Table of Contents

Advertisement

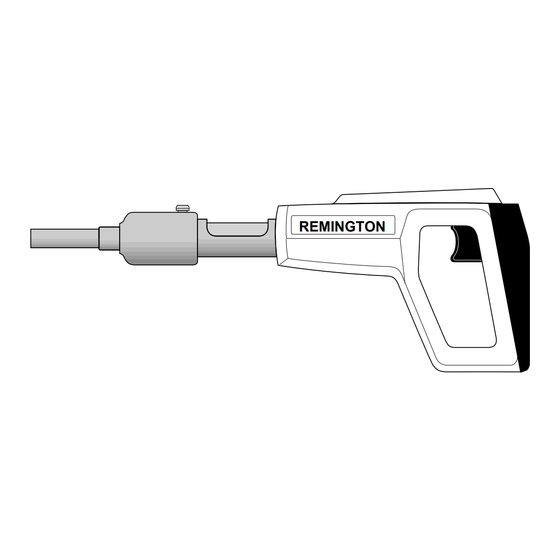

Models 489 and 490

Operating

Instructions

Important:

Read this manual and all labels carefully before operating your powder

actuated tool. This manual should always accompany the tool and be

transferred with it upon change of ownership.

REMINGTON

Powerdriver

®

G 028

REMINGTON

POWDER ACTUATED TOOL

MANUFACTURERS´ INSTITUTE INC.

G 029

482-1

®

490-01

™

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Remington 489

-

Page 1: Operating Instructions

REMINGTON ® REMINGTON Powerdriver Models 489 and 490 490-01 ™ ® POWDER ACTUATED TOOL MANUFACTURERS´ INSTITUTE INC. G 029 G 028 Operating Instructions 482-1 Important: Read this manual and all labels carefully before operating your powder actuated tool. This manual should always accompany the tool and be... -

Page 2: Table Of Contents

Warranty ................Back Cover REMINGTON Powerdriver Models 489 and 490 The Remington Powerdriver Models 489 and 490 are designed for use with Remington powder 22 caliber Type A crimped loads and Reming- ton Power Fasteners which are no longer than 2 1/2". Remington Power Fasteners are manufactured from special steel and heat treated to produce a very hard yet ductile fastener. -

Page 3: Warning: Safety Precautions

For certification procedures, call: DESA Technical Services Department, 1-800-323-5190. BEFORE USING 489-03 489-04 ALWAYS handle the tool as if it were loaded. Before starting work, check that the tool is unloaded and the muzzle is clear. NEVER load a tool unless it is going to be used. -

Page 4: Safety Precautions

WARNING POWDER ACTUATED TOOLS IN USE 482-10 489-09 ALWAYS clear the work area on all sides and post appropriate warning signs on job sites. G 018 482-12 489-10 ALWAYS make sure the work area is clean from loose material and debris. - Page 5 Safety Precautions G 018 489-16 489-15 ALWAYS store UNLOADED powder actuated tool and powder loads in a locked container. Keep powder loads of different power levels in separate containers. G 018 489-17 NEVER carry or pass a loaded powder actuated tool. NEVER point a powder actuated tool at anyone.

- Page 6 Safety Precautions G 018 An operator taking medication should take extra precautions while handling the tool. NEVER drink alcoholic beverages or take medications which impair your vision, balance or judgement before using a powder actuated tool. KNOW YOUR FASTENING BASE MATERIAL Sinks in with average...

- Page 7 G 018 G 018 482-33 489-24 NEVER attempt to drive power fasteners into very hard or brittle materials including, but not limited to cast iron, glass, tile, stone, brick, or hardened steel. Materials of this type tend to shatter and create hazard from flying particles.

-

Page 8: Operating The Tool

2" of a weld, within 1/2" of the edge, or within 1" of another power fastener. G 018 489-29 When fastening into masonry walls, always drive into horizontal mortar joints, NEVER into vertical mortar joints. BE CAREFUL. A poorly laid joint may permit too much penetration and/or unsatisfactory holding power. - Page 9 Safety Precautions 489- WATER 489-33 Should the tool fail to fire, hold the muzzle firmly against the work surface for 30 seconds. Release the trigger and remove pressure on the tool while holding the muzzle against the work surface. Again press the tool firmly against the work surface and pull the trigger.

- Page 10 482-31 482-54 Remington Powder Loads are available in four power levels with gray (1) being the lowest power level and yellow (4) being the highest power level. Always start with the lowest power level (gray-level 1) and increase until a proper fastening is made (see page 11 “Selecting Fasteners and Loads”).

