Advertisement

8

7

F

E

D

C

B

A

Zust.

Änderungsbeschreibung

8

7

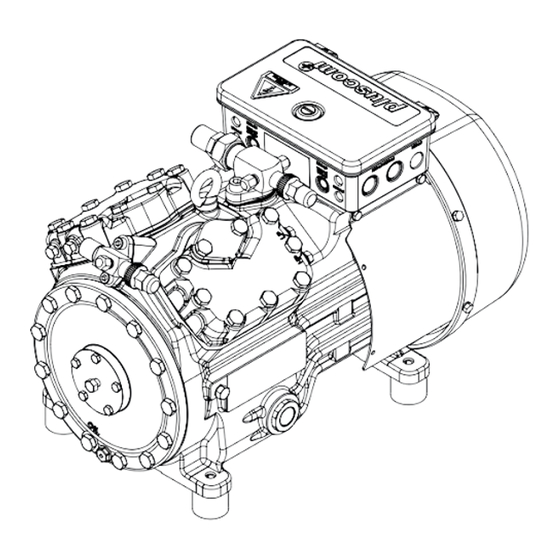

Bock HG12P/e, HG(HA)22P/e, HG(HA)34P/e

Repair instructions electric motor

09632-04.2024-Gb

Translation of the original instructions

BOCK

®

6

5

8

F

E

D

C

HA

B

Bearb.

Gepr.

Zone

Änderungs-Nr.

Datum

6

5

A

8

4

3

7

6

Gußtoleranzen:

Zeichn.-Nr.

Teile-Nr.

-

x.xxxx-xxxxx.x

Gewicht: (kg)

-

Tol.-Ang. DIN ISO 2768-mK

Benennung:

über 0.5

6

30

120

400

<Benennung>

bis

6

30

120

400

1000

<Benennung>

±0.1

±0.2

±0.3

±0.5

±0.8

Oberflächenbehandlung / Härte:

Unbemaßte Radien: -

Oberflächenangaben

-

nach DIN ISO 1302

Ra Rz

25

6,3

2

Rz 25

1,6

Rz 160

Rz 63

s

t

u

w

Diese

Zeichnung

ist

unser

Eigentum!

Sie darf ohne unsere Genehmigung weder nach-

gebildet, vervielfältigt, oder Dritten Personen zu-

gänglich gemacht

werden. Der Nachbau nach

dieser Zeichnung, oder an Hand der nach dieser

Zeichnung hergestellten Gegenstände durch den

Abnehmer oder Dritte ist nicht gestattet.

Wir behalten uns alle Rechte, gemäß DIN ISO 16016

an dieser Zeichnung vor.

Maß

Passung

Benzstraße 7

-

72636 Frickenhausen

-

Germany

4

3

Zust.

Änderungsbeschreibung

7

6

2

1

F

5

4

E

D

C

Blatt:

Maßstab:

Ausgangsteil, bzw. Rohteil:

-

B

1/x

1:1

Werkstoff:

-

Lieferantenzeichnung

Alternativbezug:

Baumustergeprüft

Entwicklungsstand

PL:

-

K.-Auftrag:

-

Zeichnung ungültig

Teil inaktiv

Rz 16

0,7

Rz 12,5

0,3

Rz 6,3

0,05

Rz 1,6

Teil keine Serie

Ersatz für:

Gußtoleranzen:

y

x

z

A

-

-

HG

Werkstückkanten

Ersetzt durch:

Gewicht: (kg)

-

DIN ISO 13715

-

2009

Datum

Name

Tol.-Ang. DIN ISO 2768-mK

Erstellt

über 0.5

Geprüft

bis

-

www.bock.de

Freigabe

±0.1

2

1

Unbemaßte Radien: -

Maß

Zone

Änderungs-Nr.

Datum

Bearb.

Gepr.

5

4

colour the world

of tomorrow

3

Zeichn.-Nr.

x.xxxx

Benennung:

6

30

120

400

6

30

120

400

1000

±0.2

±0.3

±0.5

±0.8

Oberflächena

nach DIN ISO

Ra Rz

25

Rz 160

6,3

s

Diese

Zeichnung

ist

Sie darf ohne unsere Ge

gebildet, vervielfältigt, od

gänglich gemacht

werde

dieser Zeichnung, oder a

Zeichnung hergestellten

Abnehmer oder Dritte ist nic

Wir behalten uns alle Recht

an dieser Zeichnung vor.

