Table of Contents

Advertisement

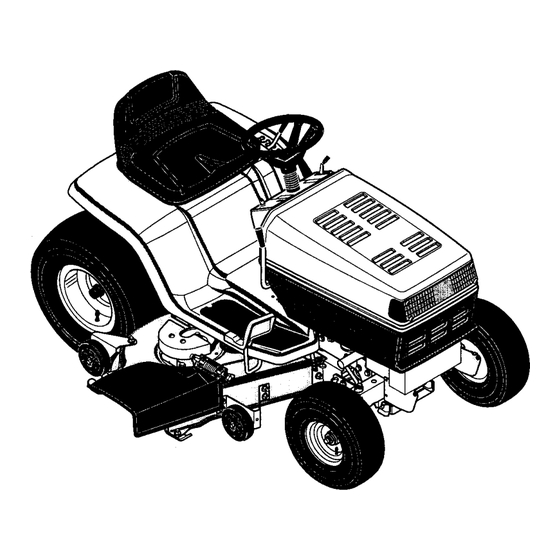

f

PFRFORMANCE

_SA_E

This Instruction Book Contains Information

For Several Models. Read And Keep This Book For

ture Reference, This Book Contains Important Information On:

TY;ASSEMBLY, OPERATION AND MAINTENANCE.

PRODUCT

INFORMATION

The owner

must be certain that all the product

information

is included

with this unit.

This Information

includes

the INSTRUCTION

BOOKS,

the REPLACEMENT

PARTS

J

and the WARRANTIES.

This Information

must be included

to make

sure state laws and other laws are followed.

JJ

Model

50565x89

Record The Following Information About Your Unit. This Information

is Necessary When Ordering Parts Or In Case Of Loss Or Theft.

WHERE PURCHASED:

DATE PURCHASED:

Month

Day

Year

MODEL NO.:

DATE OF MANUFACTURE:

BUILT

iN

THE

_,_12008B

j

Advertisement

Table of Contents

Summary of Contents for YARD KING Performance 50565x89

- Page 1 Model 50565x89 Record The Following Information About Your Unit. This Information is Necessary When Ordering Parts Or In Case Of Loss Or Theft. WHERE PURCHASED: DATE PURCHASED:...

-

Page 2: Table Of Contents

TABLE OF CONTENTS HOW TO CHECK THE MUFFLER ......WARRANTY ......... HOW TO REMOVE AND INSTALL THE BLADE ..... RESPONSIBILITY OF THE OWNER ....HOW TO SHARPEN THE BLADE ......SAFETY RULES ........HOW TO ADJUST THE BLADE ROTATION CONTROL .. -

Page 3: Responsibility Of The Owner

OWNER'S INFORMATION chased in an assembled condition. On assembled units, it is the re- This instruction book isfor several different models. The instructions sponsibility of the owner to make sure the unit is correctly are writtenfor a person with some mechanical ability.Like most ser- assembled. - Page 4 OWNER'S INFORMATION 20, Do not use this machine if you are mentally or physically unable to operate this machine safely. II. Slope operation Slopes and rough terrain are major factors related to loss-of-control and tip-over accidents, which can result In severe injury or death.

- Page 5 SAFE MOWING GUIDE controls and how they work. In an Each person t hatoperates power equipment must l earn tousecorrect emergency, how fast you can stop the blade is important. Learn how to control safe mowing procedures. To help you the mower at all times.

- Page 6 SAFE MOWING GUIDE engine and transmission cool before When you mow, remember that children store, you must still check the mower are attracted to the mower. Always use servicing the mower. Remember, exhaust according to the assembly instructions. caution when mowing around obstacles fumes are dangerous.

- Page 7 SAFE MOWING GUIDE feel new or excessive vibration, Also, the grass bagger will function better a blade that is not sharp or at a slow immediately stop the engine and check for when the engine is operating at maximum engine speed you can damage the grass. Move the throttle control to the FAST the problem.

- Page 8 STEPS TO FOLLOW BEFORE MOWING • Be sure to dress correctly. Wear hard shoes, not sandals or tennis shoes. • Examine the blade. A blade that is bent, cracked, or damaged must be replaced with a factory replacement blade. • Fill the fuel tank outside.

