Summarization of Contents

Refrigerant R410A

Safety Caution Concerned to Refrigerant (R410A)

Safety precautions for R410A refrigerant during installation and service work.

Cautions on Installation/Service

Specific guidelines for safe installation and service procedures with R410A.

Pipe Materials

Requirements for selecting appropriate copper pipes and joints for refrigerant lines.

Tools

Tools exclusive for R410A (The following tools for R410A are required.)

List of specific tools required for R410A systems and their interchangeability.

General tools (Conventional tools can be used.)

List of general tools that can also be used for R410A installations.

6. REFRIGERANT CYCLE DIAGRAM

Explanation of functional parts in indoor unit

Details the function of each component within the indoor unit's refrigerant cycle.

7. CONTROL OUTLINE

Identification of outdoor unit

Outdoor unit identification upon power reset and redirection of control.

Operation selection

Changes operation mode based on remote control commands.

Room temp. control

Controls room temperature settings for cooling and heating operations.

Automatic capacity control

Outdoor unit determines indoor unit capacity based on TA and TS differences.

Fan speed control

Controls fan speed modes (HIGH, MED, LOW, AUTO) based on temperature differences.

Cold air discharge prevention control

Details control logic to prevent cold air discharge during heating operation.

Freeze prevention control (low temp. release)

Describes operation based on temperature readings to prevent freezing during cooling.

Cooling oil (refrigerant) recovery control

Outlines indoor unit actions during outdoor unit's cooling oil recovery operation.

Heating refrigerant (oil) recovery control

Outlines indoor unit actions during outdoor unit's heating oil recovery operation.

Defrosting control

Describes indoor unit actions during the defrost cycle.

Drain pump control

Details the operation of the drain pump during cooling and error conditions.

Filter sign display

Explains the filter replacement signal display and reset function.

Selection of central control mode

Defines operations selectable via central controller settings and their accessibility.

Power saving mode

Explains how to enable power saving mode and its retained settings.

Frequency fixed operation (Test run)

Details procedures for performing test runs using wired and wireless remote controllers.

Secondary heating

Explains how secondary heating is used during heating operations based on temperature settings.

8. COMMUNICATION TYPE, MODEL NAMES AND THE MAXIMUM NUMBER OF CONNECTABLE UNITS

8-1. This air conditioning (U series) has new communication specifications...

Explains communication types (TU2C-Link, TCC-Link) and model name indications.

8-2. If TU2C-Link (U series) is combined with TCC-Link (other than U series)...

Describes wiring specifications and max connectable units for mixed communication types.

9. APPLIED CONTROL AND FUNCTIONS (INCLUDING CIRCUIT CONFIGURATION)

9-1. Indoor control block diagram

Provides a block diagram of the indoor unit's control system.

9-1-1. In Case of Connection of Wired (Simple) Remote Control

Details the indoor control block diagram when using a wired remote control.

9-1-2. In Case of Connection of Wireless Remote Control

Details the indoor control block diagram when using a wireless remote control.

9-1-3. Connection of Both Wired (Simple) Remote Control and Wireless Remote Control

Details the indoor control block diagram for connecting both wired and wireless remote controls.

9-2. Indoor Circuit Design Board MCC-1643

Illustrates the layout and connections of the indoor circuit design board MCC-1643.

9-2-1. Optional connector specifications of Indoor Circuit Design Board

Specifies the functions and pin details for optional connectors on the indoor circuit board.

9-2-2. Fan IPDU P.C. Board (MCC-1610)

Illustrates the layout and connections of the Fan IPDU P.C. Board (MCC-1610).

9-2-3. Noise filter (MCC-1551)

Illustrates the layout and connections of the Noise filter P.C. Board (MCC-1551).

9-3. Functions at test run

Details the procedures for performing test runs on the indoor unit.

9-4. Test operation of indoor unit

Explains how to perform a test operation of the indoor unit independently.

10. APPLIED CONTROL

10-1. Setup of Selecting Function in Indoor Unit

Steps to select functions and set DN codes using a wired remote controller.

