Summary of Contents for Agilent Technologies Infiniium 90000 A

- Page 1 Service Guide Publication Number 54913-97022 March 2013 © Agilent Technologies, Inc. 2007-2013 Infiniium 90000 A-Series Oscilloscopes...

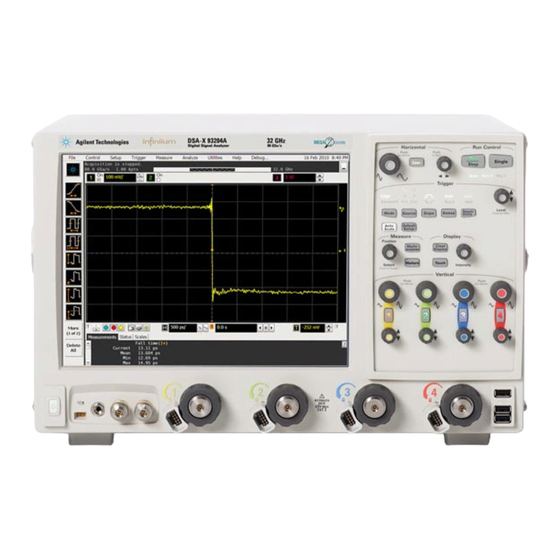

- Page 2 Agilent Infiniium 90000 A-Series Oscilloscopes at a Glance Ease of use with high performance Acquisition and general controls start and stop the scope and do basic setup The Agilent Infiniium 90000 A-Series • Run and stop controls for continuous or single oscilloscopes combine unprecedented ease-of- acquisitions.

-

Page 3: In This Service Guide

In This Service Guide This guide provides the service documentation for the Agilent Technologies 90000 A-Series oscilloscopes. It is divided into seven chapters. Chapter 1, "General Information," describes which oscilloscope models are covered by this guide, environmental requirements, and oscilloscope dimensions. -

Page 5: Table Of Contents

To check the keyboard; Trouble Isolation Procedure 84 To check the LEDs 85 Software Revisions 86 To check probe power outputs 87 Replacing Assemblies To return the oscilloscope to Agilent Technologies for service 91 To remove and replace the cover, top plate, and bottom plate 92... - Page 6 Contents To remove and replace the front panel bezel and front panel circuit assembly 97 To remove and replace the on/off board 101 To remove and replace the backlight inverter board 103 To remove and replace the touch screen, the front deck, and the controller assembly 104 To remove and replace the motherboard 107 To remove and replace the acquisition boards/backplane assembly 108 To remove the backplane assembly from the acquisition assemblies 112...

-

Page 7: General Information

Instruments covered by this service guide 8 Accessories supplied 10 Specifications and Characteristics 10 Environmental Conditions 11 Measurement Category 11 Oscilloscope Dimensions 12 General Information... -

Page 8: Instruments Covered By This Service Guide

If you have an oscilloscope that was manufactured after the release of this manual, please check the Agilent Technologies website at www.agilent.com to see whether a newer version of this manual is available. The following 90000 A-Series oscilloscopes are covered in this guide. -

Page 9: Performance-Enhanced Versus Standard Models

Performance-Enhanced Versus Standard Models Performance-Enhanced Versus Standard Models In the fall of 2009, Agilent started shipping performance-enhanced models of the 90000 A-Series oscilloscope. This service guide covers both the standard and performance-enhanced versions of the 90000 A-Series scopes. Any differences between the two versions are noted. -

Page 10: Accessories Supplied

• User's Quick Start Guide Specifications and Characteristics The following table contains a partial list of specifications and characteristics for the Agilent Infiniium A-Series oscilloscopes. For a full list of specifications and characteristics, refer to the data sheets at www.agilent.com/find/90000. -

Page 11: Environmental Conditions

Chapter 1: General Information Environmental Conditions Environmental Conditions Overvoltage Category This product is intended to be powered by MAINS that comply to Overvoltage Category II, which is typical of cord-and-plug connected equipment. Pollution Degree The 90000 Series Oscilloscope may be operated in environments of Pollution Degree 2 (or Pollution Degree 1). -

Page 12: Oscilloscope Dimensions

Chapter 1: General Information Oscilloscope Dimensions Oscilloscope Dimensions The following pictures show the dimensions of the frame. 11.13 in 283 mm 10.50 in 267 mm 17.36 in 441 mm 17.02 in 432 mm 16.78 in 426 mm 18.02 in 458 mm 19.91 in 506 mm... -

Page 13: Calibration

To run the self calibration 15 Calibration... - Page 14 Calibration This chapter provides self calibration procedures for the oscilloscope.

-

Page 15: To Run The Self Calibration

DSO90254A which can use a good quality BNC cable) 10 MHz Signal Source (required for time scale Frequency accuracy better than 0.4 ppm Agilent 53131A with Opt. 010 calibration) Self calibration Calibration time It will take approximately 1 hour to run the self calibration on the oscilloscope, including the time required to change cables from channel to channel. - Page 16 Chapter 2: Calibration To run the self calibration Figure 2-1 Clear this check box before starting calibration Click here to start calibration Calibration Dialog Click Start, then follow the instructions on the screen. The routine will ask you to do the following things in sequence: a Decide if you want to perform the Time Scale Calibration.