-

Page 9: Before You Mow

BEFORE YOU MOW ASSEMBLY nance to the mower, remove the wire from the spark This instruction book isfor several models. Some parts or accesso- WARNING: Before doing any assembly or mainte- plug. ries are not included on all models. Read and follow the assembly and adjustment instructions for your mower. -

Page 10: How To Prepare The Engine

BEFORE YOU MOW HOW TO INSTALL THE BATTERY CABLES Positive(+) Terminal the positive (+) terminal before you connect the black WARNING: To prevent sparks, fasten the red cable to cable. Use the fasteners shown below to install the battery cables. The fasteners are shown at full size. -

Page 11: Operation

OPERATION Throttle Control Lever Blade Rotation Control Brake Pedal Speed Control Pedal Lever Figure 2 LOCATION OF CONTROLS BLADE ROTATION CONTROL: usethebladerotation OK LIGHT: If this indicator light is on, the engine will not start. control to start and stop the rotation of the blade. 1. -

Page 12: How To Use The Throttle Control

OPERATION ATrACHMENTS HOW TO USE THE BLADE ROTATIONCONTROL This unit can use many different attachments. See the attachment The blade rotation control is next to the steering wheel (Figure 3). page in this book. This unit can pull attachments like a lawn Use the blade rotation control to engage the blade(s) or to operate sweeper, a lawn aerator, or a hopper spreader. -

Page 13: How To Use The Speed Control

OPERATION HOW TO DRIVE IN REVERSE HOW TO USE THE SPEED CONTROL PEDAL Look to the rear. The drive system uses a Hydrostatic Automatic Drive transmission. The Hydrostatic transmission is very easy to operate. This type of Slowly push the speed control pedal to the REVERSE drive system does not require a shift lever or a clutch pedal. -

Page 14: How To Set The Parking Brake

OPERATION HOW TO SET THE PARKING BRAKE Completely push the brake pedal forward, lift the parking brake lever (Figure 6). Remove your foot from the brake pedal and then release the parking brake lever. Make sure the parking brake will hold the unit. -

Page 15: Howto Operatewith The Mower Housing

OPERATION HOWTO OPERATEWITH THE MOWER HOUSING Move the throttle control to the SLOW position. WARNING: The deflector is a safety device. Do not re- move the deflector. The deflector forces the dis- Move the blade rotation control to the ENGAGE position. charged material toward t he ground. -

Page 16: Before Starting The Engine

OPERATION BEFORE STARTING THE ENGINE CAUTION: A mixture of alcohol (ethanol or methanol) and gasoline (called gasohol), will attract moisture and cause acid deposits during storage. While the unit Is In storage, the acids CHECK THE OIL in the fuel can damage the fuel system. NOTE: The engine was shipped from the factory filled with o11. -

Page 17: Operating Tips

OPERATION OPERATING TIPS Check the blade rotation control for correct adjustment. For the Before you make an inspection, adjustment (except forthe car- buretor) or repair, make sure the wire fTomthe spark plug is dis- blade(s) to disengage correctly, the adjustment must be cor- connected, rect. -

Page 18: Maintenance

MAINTENANCE MAINTENANCE CHART RRST EVERY EVERY EVERY EACH BEFORE PROCEDURE HOURS HOURS HOURS HOURS STORAGE Blade, Inspect and Sharpen Blade Rotation Control, Check Brake, Check Motion Drive Belt, Check Tires, Check Battery, Check and Charge Battery, Clean Lubrication Hydrostatic Cooling Fan and Fins, Check V"... -

Page 19: How To Remove And Install The Blade

MAINTENANCE "lighten the nut that holds the blade to a torque of 35 foot INSPECT BLADE pounds (47,5 N-m). WARNING: Before you inspect or remove the blade, 10. Install the mower housing. See "How To Install The Mower disconnect the wire to the spark plug. If the blade hits Housing". -

Page 20: How To Adjust The Blade Rotation Control

MAINTENANCE HOW TO ADJUST THE BLADE ROTATION CONTROL 6. Attachthewiretothesparkplug. Uowforashortdistanceand again check the quality of cut. If necessary, move the blade drive spring to the bottom ho/e. ARNING: To prevent an injury, the blade rotation control must operate correctly. Again check the quality of cut. -

Page 21: How To Check And Adjust The Drive Brake

MAINTENANCE HOW TO CHECK AND ADJUST THE DRIVE BRAKE Completely push the brake pedal forward. Set the parking brake. Move the automatic drive disconnect to the PUSH position, Push the unit. If the rear wheels rotate, adjust or replace the brake pads. Adjust the drive brake as foUows. -

