Table of Contents

Advertisement

Quick Links

Safety Instructions & Operator's Manual for

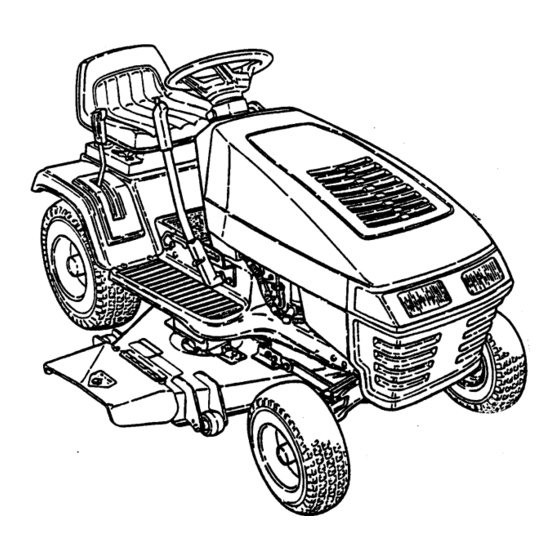

LAWN TRA C TOR S

ELECTRIC CLUTCH

SERIES D

MODELS

LT160H42DBV

L T160H42DB V2

L T180H48DB V2

MODEL NUMBER EXPLANATION

l LT I 160 I I

oo ,o T,ON--J I

ENGINE HP

DRIVE SYSTEM TYPE

CUTTING WIDTH

11421=

ENGINE OPTIONS

ENGINE TYPE

ENGINE MODEL

SERIES DESIGNATION

LT- ModelDesiqnation

I

160- 16.0HP(Engine HorsePower)

I

180 - 18.0 HP (Engine Horse Power)

H - Hydrostatic Transmission

Drive System

42 - 42" Cutting Width Mower Deck

48 -48"

Cutting Width Mower Deck

D - Series Desicjnation

B - Briggs & Stratton Enqine

V - Over Head Valve Type Engine

2 - Twin Cylinder Engine

Thank

you for buying

a SNAPPER

product!

Before

operating

the Lawn

Tractor,

read and follow

the

"IMPORTANT

SAFETY INSTRUCTIONS"

on pages 2 & 3, all other instructions

contained

in this manual and the

accompanying

booklet

"About

Power

Mower

Safety".

Lawn

mowers

and all power

equipment

can

be

potentially

dangerous if used improperly.

REMEMBER:

SAFETY REQUIRES

CAREFULL

USE IN ACCORDANCE

WITH INSTRUCTIONS

AND COMMON SENSE !

COPYRIGHT

© 1998

SNAPPER

INC.

ALL RIGHTS RESERVED

MANUAL No. 3.5624 (REV. 1, 6/98)

Advertisement

Chapters

Table of Contents

Summary of Contents for Snapper LT180H48DBV2

- Page 1 H - Hydrostatic Transmission Drive System 2 - Twin Cylinder Engine 42 - 42" Cutting Width Mower Deck 48 -48" Cutting Width Mower Deck Thank you for buying a SNAPPER product! Before operating the Lawn Tractor, read and follow "IMPORTANT SAFETY INSTRUCTIONS"...

- Page 2 If you have any questions pertaining to your machine which your dealer cannot answer to your satisfaction, call or write the Customer Service Department at SNAPPER, McDonough, Georgia 30253. Phone: (1-800-935-2967). PROTECTION FOR CHILDREN...

- Page 3 14. Have machine serviced authorized Deflector or entire grass catcher must be in place. SNAPPER dealer at least once a year and have the NEVER point discharge at people, passing cars, dealer install any new safety devices. windows or doors.

