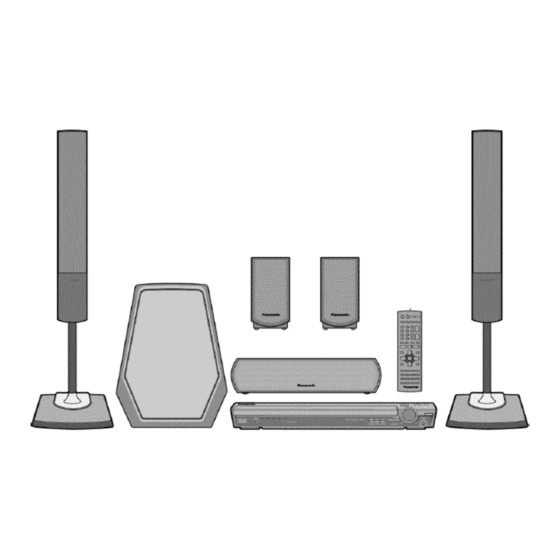

Summary of Contents for Panasonic SAHT730 - DVD THEATER RECEIVER

- Page 1 Technical Guide 5-DVD Changer Home Theater System SC-HT730, SC-HT930 Models Practical Servicing of Start Up, Shutdown, and Video Circuits Panasonic Services Company National Training...

- Page 2 Panasonic Services Company National Training Panasonic is a registered trademark of Panasonic North America "HDMI, the HDMI logo and High-Definition Multimedia Interface are trademarks or registered trademarks of HDMI Licensing LLC." BBE, the BBE logo, Sonic Maximizer and High Definition Sound are registered trademarks or trademarks of BBE Sound, Inc.

-

Page 3: Table Of Contents

Table of Contents OBJECTIVE..........................4 I NO START-UP AND DVD TRANSPORT PROBLEMS..........5 1. P – W ? ........... 5 OWER TART EQUENCE HERE IS THE PROBLEM 2. S ................6 ENSORS BELTS AND MOTOR LOCATION 3. S – ..............7 IMULATED AILURE YMPTOMS... -

Page 4: Objective

Objective This technical guide was prepared with the following objectives in mind: • Provide the servicer with a brief overview of the concepts of operation for new circuits employed in this line of models. • Provide drawings with emphasis on signal path to simplify the task of signal tracing and to locate the cause of a defect. -

Page 5: I No Start-Up And Dvd Transport Problems

I No Start-Up and DVD Transport Problems Model: SA-HT730 / HT930. Since this unit normally starts in DVD mode, start-up symptoms are often caused by DVD transport problems – A failure in the DVD transport stops the start up. Servicing the DVD section is divided into 6 groups (pick and choose what you need): 1. -

Page 6: Sensors, Belts, And Motor Location

Checkout * Disc Proof Sequence (no disc loaded) Failure a) Sled moves to home position (at f) Sled moves out to DVD TOC 1. Ribbon cable center). location. b) Sled moves out to DVD TOC g) Laser ON. 2. Mechanical location. -

Page 7: Simulated Failure Symptoms - Quick Fixes

3. Simulated Failure Symptoms – quick fixes Although sensor failures cause the following symptoms listed in table 3, the more common failure is an internally broken ribbon cable that carries the sensor signal to the microprocessor. To determine which is at fault, begin testing using figures 4 and 5 or order the cable with the corresponding sensor. -

Page 8: Tray Removal For Sensors, Belts, & Diagnostic Access

4. Tray Removal for Sensors, Belts, & Diagnostic Access Removing the tray to access the sensors and motor first requires removing the tray trim, and then the front panel (not shown) before the tray assembly will come out. Follow figure 2 for easy tray removal. CAUTION – metal chassis edges are sharp. Quick Procedure: 1. -

Page 9: Tray Installation (After Repairs)

5. Tray installation (after repairs) Refer to figure 3. Positioning the main black gear and a white gear is all that is required to slide the tray back in. Procedure: 1. Main black gear – Rotate the gear so that its hole is at the 5 o’clock position and its line across the gear is horizontal as shown in figure 3. -

Page 10: Sensor Testing

6. Sensor testing These 7 electrical parts could cause transport problems but so can a broken mechanical part. Test all 5 sensors and 2 motors as a group once the tray is removed. If the parts test OK, the problem is mechanical or a ribbon cable is bad. Testing the Tray Loading Motor and Related Sensors With the tray removed (section 4), install the front panel to test the tray loading operation. -