Page 22: Howto Adjust The Speed Control Pedal

MAINTENANCE HOWTO ADJUST THE SPEED CONTROL PEDAL If the unit will not go into REVERSE or if the unit moves very slowly Yoke Assembly in REVERSE, adjust the speed control pedal as follows. Stop the engine. Setthe parking brake. Remove the hair pin from the adjuster nut (Figure 17). Dis- connect the adjuster nut from the yoke assembly. -

Page 23: Where To Lubricate

MAINTENANCE WHERE TO LUBRICATE "j Models with grease fittings: Lubricate with grease gun. Apply grease with a brush to the areas shown. Lubricate the areas shown with engine oil. NOTE: Apply grease to the steering gear assembly. CAUTION: If the unit Is operated In dry areas that have sand, use a dry graphite spray to lubricate the unit, Figure 19 HOW TO OPERATE... -

Page 24: How To Remove The Mower Housing

MAINTENANCE HOW TO INSTALL THE MOWER HOUSING HOW TO REMOVE THE MOWER HOUSING Move the blade rotation control to the DISENGAGE position. Push the mower housing under the right side of the unit. If equipped, remove the gauge wheels. Put the mower drive belt around the stack pulley. Make sure Move the Iltt lever to the level the'V' side of the mower drive belt is against the stack pulley. -

Page 25: How To Adjust The Gauge Wheels

MAINTENANCE HOW TO ADJUST THE GAUGE WHEELS The axle bolts for the gauge wheels were mounted in the LOW cut position.To change the position of the gauge wheels, move the axle bolts as follows. Wheel IMPORTANT: Before you adjust the gauge wheels, you must do •... -

Page 26: How To Level The Mower Housing

MAINTENANCE HOW TO LEVEL THE MOWER HOUSING If the mower housing is level, the blade will cut easier and the lawn will look better. WARNING: Before you make an Inspection, adjust- ment, or repair to the unit, disconnect the wire to the spark plug. -

Page 27: How To Replace The Motion Drive Belt

MAINTENANCE Move the belt guide under the edge of the Idler pulley HOW TO REPLACE THE MOTION DRIVE BELT (Figure32). Tightenthe belt guide. REMOVAL Disengagethe parkingbrake. Remove the mower housing. See the instructions on "How To Installthe belt guide at the middle Idler pulley. Makesurethe Remove The Mower Housing". - Page 28 MAINTENANCE HOW TO REPLACE THE SECONDARY HOW TO REPLACE THE PRIMARY MOWER DRIVE BELT MOWER DRIVE BELT Remove the mower housing. See the instructions on "How To Remove the mower housing. See the instructions on "How To Remove The Mower Housing'. Remove The Mower Housing'.

-

Page 29: How To Replace The Fuses

MAINTENANCE HOW TO REPLACE THE FUSES HOW TO REPLACE THE LIGHT BULB If a fuse is blown, the engine will not start. To easily access the fuse. Raise the tractor hood. Remove the access panel on the console as shown in Figure 34. Remove the fuse and replace with an automotive fuse (Figure 35). -

Page 30: Shooting Chart

TROUBLE SHOOTING CHART Adjust the throttle control. PROBLEM: The engine will not start. Follow the steps, "How To Start The Engine" in this book. Drain the fuel tank. Clean the fuel line. Replace the fuel filter. Electric-Start Models: Clean the battery terminals. Tighten the PROBLEM: A hot engine causes... -

Page 31: Slope Guide

SLOPE GUIDE ..• . .-..7_.D_(_,... SIGHT AND HOLD THIS GUIDE LEVEL WITH A VERTICAL TREE, • ..:._-8 A CORNER OF A STRUCTURE, A POWER LINE POLE, OR A FENCE. " ..T--..• :.."--_. •":..... FOL,,- " .i' .. -

Page 32: Repair Parts

50565X89 REPAIR PARTS NOTE: ALWAYS USE ORIGINAL EQUIPMENT PARTS. ALL UNNUMBERED Use of service/replacement parts other than original ITEMS ARE INTERCHANGEABLE WITH OPPOSITE SIDE equipment parts may void your warranty. 343416A... - Page 33 FRONT CHASSIS ASSEMBLY KEY # PART# DESCRIPTION 94651-821 BRACKET, LH HOOD 94652-821 BRACKET, RH HOOD 711606 SCREW, 5116-18X.75 HHWATAP 94710 DASH 711762 SCREW, 1/4-14X.75 PHPANTAP 316868 WASHER, SHOULDER NYLON .255X.46 711592 SCREW, 1/4-20X.50 WAHHTAP 316868 WASHER, SHOULDER NYLON .255X.46 341611-823 CONSOLE, LOWER ASM.