-

Page 17: Testing Performance

Performance Test Interval 18 Performing Self-Test and Calibration 19 Vertical Performance Verification 20 Offset Accuracy Test 21 DC Gain Accuracy Test 29 Analog Bandwidth - Maximum Frequency Check 35 Time Scale Accuracy (TSA) 42 Performance Test Record 45 Testing Performance... -

Page 18: Performance Test Interval

The oscilloscopes in these lists are ones that are currently available for sale by Agilent at the time of writing this document. In some cases, the test procedures use features specific to the oscilloscopes in the recommended equipment list. -

Page 19: Performing Self-Test And Calibration

Chapter 3: Testing Performance Performing Self-Test and Calibration Performing Self-Test and Calibration Perform self tests a Pull down the Utilities menu and select Self Test. b Select Scope Self Test from the Self Test list. c Click on Start Self Test to start the self test procedure. If any of the self-tests fail, ensure that the failure is diagnosed and repaired before calibrating and testing performance. -

Page 20: Vertical Performance Verification

Vertical Performance Verification This section contains the following vertical performance verification: • Offset Accuracy Test • DC Gain Accuracy Test • Analog Bandwidth Test... -

Page 21: Offset Accuracy Test

Equipment Required Description Critical Specifications Recommended Model/ Part Numbers Digital Multimeter DC voltage measurement accuracy better than ±0.1% of reading Agilent 34401A or Agilent 3458A Cable Assembly 50Ω characteristic impedance, BNC (m) connectors Agilent 8120-1840 (2 required) Adapter BNC Tee (m)(f)(f) - Page 22 Chapter 3: Testing Performance Offset Accuracy Test b When the Acquisition Setup window is displayed, enable averaging and set the # of averages to 256 as shown below. Configure the scope to measure Average voltage on channel 1 as follows: a Change the vertical sensitivity of channel 1 to 5 mV/div.

- Page 23 Chapter 3: Testing Performance Offset Accuracy Test c When the Enter Measurement Info window is displayed, ensure that the V avg function is set up as follows and then click OK: Source = Channel 1 Measurement Area = Entire Display Press the Clear Display key on the scope and wait for the #Avgs value (top left corner of screen) to return to 256.

- Page 24 Chapter 3: Testing Performance Offset Accuracy Test Repeat step 5 for the remaining vertical sensitivities for channel 1 in the Zero Error Test section of the Performance Test Record. Press Default Setup, then turn off channel 1 and turn channel 2 display on. Configure the scope to measure V avg on Channel 2 as follows: a Pull down the Setup menu and select Acquisition.

- Page 25 Chapter 3: Testing Performance Offset Accuracy Test Offset Gain Test Make the connections to scope channel 1 as shown below. Connections Notes: • Where it is used, it is important to connect the BNC Tee adapter directly to the scope channel input to minimize ground potential differences and to ensure that the DMM measures the input voltage to the scope channel as accurately as possible.

- Page 26 Chapter 3: Testing Performance Offset Accuracy Test b Pull down the Setup menu and select Acquisition. When the Acquisition Setup window is displayed, enable averaging and set the # of averages to 256. c Change the vertical sensitivity of channel 1 to 5 mV/div. d Click the V avg measurement icon on the left side of the screen.

- Page 27 Chapter 3: Testing Performance Offset Accuracy Test Set the channel 1 offset value to 400.0 mV. This can be done using the front panel control a Pull down the Setup menu and select Channel 1 or click the Channel 1 setup icon. b Click the Offset control arrows to change the offset value or click on the offset value and enter 400.0 mV in the dialog box.

- Page 28 Chapter 3: Testing Performance Offset Accuracy Test Change the channel 1 offset value to -400.0 mV. Set the Aux Out voltage to -400.0 mV. Press the Clear Display key on the scope, wait for the #Avgs value (top left corner of screen) to return to 256 and then record the DMM voltage reading as V and the DMM-...

-

Page 29: Dc Gain Accuracy Test

Equipment Required Description Critical Specifications Recommended Model/ Part Numbers Digital Multimeter DC voltage measurement accuracy better than ±0.1% of reading Agilent 34401A or Agilent 3458A Cable Assembly 50Ω characteristic impedance, BNC (m) connectors Agilent 8120-1840 (2 required) Adapter BNC Tee (m)(f)(f) - Page 30 Chapter 3: Testing Performance DC Gain Accuracy Test Procedure Make the connections to scope channel 1 as shown below. Connections Notes: • Where it is used, it is important to connect the BNC Tee adapter directly to the scope channel input to minimize ground potential differences and to ensure that the DMM measures the input voltage to the scope channel as accurately as possible.

- Page 31 Chapter 3: Testing Performance DC Gain Accuracy Test b When the Acquisition Setup window is displayed, enable averaging and set the # of averages to 256 as shown below. Set the Aux Out voltage (V ) to +15 mV as follows: Aux Out a Pull down the Utilities menu and select Calibration.

- Page 32 Chapter 3: Testing Performance DC Gain Accuracy Test c Select the Vavg measurement as shown below. V avg measurement d When the Enter Measurement Info window is displayed, ensure that the V avg function is set up as follows and then click OK: Source = Channel 1 Measurement Area = Entire Display Press the Clear Display key on the scope, wait for the #Avgs value (top left corner of...

- Page 33 Chapter 3: Testing Performance DC Gain Accuracy Test Record the mean reading Change the Aux Out voltage to -15 mV. Press the Clear Display key on the scope, wait for the #Avgs value to return to 256 and then record the DMM voltage reading and the scope V avg reading in the DC Gain Test section of the Performance Test Record.

- Page 34 Chapter 3: Testing Performance DC Gain Accuracy Test Calculate the offset gain using the following expression and record this value in the DC Gain Test section of the Performance Test Record. For vertical sensitivities of less than 1 volt use the following equation: ΔV –...