10-2. Applied Control in Indoor Unit

Details applied control methods for indoor units.

Remote location ON/OFF control box (TCB-IFCB-4UL)

Details the wiring and control items for remote ON/OFF operation.

Ventilating fan control from remote controller

Explains how to control the ventilating fan using the remote controller.

Auto-off feature control

[Setup method]

Details the wiring and DN code setup for the auto-off feature.

[Card input setup.5 Code (DN)]

Provides a table of DN codes for card input setup and their corresponding functions.

Notice code signal

[Function]

Explains the purpose and usage of the Notice Code function for TU2C-Link communication.

[Setup method]

Details wiring and DN code setup for displaying Notice Codes on the remote controller.

Manual address setting using the remote controller

Wiring example of 2 refrigerant lines

Illustrates wiring configurations for setting addresses with two refrigerant lines.

Check code clearing function

How to clear the check code using the wired remote controller

Procedure for clearing outdoor and indoor unit check codes via wired remote controller.

Deleting check code history

Steps to delete check code history using the remote controller's alarm history function.

Monitoring function of wired remote controller

Indoor service monitor list

Lists available indoor service monitor codes and their corresponding data.

11. TROUBLESHOOTING

11-1. Overview

General troubleshooting guidelines, applicable models, required tools, and normal behaviors.

11-2. Troubleshooting method

Methodology for analyzing and resolving troubles using check codes.

List of check codes (indoor unit)

Details check codes detected by indoor units, their display, and possible causes.

(Check code detected by remote controller)

Lists check codes detected by remote controllers, display indicators, and typical troubles.

(Check code detected by central control device)

Lists check codes detected by central control devices and their typical causes.

Flow selector unit (FS unit) Relation

Details check codes related to the flow selector unit and their typical problems.

List of Check Codes (Outdoor Unit)

Details check codes detected by outdoor units, display indicators, and typical causes.

11-3. Troubleshooting by check Display on Remote Controller

Guides on interpreting and troubleshooting errors displayed on the remote controller.

(1) Checking and testing

How to check and test for errors displayed on the remote controller.

(2) Trouble history

Procedure to access and view the trouble history on the remote controller.

Contact information for repairs

Guides on how to find contact information for repair services via the remote controller.

11-4. Check Codes Displayed on Remote Controller and SMMS series Outdoor Unit (7-Segment Display on I/F Board) and Locations to Be Checked

Troubleshooting guide for check codes on remote controller and outdoor unit I/F board.

Check codes Displayed on by Central Control Device

Lists check codes displayed by the central control device and their causes.

11-5. Diagnostic Procedure for Each Check Code (Indoor Unit)

Detailed diagnostic procedures for various indoor unit check codes.

[E01]

Diagnostic steps for communication trouble between indoor unit and remote controller.

[E02]

Diagnostic steps for signal transmission trouble from the remote controller.

[E03]

Diagnostic steps for communication trouble between indoor unit and remote controller (detected at indoor).

[E04]

Diagnostic procedure for indoor/outdoor communication circuit trouble detected at the indoor side.

[E08]

Diagnostic procedure for duplicated indoor addresses.

[E09]

Diagnostic procedure for duplicated header remote controller setup.

[E10]

Diagnostic procedure for communication trouble between indoor MCUs.

[E11]

Diagnostic procedure for communication trouble between application control kit and indoor unit.

[E18]

Diagnostic procedure for communication trouble between indoor header and follower.

[F01]

Diagnostic procedure for indoor TCJ sensor trouble.

[F02]

Diagnostic procedure for indoor TC2 sensor trouble.

[F03]

Diagnostic procedure for indoor TC1 sensor trouble.

[F10]

Diagnostic procedure for indoor TA/TSA sensor trouble.

[F29]

Diagnostic procedure for indoor unit other trouble (EEPROM issue).

[F30]

Diagnostic procedure for occupancy sensor trouble.

[L03]

Diagnostic procedure for duplicated indoor header units.