Passung

Benzstraße 7

-

726

3

Advertisement

Table of Contents

Summary of Contents for BOCK HG

- Page 1 Wir behalten uns alle Recht an dieser Zeichnung vor. Maß Passung Zust. Änderungsbeschreibung Zone Änderungs-Nr. Datum Bearb. Gepr. Benzstraße 7 Bock HG12P/e, HG(HA)22P/e, HG(HA)34P/e Repair instructions electric motor 09632-04.2024-Gb Translation of the original instructions BOCK ® colour the world of tomorrow...

-

Page 2: Liability And Warranty

Safety Information Contents Liability and Warranty ............................2 Additional Safety Information ..........................2 Disassembly ................................4 Installation ................................9 Liability and Warranty Liability and the manufacturer's warranty are excluded if • alterations and functional modifications have been carried out • original spare parts have not been used. Safety Information Target group for this repair information ¾... -

Page 3: Important Prerequisites

Safety Information Important prerequisites DANGER Risk of electric shock Before you carry out any repair work, disconnect the compressor from the electricity network. Turn the main switch to "O" (OFF) and secure the main switch against an unauthorised restart. Before starting any work, ensure that there is no voltage, then earth and short-circuit. Cover or cordon off neighboring live parts. -

Page 4: Draining The Oil

Disassembly Disassembly WARNING Ensure that the compressor is depressurised before starting work. 3.1 Draining the oil NOTE Do not dispose of oil in domestic waste. Dispose of the old oil in accordance with the environmental regulations and observe national regulations. Gußtoleranzen: Zeichn.-Nr. - Page 5 Disassembly 3.2 Removing the air guide hood (only for HA)

- Page 6 Do not damage any cables and components. Damaged parts must be repaired or replaced immediately. ¾ Remove the terminal board and, if available, the PTC terminal board. ¾ Remove the fan (only for HA). Up to design key 056 From design key 057...

- Page 7 Disassembly 3.4 Removing case cover WARNING The heavy weight of the compressor and parts can potentially be dangerous; risk of falling, danger of crushing. ATTENTION! The residual oil flows out when the case cover is removed. Lay an absorbent material under the area and dispose of it in accordance with the environmental regulations.

-

Page 8: Removing The Stator

Disassembly 3.5 Removing the stator WARNING The heavy weight of the stator can potentially be dangerous; risk of falling, danger of crushing. Take appropriate measures to provide a secure location for the stator. Prevent inadvertent rolling. ¾ Remove the locking screw and the stator screw underneath it. Do not damage any cables or components. -

Page 9: Installation

Installation Installation We recommend cleaning the inside of the case before the installation. There must not be any particles and dirt in the compressor. To assemble, reverse the order of the steps. Note any particular features such as observance of different torques. Connecting the stator to the motor housing WARNING The heavy weight of the stator can potentially be dangerous;... - Page 10 Installation 4.2 Installing the terminal board and PTC terminal board Slightly oil the new seals. ¾ Connect the electrical connections as per the illustration on page 11. Up to design key 056 From design key 057 SW 10 15 Nm SW 10 16 Nm...

- Page 11 4.3 Connecting the electrical connections to the terminal box Klemmbrett HA / HG 3 (Oberseite) Terminal board HA/HG 3 (top view) Planche à bornes HA / HG 3 (Vue de dessus) Terminal assignment on the terminal board up to design key 056 Kabelbaum (2)

- Page 12 Installation 4.3 Installing the case cover 14 x SW 17 75 Nm...

- Page 13 4.4 Assembling and making the electrical connections ¾ Install the fan (only for HA). ¾ Install the electrical connection of the fan on the terminal box (only for HA). ¾ Fit the air guide hood (only for HA). ¾ Fit the cover on the terminal box.

- Page 14 The Bock service team can be contacted by phone +49 (0)7022 9454-0 or via service@bock.de Yours faithfully Bock GmbH...

- Page 16 BOCK ® Bock GmbH Benzstraße 7 72636 Frickenhausen Germany Tel +49 7022 9454-0 Fax +49 7022 9454-137 www.bock.de © Bock GmbH. All rights reserved. Subject to modifications.

Need help?

Do you have a question about the HG and is the answer not in the manual?

Questions and answers