-

Page 4: Table Of Contents

TABLE OF CONTENTS IMPORTANT SAFETY INSTRUCTIONS .... 2-3 MAINTENANCE INSTRUCTIONS (Continued) TABLE of CONTENTS ......... Battery Service ..........Battery Electrolyte Check ......FAMILIARIZATION ..........Battery Removal ..........Serial & Model Number Location ....... Battery Charging ..........Controls .............. Activating New Battery ........Components ............ -

Page 5: Familiarization

SERIAL & MODEL NUMBER LOCATION FAMILIARIZATION The Serial and Model numbers of your SNAPPER Series D Lawn Tractor are located on the rear face of the tractor frame as shown in Figure 1. Record these numbers in the spaces provided below. The... -

Page 6: Components

FAMILIARIZATION COMPONENTS Figures 2 and 3 show the location of essential components of the SNAPPER Series D Lawn Tractors. It is recommended that all operators of this equipment become thoroughly familiar with the components and their operation BEFORE OPERATING. Specific... -

Page 7: Pre-Start Checklist

OPERATING INSTRUCTIONS ADJUSTING OPERATOR'S SEAT PRE-START CHECKLIST Make the following checks and perform service With engine "OFF", raise operator's seat and loosen the as required before each start.up. two adjusting knobs on the seat support. See Figure 5. Check tires and add air as needed to bring pressure to 12 psi in front tires and 10 psi in rear tires. - Page 8 Little or no interlocks controlling any of the above functions choking will be needed when restarting a warm en- fail. Contact an authorized SNAPPER dealer to have gine. See Figure 8. the interlock system repaired. 5. Insert Key in Ignition Switch. CONTROL...

- Page 9 5 seconds. Contact your authorized SNAPPER dealer for inspection repair. i PULL (PTO) SWITCH "OUT" TO TURN CUTTING BLADES ON I I PUSH (PTO) SWITCH "IN" TO TURN THE BLADES OFF I (2) MOVE PARK BRAKE...

-

Page 10: Tips On Mowing

OPERATING INSTRUCTIONS ADJUSTING CUTTING HEIGHT RAISING CHUTE DEFLECTOR (For Clearance Through Gates or 1. Depress the lock button on Deck Lift Lever shown For Transporting Tractor). in Figure 12 and pull lever backward to go to higher 1. Remove wing-nuts flat washers (if used) -

Page 11: Operating Instructions

FIGURE AVAILABLE ACCESSORIES The SNAPPER Series D Lawn Tractor can be equipped with a variety of Accessories that increase its versatility. The Accessories available for each model are listed in the chart below. Contact an authorized SNAPPER Dealer for ordedng any of the Accessories desired. -

Page 12: Guide

3. Electrical connections loose or 3. Clean and check connections for good corroded. contact. 4. Contact authorized SNAPPER dealer. 4. Defective ignition switch. 5. Starter Spins without engaging. 5. Release Start key and repeat attempt. If starter continues to spin, contact Dealer. - Page 13 ..2. Blade belt requires adjustment. 2. Adjust mower belt. 3. Blade belt requires replacement. 3. Replace mower belt. 4. Contact authorized SNAPPER dealer. 4. Electric clutch not functioning. Cutting Grass 1. Uneven tire pressure. 1. Bring to proper pressure.

-

Page 14: Parts

MAINTENANCE INSTRUCTIONS SERVICE SCHEDULE SUBJECT SERVICE REFERENCE EACH EACH HOURS HOURS SEASON TO BE PERFORMED PAGES HOURS HOURS Engine Check Oil Level. Page 7 Engine Initial Oil Change. Pages 16 Engine Periodic Oil Change. Page 16 Air Pre-Cleaner Service Sponge Pre- Engine Manual Cleaner Element. -

Page 15: Oil

MAINTENANCE INSTRUCTIONS 4. Slide the red protective boot away from its termi- nal, then disconnect the Positive (RED) Battery Cable from the + Terminal. Before attempting any adjustments, maintenance, 5. Remove the Battery and the Battery Tray from the WARNING repairs, STOP engine. -

Page 16: Front Wheel Bearings

MAINTENANCE INSTRUCTIONS CHANGING ENGINE LUBRICATION (Each 25 Hours) The engine is equipped with a no-tools type oil drain which can be opened and closed by hand. The service points listed on this page 16 and the Figure 18 shows the drain location on a single next... -