-

Page 35: Analog Bandwidth - Maximum Frequency Check

Power Splitter 2 Resistor Power Splitter Agilent 11667B Max Frequency ≥18 GHz Power Meter Agilent E-series with power sensor compatibility Agilent E4418B or E4419B Maximum Frequency ≥ 14 GHz Power Sensor Agilent E4413A Power range: -24 dBm to +16 dBm Microwave Cable 50Ω... - Page 36 Chapter 3: Testing Performance Analog Bandwidth - Maximum Frequency Check Connections Microwave CW Generator E8257D Power meter E4418A or E4419A Power splitter 11667B Power sensor cable SMA to BNC adapter SMA adapter Microwave cable Power sensor E4413A Notes • Connect output 1 of the 11667B splitter to the scope Channel n input directly using the 54855-67604 adapter, without any additional cabling or adapters.

- Page 37 Chapter 3: Testing Performance Analog Bandwidth - Maximum Frequency Check c Set the horizontal scale to 16 ns/div (to display 8 cycles of a 50 MHz waveform). Click here and enter 16E-9 d Pull down the Setup menu, select Acquisition and then set up the acquisition parameters as follows: Memory Depth = Automatic Sampling rate = Maximum (40 GSa/s)

- Page 38 Chapter 3: Testing Performance Analog Bandwidth - Maximum Frequency Check f When the RMS voltage measurement setup window is displayed, configure this measurement as follows: Source = Channel 1 Measurement Area = Entire Display RMS Type = AC Set the generator to apply a 50 MHz sine wave with a peak-to-peak amplitude of about 4 divisions.

- Page 39 Chapter 3: Testing Performance Analog Bandwidth - Maximum Frequency Check Press the Clear Display key on the scope and record the scope V rms reading in the Analog Bandwidth - Maximum Frequency Check section of the Performance Test Record (Vout @ 50 MHz). For all scope readings in this procedure, use the mean value in the Measurements display area at the bottom of the screen.

- Page 40 Chapter 3: Testing Performance Analog Bandwidth - Maximum Frequency Check Change the generator frequency to the maximum value for the model being tested as shown in the table below. It is not necessary to adjust the signal amplitude at this point in the procedure.

- Page 41 Chapter 3: Testing Performance Analog Bandwidth - Maximum Frequency Check Change the scope set up as follows: a Change the channel vertical sensitivity to 10 mV/div. b Reset the horizontal scale to 16 ns/div (to display 8 cycles of a 50 MHz waveform). Change the generator output as follows: a Reset the generator frequency to 50 MHz.

-

Page 42: Time Scale Accuracy (Tsa)

Agilent service center. The aging component scales linearly from the time since the last time base calibration and adds to the initial accuracy component. - Page 43 Chapter 3: Testing Performance Time Scale Accuracy (TSA) Connections Connect the equipment as shown in the following figure. Procedure Configure the sine wave source to output a 0 dBm (600 mVpp) sine wave into 50 ohms with a frequency of 10.00002000 MHz. Adjust source amplitude such that displayed sine wave is 600 mVpp.

- Page 44 Chapter 3: Testing Performance Time Scale Accuracy (TSA) measurement result should exceed the specified accuracy by at least 0.1 ppm in order to guarantee compliance to the specification. Record the results in the Performance Test Record.

-

Page 45: Performance Test Record

Performance Test Record Agilent Technologies Agilent 90000 Series Oscilloscopes Model Number _____________________ Tested by___________________ Serial Number ___________________________ Work Order No.___________________ Recommended Test Interval - 1 Year/2000 hours Date___________________ Recommended next test date ___________________ Ambient temperature ___________________ Offset Performance Test Zero Error Test... - Page 46 Chapter 3: Testing Performance Performance Test Record Offset Gain Test Vertical Calculated Offset Gain Aux Out DMM+ DMM- DMM0 Scope+ Scope- Scope0 Sensitivity Offset Gain Error Test Setting Error Limits Channel 1 5 mV/div ±400 mV ±2 % 10 mV/div ±400 mV ±2 % 20 mV/div...

- Page 47 Chapter 3: Testing Performance Performance Test Record DC Gain Test Vertical Calculated DC Gain Error Aux Out DMM+ DMM- Scope+ Scope- Sensitivity DC Gain Test Limits Setting Error Channel 1 5 mV/div ±15 mV ±2 % 10 mV/div ±30 mV ±2 % 20 mV/div ±60 mV...

- Page 48 Chapter 3: Testing Performance Performance Test Record Analog Bandwidth - Maximum Frequency Check Max frequency: DSO/DSA90254A = 2.5 GHz, DSO/DSA90404A = 4.0 GHz, DSO/DSA90604A = 6.0 GHz, DSO/DSA90804A = 8.0 GHz DSO/DSA91204A = 12.0 GHz (11.8 GHz at 5 mV/div), DSO/DSA91304A = 12.0 GHz (11.8 GHz at 5 mV/div). Measurement Vin @ 50 MHz Vout @ 50...

- Page 49 Chapter 3: Testing Performance Performance Test Record Test Limits Results Time Scale Limit Calculated Measured time Pass/Fail Accuracy TSA Spec scale error Limit is based on years since oscilloscope’s last calibration TSA = ±(0.4 + 0.5(Years Since Calibration)) ppm ___________ ___________ ___________...

- Page 50 Chapter 3: Testing Performance Performance Test Record...