[L07]

Diagnostic procedure for a group line connected to an individual indoor unit.

[L08]

Diagnostic procedure for unset indoor group/address.

[L09]

Diagnostic procedure for unset indoor unit capacity.

[L20]

Diagnostic procedure for duplicated central control addresses.

[L30]

Diagnostic procedure for interlock input from outside device.

[P10]

Diagnostic procedure for water overflow in an indoor unit.

[P12]

Diagnostic procedure for indoor fan motor trouble.

[P31]

Diagnostic procedure for other indoor trouble (group follower unit).

11-6. Sensor characteristics

Indoor unit Temperature sensor characteristics

Provides resistance vs. temperature data for indoor TA, TC1, TC2, and TCJ sensors.

12. REPLACEMENT OF SERVICE P.C. BOARD

Indoor Unit

CAUTION and notes regarding P.C. board replacement for indoor units.

CASE 1

Procedure for P.C. board replacement when setting data is readable.

CASE 2

Procedure for P.C. board replacement when setting data is not readable.

[1] Setting data read out from EEPROM

Steps to read setting data from EEPROM using the remote controller.

[2] P.C. Board for indoor unit servicing replacement procedures

Detailed steps for replacing the indoor unit P.C. board and system configuration.

[3] Writing the setting data to EEPROM

Procedure to write setting data to EEPROM using the remote controller.

13. DETACHMENTS

Electrical parts box cover

Procedure for detaching and attaching the electrical parts box cover.

Control P.C. board MCC-1643

Procedure for detaching and attaching the control P.C. board MCC-1643.

Fan control P.C. board MCC-1610

Procedure for detaching and attaching the fan control P.C. board MCC-1610.

Noise filter P.C. board MCC-1551

Procedure for detaching and attaching the noise filter P.C. board MCC-1551.

Application control P.C. board

Procedure for detaching and attaching the application control P.C. board.

PMV motor

Procedure for detaching and attaching the PMV motor.

Bottom plate (fan side)

Procedure for detaching and attaching the bottom plate (fan side).

Fan motor, Fan

Procedure for detaching the fan motor and fan assembly.

Sensor TC1, TC2, TCJ

Procedure for detaching and attaching TC1, TC2, and TCJ sensors.

Heat exchanger

Procedure for detaching and attaching the heat exchanger.

Sensor TA

Procedure for detaching and attaching the TA sensor.

Reactor

Procedure for detaching and attaching the reactor.

14. EXPLODED VIEWS AND PARTS LIST

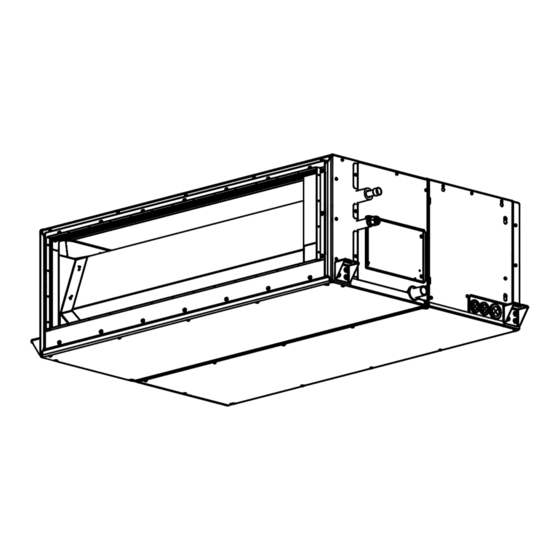

14-1. Indoor Unit

Exploded view and parts list for the indoor unit components.

14-2. Electric Parts

List and diagrams of electrical parts used in the unit.

WARNINGS ON REFRIGERANT LEAKAGE

Check of Concentration Limit

Information on refrigerant concentration limits and required measures to prevent exceeding them.

Important

Key considerations for multi air conditioner system installation in small rooms.

Need help?

Do you have a question about the MMD-UP0961HP-UL and is the answer not in the manual?

Questions and answers