Page 17: Maintenance Instructions

MAINTENANCE INSTRUCTIONS LUBRICATION (Continued) STEERING TIE ROD LUBRICATION CLUTCHIBRAKE PIVOT LUBRICATION Lubricate both ends of the Steering Tie Rod with ClutchlBrake Pivot located on the left motor oil from an oil can. See Figure 23. underside of the tractor and is lubricated with 1 shot of general purpose grease from the grease gun. -

Page 18: Engine Air Cleaner

CARTRIDGE the container. Install a new SNAPPER Part Number 1-4359 Fuel Filter in place of the old Filter. Re-install the Hose Clamps and reconnect the Fuel Lines. -

Page 19: Battery Service

MAINTENANCE INSTRUCTIONS BATTERY SERVICE The battery should be checked and serviced every 25 hours of operation as follows: FILL Tilt Operator's Seat forward and remove the two adjusting knobs then lift the seat assembly off tractor frame and move it forward out of the way. Be careful not to disconnect wires from seat switches. - Page 20 ....MAINTENANCE INSTRUCTIONS -..... MOWER DECK SERVICE 6. Disconnect the Deck Front Lift Cable by removing the Hairpin and Washer first. See Figure 32. MOWER DECK REMOVAL (42" Mower Deck) The Mower Deck will have to be removed to replace WASHER blades or deck belts as described...

-

Page 21: Sharpening Standard Blade(S)

The same procedure should be used when removing swivels from the rear deck brackets. 4. Install sharpened or new Blades, (SNAPPER Part WEAR LIMITS - STANDARD BLADES No. 2-6691) and secure each with the Cone Wash-... -

Page 22: Ninja Mower Blade Service

Instructions are provided in the Air Lift Kits. Use Air Lift Kit Part Num- NINJATMBLADE SHARPENING PROCEDURE ber 6-0735. See Figure 37. AIR UFT SNAPPER NINJA Recycling Blades require more frequent sharpening than standard Blades because of their recycling function. -

Page 23: Belt Service

INSTRUCTIONS DECK DRIVE BELT SERVICE For 42" Cutting Deck, remove old Belt and install new 42" DECK DRIVE BELT REMOVAL AND Belt, SNAPPER P.N. 2-8582 on Model LT160H42DBV REPLACEMENT or P.N. 2-9205 on LT160H42DBV2. Install new Belt in the reverse order of removal. -

Page 24: Traction Drive Belt Removal

MAINTENANCE INSTRUCTIONS ......TRACTION DRIVE BELT SERVICE ....Check the Traction Drive Belt for damage and wear after Loosen Mounting Nuts on Traction Drive Belt Idlers just enough to allow Belt to clear Belt Guides. Remove Trac- 25 operating hours. The Traction Drive Belt is located tion Drive Belt from top groove of Engine Pulley. -

Page 25: Traction Drive Belt Adjustment

MAINTENANCE INSTRUCTIONS TRACTION DRIVE BELT ADJUSTMENT, If a gradual loss of traction is noticed, it may be neces- LEADING sary to adjust the Traction Drive Belt tension by reposi- tioning the Stationary Idler as follows: BLADE NOTE the position of Belt Guide on Stationary Idler and make certain it remains the same after moving Idler. -

Page 26: Side To Side Level

MAINTENANCE INSTRUCTIONS MOWER DECK ADJUSTMENT (LEVELNESS) 4.3.4. MOWER DECK ADJUSTMENT (LEVELNESS) Side To Side Level (48" Cutting Deck) Front to Rear Deck Pitch (48" Deck) Before making deck leveling adjustments, check the tire Before making deck leveling adjustments, check the pressure. -

Page 27: Front To Rear Level

MAINTENANCE INSTRUCTIONS Remove Hair-Pin and Washer securing FRONT Lift FRONT TO REAR LEVEL ADJUSTMENT Cable to FRONT Lift Arm. See Figure 53. at SECTOR PLATES Remove Hair-Pins and Washers securing Sector HAIR4PIN CLEVIS Plates to rear Lift Arms. See Figure 52. Move Sector Plates the same number of holes as required to raise or lower the Deck. -