- Page 34 50565X89 REPAIR PARTS ® ALLUNNUMBERED NOTE: ALWAYS USE ORIGINAL EQUIPMENT PARTS. ITEMS AREINTERCHANGEABLE Use of service/replacement parts other than original WITH OPPOSITESIDE equipment parts may void your warranty. 343393_...

- Page 35 REAR CHASSIS ASSEMBLY PART DESCRIPTION 94629-823 SEAT DECK 95438 FOOTREST PAD RH 95437 FOOTREST PAD LH 94069 CONTAINER, BATTERY 711642 SCREW 1/4-20X.63 HHWATAPSER 94194 PLATE, LIFT DETENT LG. 94492 PLATE-DETENT LOCKOUT 711679 SCREW, .230X.135 PPANTAP10-32B 94154-823 SUPPORT, SEAT 95294 HINGE SEAT PIVOT 711627 NUT, PUSH CAP .375 (28X23) 710136...

- Page 36 50565X89 REPAIR PARTS NOTE: ALWAYS USE ORIGINAL EQUIPMENT PARTS. ALL UNNUMBERED Use of service/replacement parts other than original ITEMS ARE INTERCHANGEABLE equipment parts may void your warranty. WITH OPPOSITE SIDE 343398A...

- Page 37 FRAME ASSEMBLY KEY PART DESCRIPTION 95110 FRAME,RAIL RH 95111 FRAME,RAIL LH 94184 BRACKET, TRANSAXLE 94185 BRACKET, TRANSAXLE 71O079 SCREW, 5/16-18X.75HHWATAP 94002 HITCH PLATE 710079 SCREW, 5/16-18X.75HHWATAP 94431 BRACKET, IDLER/TRUNNION SUPP 710079 SCREW 5/16-18X.75HHWATAP 94187 PLATE, REAR LARGE SEAT DECK 710079 SCREW 5/16-18X.75 HHWATAP 94063 TUBE, LIFTER...

- Page 38 50565X89 REPAIR PARTS ® TORQUE 2540 FT"LBI NOTE: ALWAYS USE ORIGINAL EQUIPMENT PARTS. ALL UNNUMBERED Use of service/replacement parts other than original ITEMS ARE INTERCHANGEABLE equipment parts may void your warranty. WITH OPPOSITE SIDE 343398A...

- Page 39 FRAME ASSEMBLY KEY PART DESCRIPTION 94006 PLATE, ENGINE 710079 SCREW, 5/16-18X.75HHWATAP 710205 NUT, 5/16-18 WDFLLK (15X88) 94306 MUFFLER BRACKET 710079 SCREW, 5/16-18X.75HHWATAP GREASE, ZERK FITTING 94203 AXLE, FRONT CAST IRON 94736 SPINDLE, RH/STD. SPIN/NO BRG 94737 SPINDLE, LH/STD. SPIN/NO BRG 92527 BEARING, SPINDLE 711758...

- Page 40 50565X89 REPAIR PARTS -=;_+ • • • • • °° NOTE: ALWAYS USE ORIGINAL EQUIPMENT PARTS. ALL UNNUMBERED ITEMS ARE INTERCHANGEABLE Use of service/replacement parts other than original WITH OPPOSITE SIDE equipment parts may void your warranty. 3434141 41")

- Page 41 MOTION DRIVE ASSEMBLY PART DESCRIPTION HYDRO, PEERLESS VST205-O23B 711669 SCREW, 5/16-18X2.50 711634 NUT, 5/16-18 WDFLLK (15X88) 94429-821 BRACKET, DISCONNECT 94432-821 TORQUE STRAP 710268 SCREW, 5/16-18X.75 WAHHTAP 711661 BOLT, 5/16-18X.63 CARRLN 711634 NUT, 5/16-18 WDFLLK (15X88) 94422-821 ASSEMBLY, PEDAL (PEERLESSS) 711688 BOLT, 5/16-18X.75 CARRSN 711633 NUT, 5/16-18 HEXWDFLLK WHIZ...