- Page 11 Appropriate safety precautions must be taken. Head Shank Plastic Flute 482-60 NEVER use common nails or other materials as fasteners. Remington Power Fasteners are manufactured from special steel and heat treated to produce a very hard yet ductile fastener. G 018 482-61 NEVER pry a powder load out of the chamber.

-

Page 12: Why A Fastener Holds

Why A Power Fastener Holds WHY A POWER FASTENER HOLDS IN CONCRETE The compression bond of the concrete to the power fastener accounts for the majority of the holding power. The fastener displaces the concrete which tries to return to its original form causing a squeezing effect. Maximum holding power is achieved when the depth of penetration produces a bond on the power 482-64... -

Page 13: Selecting Fasteners And Powder Loads

Selecting Power Fasteners and Powder Loads FASTENING INTO CONCRETE The proper power fastener length can be determined by adding the thickness of the material to be fastened and the amount of fastener that will actually penetrate the concrete. The concrete must be three times as thick as the intended fastener penetration. -

Page 14: Operation

482-72 482-73 damage to tool (see page 11). Select the proper Remington Powder Load (see Application Chart on pages 20 and 21) and insert into the chamber until it stops. 489-3 Push barrel into housing to the closed position. -

Page 15: Operation

Operation 90˚ 489-40 Place the muzzle of tool perpendicular to work surface without tilting the tool. Push tool against work surface until sliding action of barrel stops. 489-41 Squeeze trigger to set power fastener. Be sure to keep pressure on tool during this operation. -

Page 16: Parts List

Parts List Part No. Part No. 490-03 Description Qty. TA4000 TA4000 BARREL, Assembly and Piston 076659 076659 BREECH 076620-02 076620 HOUSING, Handle, Right 076630-02 076630 HOUSING, Handle, Left 078334 078334 LINK, Trigger 076943 076943 NUT, Pad Recoil 098679-01 098679-01 PAD, Recoil 075370 075370 PIN, Firing... -

Page 17: Barrel Replacement

WARNING ICON G 001 actuated tool while it is loaded. REMINGTON REMINGTON REMINGTON 489-43 489-45 Remove front screw (A). Slide barrel assembly (B) from receiver (C). Remove pressure pad assembly (D). 489-46 489-47 If tool has been overdriven, tap piston (E) on a hard surface until the piston is pushed back into the muzzle. -

Page 19: Tool Disassembly And Assembly

Tool Disassembly And Assembly TOOL DISASSEMBLY Remove screw (G) from recoil pad (H). Lift pad away from handle. Separate housing halves by removing the seven housing screws (I & J). Remove receiver (C), firing pin (K), firing pin spring (L), sheet metal nut (M), trigger link (N), link pin (O), sear (P), and trigger (R). -

Page 20: Troubleshooting

Troubleshooting Guide REMEDY PROBLEM POSSIBLE CAUSE Piston hangs out Tool overdriven. Tap piston on a hard surface of muzzle. until piston is pushed back into the muzzle (see “Over- driven Fastener” below). Piston not properly as- Remove barrel assembly. sembled in relation to barrel Follow instructions for barrel screw. -

Page 21: Troubleshooting

Troubleshooting Guide (cont.) REMEDY POSSIBLE CAUSE PROBLEM Tool does not fire. Dirt build-up on breech not Check firing pin indentation allowing proper penetration on cartridge. Clean breech, of firing pin. breech face, sear and firing pin. Replace worn or dam- aged parts. -

Page 22: Application Chart

Power fasteners and powder loads are available in poly packages of 10, blister packs of 25 and cartons of 100. IMPORTANT • Recommended for use with Remington powder loads and power fasteners. • Do not use power fasteners longer than 2 1/2". •... -

Page 23: Parts And Accessories

Parts Central (see below) or call DESA International’s Parts Department at 1-800-972-7879. When calling DESA International, have ready • model number of your tool • replacement part number REMINGTON IPAT PARTS CENTRALS RAILWAY DISTRIBUTORS MASTER SERVICE CENTER 264 Railway Avenue 1184 Wilson NW... -

Page 24: Powerdriver Models 489 And

Limited Warranty Agreement DESA International warrants the Remington Powerdriver Models 489 and 490 against defects in materials and workmanship for a period of one (1) year from the date of purchase. If within one (1) year from the purchase date this Powder Actuated Tool fails due to a defect in material or workmanship, DESA will repair or replace the tool at DESA’s...

Need help?

Do you have a question about the 489 and is the answer not in the manual?

Questions and answers