Page 28: Steering Adjustment

..MAINTENANCE INSTRUCTIONS SHIFTER ADJUSTMENT STEERING ADJUSTMENT If movement of Tractor does not correspond with Should excessive "Play" be noted in the steedng, the selected speed or Shift Quadrant, adjust the adjust at the Steering Sector as follows: Speed Control Lever as follows: Turn Engine "OFF"... -

Page 29: Wheel Brake Adjustment

Continue adjustment as described above until proper install the Fuse in the holder and check for some other adjustment is achieved. cause. If the Fuse is blown, install a new 20 Amp Fuse, (SNAPPER Part Number 2-3653) in the holder. FUEL LOOSEN TIGHTEN (COUNTER-... -

Page 30: Electrical System

ELECTRICAL SYSTEM,_ BRAKE swrr_t SWITCH CLUTCH LOAD' (SHOWN DISENGAGED) OFF) BLACK GREEN PURPLE ANTI-AFTER SOLENOID ENGINE ,,d=.,,--IGNITION GROUND ALTERNATOR STARTER YELLOW UGHT SWITCH KEY_ GREEN WHITE PINK -'='. BLUE SCHEMATIC WIRING DIAGRAM PURPLE for MODEL LT160H42DBV TO RELAY ILLUSTRATED DIAGRAM for Model LT160H42DBV SWITCH TO PEDAL... - Page 31 ,ELECTRICAL SYSTEM, BRAKE SWITCH Pro SWITCH CLUTCH LOAD (SHOWN DISENGAGED) BLACK (SHOWN OFF) GREEN WHITE PURPLE ANTI-AFTER .--- RELAY RRE SOLENOID'. ENC, SENSOR ,_,,IGNITION GROUND LIGHT PURPLE STARTER YELLOW BLACK SOLENOID GREEN WHITE BATTERY 8LUE PURPLE OIL PRESSURE uaN,y SCHEMATIC WIRING DIAGRAM for MODELS...

-

Page 32: Warranty

For ninety (90) days from purchase date for the original purchaser's commercial, rental, or other non-residential use, SNAPPER, through any SNAPPER dealer will replace, free of charge, any part or parts found upon examination by the factory at McDonough, Georgia, to be defective in material or workmanship or both. - Page 33 SERVICE NOTES...

-

Page 34: Primary Maintenance

,engine & how reasonable maintenance can protect it! Snapper uses the best avail- able engines and components In their products In order to provide long, satisfactory service. However, proper care is essential prolonging engine life. - Page 35 Because of Its working environ. ment, the air available to your Snapper engine Is " heavily saturated with air- borne dirt particles. As the dirt particles are stopped, Damage caused by a poorly serviced air...

-

Page 36: Primary Maintenance

PRIMARY MAINTENANCE Air Is also needed to keep your engine cool. Dirt, dust & debris build up to restrict and clog cooling air Intake screens and fins. Clean screens and fins at frequent Intervals. The engine blower housing and shrouds should be removed at least once each season or more often l under dry, dusty conditions... - Page 37 Snapper 2-cycle o11. Pre-mix the fuel and always shake the container before filling the tank. Change oil at regular Intervals using a a high...

- Page 38 J_ WARNI NG: The engine exhaust from this product contains chemicals known to the State J j==m., of California to cause cancer, birth defects or other reproductive harm. COPYRIGHT O 1998 SNAPPER INC, ALL RIGHTS RESERVED MANUAL No. 3-5624 (REV. 1, 6/98)

- Page 39 H - Hydrostatic Transmission Drive System 2 - Twin Cylinder Engine 42 - 42" Cutting Width Mower Deck 48 -48" Cutting Width Mower Deck Thank you for buying a SNAPPER product! Before operating the Lawn Tractor, read and follow "IMPORTANT SAFETY INSTRUCTIONS"...

- Page 40 If you have any questions pertaining to your machine which your dealer cannot answer to your satisfaction, call or write the Customer Service Department at SNAPPER, McDonough, Georgia 30253. Phone: (1-800-935-2967). PROTECTION FOR CHILDREN...