- Page 42 50565X89 REPAIR PARTS TORQUE1_15FT-LB] GREASE APPLIED TO TEETH ON GEAR ![I]ll GREASE APPLIED TO SPINDLE SHAFT ALL UNNUMBERED NOTE: ALWAYS USE ORIGINAL EQUIPMENT PARTS• ITEMS ARE INTERCHANGEABLE Use of service/replacement parts other than original WITH OPPOSITE SIDE equipment parts may void your warranty.

- Page 43 STEERING ASSEMBLY PART DESCRIPTION 94618 HUB CAP 95228 STEERING WHEEL 94520 SHAFT, STEERING 94124 BEARING-LOWER 711606 SCREW, 5/16-18X.75HHWATAPSGIBP 94122 GEAR PINNION 710102 RING, RET E.541D .59SH (11X25) 94755 TIRE & RIM 16X6.5-8 31-1 338512 VALVE STEM 31-2 342115 RIM, CARLISLE 31-3 338513 BEARING...

- Page 44 50565X89 REPAIR PARTS NOTE: ALWAYS USE ORIGINAL EQUIPMENT PARTS• ALLUNNUMBERED Use of service/replacement parts other than original ITEMS AREINTERCHANGEABLE equipment parts may void your warranty. WITH OPPOSITESIDE 343421A ,t.t...

- Page 45 MOWER SUSPENSION ASSEMBLY PART DESCRIPTION 711676 HAIR PIN 94858-821 LINK, LIFT LH EXTENDED 94857-821 LINK, LIFT RH EXTENDED 711617 FLATWASHER 711676 HAIR PIN 711617 FLATWASHER 711676 HAIR PIN 95285 LINK LIFT HANDLE 711617 WASHER, FLAT 711676 PIN, HAIR 94506 GRIP, LIFT 1/2" ID 95296 HANDLE, LIFT 711616...

- Page 46 50565X89 REPAIR PARTS REF. KEY #37 • ..-... INSET 'A' NOTE: ALWAYS USE ORIGINAL EQUIPMENT PARTS. ALLUNNUMSERED ITEMS AREINTERCHANGEABLE Use of service/replacement parts other than original WITH OPPOSITESIDE equipment parts may void your warranty. 343501A...

- Page 47 ENGINE & CONTROL ASSEMBLY KEY PART NO. NO. DESCRIPTION ENGINE 20HP (SEE ENGINE MANUAL) 710199 SCREW, 3/8-16X1.25 WAHHSPTAPP 711722 DECAL, ENGINE 711601 NUT, 1/4-20 REGHEXJAM 711851 EXHAUST GASKET B/S #273485 711660 SCREW, 1/4-20X.75 WAHHTAP 94655 MUFFLER, TWIN-CYLINDER 95204 EXHAUST TUBE 711852 SCREW (B/S 94755) 314797...

- Page 48 50565X89 REPAIR PARTS NOTE: ALWAYS USE ORIGINAL EQUIPMENT PARTS. ALL UNNUMBERED Use of service/replacement parts other than original iTEMS ARE INTERCHANGEABLE WITH OPPOSITE SIDE equipment parts may void your warranty. 341592A...

- Page 49 PRE-PAINTED DECK ASSEMBLY PART DESCRIPTION BLADE HOUSING 50" 94663 94693 BRACKET, FRONT DECK BOLT, 5/16-18X.63 CARR. 57072 710204 NUT, 5/16-18 HEXWDFLLK WHIZ 95176 BRACKET, CHUTE SUPPORT 57072 BOLT, 5/16-18X.63 CARR. 710205 NUT 5/16-18 WDFLLK (15X88) 92104 HINGE, CHUTE BRACKET BOLT 5/16-18X.63 CARR. 57072 710205 NUT, 5/16-18 WDFLLK (15X88)

- Page 50 50565X89 REPAIR PARTS REF. KEY#74 NQ_"E: ALWAYS USE ORIGINAL EQUIPMENT PARTS. ALL UNNUMBERED Use of service/replacement parts other than original ITEMS ARE INTERCHANGEABLE WITH OPPOSITE SIDE equipment parts may void your warranty. 343418A...