Page 11: Testing The Tray Rotation Motor And Related Sensors

Testing the Tray Rotation Motor and Related Sensors 1. With the tray removed, install the front panel to begin the remaining tests. 2. Place the plastic tray on top of the unit between the laser block and front panel. 3. Plug the tray ribbon cable into CN2010 for testing. Testing Parts 2/2 Part Setup... -

Page 12: Shutdown Problem

II Shutdown Problem Protection Concept – all the shutdown possibilities Refer to figure 6. The models SCHT730 and SCHT930 are both 2-piece units (with speakers). The SA-HT930 / SA-HT730 control piece (figure 6, right) has no AC input. The control unit power comes from the SB-WA 30 “Subwoofer” piece through a 25 pin umbilical cable (not shown). -

Page 13: Control Unit Repair (Sa-Ht730 / Sa-Ht930) Strategy

Figure 7 – Repair Information Control Unit Repair (SA-HT730 / SA-HT930) Strategy SC-HT730 / SC-HT930 Repair Strategy for a shutdown (F61) symptom: These two units differ in power output so the ‘HT930 has an additional board in the subwoofer. Troubleshooting of the control unit is almost identical for both models. Shutdown can be either in the control unit or subwoofer. -

Page 14: Control Unit Repair Procedure

Control unit repair Procedure To perform the following steps, you need to locate the jumper wires and identify which jumpers carry what shutdown signals to the IC2018 microprocessor (using figure 9). The purpose of the jumpers is found in the concept diagram figure 10. Procedure: 1. -

Page 15: Jumper Paths To System Control Ic2018 For Shutdown Problems

Jumper Paths to System Control IC2018 for Shutdown Problems SYS 6 from JK2000 TP Jumpers (eg. W____ ) are accessible from the top of the board / PIN 4 Subwoofer W2855 / H6 load W2145 /M6 W2417 /I7 Stby 6V SW5V SYSTEM W2550 /M7... -

Page 16: Control Unit Protection Concept

Control Unit Protection Concept Figure 10 – Control Unit Shutdown Simplified Schematic SA-HT730 / SAHT930... -

Page 17: Subwoofer Unit Repair (Sb-Wa730 / Sa-Wa930)

Subwoofer Unit Repair (SB-WA730 / SA-WA930) Overview - Refer to figure 11. The SC-HT930 consists of a Subwoofer and Control unit. The units are connected by a 25 pin round umbilical cord that carries power from the Subwoofer to the control unit and audio from the control unit back to the subwoofer. -

Page 18: Subwoofer Repair Procedure

Follow this procedure to determine if the Subwoofer causes shut down: Refer to the subwoofer protection simplified troubleshooting circuit, in figure 12. Disassembly and service positions are shown in figures 13 and 14. 3. Do not connect the Control unit to the Subwoofer. On the larger power board of the subwoofer, tack a 10k ohm test resistor across D508 to serve as a temporary “DC Det”... - Page 19 Figure 12 – Subwoofer Power On / Protection Circuit SA-HT730 / SAHT930...

-

Page 20: Subwoofer Disassembly

Subwoofer Disassembly Figure 13 – Subwoofer Disassembly SA-HT730 / SAHT930... -

Page 21: Subwoofer Test / Operating Position

Subwoofer Test / Operating Position After removing the boards, the grounds must be reconnected for operation and testing. Procedure: 1. Remove screws to free the bottom frame from the heat sink and PC boards. 2. Rotate the assembly and rest the heat sink on the bottom frame as shown. 3. -

Page 22: No Audio Problems

III “No Audio” Problems A loss of audio in one or more channels can either be caused by a break in the signal flow or a line being muted. Use the following two diagrams to see the audio signal flow, the mute locations, and the location of accessible capacitors in the signal path for signal tracing. - Page 23 3. Internal test tone - An alternative to input a signal to test the amplifier is to use the internal speaker level test mode. Once in this test mode, IC2011 generates a fixed level signal to each speaker, one at a time except the subwoofer. The test tone lasts for approx half second at each speaker and repeats.

Need help?

Do you have a question about the SAHT730 - DVD THEATER RECEIVER and is the answer not in the manual?

Questions and answers

ola bom dia meu sa-ht 930 qunado ligo so fica INITIAL nao aceita comandos ,pensei emum RESET solucionar sera?