- Page 41 14. Have machine serviced authorized Deflector or entire grass catcher must be in place. SNAPPER dealer at least once a year and have the NEVER point discharge at people, passing cars, dealer install any new safety devices. windows or doors.

-

Page 42: Ninja Blade Wear Ninja Blade Sharpening

TABLE OF CONTENTS IMPORTANT SAFETY INSTRUCTIONS .... 2-3 MAINTENANCE INSTRUCTIONS (Continued) TABLE of CONTENTS ......... Battery Service ..........Battery Electrolyte Check ......FAMILIARIZATION ..........Battery Removal ..........Serial & Model Number Location ....... Battery Charging ..........Controls .............. Activating New Battery ........Components ............ - Page 43 SERIAL & MODEL NUMBER LOCATION FAMILIARIZATION The Serial and Model numbers of your SNAPPER Series D Lawn Tractor are located on the rear face of the tractor frame as shown in Figure 1. Record these numbers in the spaces provided below. The...

- Page 44 FAMILIARIZATION COMPONENTS Figures 2 and 3 show the location of essential components of the SNAPPER Series D Lawn Tractors. It is recommended that all operators of this equipment become thoroughly familiar with the components and their operation BEFORE OPERATING. Specific...

- Page 45 OPERATING INSTRUCTIONS ADJUSTING OPERATOR'S SEAT PRE-START CHECKLIST Make the following checks and perform service With engine "OFF", raise operator's seat and loosen the as required before each start.up. two adjusting knobs on the seat support. See Figure 5. Check tires and add air as needed to bring pressure to 12 psi in front tires and 10 psi in rear tires.

- Page 46 Little or no interlocks controlling any of the above functions choking will be needed when restarting a warm en- fail. Contact an authorized SNAPPER dealer to have gine. See Figure 8. the interlock system repaired. 5. Insert Key in Ignition Switch. CONTROL...

- Page 47 5 seconds. Contact your authorized SNAPPER dealer for inspection repair. i PULL (PTO) SWITCH "OUT" TO TURN CUTTING BLADES ON I I PUSH (PTO) SWITCH "IN" TO TURN THE BLADES OFF I (2) MOVE PARK BRAKE...

- Page 48 OPERATING INSTRUCTIONS ADJUSTING CUTTING HEIGHT RAISING CHUTE DEFLECTOR (For Clearance Through Gates or 1. Depress the lock button on Deck Lift Lever shown For Transporting Tractor). in Figure 12 and pull lever backward to go to higher 1. Remove wing-nuts flat washers (if used)

- Page 49 FIGURE AVAILABLE ACCESSORIES The SNAPPER Series D Lawn Tractor can be equipped with a variety of Accessories that increase its versatility. The Accessories available for each model are listed in the chart below. Contact an authorized SNAPPER Dealer for ordedng any of the Accessories desired.

-

Page 50: Guide

3. Electrical connections loose or 3. Clean and check connections for good corroded. contact. 4. Contact authorized SNAPPER dealer. 4. Defective ignition switch. 5. Starter Spins without engaging. 5. Release Start key and repeat attempt. If starter continues to spin, contact Dealer. - Page 51 ..2. Blade belt requires adjustment. 2. Adjust mower belt. 3. Blade belt requires replacement. 3. Replace mower belt. 4. Contact authorized SNAPPER dealer. 4. Electric clutch not functioning. Cutting Grass 1. Uneven tire pressure. 1. Bring to proper pressure.

-

Page 52: Parts

MAINTENANCE INSTRUCTIONS SERVICE SCHEDULE SUBJECT SERVICE REFERENCE EACH EACH HOURS HOURS SEASON TO BE PERFORMED PAGES HOURS HOURS Engine Check Oil Level. Page 7 Engine Initial Oil Change. Pages 16 Engine Periodic Oil Change. Page 16 Air Pre-Cleaner Service Sponge Pre- Engine Manual Cleaner Element. - Page 53 MAINTENANCE INSTRUCTIONS 4. Slide the red protective boot away from its termi- nal, then disconnect the Positive (RED) Battery Cable from the + Terminal. Before attempting any adjustments, maintenance, 5. Remove the Battery and the Battery Tray from the WARNING repairs, STOP engine.