-

Page 51: Troubleshooting

Safety 52 Tools Required 52 ESD Precautions 52 Default Setup 52 To troubleshoot the oscilloscope 53 Primary Trouble Isolation 54 Power Supply Trouble Isolation 57 Display Trouble Isolation 71 To check the backlight inverter voltages 73 To check the display board video signals 74 Front Panel Display Trouble Isolation 75 Front Panel Trouble Isolation 77 Motherboard Verification 78... -

Page 52: Safety

Troubleshooting This section provides troubleshooting information for the Agilent Technologies 90000 Series oscilloscopes. The service strategy of this oscilloscope is replacement of defective assemblies. Safety Read the Safety Notices at the back of this manual before servicing the oscilloscope. Before performing any procedure, review it for cautions and warnings. -

Page 53: To Troubleshoot The Oscilloscope

Chapter 4: Troubleshooting To troubleshoot the oscilloscope To troubleshoot the oscilloscope The troubleshooting procedure is used to isolate problems to a faulty assembly. When you find the faulty assembly, use the disassembly and assembly procedures in "Replacing Assemblies," beginning on page 89 to replace the assembly. The primary procedural tool in this section is the Primary Trouble Isolation section. -

Page 54: Primary Trouble Isolation

Chapter 4: Troubleshooting Primary Trouble Isolation Primary Trouble Isolation Perform power-up. Connect the oscilloscope power cord and press the power button in the lower left corner of the front panel. If the oscilloscope is working properly, it will start up and the graticule will appear on the screen. - Page 55 Chapter 4: Troubleshooting Primary Trouble Isolation Check the front panel response by running the Keyboard and LED self tests. Use this procedure to verify correct keyboard operation. 1 Select Self Test from the Utilities menu. 2 Select Keyboard Test from the Self Test drop down list box, then click Start. A new window appears with a symbolic representation of the keyboard.

- Page 56 Chapter 4: Troubleshooting Primary Trouble Isolation Figure 4-3 LED Test Screen 3 Repeatedly press the Single button on the front panel to step through and highlight each LED symbol in the test screen. You can also step through the LEDs by pressing the <<Prev or Next>>...

-

Page 57: Power Supply Trouble Isolation

Chapter 4: Troubleshooting Power Supply Trouble Isolation Power Supply Trouble Isolation W A R N I N G SHOCK HAZARD! The maintenance described in this section is performed with power supplied to the oscilloscope and with the protective covers removed. Only trained service personnel who are aware of the hazards involved should perform the maintenance. - Page 58 Chapter 4: Troubleshooting Power Supply Trouble Isolation Figure 4-4...

- Page 59 Chapter 4: Troubleshooting Power Supply Trouble Isolation These trouble isolation instructions help isolate the problem to the assembly level when the power system is not operating. Because of advanced power system protection features, the problem may not be with the supply itself, and therefore you will need to work through the procedure systematically to determine the source of the fault.

-

Page 60: Under-Voltage Fault

Chapter 4: Troubleshooting Under-Voltage Fault Under-Voltage Fault If the oscilloscope turns off without you pressing the front panel power button then the first step is to unplug the oscilloscope so the +5V standby supply can fully discharge (this takes around 30 seconds). Then plug the oscilloscope back in. Press the front panel power button and count how many seconds it takes for the oscilloscope to lose power again (once the oscilloscope loses power, keep it plugged in). - Page 61 Chapter 4: Troubleshooting Under-Voltage Fault (LOWER ACQ). If any of the following three indicator LEDs are illuminated (BP POL FAIL, NEG SUPPLY FAIL, or FPGA SUPPLY FAIL), replace the backplane assembly. If the FP SUPPLY FAIL LED is on by itself, there may be a problem with one of the supplies that goes to the front panel assembly or there may be a problem on the front panel assembly itself.

- Page 62 Chapter 4: Troubleshooting Under-Voltage Fault oscilloscope. On the backplane assembly, measure the resistance across the FET (Q1409) between +12V and ground as shown in Figure 4-10 (Q1409 is located in the upper right hand corner of the backplane) or measure the resistance across the bulk supply input pins on the backplane assembly.

- Page 63 Chapter 4: Troubleshooting Under-Voltage Fault If there is still a short circuit, then both acquisition boards need to be removed. Once the acquisition assemblies have been removed and unplugged from the backplane assembly, measure each assembly individually to see if there is a short between the +12V net and ground (see the figure below).

- Page 64 Chapter 4: Troubleshooting Under-Voltage Fault Figure 4-10 This figure shows how to measure the backplane assembly resistance between +12V and ground across Q1409. If the oscilloscope still will not power on after you have followed the required steps in this Power Supply Trouble Isolation section (and assuming you have looked through the other two sections included in this Power Supply Trouble Isolation section to ensure your problem cannot be fixed there), refer to the Motherboard Verification section in this chapter for additional...

-

Page 65: Over-Temperature Fault

Chapter 4: Troubleshooting Over-Temperature Fault Over-Temperature Fault If the oscilloscope turns off without you pressing the front panel power button, the first step is to unplug the oscilloscope so the +5V standby supply can fully discharge (this takes around 30 seconds). - Page 66 Chapter 4: Troubleshooting Over-Temperature Fault Once you can see the case fans, apply AC power to the instrument and turn it on if it does not start up automatically. Visually check to see if any of the fans are not turning. If all the fans are not turning, it is probably a problem with the high side drive circuitry for the case fans.

- Page 67 Chapter 4: Troubleshooting Over-Temperature Fault Apply AC power and turn the instrument on if it does not start up on its own. Observe whether the trigger ICs fan is turning. If it is not, replace it and redo this part of the diagnostic test. If it is turning and the instrument turns off after four seconds or more then consider the following.

-

Page 68: Over-Voltage Fault

Chapter 4: Troubleshooting Over-Voltage Fault Over-Voltage Fault If the oscilloscope turns off without you pressing the front panel power button, the first step is to unplug the oscilloscope so the +5V standby supply can fully discharge (this takes around 30 seconds). - Page 69 Chapter 4: Troubleshooting Over-Voltage Fault Figure 4-15 The second and third groups of over-voltage LEDs are located behind this fan Fan opening to look through to see the second and third groups of over-voltage indicator LEDs. The following picture (Figure 4-16) shows the fan opening with the fan removed. This is done to shows where these LEDs are located on the acquisition assemblies and is not required in your actual diagnosis.

