pilot Orifi ce LP 593-527 Regulator NG NGK-DXV-50 Regulator LP LGK-DXV-50 Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

-

Page 83: Optional Components

LDS33 LDS46 1219 1829 LDSCP-M Shroud Leg Multipack (not shown) LDS-BV Decorative Shroud Catalog # 12.5 15.5 LDS-BV See your Heatilator dealer for a complete listing of optional components. Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10... - Page 84 Operable Arch Decorative Front FFDEMI30 Non-operable Decorative Front FFDEMI33 Non-operable Decorative Front DFNMESH30 Mesh Front DFNMESH33 Mesh Front DFNMESH30M Multi-pak of 4 Mesh Fronts DFNMESH33M Multi-pak of 4 Mesh Fronts Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

-

Page 85: Contact Information

5647340, 5890485, 5941237, 5947112, 5996575, 6006743, 6019099, 6053165, 6145502, 6170481, 6374822, 6484712, 6601579, 6769426, 6863064, 7077122, 7098269, 7258116, 7470729 or other U.S. and foreign patents pending. 2000-945 Printed in U.S.A. - Copyright 2010 Heatilator • Novus NNXT • 4055-879 • Rev E • 5/10...

Need help?

Do you have a question about the NNXT4236I and is the answer not in the manual?

Questions and answers