-

Page 54: Oil

MAINTENANCE INSTRUCTIONS CHANGING ENGINE LUBRICATION (Each 25 Hours) The engine is equipped with a no-tools type oil drain which can be opened and closed by hand. The service points listed on this page 16 and the Figure 18 shows the drain location on a single next... - Page 55 MAINTENANCE INSTRUCTIONS LUBRICATION (Continued) STEERING TIE ROD LUBRICATION CLUTCHIBRAKE PIVOT LUBRICATION Lubricate both ends of the Steering Tie Rod with ClutchlBrake Pivot located on the left motor oil from an oil can. See Figure 23. underside of the tractor and is lubricated with 1 shot of general purpose grease from the grease gun.

- Page 56 CARTRIDGE the container. Install a new SNAPPER Part Number 1-4359 Fuel Filter in place of the old Filter. Re-install the Hose Clamps and reconnect the Fuel Lines.

- Page 57 MAINTENANCE INSTRUCTIONS BATTERY SERVICE The battery should be checked and serviced every 25 hours of operation as follows: FILL Tilt Operator's Seat forward and remove the two adjusting knobs then lift the seat assembly off tractor frame and move it forward out of the way. Be careful not to disconnect wires from seat switches.

- Page 58 ....MAINTENANCE INSTRUCTIONS -..... MOWER DECK SERVICE 6. Disconnect the Deck Front Lift Cable by removing the Hairpin and Washer first. See Figure 32. MOWER DECK REMOVAL (42" Mower Deck) The Mower Deck will have to be removed to replace WASHER blades or deck belts as described...

-

Page 59: Sharpening Standard Blade(S)

The same procedure should be used when removing swivels from the rear deck brackets. 4. Install sharpened or new Blades, (SNAPPER Part WEAR LIMITS - STANDARD BLADES No. 2-6691) and secure each with the Cone Wash-... -

Page 60: Ninja Mower Blade Service

Instructions are provided in the Air Lift Kits. Use Air Lift Kit Part Num- NINJATMBLADE SHARPENING PROCEDURE ber 6-0735. See Figure 37. AIR UFT SNAPPER NINJA Recycling Blades require more frequent sharpening than standard Blades because of their recycling function. - Page 61 INSTRUCTIONS DECK DRIVE BELT SERVICE For 42" Cutting Deck, remove old Belt and install new 42" DECK DRIVE BELT REMOVAL AND Belt, SNAPPER P.N. 2-8582 on Model LT160H42DBV REPLACEMENT or P.N. 2-9205 on LT160H42DBV2. Install new Belt in the reverse order of removal.

-

Page 62: Traction Drive Belt Service

MAINTENANCE INSTRUCTIONS ......TRACTION DRIVE BELT SERVICE ....Check the Traction Drive Belt for damage and wear after Loosen Mounting Nuts on Traction Drive Belt Idlers just enough to allow Belt to clear Belt Guides. Remove Trac- 25 operating hours. The Traction Drive Belt is located tion Drive Belt from top groove of Engine Pulley. -

Page 63: Traction Drive Belt Adjustment

MAINTENANCE INSTRUCTIONS TRACTION DRIVE BELT ADJUSTMENT, If a gradual loss of traction is noticed, it may be neces- LEADING sary to adjust the Traction Drive Belt tension by reposi- tioning the Stationary Idler as follows: BLADE NOTE the position of Belt Guide on Stationary Idler and make certain it remains the same after moving Idler. -

Page 64: Side To Side Level

MAINTENANCE INSTRUCTIONS MOWER DECK ADJUSTMENT (LEVELNESS) 4.3.4. MOWER DECK ADJUSTMENT (LEVELNESS) Side To Side Level (48" Cutting Deck) Front to Rear Deck Pitch (48" Deck) Before making deck leveling adjustments, check the tire Before making deck leveling adjustments, check the pressure. -