- Page 70 Chapter 4: Troubleshooting Over-Voltage Fault Figure 4-16 The acquisition assembly nearest the bottom of the instrument is the channels 1 and 2 acquisition assembly (LOWER ACQ) while the one above it is the channels 3 and 4 acquisition assembly (UPPER ACQ). If you look through the fan and see any of these over-voltage LEDs illuminated, that acquisition assembly needs to be replaced.

-

Page 71: Display Trouble Isolation

Chapter 4: Troubleshooting Display Trouble Isolation Display Trouble Isolation... - Page 72 Chapter 4: Troubleshooting Display Trouble Isolation No Display Trouble Isolation Remove cabinet and Replace Display install fan guard Board Check fan connections and Display on Done. power-on oscilloscope? Fans running? Go to 'Power Supply Power LED lit? Trouble Isolation.' Replace Motherboard Assembly Connect external...

-

Page 73: To Check The Backlight Inverter Voltages

Chapter 4: Troubleshooting To check the backlight inverter voltages To check the backlight inverter voltages The backlight inverter board MP13 is located in the front-left corner of the oscilloscope (as you face the front panel). • There is an input connector at one side of the board. •... -

Page 74: To Check The Display Board Video Signals

Chapter 4: Troubleshooting To check the display board video signals To check the display board video signals The video signals are checked on the 32-pin connector J2 on the display board MP12. You can use an oscilloscope with a bandwidth of at least 100 MHz to verify the signals. Even-numbered pins are closest to the PC board. -

Page 75: Front Panel Display Trouble Isolation

Chapter 4: Troubleshooting Front Panel Display Trouble Isolation Front Panel Display Trouble Isolation Front Panel Display Trouble Isolation Connect external monitor to VGA port. Turn unit on. Does display appear Replace on ext. monitor motherboard. Check display cable connection to display card front Panel and LCD black? - Page 76 Chapter 4: Troubleshooting Front Panel Display Trouble Isolation W A R N I N G SHOCK HAZARD! The backlight inverter assembly, which is mounted at the front corner of the oscilloscope near the flat-panel display, operates at 1.65 kV at turn on. DO NOT handle this assembly while it is in operation.

-

Page 77: Front Panel Trouble Isolation

Chapter 4: Troubleshooting Front Panel Trouble Isolation Front Panel Trouble Isolation Front Panel Trouble Isolation Follow the keyboard troubleshooting guide for just the power button. Go to 'Primary Trouble Isolation'. -

Page 78: Motherboard Verification

Chapter 4: Troubleshooting Motherboard Verification Motherboard Verification If you have been through the Power Supply Trouble Isolation section of this chapter and the oscilloscope still does not stay powered up, the problem may be with the motherboard. To diagnose this problem, follow these steps. First remove the handle, outer case, and top shield. -

Page 79: To Setup The Bios

Chapter 4: Troubleshooting To setup the BIOS To setup the BIOS If the BIOS settings become corrupt, the Infiniium oscilloscope PC motherboard will not recognize the hard drive and the oscilloscope may not start. To configure the motherboard BIOS parameters to the default settings, follow these steps: Connect the power cable to the Infiniium oscilloscope. -

Page 80: Acquisition/Backplane Assembly Trouble Isolation - Scope Self Tests

Chapter 4: Troubleshooting Acquisition/Backplane Assembly Trouble Isolation - Scope Self Tests Acquisition/Backplane Assembly Trouble Isolation - Scope Self Tests If the Acquisition assemblies or Backplane assembly have been removed by a prior procedure, reinstall them. Power up the oscilloscope and then go under Utilities > Self Test. Select the Scope Self Test option from the Self Test pull-down menu and then press the Start Test button. - Page 81 Chapter 4: Troubleshooting Acquisition/Backplane Assembly Trouble Isolation - Scope Self Tests Timebase Test Group • Timebase Interpolator Test - This test validates the timebase interpolator hardware by verifying that it is able to produce unique values for different trigger settings. If this test fails, there may be a problem with the timebase interpolator IC located on the backplane board.

- Page 82 Chapter 4: Troubleshooting Acquisition/Backplane Assembly Trouble Isolation - Scope Self Tests Misc. Scope Test Group • Temp Sensor Test - This test verifies that all of the temperature sensors in the oscilloscope are reading values within the expected range. Temperature sensors exist for each of the Hedwig memory controller ICs, each of the ADC ICs, and each of the front end ICs.

-

Page 83: Autoprobe Board Trouble Isolation

Chapter 4: Troubleshooting AutoProbe Board Trouble Isolation AutoProbe Board Trouble Isolation AutoProbe Board Trouble Isolation Inspect the cable between the AutoProbe assembly and the power board. Cable Replace bad cable. Turn unit on. Does Replace unit turn AutoProbe assembly. Go to 'Primary Trouble Isolation. -

Page 84: To Check The Keyboard; Trouble Isolation Procedure

Chapter 4: Troubleshooting To check the keyboard; Trouble Isolation Procedure To check the keyboard; Trouble Isolation Procedure Use this procedure only if you encounter key failures in the keyboard self test procedure. If any knobs fail, replace the keyboard assembly. Disconnect the power cord and remove the cover. -

Page 85: To Check The Leds

Chapter 4: Troubleshooting To check the LEDs To check the LEDs If you see a failure with the on/off switch backlight LED, replace the ON/OFF board. If the LED will still not illuminate, replace the motherboard and see if this fixes the problem. If the LED still does not work, the last option is to check the on/off cable connecting the ON/OFF board to the motherboard. -

Page 86: Software Revisions

• Select About Infiniium... from the Help Menu. A dialog box appears showing the current version number for the scope software and on-line information system software. This information may be useful when contacting Agilent Technologies for further service information. See Figure 4-20. -

Page 87: To Check Probe Power Outputs

Chapter 4: Troubleshooting To check probe power outputs To check probe power outputs Probe power outputs are on the front panel, surrounding each BNC input. Use the table and figure to the right Supply to check the power output at the connectors. - Page 88 Chapter 4: Troubleshooting To check probe power outputs...