- Page 51 DECKASSEMBLY PART DESCRIPTION 341592-821 ASM, BLADE HOUSING 50" 94702-821 ARM, IDLER CLUTCHING 50" 711613 BOLT, .50X.75 HHSH 3/8-16 9X39 711622 NUT, 3/8-16 HWDFLLK MACK 15X84 95272 IDLER PULLEY 5" 94809 SPRING, BELT GUIDE 711609 SCREW 3/8-16X2.00 711622 NUT 3/8-16 HWDFLLK MACK 15X84 94697-921 ASM.

- Page 52 50565X89 REPAIR PARTS F'r-LB I I TORQUE 35-45 NOTE: ALWAYS USE ORIGINAL EQUIPMENT PARTS. ALL UNNUMBERED ITEMS ARE INTERCHANGEABLE Use of service/replacement parts other than original WITH OPPOSITE SIDE equipment parts may void your warranty. 343418A...

- Page 53 DECK ASSEMBLY PART DESCRIPTION 94752 ASM., JACKSHAFT, HVY DUlY 95310 PULLEY, JACKSHAFT 95402 SHAFT, SPLINED JACKSHAFT 94150 SPACER, ,625X.875X1.858 711626 NUT, 9/16-18 UNF-2R 15X121 95416 HUB, BLADE ADAPTOR 94692 BLADE 710118 WASHER BELLEVILLE 17X166 710117 WASHER, FLAT .625X1.00X.188 710104 NUT, 9/16 REGHEX(15X100) 710199 SCREW, 3/8-16X1.25 WAHHSPTAPP...

- Page 54 50565X89 REPAIR PARTS RED & BLACK BLUE/ORANGE BLUE & BLACK REAR HARNESS • . .9 TO STARTER PURPLE_LACK ] BLUE/BLACK ] [ GREYHELL0W [ WHffE_IEO DETAIL *A' 343502A...

- Page 55 ELECTRICAL ASSEMBLY PART DESCRIPTION WIRE HARNESS 941O2 94739 IND. HARNESS,-OIL,CHG,PTO/CLUTCH 34O530 WIRE HARNESS, REAR 941O3 WIRE HARNESS FOR HEADLIGHT HEADLIGHT BULB 52572 57444 TIE, CABLE BLACK NYLON 5.62L WIRE CLIP, ADHESIVE 55939 94762 SWITCH, IGNITION DELTA 7 TERM 327350 KEY, IGNITION BULB INDICATOR 57769 SWITCH LIMIT DELTA...

- Page 56 50565X89 DECAL ASSEMBLY PART DESCRIPTION 711066 DECAL, NO STEP 711469 DECAL, CUT FINGER 711301 DECAL, CUBRAKETOE 710638 DECAL, HEIGHT ADJUST1-6 710639 DECAL, DECKLEVEL 710720 DECAL, AUTODRIVEINSTR DASH RT 711555 DECAL. HYDRO REL. VALVE 711468 DECAL, INSTR. CON& 341785_...

- Page 57 DECALASSEMBLY DASH DETAIL PART DESCRIPTION 710506 DECAL, YARDKING RH 20/50" 710507 DECAL, YARDKING LH 20150" 710514 DECAL, PEDAL CTRL RH AUTODRIVE 710513 DECAL, PEDAL CTRL LH AUTODRIVE 710511 DECAL, TWIN DURA-BEAM FRAME 710510 DECAL, ALL PERF. DECK 44X6700 710637 DECAL, PERF. CUT LEVELING SYS. NOT A SERVICEABLE PART 710238 DECAL, LH RH HOOD...

- Page 58 NOTES 712008...

-

Page 59: Lawn Tractor Accessories

LAWN TRACTOR ACCESSORIES Make your Lawn Tractor do more than you ever imagined. The accessories shown on this page can be used on your Lawn Tractor. See the Store or Dealer where you purchased your Lawn Tractor. If you are unable to obtain the necessary information, contact the Central Parts Distribution... - Page 60 HOW TO QRGIERREPAIR Only use a factory repairpart. Repair pads, exceptfor the engineor the transmission,are available fromthe store where the unitwas purchased, a serviceshoprecommendedbythe store,or an aulhorizedserviceshopfound in theyellowpages ofthetelephonedirectory. If you cannotget a repairpart or serviceas describedabove,call or write to the Central Parts Distributor s hownbelow.When you order, includethe following information:(1) CompleteModel Number (see nameplate),(2) Date of Manufacture,(3) CompletePart Number, (4) Description, ( 5) Quantity.

Need help?

Do you have a question about the Performance 50565x89 and is the answer not in the manual?

Questions and answers