Page 65: Front To Rear Level

MAINTENANCE INSTRUCTIONS Remove Hair-Pin and Washer securing FRONT Lift FRONT TO REAR LEVEL ADJUSTMENT Cable to FRONT Lift Arm. See Figure 53. at SECTOR PLATES Remove Hair-Pins and Washers securing Sector HAIR4PIN CLEVIS Plates to rear Lift Arms. See Figure 52. Move Sector Plates the same number of holes as required to raise or lower the Deck. - Page 66 ..MAINTENANCE INSTRUCTIONS SHIFTER ADJUSTMENT STEERING ADJUSTMENT If movement of Tractor does not correspond with Should excessive "Play" be noted in the steedng, the selected speed or Shift Quadrant, adjust the adjust at the Steering Sector as follows: Speed Control Lever as follows: Turn Engine "OFF"...

- Page 67 Continue adjustment as described above until proper install the Fuse in the holder and check for some other adjustment is achieved. cause. If the Fuse is blown, install a new 20 Amp Fuse, (SNAPPER Part Number 2-3653) in the holder. FUEL LOOSEN TIGHTEN (COUNTER-...

- Page 68 ELECTRICAL SYSTEM,_ BRAKE swrr_t SWITCH CLUTCH LOAD' (SHOWN DISENGAGED) OFF) BLACK GREEN PURPLE ANTI-AFTER SOLENOID ENGINE ,,d=.,,--IGNITION GROUND ALTERNATOR STARTER YELLOW UGHT SWITCH KEY_ GREEN WHITE PINK -'='. BLUE SCHEMATIC WIRING DIAGRAM PURPLE for MODEL LT160H42DBV TO RELAY ILLUSTRATED DIAGRAM for Model LT160H42DBV SWITCH TO PEDAL...

- Page 69 ,ELECTRICAL SYSTEM, BRAKE SWITCH Pro SWITCH CLUTCH LOAD (SHOWN DISENGAGED) BLACK (SHOWN OFF) GREEN WHITE PURPLE ANTI-AFTER .--- RELAY RRE SOLENOID'. ENC, SENSOR ,_,,IGNITION GROUND LIGHT PURPLE STARTER YELLOW BLACK SOLENOID GREEN WHITE BATTERY 8LUE PURPLE OIL PRESSURE uaN,y SCHEMATIC WIRING DIAGRAM for MODELS...

- Page 70 For ninety (90) days from purchase date for the original purchaser's commercial, rental, or other non-residential use, SNAPPER, through any SNAPPER dealer will replace, free of charge, any part or parts found upon examination by the factory at McDonough, Georgia, to be defective in material or workmanship or both.

- Page 71 SERVICE NOTES...

- Page 72 ,engine & how reasonable maintenance can protect it! Snapper uses the best avail- able engines and components In their products In order to provide long, satisfactory service. However, proper care is essential prolonging engine life.

- Page 73 Because of Its working environ. ment, the air available to your Snapper engine Is " heavily saturated with air- borne dirt particles. As the dirt particles are stopped, Damage caused by a poorly serviced air...

- Page 74 PRIMARY MAINTENANCE Air Is also needed to keep your engine cool. Dirt, dust & debris build up to restrict and clog cooling air Intake screens and fins. Clean screens and fins at frequent Intervals. The engine blower housing and shrouds should be removed at least once each season or more often l under dry, dusty conditions...

- Page 75 Snapper 2-cycle o11. Pre-mix the fuel and always shake the container before filling the tank. Change oil at regular Intervals using a a high...

- Page 76 J_ WARNI NG: The engine exhaust from this product contains chemicals known to the State J j==m., of California to cause cancer, birth defects or other reproductive harm. COPYRIGHT O 1998 SNAPPER INC, ALL RIGHTS RESERVED MANUAL No. 3-5624 (REV. 1, 6/98)

Need help?

Do you have a question about the LT180H48DBV2 and is the answer not in the manual?

Questions and answers