-

Page 89: Replacing Assemblies

ESD Precautions 90 Tools Required 90 To return the oscilloscope to Agilent Technologies for service 91 To remove and replace the cover, top plate, and bottom plate 92 To remove and replace the on/off board 101 To remove and replace the backlight inverter board 103... -

Page 90: Esd Precautions

Replacing Assemblies Use the procedures in this chapter when removing and replacing assemblies and parts in the Agilent Technologies oscilloscopes. In general, the procedures that follow are placed in the order to be used to remove a particular assembly. The procedures listed first are for assemblies that must be removed first. -

Page 91: To Return The Oscilloscope To Agilent Technologies For Service

Pack the oscilloscope in foam or other shock absorbing material and place it in a strong shipping container. You can use the original shipping materials or order materials from an Agilent Technologies Sales Office. If neither are available, place 8 to 10 cm (3 to 4 inches) of shock-absorbing material around the oscilloscope and place it in a box that does not allow movement during shipping. -

Page 92: To Remove And Replace The Cover, Top Plate, And Bottom Plate

Chapter 5: Replacing Assemblies To remove and replace the cover, top plate, and bottom plate To remove and replace the cover, top plate, and bottom plate Use this procedure to remove and replace the cover, top plate, and bottom plate. When necessary, refer to other removal procedures. - Page 93 Chapter 5: Replacing Assemblies To remove and replace the cover, top plate, and bottom plate Figure 5-3 Figure 5-4 Carefully slide the cover towards the rear of the instrument and off the chassis as shown in Figure 5-5. Figure 5-5 Once the cover is removed, you can remove the top plate by removing the twelve Torx...

- Page 94 Chapter 5: Replacing Assemblies To remove and replace the cover, top plate, and bottom plate T10 screws from its edges as shown in Figure 5-6. Then pull back on the top plate and lift off as shown in Figure 5-7. Figure 5-6 Figure 5-7 To remove the bottom plate, flip the oscilloscope upside down and remove the three...

- Page 95 Chapter 5: Replacing Assemblies To remove and replace the cover, top plate, and bottom plate Figure 5-8 Figure 5-9 Figure 5-10 To replace the cover, top plate, and bottom plate, reverse the above procedure. Please note that all sheet metal holes that are supposed to have screws placed in them are...

- Page 96 Chapter 5: Replacing Assemblies To remove and replace the cover, top plate, and bottom plate marked by lines on four sides of the hole as shown in Figure 5-11 Figure 5-11 C A U T I O N PROPERLY TIGHTEN HANDLE AND SCREWS! Tighten the side handle screws to 2.4 Nm (21 in-lbs).

-

Page 97: To Remove And Replace The Front Panel Bezel And Front Panel Circuit Assembly

Chapter 5: Replacing Assemblies To remove and replace the front panel bezel and front panel circuit assembly To remove and replace the front panel bezel and front panel circuit assembly Disconnect the power cable and remove the cover, top plate, and bottom plate as described above in the section on removing the cover, top plate, and bottom plate. - Page 98 Chapter 5: Replacing Assemblies To remove and replace the front panel bezel and front panel circuit assembly Figure 5-13 Figure 5-14 Remove two Torx T10 screws from the front panel printed circuit assembly as shown in Figure 5-15.

- Page 99 Chapter 5: Replacing Assemblies To remove and replace the front panel bezel and front panel circuit assembly Figure 5-15 Disengage the tabs located along the edges of the control panel faceplate. There are three tabs located along the right hand side (see Figure 5-16). There are two additional tabs located on the top and bottom of the left edge.

- Page 100 Chapter 5: Replacing Assemblies To remove and replace the front panel bezel and front panel circuit assembly Figure 5-16 Figure 5-17 This figure shows the top left hand side tab for the control panel faceplate. The view is through the top cavity, standing at the rear of the instrument, and looking towards the front (over the backplane board).

-

Page 101: To Remove And Replace The On/Off Board

Chapter 5: Replacing Assemblies To remove and replace the on/off board Figure 5-18 This figure shows the other left hand side tab for the control panel faceplate. This view is with the oscilloscope turned on its side and looking at this tab from underneath the instrument. To replace the front panel assembly, reverse the above procedure. - Page 102 Chapter 5: Replacing Assemblies To remove and replace the on/off board Figure 5-20 To replace the on/off board, reverse the above procedure.

-

Page 103: To Remove And Replace The Backlight Inverter Board

Chapter 5: Replacing Assemblies To remove and replace the backlight inverter board To remove and replace the backlight inverter board Use this procedure to remove and replace the backlight inverter board. When necessary, refer to other removal procedures. The graphics in this chapter are representative of the oscilloscope at the time of this printing. -

Page 104: To Remove And Replace The Touch Screen, The Front Deck, And The Controller Assembly

Chapter 5: Replacing Assemblies To remove and replace the touch screen, the front deck, and the controller assembly To remove and replace the touch screen, the front deck, and the controller assembly Use this procedure to disassemble and reassemble the keyboard, touch screen, and flat-panel display. - Page 105 Chapter 5: Replacing Assemblies To remove and replace the touch screen, the front deck, and the controller assembly To remove the front deck off the chassis, remove four Torx T10 screws from the front deck (two on the right hand side and two on the left hand side) - See Figure 5-24. Figure 5-24 Turn the oscilloscope upside down or on its side and look through the bottom cavity to see the SMA connectors attached to the front deck (Figure 5-25).

- Page 106 Chapter 5: Replacing Assemblies To remove and replace the touch screen, the front deck, and the controller assembly Figure 5-26 You can now remove the controller board and backlight inverter board from the back of the front deck if these need to be replaced by removing the Torx T20 screws attached to them.

-

Page 107: To Remove And Replace The Motherboard

Chapter 5: Replacing Assemblies To remove and replace the motherboard To remove and replace the motherboard Disconnect the power cable and remove the cover and top plate. Disconnect all the cables from the motherboard (see a list of these cables on page 117). Remove the Torx T10 screws attaching the motherboard to the frame (Figure 5-28). -

Page 108: To Remove And Replace The Acquisition Boards/Backplane Assembly

Chapter 5: Replacing Assemblies To remove and replace the acquisition boards/backplane assembly To remove and replace the acquisition boards/backplane assembly Use this procedure to remove and replace the acquisition boards/backplane assembly. When necessary, refer to other removal procedures. The graphics in this chapter are representative of the oscilloscope at the time of this printing. - Page 109 Chapter 5: Replacing Assemblies To remove and replace the acquisition boards/backplane assembly Figure 5-32 Remove the Torx T20 screws from the top of the backplane assembly (Figure 5-33). Figure 5-33 Flip the instrument so it is upside down or on its side. Remove the Torx T20 screws from back lower side of the rear of the instrument (Figure 5-34).

- Page 110 Chapter 5: Replacing Assemblies To remove and replace the acquisition boards/backplane assembly Figure 5-34 Remove the two Torx T20 screws from the underside of the backplane assembly (Figure 5-35). Figure 5-35 If unit is not upside down (if you chose to just lay it on its side), go ahead and flip it upside down right now.

- Page 111 Chapter 5: Replacing Assemblies To remove and replace the acquisition boards/backplane assembly Figure 5-36...

-

Page 112: To Remove The Backplane Assembly From The Acquisition Assemblies

Chapter 5: Replacing Assemblies To remove the backplane assembly from the acquisition assemblies To remove the backplane assembly from the acquisition assemblies Remove the entire acquisition/backplane assembly as described in the previous section. Remove the four Torx T20 screws (two per acquisition assembly) on the side of the backplane assembly (Figure 5-37). -

Page 113: To Set The Calibration Factors After Replacing The Acquisition Board

Critical Specifications Recommended Model/ Part Numbers Digital Multimeter No substitute Agilent 34401A 10 MHz Signal Frequency accuracy better than 0.4 ppm Agilent 53131A with Source (required for Opt. 010 time scale calibration) Cable Assembly No substitute Agilent 54855-61620 Cable Assembly... - Page 114 Chapter 5: Replacing Assemblies To set the calibration factors after replacing the acquisition board c Pull down the Utilities menu and select Calibration. d Uncheck the Cal Memory Protect box to allow calibration. e Click on Start to start the calibration procedure. Follow the on-screen instructions as calibration proceeds.

-

Page 115: To Remove And Replace The Hard Disk Drive And The Hard Drive Control Board

Chapter 5: Replacing Assemblies To remove and replace the hard disk drive and the hard drive control board To remove and replace the hard disk drive and the hard drive control board Use this procedure to remove and replace the hard disk drive. When necessary, refer to other removal procedures. - Page 116 Chapter 5: Replacing Assemblies To remove and replace the hard disk drive and the hard drive control board Figure 5-41 To replace the hard disk drive and hard drive control board, reverse the above procedure.

-

Page 117: Cable Removal (For Replacing The Motherboard)

Chapter 5: Replacing Assemblies Cable removal (for replacing the motherboard) Cable removal (for replacing the motherboard) This section shows the various cables that need to be removed when replacing the motherboard. Disconnect the power cable and remove the top cover. Disconnect all cables from the motherboard. - Page 118 Chapter 5: Replacing Assemblies Cable removal (for replacing the motherboard) Figure 5-43 S A T A ca ble betwe en m otherboard a nd ha rd drive Figure 5-44 F ront pa ne l U S B ca ble Figure 5-45 S A T A ca bles between ba ckplane a nd...

- Page 119 Chapter 5: Replacing Assemblies Cable removal (for replacing the motherboard) Figure 5-46 D ispla y ca ble between m otherboard a nd front pa nel Figure 5-47 P ower harness between ba ckplane a nd m otherboard Figure 5-48 P ower cab le for C P U fa n...

- Page 120 Chapter 5: Replacing Assemblies Cable removal (for replacing the motherboard) Figure 5-49 P ower harness between backplane and m otherboard Figure 5-50 O n/ O ff ca ble...

- Page 121 Chapter 5: Replacing Assemblies Cable removal (for replacing the motherboard) Figure 5-51 Motherboard and cables in performance-enhanced 90000 A-Series models...

-

Page 122: To Remove And Replace The Power Supply

Chapter 5: Replacing Assemblies To remove and replace the power supply To remove and replace the power supply Use this procedure to remove and replace the power supply. When necessary, refer to other removal procedures. The graphics in this chapter are representative of the oscilloscope at the time of this printing. -

Page 123: To Remove And Replace The Fans

Chapter 5: Replacing Assemblies To remove and replace the fans To remove and replace the fans W A R N I N G AVOID INJURY! The fan blades are exposed both inside and outside the chassis. Disconnect the power cable before working around the fan. -

Page 124: To Remove And Replace The Power Cord

Chapter 5: Replacing Assemblies To remove and replace the power cord To remove and replace the power cord Use this procedure to remove and replace the power cord. When necessary, refer to other removal procedures. The graphics in this chapter are representative of the oscilloscope at the time of this printing. -

Page 125: To Remove And Replace The Usb Or Gpib Port

Chapter 5: Replacing Assemblies To remove and replace the USB or GPIB port To remove and replace the USB or GPIB port Use this procedure to remove and replace the USB or GPIB port (GPIB is an option and may not be on your oscilloscope). - Page 126 Chapter 5: Replacing Assemblies To remove and replace the USB or GPIB port...

-

Page 127: Replaceable Parts

Ordering Replaceable Parts 128 Listed Parts 128 Unlisted Parts 128 Direct Mail Order System 128 Exchange Assemblies 128 Exploded Views 129 Replaceable Parts List 133 Replaceable Parts... -

Page 128: Ordering Replaceable Parts

Ordering Replaceable Parts Listed Parts To order a part in the parts list, quote the Agilent Technologies part number, indicate the quantity desired, and address the order to the nearest Agilent Technologies Sales Office. Unlisted Parts To order a part not listed in the parts list, include the oscilloscope part number, oscilloscope serial number, a description of the part (including its function), and the number of parts required. -

Page 129: Exploded Views

Chapter 6: Replaceable Parts Exploded Views Exploded Views Front Frame and Front Panel... - Page 130 Chapter 6: Replaceable Parts Exploded Views Fan and Acquisition Assembly...

- Page 131 Chapter 6: Replaceable Parts Exploded Views Power Supply and PC Motherboard...

- Page 132 Chapter 6: Replaceable Parts Exploded Views Sleeve and Accessory Pouch...

-

Page 133: Replaceable Parts List

It is a part of the chassis on standard models.) 54913-68701 Replacement HDD for M880/XP-based 90000 Series scopes 54913-83503 Infiniium 90000 A-Series imaged hard-drive, version M880-9XB (Service Centers only) 54913-83505 Infiniium series Imaged HDD for M890/WinXP (Service Centers only) - Page 134 Chapter 6: Replaceable Parts Replaceable Parts List Replaceable Parts Ref. Agilent Part Des. Number Description 54913-68718 Replacement HDD for M890/Win7-based DSO90000 series scopes 54932-83501 Removable hard drive only: Imaged Solid State HDD for M890/Win7-based 90000 Series scopes (Service Centers only)

- Page 135 Chapter 6: Replaceable Parts Replaceable Parts List Replaceable Parts Ref. Agilent Part Des. Number Description MP18 54913-00103 RHDD Deck MP19 54913-94306 Label - Rear Panel without RHDD MP20 54913-62301 Accessory Pouch MP21 54913-94307 RHDD Label MP22* 54913-04101* Cover (standard models)

- Page 136 Chapter 6: Replaceable Parts Replaceable Parts List...

- Page 137 Block-Level Theory 139 Power Supply Assembly 141 Monitor Assembly 141 Acquisition System 141 Front Panel 142 Motherboard 144 On/Off Board 144 Theory of Operation...

-

Page 138: Theory Of Operation

Chapter 7: Theory of Operation Figure 7-1 Oscilloscope Block Diagram... -

Page 139: Block-Level Theory

Theory of Operation This Service Guide supports troubleshooting the Agilent Technologies oscilloscopes to assembly level. Theory of operation is included only as supplemental information. It is not comprehensive enough for component-level troubleshooting. Block-Level Theory The front panel provides: • Dedicated knobs and pushbuttons for major oscilloscope functions. - Page 140 Chapter 7: Theory of Operation Block-Level Theory Figure 7-2 Backplane Board Acquisition Boards...

- Page 141 Chapter 7: Theory of Operation Block-Level Theory Power Supply Assembly The AC input to the power supply is 100–240 VAC ±10%. Maximum input power is 800 W. The AC input frequency is 47 to 63 Hz. Filtered voltages of +3.3 V, +2.5 V, +1.8 V, +1.2 V, -6 V, -5.2 V, -5 V, and –2.3 V are supplied and distributed throughout the oscilloscope.

- Page 142 Chapter 7: Theory of Operation Block-Level Theory Figure 7-3 Backplane assembly block diagram Front Panel The front panel board combines functions from the main keyboard and the Autoprobe interface board in a single PCA. Refer to the keyboard block diagram in Figure 7-4. The keyboard links to the scope PC motherboard through a high-speed USB 2.0 interface.

- Page 143 Chapter 7: Theory of Operation Block-Level Theory Figure 7-4 Keyboard block diagram Disk Drive The hard disk drive is a high-capacity, shock-resistant unit. It is used to store the oscilloscope’s operating system and certain system configuration data. The drive can also be used to store and recall oscilloscope setups and waveforms.

- Page 144 Chapter 7: Theory of Operation Block-Level Theory Motherboard The motherboard provides all system control and interface functions for the oscilloscope. It contains a CPU, ROM, and RAM; keyboard and mouse interfaces, serial and parallel interfaces, CDROM, hard disk drive interface, PCI buses, etc. Display Board The Display Board controls the flat-panel display monitor.

- Page 145 Chapter 7: Theory of Operation Block-Level Theory Figure 7-5 Config Hedwig Hedwig PROM Memory Memory Controller Controller JTAG Conn JTAG Conn FPGA Acq board Philips PCIe SATA Cables Conn Main 1011A Hedwig Hedwig FPGA Memory Memory Controller Controller Trigger FPGA FPGA Acq board Configuration...

- Page 146 Figure 7-6 Acquisition board block diagram...

- Page 147 • Do not install substitute parts or perform any unauthorized modification to the instrument. Agilent Technologies P.O. Box 2197 1900 Garden of the Gods Road Colorado Springs, CO 80901...

- Page 148 Do not proceed agreement and written consent regard to this manual and beyond a WARNING from Agilent Technologies, Inc. as any information contained governed by United States and notice until the indicated herein, including but not lim- international copyright laws.